Douglas Dynamics PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Douglas Dynamics Bundle

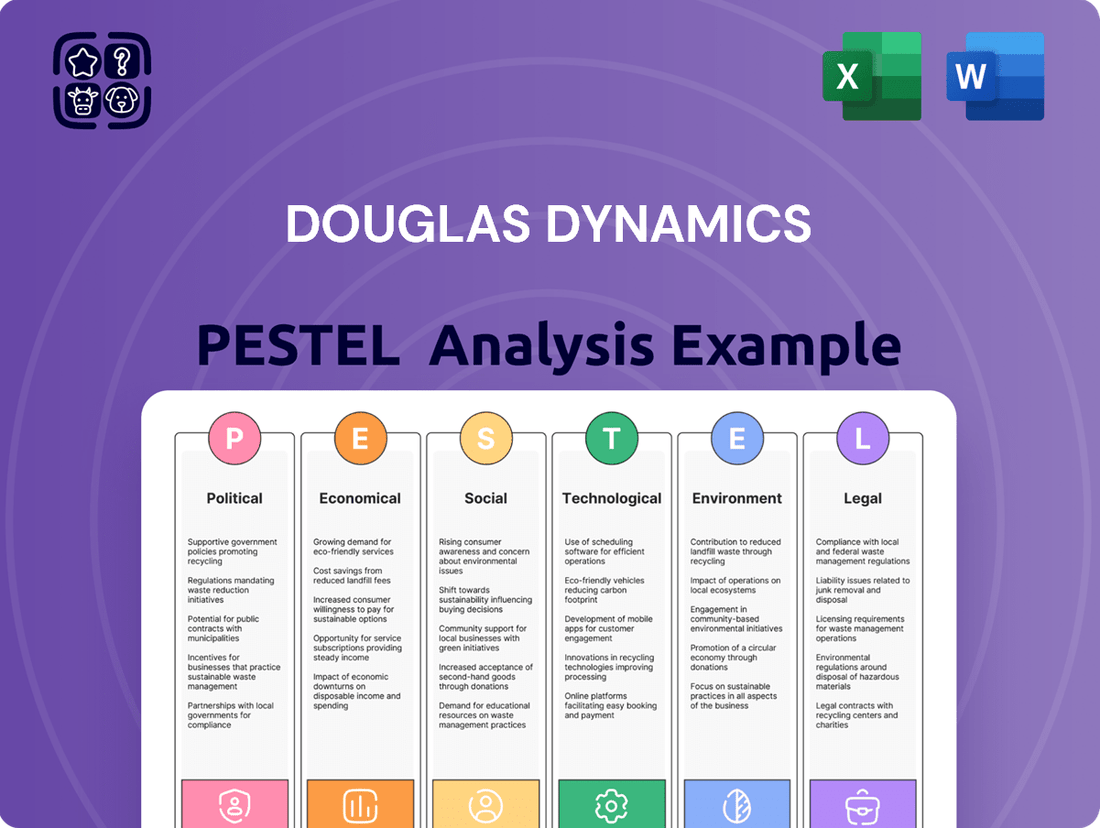

Unlock the critical external forces shaping Douglas Dynamics's trajectory with our comprehensive PESTLE analysis. Understand the political, economic, social, technological, legal, and environmental factors that present both opportunities and challenges for the company. Equip yourself with actionable intelligence to refine your strategies and gain a competitive edge. Download the full report now for immediate insights.

Political factors

Government investments in infrastructure, especially for road maintenance and public works, directly impact the demand for Douglas Dynamics' snow and ice control equipment. Federal and state initiatives, such as the Infrastructure Investment and Jobs Act (IIJA) in the US, are channeling substantial funds into projects that necessitate this type of equipment, fostering market expansion. This ongoing financial commitment creates a steady requirement for effective snow removal solutions for local governments.

Changes in trade policies and the imposition of tariffs, especially on key manufacturing inputs like steel and aluminum, directly influence Douglas Dynamics' cost of goods sold and overall profitability. For instance, the U.S. imposed tariffs on steel and aluminum imports in recent years, which could increase raw material expenses for manufacturers.

Higher tariffs on imported components necessitate strategic adjustments, potentially leading to price increases for end products or a push towards securing more domestic supply chains. This can also impact the company's competitive positioning if rivals have different sourcing strategies.

Douglas Dynamics' significant reliance on a U.S.-based supply chain, as of their 2023 reporting, provides a degree of insulation from the direct impact of tariffs on imported parts. However, the cost of domestically sourced materials can still be affected by broader economic conditions and global commodity prices influenced by international trade dynamics.

New and stricter vehicle emission standards, like the EPA's proposed rules for 2027 and beyond affecting light and medium-duty trucks, directly impact how Douglas Dynamics designs its attachments. These regulations are pushing for reduced pollutants and greenhouse gases, which could increase demand for attachments compatible with greener truck technologies.

For instance, the push towards electrification in the medium-duty truck sector, with manufacturers like Ford and Stellantis introducing electric vans and trucks, means Douglas Dynamics must consider how its snowplows, salt spreaders, and other equipment will integrate with these evolving vehicle platforms.

Local and Municipal Regulations

Local and municipal regulations significantly shape the operational landscape for Douglas Dynamics, particularly concerning snow and ice management. These rules dictate everything from the types of de-icing agents permitted to the specific methods and timelines for snow removal. For instance, many municipalities are increasingly restricting the use of traditional salt chlorides due to their environmental impact on waterways and infrastructure.

This regulatory pressure directly influences product development. Douglas Dynamics must innovate to offer equipment and solutions that comply with these evolving environmental standards. A key area of focus is the development of more sustainable snow removal practices and equipment that minimize environmental harm. For example, the push to reduce salt usage by 10-20% in certain regions by 2025 necessitates the exploration of alternative de-icing materials or more efficient application technologies.

- Environmental Mandates: Stricter local ordinances on de-icing agents, aiming to curb salt runoff into water sources, are becoming more common.

- Operational Guidelines: Municipalities often set specific requirements for snow clearing response times and the types of equipment that can be used on public roads.

- Innovation Driver: Adherence to these local environmental and operational rules drives demand for Douglas Dynamics' advanced plows, spreaders, and other snow management attachments.

Government Incentives for Green Technology

Government incentives for adopting electric equipment in the snow removal sector, like electric plows and spreaders, can significantly shape Douglas Dynamics' product development. For instance, the Inflation Reduction Act of 2022 offers tax credits for commercial clean vehicles, which could extend to electric snow removal machinery, potentially boosting demand. This push towards sustainability can accelerate the market for electric and autonomous snow removal gear.

Douglas Dynamics may need to strategically invest in research and development to effectively leverage these emerging trends. The company could explore partnerships or acquisitions to gain access to advanced electric powertrain technologies. As of early 2024, several states, including California and New York, have announced ambitious targets for electrifying commercial fleets, setting a precedent that could influence federal policy and industry adoption rates.

- Government support for electric snow removal equipment adoption is growing.

- Incentives can accelerate demand for sustainable and autonomous solutions.

- Douglas Dynamics may need R&D investment to capitalize on these trends.

Government infrastructure spending, particularly through initiatives like the Infrastructure Investment and Jobs Act (IIJA), directly fuels demand for Douglas Dynamics' snow and ice control equipment. These investments in road maintenance and public works create a consistent need for effective snow removal solutions from local governments.

Evolving vehicle emission standards, such as the EPA's proposed rules for 2027 and beyond, necessitate Douglas Dynamics to adapt its attachment designs for compatibility with greener truck technologies, including electric vehicles. This regulatory shift is a key driver for innovation in the company's product line.

Local environmental regulations, like restrictions on traditional salt usage due to waterway contamination, are pushing Douglas Dynamics to develop more sustainable snow removal equipment and practices. For example, a 10-20% reduction in salt usage by 2025 in certain regions highlights the need for alternative de-icing technologies.

Government incentives, such as tax credits for commercial clean vehicles under the Inflation Reduction Act of 2022, can boost demand for electric snow removal machinery. As of early 2024, states like California and New York are setting ambitious targets for commercial fleet electrification, signaling a growing market for these advanced solutions.

What is included in the product

This PESTLE analysis provides a comprehensive examination of the external macro-environmental factors influencing Douglas Dynamics, covering Political, Economic, Social, Technological, Environmental, and Legal dimensions.

The Douglas Dynamics PESTLE analysis provides a structured framework to identify and mitigate external threats and opportunities, simplifying complex market dynamics for strategic decision-making.

Economic factors

The overall health of the U.S. economy, particularly its Gross Domestic Product (GDP) growth and consumer confidence, significantly influences the demand for work trucks and their associated attachments, a core market for Douglas Dynamics. A robust economy, characterized by a strong labor market and sustained consumer spending, is projected to continue into 2025, which is a positive indicator for Douglas Dynamics' sales performance.

For instance, the U.S. GDP growth rate was approximately 2.5% in 2024, and forecasts for 2025 suggest a similar or slightly higher expansion, driven by resilient consumer demand and business investment. This economic stability translates directly into increased infrastructure projects and a greater need for commercial vehicles and equipment, benefiting companies like Douglas Dynamics.

Conversely, economic slowdowns or recessions can dampen infrastructure spending and reduce the overall demand for large-scale equipment, potentially impacting Douglas Dynamics' revenue streams. A contraction in GDP, even by a few percentage points, can lead to delayed or canceled projects, directly affecting sales volumes for the company's products.

The construction sector, a primary market for Douglas Dynamics' work truck attachments, experienced headwinds in 2024. However, forecasts suggest a positive shift, with projections indicating a rebound in construction spending for 2025. This anticipated growth is vital for Douglas Dynamics, as increased building activity directly correlates with higher demand for their specialized equipment.

Similarly, the manufacturing sector's outlook impacts Douglas Dynamics. While 2024 presented a mixed picture, expectations for 2025 point towards a mild increase in industrial production. This uptick in manufacturing activity generally translates to greater investment in operational equipment, benefiting companies like Douglas Dynamics that supply essential components.

Douglas Dynamics' financial performance is intrinsically linked to the capital expenditure cycles of both construction and manufacturing. As these industries invest more in new projects and upgrades, the demand for work truck attachments, such as those produced by Douglas Dynamics, is expected to rise, supporting their sales trajectory through 2025.

Fluctuations in interest rates directly impact the cost of financing for Douglas Dynamics' customers, including municipalities, businesses, and individual consumers acquiring snow and ice control equipment. Lower interest rates, such as those projected for late 2025, can significantly reduce the burden of financing, potentially boosting demand for new equipment purchases.

Conversely, elevated interest rates increase financing costs, which can discourage capital expenditures on new machinery. This scenario might lead customers to extend the lifespan of existing equipment or opt for leasing arrangements instead of outright purchases, impacting Douglas Dynamics' sales volumes.

Raw Material Prices and Supply Chain Costs

The price of steel, a key component for Douglas Dynamics, experienced significant fluctuations. For instance, in early 2024, hot-rolled coil steel prices hovered around $750-$850 per ton, a notable decrease from the peaks seen in previous years but still subject to upward pressure from demand and production issues.

Supply chain challenges continue to impact manufacturers. Geopolitical tensions and labor availability issues in 2024 have contributed to increased freight costs and lead times for essential components, potentially adding 5-10% to material acquisition expenses for companies like Douglas Dynamics.

- Steel Price Volatility: Hot-rolled coil steel prices in early 2024 ranged from $750 to $850 per ton, impacting manufacturing costs.

- Supply Chain Disruptions: Increased freight and component costs, estimated at 5-10%, stem from geopolitical events and labor shortages.

- Cost Management: Douglas Dynamics must actively manage these raw material and supply chain cost increases to maintain competitive pricing.

Labor Market Conditions and Wages

Labor market tightness, especially in skilled trades and manufacturing, directly affects Douglas Dynamics' operational expenses and production capabilities. For instance, the U.S. unemployment rate hovered around 3.9% in early 2024, indicating a relatively tight labor market. Rising wages, a common consequence of such conditions, can increase the company's cost of goods sold and potentially squeeze profit margins.

A shortage of qualified workers presents a significant hurdle. In 2024, industries like manufacturing continued to face challenges in finding and retaining skilled labor, with some reports indicating a persistent gap in available positions versus qualified candidates. This scarcity can lead to increased recruitment costs and, more critically, production delays if key roles remain unfilled, impacting Douglas Dynamics' ability to meet demand.

To counter these labor market pressures, Douglas Dynamics may need to prioritize investments in employee training and robust retention programs. Strategies such as offering competitive compensation and benefits packages, fostering a positive work environment, and providing opportunities for skill development are crucial. These initiatives can help mitigate increased labor costs and ensure a stable, skilled workforce capable of supporting production goals throughout 2024 and into 2025.

- Tight Labor Market: U.S. unemployment rate around 3.9% in early 2024 highlights a competitive environment for talent.

- Rising Wage Pressures: Increased demand for labor translates to higher wage expectations, impacting operational costs.

- Skilled Worker Shortages: Persistent gaps in manufacturing and skilled trades can lead to production bottlenecks and increased recruitment expenses.

- Mitigation Strategies: Investment in training and retention programs is essential for maintaining workforce stability and operational efficiency.

The economic outlook for 2024 and 2025 remains a key driver for Douglas Dynamics. Projections indicate continued GDP growth, with the U.S. economy expanding around 2.5% in 2024 and expected to maintain similar or slightly higher growth into 2025, fueled by consumer spending and business investment. This positive economic environment directly supports demand for work trucks and associated equipment, benefiting Douglas Dynamics.

Interest rate trends will play a crucial role, with anticipated rate decreases by late 2025 potentially lowering financing costs for customers and stimulating equipment purchases. However, the company must also navigate the volatility of steel prices, with hot-rolled coil steel trading between $750-$850 per ton in early 2024, and manage supply chain disruptions that have added an estimated 5-10% to material acquisition costs.

The labor market in early 2024, characterized by a U.S. unemployment rate around 3.9%, presents challenges due to wage pressures and shortages of skilled workers in manufacturing. Douglas Dynamics needs to focus on retention and training to maintain operational efficiency amidst these conditions.

| Economic Factor | 2024 Status/Projection | 2025 Outlook | Impact on Douglas Dynamics |

|---|---|---|---|

| U.S. GDP Growth | ~2.5% | Similar or slightly higher | Increased demand for work trucks and attachments |

| Interest Rates | Elevated, potential for decrease | Anticipated decrease by late 2025 | Lower financing costs can boost equipment sales |

| Steel Prices (Hot-Rolled Coil) | $750-$850/ton (early 2024) | Volatile, subject to demand/production | Affects cost of goods sold and pricing |

| Supply Chain Costs | 5-10% increase (freight/components) | Potential ongoing pressure | Impacts material acquisition expenses |

| U.S. Unemployment Rate | ~3.9% (early 2024) | Likely to remain tight | Increased labor costs and potential production delays |

Same Document Delivered

Douglas Dynamics PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive Douglas Dynamics PESTLE Analysis breaks down the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the company. It provides a thorough understanding of the external forces shaping Douglas Dynamics' strategic landscape.

Sociological factors

The aging workforce in skilled trades and manufacturing presents a notable challenge for Douglas Dynamics. As experienced workers retire, there's a growing scarcity of qualified individuals to fill critical roles, impacting industries reliant on specialized labor. This demographic trend directly affects the demand for equipment that can enhance productivity and mitigate labor dependency.

In 2024, the U.S. Bureau of Labor Statistics projected that the median age of workers in manufacturing occupations was around 44 years, significantly higher than in many other sectors. This aging demographic, combined with a slower influx of younger workers into skilled trades, exacerbates the labor shortage. Consequently, companies like Douglas Dynamics may see increased demand for their innovative equipment solutions designed to optimize operations and reduce the reliance on manual labor in snow and ice management.

Societal biases often favor traditional four-year college degrees, leading many younger individuals to overlook the significant financial and career stability offered by skilled trades. This perception gap directly contributes to the ongoing shortage of skilled labor, impacting industries that rely on hands-on expertise.

In 2024, the U.S. Bureau of Labor Statistics reported that median annual wages for occupations like electricians and plumbers were well over $60,000, with many trades offering comparable or even higher earnings than some college-graduate professions, yet the allure of vocational training remains subdued for many.

This societal undervaluation of trades careers can create a smaller talent pool for operating and maintaining complex equipment, such as the work truck attachments manufactured by Douglas Dynamics. Consequently, this labor shortage may drive increased demand for more automated, user-friendly, or technologically advanced solutions that require less specialized manual skill for operation.

The ongoing shift towards urban living, particularly in areas prone to snowfall, is a significant tailwind for Douglas Dynamics. As more people move into cities and smart city initiatives take hold, the need for professional snow and ice management services escalates for both commercial properties and residential developments. This trend directly translates to a larger potential customer base for Douglas Dynamics’ snow and ice control equipment.

For instance, by 2023, over 60% of the global population resided in urban areas, a figure projected to reach 68% by 2050 according to UN data. This increasing urban density in snow-prone regions means more concentrated demand for efficient winter maintenance solutions, directly benefiting manufacturers like Douglas Dynamics.

Safety Concerns and Road Maintenance Importance

Growing worries about road safety, especially following accidents linked to bad weather, are pushing governments and local authorities to put winter road upkeep at the top of their agendas. This increased emphasis on safety directly boosts the need for tough and dependable snow removal vehicles and equipment, as clearing snow efficiently is key to keeping roads passable and cutting down on accidents.

For instance, in the United States, the Federal Highway Administration (FHWA) reported that in 2023, weather-related factors were responsible for approximately 22% of all vehicle crashes, with winter weather being a significant contributor. This underscores the critical role of effective snow and ice management in ensuring public safety and maintaining economic activity during winter months.

- Increased Safety Focus: Public demand for safer roads, especially during winter, drives investment in better maintenance.

- Weather Impact: Adverse weather conditions, such as heavy snowfall and ice, directly correlate with a higher need for road clearing services.

- Economic Continuity: Reliable road maintenance ensures businesses can operate and supply chains remain unbroken, even in harsh weather.

- Government Spending: Municipalities are allocating more resources to winter road maintenance, with some regions seeing budget increases of 5-10% year-over-year for snow removal services.

Customer Preference for Diversified Services

Customers are increasingly seeking integrated solutions from service providers, pushing businesses like snow removal companies to offer a wider array of services. This shift encourages a move towards year-round operations, often by adapting existing equipment for different seasons. For instance, many snow removal outfits are now offering lawn care, landscaping, and general property maintenance, aiming to retain clients and revenue streams throughout the year.

This evolving customer preference directly impacts equipment manufacturers like Douglas Dynamics. The demand for multi-functional attachments and equipment that can be repurposed for various tasks, from snow plowing in winter to landscaping in summer, is growing. This trend suggests an opportunity for Douglas Dynamics to innovate and expand its product lines to support this diversification, potentially boosting sales by meeting the demand for versatile work truck solutions.

- Diversification Trend: Snow removal companies are expanding services to include landscaping and property maintenance, aiming for year-round revenue.

- Customer Demand: Clients prefer single providers for multiple services, simplifying their vendor management.

- Equipment Versatility: There's a growing market for attachments and equipment that can be used across different seasons and applications.

The aging workforce in skilled trades, with a median age around 44 in manufacturing as of 2024, presents a challenge for Douglas Dynamics by creating labor shortages. Societal biases favoring college degrees over vocational training further shrink the talent pool for operating complex equipment, potentially increasing demand for more user-friendly solutions.

Increasing urbanization, with over 60% of the global population living in cities by 2023, drives demand for professional snow and ice management in concentrated areas. This growth in urban density, especially in snow-prone regions, directly benefits manufacturers of winter maintenance equipment like Douglas Dynamics.

A heightened focus on road safety, with weather-related crashes accounting for about 22% of U.S. vehicle accidents in 2023, compels greater investment in winter road maintenance. This emphasis on safety and economic continuity necessitates reliable snow removal equipment, creating a strong market for Douglas Dynamics.

Customers increasingly seek integrated services, prompting snow removal companies to diversify into year-round offerings like landscaping. This trend fuels demand for versatile equipment that can be adapted for multiple seasonal applications, presenting an opportunity for Douglas Dynamics to expand its product lines.

Technological factors

Technological advancements are significantly reshaping the snow removal industry. Innovations like digital systems for precise de-icing material application, GPS-enabled route optimization, and integrated obstacle-detecting sensors are dramatically boosting efficiency and safety for operators. For instance, advanced GPS systems can reduce fuel consumption by an estimated 10-15% through optimized plowing paths.

Douglas Dynamics can capitalize on these trends by integrating such cutting-edge technologies into its product lines. This proactive approach allows the company to offer more sophisticated, user-friendly, and environmentally conscious snowplow solutions, directly appealing to a growing customer base prioritizing performance and sustainability. The market for smart snow removal equipment is projected to see substantial growth, with some estimates suggesting a CAGR of over 7% through 2028.

Autonomous and robotic snow removal solutions are transforming the industry, promising reduced reliance on manual labor and improved safety. For instance, companies like Snowbot are developing AI-powered robots capable of clearing sidewalks and pathways, aiming to address labor shortages faced by municipalities and private snow removal services. This technological advancement presents a clear opportunity for Douglas Dynamics to consider integrating such autonomous capabilities into its future product development, potentially enhancing operational efficiency and offering innovative solutions to its customer base.

The electrification of snow removal equipment, including snow blowers, commercial plows, and spreaders, is rapidly gaining traction. This shift is driven by both customer demand for more sustainable options and growing government incentives supporting greener technologies. For instance, by late 2024, several states were expanding tax credits for electric vehicle purchases, a trend likely to extend to related electric equipment.

Douglas Dynamics has a clear opportunity to leverage this trend by expanding its portfolio of electric-powered equipment. This strategic move would not only align with evolving customer preferences for energy efficiency but also position the company to benefit from favorable regulatory environments and potential subsidies aimed at promoting electrification in the commercial sector.

Integration of Digital Fleet Management and IoT

The increasing adoption of digital fleet management systems, powered by cloud platforms, GPS tracking, and IoT sensors, is revolutionizing snow removal operations. These technologies enable real-time vehicle monitoring, dynamic route optimization, and improved resource management, leading to significant gains in efficiency. For instance, by 2024, the global fleet management market was projected to reach over $35 billion, with a substantial portion driven by telematics and IoT integration, highlighting a strong trend towards digitally managed fleets.

Douglas Dynamics can enhance its product offerings by ensuring compatibility with these advanced digital tools. Integrating features that allow its snowplows and other equipment to seamlessly connect with popular fleet management software provides customers with a competitive edge. This integration facilitates better data capture on equipment usage, maintenance needs, and operational performance, directly contributing to cost savings and improved service delivery for municipalities and commercial snow removal businesses.

The benefits for customers are substantial:

- Enhanced Operational Efficiency: Real-time data allows for immediate adjustments to routes and deployment, minimizing downtime and maximizing coverage.

- Cost Reduction: Optimized routes and predictive maintenance, facilitated by IoT sensors, reduce fuel consumption and unexpected repair costs.

- Improved Resource Allocation: Managers gain clear visibility into fleet status and performance, enabling smarter allocation of equipment and personnel.

- Data-Driven Decision Making: Comprehensive data on operational metrics empowers businesses to refine strategies and improve profitability.

Predictive Analytics and Weather Forecasting Technology

The increasing accuracy of weather forecasting, with advancements like AI-driven models, allows snow removal operations to better anticipate snowfall events. This predictive capability is crucial for businesses relying on Douglas Dynamics' equipment, enabling more efficient deployment of plows and salt spreaders. For instance, improved short-term forecasts can reduce unnecessary idling of equipment, leading to cost savings and better resource allocation for fleet managers.

Douglas Dynamics can leverage these technological trends by integrating smart features into its product lines. Imagine snowplows equipped with sensors that automatically adjust blade angle or salt application rates based on real-time weather data and predictive analytics. This not only enhances operational efficiency but also positions Douglas Dynamics as an innovator in a market increasingly driven by data and automation. The global weather forecasting market, valued at approximately $2.7 billion in 2023, is projected to grow, indicating a strong demand for such integrated solutions.

- Enhanced Resource Allocation: Predictive analytics allow for more precise scheduling of equipment and personnel, minimizing waste.

- Smart Equipment Integration: Opportunities exist for Douglas Dynamics to embed technology that responds to real-time weather data and forecasts.

- Operational Efficiency Gains: Better forecasting can lead to reduced fuel consumption and wear-and-tear on equipment by avoiding unnecessary operations.

- Market Differentiation: Offering equipment with advanced weather-responsive features can provide a competitive edge.

Technological advancements are driving significant innovation in snow management, from GPS optimization reducing fuel use by up to 15% to AI-powered robots addressing labor shortages. Douglas Dynamics can integrate these smart features, like weather-responsive sensors, into its product lines, aligning with a market projected for over 7% CAGR in smart equipment through 2028.

The electrification trend is also prominent, with states expanding tax credits for electric vehicles by late 2024, a move likely to influence related equipment. Douglas Dynamics can expand its electric-powered offerings to meet customer demand for sustainable options and benefit from supportive regulatory environments.

Digital fleet management systems, utilizing IoT and cloud platforms, are transforming operations. By ensuring compatibility with these systems, Douglas Dynamics can offer customers enhanced efficiency and cost savings, tapping into a global fleet management market projected to exceed $35 billion by 2024.

Legal factors

Douglas Dynamics operates under strict vehicle safety and performance standards mandated by agencies like the National Highway Traffic Safety Administration (NHTSA) and similar international bodies. These regulations, which can include requirements for crashworthiness and emissions, directly impact the design and manufacturing of their snowplows, truck beds, and other vocational vehicle equipment. For instance, in 2024, NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) continue to evolve, requiring ongoing validation of attachment integration with light trucks and work vehicles to ensure safe operation.

Environmental regulations concerning de-icing agents are tightening globally, pushing for greener alternatives to traditional salt-based compounds. This trend directly impacts companies like Douglas Dynamics, which manufacture snow and ice control equipment.

For instance, in 2024, several US states, including Vermont and New York, continued to emphasize reducing chloride runoff into waterways, leading to increased interest in alternative de-icers like calcium magnesium acetate (CMA) and potassium acetate. Douglas Dynamics will likely need to ensure its spreader technologies are compatible with these newer, often more expensive, but environmentally preferred materials to maintain market relevance.

Douglas Dynamics, as a manufacturer of snow and ice control equipment, must strictly adhere to product liability and consumer protection laws. These regulations, like the Consumer Product Safety Act in the US, require that all products are safe for intended use and accurately represented. For instance, in 2023, the Consumer Product Safety Commission (CPSC) reported over 100,000 product-related injuries treated in emergency rooms, highlighting the importance of robust safety standards.

Failure to comply can lead to costly lawsuits, significant fines, and severe damage to brand reputation. Douglas Dynamics' commitment to rigorous testing and quality control, a standard practice in the industry, directly addresses these legal obligations. This proactive approach is essential for maintaining customer trust and ensuring the long-term viability of its operations.

Labor Laws and Employment Regulations

Labor laws significantly shape Douglas Dynamics' operational landscape, dictating everything from minimum wages and overtime pay to workplace safety standards and employee benefits. For instance, the Fair Labor Standards Act (FLSA) in the US mandates minimum wage and overtime pay, directly influencing labor costs for manufacturing. Changes in these regulations, such as potential increases in the federal minimum wage, could impact the company's cost structure and pricing strategies.

Navigating the complexities of employment regulations is crucial for minimizing legal risks and ensuring smooth operations. Douglas Dynamics must adhere to a patchwork of federal, state, and local laws concerning hiring, firing, discrimination, and unionization. Failure to comply can result in costly lawsuits, fines, and reputational damage. The increasing focus on fair labor practices and worker protections underscores the importance of robust compliance programs.

The current environment is marked by significant skilled labor shortages across manufacturing sectors, including those served by Douglas Dynamics. This scarcity puts upward pressure on wages and benefits as companies compete for talent. In 2024, the US Bureau of Labor Statistics reported a manufacturing job opening rate that often outpaced the number of hires, highlighting this challenge. This necessitates strategic workforce planning, investment in training, and potentially higher compensation packages to attract and retain skilled employees.

- Wage and Hour Laws: Compliance with federal and state minimum wage, overtime, and equal pay regulations directly affects labor expenses.

- Workplace Safety: Adherence to Occupational Safety and Health Administration (OSHA) standards is mandatory to prevent accidents and associated costs.

- Skilled Labor Availability: Shortages in skilled trades, such as welders and machinists, can drive up recruitment costs and impact production capacity.

- Employee Benefits: Regulations concerning health insurance, retirement plans, and paid leave influence overall compensation packages and operational overhead.

Trade Regulations and Import/Export Laws

International trade regulations, including tariffs and import/export restrictions, directly impact Douglas Dynamics' global supply chain and market access. For instance, ongoing trade tensions, particularly between major economies, could lead to increased tariffs on components or finished goods, affecting production costs and pricing strategies. Adapting to these evolving rules is paramount for maintaining cost efficiency and securing necessary raw materials.

Trade agreements, such as the United States-Mexico-Canada Agreement (USMCA), can create both opportunities and challenges. While the USMCA aims to streamline trade within North America, changes in rules of origin or other provisions could necessitate adjustments in sourcing and manufacturing. Douglas Dynamics must actively monitor these agreements to leverage favorable terms and mitigate potential disruptions, ensuring continued market access and competitive positioning.

- Tariff Impact: Potential for increased tariffs on steel and aluminum, key materials for Douglas Dynamics, could raise production costs by an estimated 5-10% if not strategically managed through sourcing diversification or hedging.

- Import/Export Compliance: Strict adherence to evolving import/export documentation and compliance standards is critical to avoid delays and penalties, especially when shipping to diverse international markets.

- Trade Agreement Analysis: Ongoing assessment of trade agreement impacts, such as potential changes in local content requirements within the USMCA, is vital for supply chain planning.

- Market Access: Navigating varying import duties and non-tariff barriers in key international markets is essential for successful market expansion and revenue growth.

Legal factors significantly shape Douglas Dynamics' operations, from product safety mandates to labor regulations. Compliance with vehicle safety standards set by bodies like NHTSA is paramount, influencing product design and validation. Environmental regulations, particularly concerning de-icing agents, also necessitate adaptation in equipment design to accommodate greener alternatives.

Product liability and consumer protection laws demand rigorous testing and accurate product representation, with failure to comply leading to substantial financial and reputational risks. Furthermore, labor laws, including minimum wage and workplace safety standards, directly impact operational costs and require careful management of workforce relations.

International trade regulations, tariffs, and trade agreements present both opportunities and challenges, requiring strategic sourcing and market access planning. The company must remain agile in adapting to these evolving legal frameworks to maintain competitiveness and mitigate risks.

Environmental factors

Climate change is altering snowfall patterns, with some regions experiencing less snow overall and shorter winters. This directly affects the demand for snow removal equipment, a key market for Douglas Dynamics. For instance, a report from NOAA in early 2024 indicated a trend of milder winters in parts of the Northern U.S.

However, climate change also means increased unpredictability, with some areas facing more intense, albeit less frequent, snowstorms. This necessitates that Douglas Dynamics designs adaptable and durable equipment to meet these varied conditions.

Douglas Dynamics needs to factor these evolving weather patterns into its product development cycles and sales forecasts, ensuring it can meet fluctuating market demands driven by climate-induced weather variability.

There's a significant push towards greener snow removal methods, moving away from traditional, harsh chemicals that can harm ecosystems. This shift is driving innovation in equipment designed for more precise application of de-icers, the use of biodegradable materials, and even exploring entirely new ways to clear snow. For instance, the global de-icing market, which includes road salt and alternatives, was valued at over $6 billion in 2023 and is projected to grow, with a notable segment focusing on eco-friendly solutions.

Douglas Dynamics can capitalize on this environmental trend by developing and marketing equipment that supports these sustainable practices. Offering solutions that reduce chemical runoff or improve the efficiency of de-icer usage positions the company as a leader in an increasingly environmentally aware market. Companies that can demonstrate a commitment to sustainability are likely to see increased demand from municipalities and commercial clients facing stricter environmental regulations and public scrutiny.

Douglas Dynamics' manufacturing processes, like many in the heavy equipment sector, face scrutiny over their environmental footprint. This includes significant energy consumption for machinery, waste generated from material processing, and emissions from various stages. For instance, in 2023, the industrial manufacturing sector in the US was responsible for approximately 20% of total greenhouse gas emissions, a figure that directly impacts companies like Douglas Dynamics.

The company's commitment to sustainability is becoming a key differentiator. By actively pursuing greener alternatives, such as exploring less environmentally impactful deicing solutions or enhancing energy efficiency in its production facilities, Douglas Dynamics can bolster its reputation. This focus on corporate social responsibility is particularly relevant as consumer and investor demand for sustainable business practices continues to grow, with a growing number of investors prioritizing ESG (Environmental, Social, and Governance) factors in their portfolios.

Resource Scarcity and Raw Material Sourcing

The availability and responsible sourcing of key raw materials, especially metals like steel and aluminum, present a significant environmental challenge for Douglas Dynamics. Fluctuations in commodity prices and supply chain disruptions due to geopolitical events or increased demand can directly impact production costs and output. For instance, steel prices, a primary component in their products, saw considerable volatility in 2024, with some benchmarks experiencing double-digit percentage swings within months.

Douglas Dynamics must actively manage its supply chain to ensure ethical and sustainable sourcing practices. This involves scrutinizing suppliers for their environmental impact and labor practices. The company could also explore incorporating recycled materials or developing products that utilize more readily available or less environmentally intensive resources. This proactive approach helps mitigate risks associated with resource depletion and enhances brand reputation among environmentally conscious consumers and investors.

- Steel Price Volatility: Global steel prices, critical for Douglas Dynamics' manufacturing, experienced significant fluctuations in 2024, impacting input costs.

- Supply Chain Scrutiny: Increased focus on responsible sourcing of metals like steel and aluminum is paramount for mitigating environmental and ethical risks.

- Material Innovation: Exploring recycled content and alternative, more sustainable materials can reduce reliance on scarce resources and lower environmental footprints.

- Resource Depletion Concerns: Growing global demand for metals raises long-term concerns about resource availability and the environmental impact of extraction.

Demand for Electric and Low-Emission Equipment

The increasing demand for electric and low-emission equipment directly impacts companies like Douglas Dynamics. As environmental regulations tighten and public awareness grows, there's a significant shift towards adopting cleaner technologies in sectors like snow removal. This trend is not just about compliance; it's about aligning with global sustainability efforts to reduce air pollution and carbon footprints.

Douglas Dynamics is strategically positioned to capitalize on this demand. The company is actively developing and marketing electric or lower-emission alternatives for its extensive range of snow and ice control equipment. This proactive approach allows them to meet the evolving needs of their customer base, which is increasingly prioritizing environmentally friendly solutions. For instance, the North American commercial vehicle market, a key segment for Douglas Dynamics, saw a notable increase in interest and early adoption of electric vocational trucks in 2024, signaling a broader trend that will likely extend to the equipment powering them.

- Growing Market for Electric Vehicles: The global electric vehicle market is projected to reach over 30 million units sold annually by 2025, indicating a strong underlying trend towards electrification across various vehicle types.

- Regulatory Push for Emissions Reduction: Many governments are implementing stricter emissions standards for commercial vehicles and equipment, creating a favorable environment for low-emission alternatives.

- Douglas Dynamics' Product Development: The company's investment in R&D for electric and hybrid power solutions for its plows and spreaders directly addresses this market demand.

- Customer Demand for Sustainability: End-users, including municipalities and large fleet operators, are increasingly incorporating sustainability metrics into their purchasing decisions, favoring suppliers with eco-friendly product offerings.

Shifting weather patterns due to climate change are directly impacting the demand for snow removal equipment, creating both challenges and opportunities for Douglas Dynamics. While some regions experience less snowfall, others face more intense storms, necessitating adaptable and durable product designs.

The growing emphasis on eco-friendly snow removal methods is driving innovation, with a market for greener solutions expanding rapidly. Douglas Dynamics can leverage this by developing equipment that supports sustainable practices, such as precise de-icer application and the use of biodegradable materials, aligning with a global de-icing market valued over $6 billion in 2023.

The environmental footprint of manufacturing processes, including energy consumption and emissions, is under increasing scrutiny. Douglas Dynamics' commitment to sustainability, demonstrated through greener production methods and materials, is becoming a crucial differentiator in a market where ESG factors are gaining investor and consumer importance.

Resource availability and responsible sourcing of raw materials like steel are critical environmental considerations. Price volatility in commodities like steel, which saw significant swings in 2024, underscores the need for robust supply chain management and exploration of recycled or alternative materials.

PESTLE Analysis Data Sources

Our PESTLE Analysis for Douglas Dynamics is built upon a comprehensive review of official government publications, industry-specific market research, and reputable economic forecasting agencies. This ensures a robust understanding of the political, economic, social, technological, legal, and environmental factors impacting the company.