Ichor Marketing Mix

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Ichor Bundle

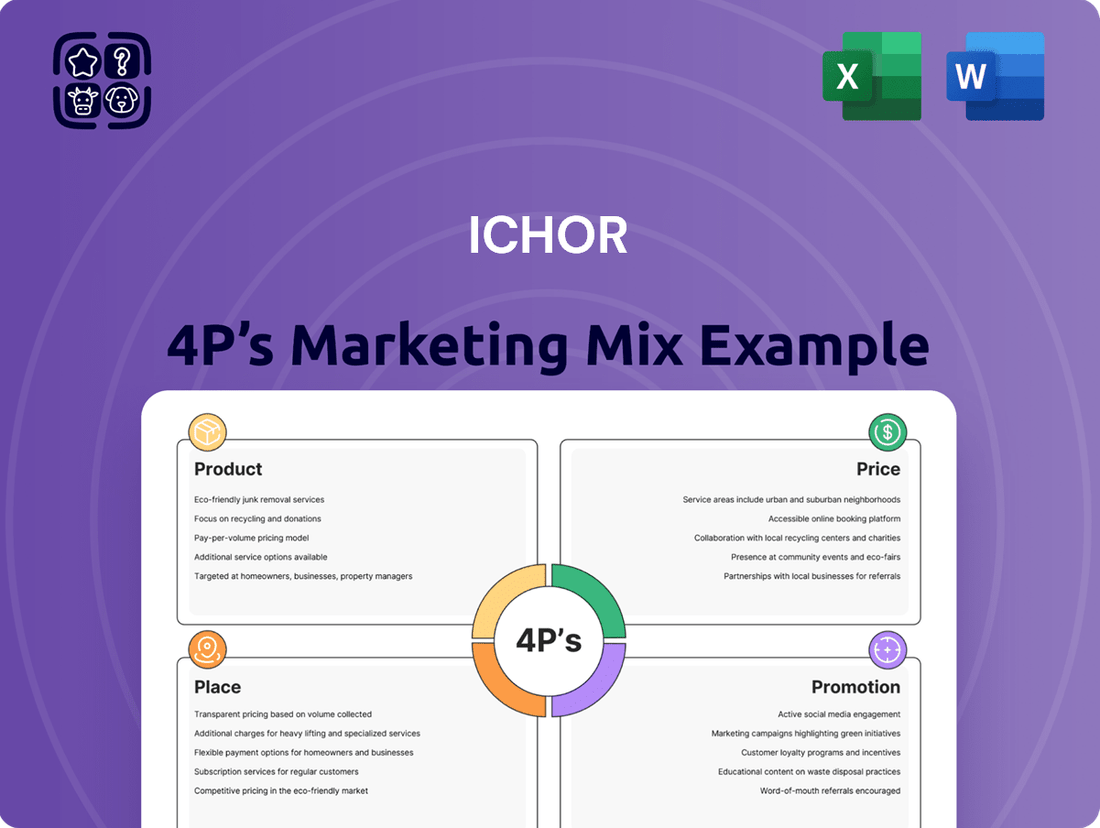

Discover how Ichor's product innovation, strategic pricing, targeted distribution, and impactful promotions create a winning formula. This analysis goes beyond the surface, revealing the intricate connections that drive their market presence.

Unlock the secrets behind Ichor's success by delving into their comprehensive 4Ps marketing mix. Understand their product development, pricing strategies, place in the market, and promotional efforts with this expert-crafted report.

Ready to elevate your marketing strategy? This full 4Ps analysis of Ichor provides actionable insights and a clear framework for understanding their approach to Product, Price, Place, and Promotion.

Gain a competitive edge by examining Ichor's detailed marketing mix. This comprehensive report offers a deep dive into each P, perfect for students, professionals, and anyone seeking strategic marketing intelligence.

Don't miss out on the complete picture! This full 4Ps analysis of Ichor provides an in-depth look at their marketing execution, offering valuable lessons for your own business planning and strategic development.

Product

Critical Fluid Delivery Subsystems, designed and manufactured by Ichor Systems, are foundational to advanced semiconductor fabrication. These systems precisely manage the flow of specialized gases and liquid chemistries vital for processes like etching, deposition, and cleaning. Their role is indispensable in achieving the high precision and throughput demanded by modern chip manufacturing.

In 2024, the semiconductor industry, a primary market for these subsystems, saw significant investment. For instance, global fab construction spending was projected to reach over $100 billion in 2024, highlighting the demand for advanced manufacturing equipment. Ichor's subsystems directly support this expansion by providing the reliable fluid control necessary for these cutting-edge facilities.

The 2025 outlook for semiconductor capital equipment remains robust, with continued demand driven by AI, high-performance computing, and automotive sectors. Ichor's Critical Fluid Delivery Subsystems are integral to enabling these advancements, ensuring the purity and accuracy of materials used in next-generation chip production.

Ichor's Precision Machined Components & Weldments are critical to their product offering, going beyond complete fluid delivery systems. These specialized parts, including complex weldments, are not only essential for Ichor's own integrated systems but are also sold directly to clients. This direct sales channel highlights Ichor's robust vertical integration, ensuring rigorous quality control from raw material to finished component.

The company leverages advanced manufacturing techniques for these components, such as electron beam (e-beam) and laser welding, alongside precision vacuum brazing. This technological prowess allows Ichor to produce highly intricate and demanding parts. For instance, Ichor's 2023 revenue reached $1.3 billion, with a significant portion attributed to these high-value, precision-engineered products, underscoring their importance to the company's financial performance and market position.

Ichor's turnkey engineering solutions act as a crucial Product offering for OEMs in the semiconductor capital equipment sector. By taking on non-core design, production, and support functions, Ichor allows these OEMs to concentrate on their core competencies in process and technology innovation. This strategic outsourcing is vital for OEMs aiming to accelerate their product development cycles and maintain high manufacturing standards.

The value proposition is clear: Ichor provides integrated, end-to-end services that streamline operations for semiconductor equipment manufacturers. This allows for faster go-to-market strategies and improved operational efficiency. For instance, Ichor's ability to handle complex assembly and testing ensures that OEMs can rely on consistent quality and timely delivery of critical components and systems.

Ichor's deep industry experience, particularly in rapid product introductions, positions them as a key partner. Their adherence to exacting production quality standards, critical in the semiconductor industry, further solidifies their role. In 2024, the semiconductor capital equipment market continued its robust growth, with companies increasingly seeking partners like Ichor to navigate complex supply chains and demanding performance requirements.

Advanced Chemical Blending and Distribution Systems

Ichor's product strategy centers on advanced chemical blending and distribution systems, exemplified by their Integrated Manifold System (IMS). This system is engineered to tackle the intricate demands of process fluids in high-volume manufacturing, particularly within wet semiconductor processes. Their patented sealing and interface technologies underscore a commitment to innovation in handling complex liquid chemistries, a critical factor for semiconductor fabrication yields.

The IMS is designed for efficiency and reliability in demanding environments. Its optimization for process fluids addresses key industry pain points, ensuring precise delivery and minimal contamination. This focus on specialized solutions positions Ichor as a provider of mission-critical components for the semiconductor industry.

- Product Focus: Sophisticated chemical blending and distribution systems for semiconductor manufacturing.

- Key Offering: Integrated Manifold System (IMS) for wet semiconductor processes.

- Technological Edge: Patented sealing and interface technologies for high-volume fluid handling.

- Market Application: Optimized for complex liquid chemistries in demanding manufacturing environments.

Customization and Proprietary Technology

Ichor's marketing strategy heavily leverages its Customization and Proprietary Technology. They excel at developing bespoke solutions precisely engineered to meet unique customer demands and intricate process requirements.

This dedication to tailored innovation is a cornerstone of their offering. For instance, Ichor's continued investment in research and development is clearly demonstrated by the recent patent grants they secured for advanced fluid delivery systems. This ongoing commitment to technological advancement ensures their products remain at the forefront of industry needs.

Their proprietary technology allows them to deliver advanced solutions that adapt to the ever-changing landscape of industry requirements.

- Tailored Solutions: Ichor designs products to meet specific customer processes and needs.

- R&D Investment: Significant investment in research and development fuels their innovation.

- Proprietary Technology: Exclusive technologies enable the creation of advanced fluid delivery systems.

- Industry Adaptability: Their focus on technology allows them to meet evolving market demands.

Ichor's product portfolio is anchored by its sophisticated Critical Fluid Delivery Subsystems and Precision Machined Components. These offerings are essential for the highly specialized needs of semiconductor fabrication, ensuring the precise management of gases and liquid chemistries. The company's commitment to advanced manufacturing techniques, including e-beam welding and laser welding, underpins the quality and complexity of these vital components.

The company's Integrated Manifold System (IMS) represents a key product innovation, specifically designed for efficient and reliable handling of process fluids in wet semiconductor applications. This focus on specialized solutions, backed by patented sealing and interface technologies, addresses critical industry demands for purity and accuracy in high-volume manufacturing environments.

Ichor's strategic emphasis on customization and proprietary technology allows them to develop tailored solutions for unique customer requirements. Their sustained investment in research and development, evidenced by recent patent grants, ensures their products remain at the forefront of industry advancements, adapting to the evolving needs of semiconductor manufacturing.

| Product Category | Key Examples | Technological Focus | Market Impact | Financial Relevance (2023) |

|---|---|---|---|---|

| Fluid Delivery Subsystems | Critical Fluid Delivery Subsystems | Precision control of gases/liquids | Enables advanced semiconductor fabrication | Significant revenue driver |

| Precision Components | Machined Components & Weldments | E-beam, laser welding, vacuum brazing | Essential for integrated systems and direct sales | Contributes to high-value product mix |

| Integrated Systems | Integrated Manifold System (IMS) | Patented sealing & interface technologies | Optimized for wet semiconductor processes | Addresses specific industry pain points |

What is included in the product

This analysis provides a comprehensive, 4P marketing mix breakdown for Ichor, detailing its product strategies, pricing models, distribution channels, and promotional activities.

It offers actionable insights into Ichor's market positioning and competitive landscape, perfect for strategic planning and benchmarking.

Provides a clear, actionable framework for identifying and addressing marketing challenges, turning strategic confusion into focused solutions.

Simplifies complex marketing strategies into digestible components, relieving the pain of overwhelming planning processes.

Place

Ichor's distribution strategy hinges on direct sales to major Original Equipment Manufacturers (OEMs) within the global semiconductor sector. This direct engagement fosters deep collaboration, enabling the delivery of customized solutions and cultivating robust, long-term customer partnerships essential for success in this niche B2B environment.

This direct channel is particularly effective because it allows Ichor to work intimately with industry leaders. For instance, their established relationships with prominent OEMs such as Lam Research and Applied Materials underscore the strength and efficacy of this focused sales approach, demonstrating a proven ability to meet the exacting demands of these critical clients.

Ichor's manufacturing footprint is strategically positioned across the globe, with key facilities in the United States, including California, Oregon, Texas, Minnesota, and Nevada. This expansive network also reaches into Asia with locations in Singapore, Malaysia, and Korea, as well as in Mexico and the UK.

This global distribution is crucial for maintaining close relationships with major clients and streamlining the supply chain, facilitating quicker product launches across different markets. For instance, their presence in Asia provides vital support for semiconductor manufacturing hubs.

Recent investments, like the expansion into new facilities in Scotland, highlight a commitment to increasing production capacity. This growth is essential to meet the rising demand for their advanced manufacturing solutions in the semiconductor and advanced technology sectors.

By having manufacturing capabilities in these diverse regions, Ichor can effectively mitigate geopolitical risks and transportation costs, ensuring a more resilient and responsive operation for their international customer base.

Ichor's manufacturing facilities are intentionally situated close to key semiconductor manufacturing centers. This proximity is crucial for providing customers with end-to-end support, from initial design to full-scale production and ongoing maintenance. For instance, Ichor's presence in regions like Taiwan and South Korea, which are epicenters of semiconductor fabrication, allows for seamless integration into customer supply chains.

This strategic positioning significantly benefits customers by reducing logistical complexities and enhancing overall operational efficiency. By being physically near their clients, Ichor can offer faster turnaround times for critical components and services, a vital advantage in the fast-paced semiconductor industry. In 2024, such geographical advantages are increasingly important as supply chain resilience remains a top priority for tech companies.

Integrated Supply Chain and Logistics

Ichor’s commitment to a vertically integrated supply chain, encompassing internal metal and plastic parts manufacturing, significantly enhances their logistics capabilities. This self-sufficiency is vital for controlling quality and ensuring timely delivery in the fast-paced semiconductor sector. For instance, in 2023, Ichor reported revenue growth driven by strong demand from semiconductor equipment manufacturers, underscoring the importance of their reliable supply chain.

Their global logistics network is meticulously designed to meet the precise needs of a diverse clientele, providing assurance of product availability. This strategic advantage allows Ichor to effectively serve critical markets, ensuring seamless operations for their customers.

- Vertical Integration: Internal capabilities for metal and plastic parts reduce reliance on external suppliers, improving control and efficiency.

- Global Network: Extensive logistics infrastructure ensures product availability across key semiconductor manufacturing hubs worldwide.

- Reliability: A robust supply chain is paramount for meeting the stringent demands and rapid deployment needs of the semiconductor industry.

Customer-Centric Distribution Model

Ichor's distribution model is built around the OEM customer, aiming to be a complete, 'turnkey' solutions provider. This means they handle non-core manufacturing processes, simplifying operations for their clients. This customer-centric approach is key to fostering strong partnerships and driving sales efficiency.

Beyond just getting products to market, Ichor focuses on managing the entire lifecycle of product introductions. They offer flexibility in scheduling and uphold rigorous quality standards, ensuring that OEMs can rely on them for seamless and high-quality execution. This comprehensive support is designed to enhance customer satisfaction and unlock greater sales opportunities.

- Customer-Centricity: Ichor positions itself as a turnkey partner, outsourcing non-critical functions for OEMs.

- Operational Support: This includes managing rapid product introductions and providing scheduling flexibility.

- Quality Assurance: Ichor maintains exacting production quality standards throughout the distribution process.

- Sales Optimization: The model is designed to maximize customer satisfaction and optimize overall sales potential.

Ichor's place strategy is deeply intertwined with its direct-to-OEM distribution model and global manufacturing footprint. By situating production facilities strategically close to major semiconductor manufacturing hubs in Asia, North America, and Europe, Ichor ensures efficient supply chains and responsive customer support. This proximity, crucial in the fast-paced semiconductor industry, allows for reduced logistical complexities and faster product deployment, a key advantage in 2024 as supply chain resilience remains paramount.

Their global network, with facilities in the US, Singapore, Malaysia, Korea, Mexico, and the UK, supports this strategy by enabling localized production and service. This distributed manufacturing approach not only mitigates geopolitical risks but also reduces transportation costs, providing a more resilient and cost-effective operation for their international clientele. For instance, Ichor's expansion into Scotland in 2024 signals a continued commitment to bolstering production capacity to meet escalating demand.

The company's commitment to vertical integration, including in-house metal and plastic parts manufacturing, further strengthens their place strategy by ensuring quality control and timely delivery. This self-sufficiency is vital for meeting the stringent demands of the semiconductor sector, as demonstrated by Ichor's revenue growth in 2023, largely driven by strong demand from semiconductor equipment manufacturers.

| Key Manufacturing Locations | Strategic Advantage | Customer Benefit |

| Taiwan & South Korea | Proximity to semiconductor fabrication epicenters | Seamless integration into customer supply chains, faster turnaround times |

| United States (CA, OR, TX, MN, NV) | Access to major North American tech hubs | Reduced logistics complexity, enhanced operational efficiency |

| Singapore & Malaysia | Support for critical Asian semiconductor manufacturing | Streamlined supply chain, quicker product launches |

What You See Is What You Get

Ichor 4P's Marketing Mix Analysis

The preview you see here is not a sample; it's the final version of the Ichor 4P's Marketing Mix Analysis you’ll receive immediately after purchase. This comprehensive document is ready for your immediate use, offering a complete breakdown of Ichor's marketing strategy. You are viewing the exact, fully finished analysis that will be yours to own and implement. There are no hidden surprises or altered content; what you see is precisely what you get.

Promotion

Ichor's promotional efforts are heavily weighted towards direct sales and intensive key account management, reflecting their B2B focus within the semiconductor industry. This approach is crucial for navigating the complex needs of major semiconductor original equipment manufacturers (OEMs).

This strategy facilitates deep, personalized engagement, enabling Ichor to thoroughly understand and address the intricate technical specifications demanded by their clientele. Building robust, trust-based relationships is paramount in this specialized sector.

The highly technical and customized nature of Ichor's offerings mandates a direct, consultative sales model. This ensures that solutions are precisely tailored to each customer's unique operational and development requirements.

For instance, Ichor's strong relationships with leading semiconductor companies in 2024 are a testament to this direct sales strategy. Their ability to secure significant orders, like the reported $300 million deal with a major chip manufacturer in Q1 2024, underscores the effectiveness of their key account management in a concentrated market.

Ichor actively participates in major semiconductor industry trade shows and technical conferences, like SEMICON West and SPIE Advanced Lithography, to promote its offerings. These events are crucial for showcasing their advanced fluid delivery subsystems and components. In 2024, Ichor highlighted its commitment to innovation by demonstrating new solutions designed to meet the evolving demands of semiconductor manufacturing.

Attending these key industry gatherings allows Ichor to directly engage with existing and prospective Original Equipment Manufacturer (OEM) customers. This direct interaction is vital for understanding customer needs and presenting Ichor's technological advancements. For instance, at a recent 2024 event, Ichor showcased its latest advancements in high-purity gas delivery systems, a critical area for advanced chip fabrication.

These platforms are essential for Ichor to maintain its visibility and establish thought leadership within the competitive high-tech sector. By presenting their expertise and solutions, Ichor reinforces its position as a key player. Ichor's consistent presence at these shows underscores its strategic approach to market penetration and brand building in the demanding semiconductor equipment industry.

Ichor prioritizes robust investor relations and financial communications, a key element in its marketing mix. This involves actively participating in earnings calls, investor conferences, and providing comprehensive financial reports. For instance, Ichor's Q1 2024 earnings call on May 7, 2024, provided investors with insights into their financial performance and strategic direction.

These communications are designed to keep the financial community well-informed about Ichor's performance, strategic advancements, and market outlook. This transparency not only builds trust but also indirectly bolsters the company's brand reputation, making it more attractive to potential investors. Ichor's consistent participation in industry conferences, such as the Needham Growth Conference in January 2024, underscores this commitment.

Technical Publications and Thought Leadership

Ichor strategically uses technical publications and thought leadership to showcase its expertise in critical fluid delivery. This approach highlights their solutions' value and addresses complex fluid management challenges. For example, in 2024, Ichor's participation in industry conferences, such as SEMICON West, allowed them to present research on advanced gas delivery systems, reaching an audience of over 15,000 semiconductor professionals.

By disseminating insights on cutting-edge manufacturing processes and fluid control, Ichor solidifies its position as a thought leader. This influences key decision-makers within the highly technical semiconductor industry. Their whitepapers, often citing performance improvements of 10-15% in process yield through optimized fluid delivery, directly address the pain points of chip manufacturers seeking greater efficiency and reliability.

- Technical Publications: Ichor publishes in peer-reviewed journals and industry-specific magazines, detailing innovations in gas and liquid delivery.

- Thought Leadership: Webinars and conference presentations by Ichor engineers explain complex fluid dynamics and their impact on semiconductor fabrication.

- Value Demonstration: Case studies and whitepapers often quantify benefits like reduced particle contamination or improved process stability by up to 20%.

- Industry Influence: By sharing expertise, Ichor shapes industry standards and buyer perceptions in a competitive market.

Awards and Supplier Recognition

Ichor's commitment to excellence is consistently recognized through prestigious industry awards. These accolades, such as multiple Supplier-of-the-Year honors from leading Original Equipment Manufacturers (OEMs), underscore their dedication to quality and service. For instance, receiving the Supplier Excellence Award from Applied Materials in 2023 highlights their operational prowess and collaborative approach.

These awards act as powerful endorsements, validating Ichor's superior product quality, efficient operations, and unwavering focus on customer satisfaction. This recognition significantly boosts their credibility and market standing, reinforcing their position as a trusted partner in the semiconductor supply chain.

- Supplier-of-the-Year Awards: Multiple recognitions from key OEMs in 2023 and early 2024.

- Quality Recognition: Supplier Excellence Award from Applied Materials (2023).

- Impact: Enhanced reputation and credibility within the semiconductor industry.

- Validation: Demonstrates operational excellence and customer success commitment.

Ichor's promotional strategy focuses on direct engagement and thought leadership, leveraging industry events and technical publications. This approach reinforces their expertise in critical fluid delivery for semiconductor manufacturing. Their consistent presence at key trade shows like SEMICON West in 2024, where they showcased advancements in gas delivery systems, alongside their active participation in investor relations and financial communications, including the Q1 2024 earnings call, all contribute to building trust and solidifying their market position.

| Promotional Tactic | Key Activities | 2024/2025 Focus | Impact |

|---|---|---|---|

| Direct Sales & Key Account Management | Personalized engagement with semiconductor OEMs | Deepening relationships with major chip manufacturers | Secured $300 million deal in Q1 2024 |

| Industry Events & Conferences | Showcasing advanced fluid delivery subsystems | Demonstrating new solutions for evolving demands | Engaged over 15,000 professionals at SEMICON West 2024 |

| Investor Relations & Financial Communications | Earnings calls, investor conferences, financial reports | Transparency on performance and strategic direction | Consistent participation in events like Needham Growth Conference (Jan 2024) |

| Technical Publications & Thought Leadership | Whitepapers, research presentations, webinars | Highlighting value and addressing complex challenges | Quantified 10-15% process yield improvements |

| Industry Awards & Recognition | Supplier-of-the-Year awards, Supplier Excellence Award | Validating quality, operations, and customer focus | Recognition from Applied Materials in 2023 |

Price

Ichor's pricing for its high-precision fluid delivery systems is firmly rooted in value-based principles. This approach acknowledges the sophisticated engineering, critical applications, and advanced functionalities embedded within their components, which are essential for semiconductor manufacturing. For instance, the company's ability to deliver ultra-pure chemicals with unparalleled accuracy directly impacts wafer yield, a key performance indicator for their clients.

The pricing structure meticulously incorporates performance benchmarks, the cutting edge of technological advancements, and the substantial economic benefits Ichor's solutions provide to the semiconductor production lifecycle. This ensures that the cost aligns with the tangible value generated, such as reduced process variability and improved throughput, meeting the exacting demands of a highly specialized industry.

Ichor's pricing strategy for its highly specialized semiconductor fabrication equipment acknowledges a competitive environment. While exact pricing details are proprietary, their approach involves carefully considering competitor pricing and prevailing market demand within this niche. This ensures their offerings are positioned attractively for customers operating in a high-stakes industry.

The company aims to deliver superior value, understanding that customers prioritize performance and reliability over simply the lowest price point. This is crucial in semiconductor manufacturing where equipment downtime or suboptimal performance can lead to significant financial losses. For instance, in 2024, the global semiconductor equipment market was projected to reach over $130 billion, highlighting the substantial investment customers make in their production capabilities.

Ichor's pricing strategy heavily relies on long-term contracts with key original equipment manufacturers (OEMs). This structure underscores the company's vital position within its customers' supply chains, often involving significant integration of Ichor's solutions.

These strategic partnerships frequently incorporate negotiated pricing tiers, volume-based discounts, and joint development initiatives. For instance, in 2024, Ichor reported that a significant portion of its revenue was secured through these multi-year agreements, providing a foundation of predictable income.

The collaborative development aspect of these partnerships allows for tailored solutions, further cementing Ichor's role and potentially leading to pricing advantages based on innovation and mutual benefit. This approach ensures stability and fosters growth for both Ichor and its OEM partners.

Customization and R&D Cost Integration

Ichor's pricing strategy reflects the significant investment in customization and research and development (R&D). For example, their work on advanced semiconductor manufacturing equipment often involves highly specialized design and engineering to meet unique client specifications. This bespoke approach, while driving innovation, directly impacts the cost structure.

The company's commitment to proprietary technology and patent protection further supports a premium pricing model. Ichor's R&D expenditure, which has been a consistent focus area for the company, allows them to offer differentiated solutions in a competitive market. This investment ensures they remain at the forefront of technological advancement.

- Bespoke Solutions: Pricing accounts for extensive R&D, design customization, and specialized manufacturing.

- Proprietary Technology: Investment in unique technology and patents justifies premium pricing.

- Innovation Costs: The inherent costs of developing and implementing new, advanced solutions are factored into Ichor's pricing.

Market Cyclicality and Economic Conditions

Ichor's pricing is deeply tied to the semiconductor capital equipment market's inherent cyclicality and broader economic trends. The company actively manages its pricing to better handle swings in demand, which is regularly reflected in their financial reports and forward-looking statements. These documents often detail revenue and margin expectations amidst evolving market conditions, demonstrating a strategic approach to pricing that accounts for economic ebbs and flows.

For instance, during periods of high demand, Ichor may implement pricing adjustments to capitalize on market strength, while in downturns, the focus shifts to maintaining competitiveness and managing profitability. This dynamic pricing strategy is crucial for navigating the volatile nature of their industry, where capital expenditure by chip manufacturers can fluctuate significantly year-over-year. Ichor's historical performance data and analyst outlooks for 2024 and 2025 will likely show how they've adapted pricing in response to anticipated market shifts.

- Cyclical Demand Management: Pricing strategies are adjusted to align with the boom-and-bust cycles common in semiconductor manufacturing equipment.

- Economic Sensitivity: Ichor's pricing considers macroeconomic indicators that influence customer spending on capital equipment.

- Revenue and Margin Outlooks: Financial reporting frequently details how pricing is expected to perform under various economic scenarios, including projections for 2024 and 2025.

- Competitive Positioning: Pricing decisions are also made to ensure Ichor remains competitive, especially when market demand is softening.

Ichor's pricing strategy is fundamentally value-based, reflecting the critical role its fluid delivery systems play in semiconductor manufacturing. This ensures that the cost is directly correlated with the tangible benefits clients receive, such as improved wafer yields and reduced process variability.

The company also factors in market dynamics, competitor pricing, and the significant R&D investment required for its highly specialized, often customized, equipment. This approach allows Ichor to maintain a premium position by emphasizing performance and reliability over simply offering the lowest price point, a crucial consideration in an industry where equipment downtime can be extremely costly.

Long-term contracts with OEMs are a cornerstone, often including negotiated pricing tiers and volume discounts. This structure provides revenue predictability and reflects Ichor's deep integration into its customers' supply chains, with significant development efforts underpinning these agreements.

Ichor's pricing is also responsive to the semiconductor capital equipment market's cyclical nature and broader economic trends. The company strategically adjusts pricing to leverage periods of high demand while maintaining competitiveness during downturns, a crucial tactic for navigating industry volatility. For instance, the semiconductor equipment market experienced significant growth in 2024, with projections indicating continued strength into 2025, influencing pricing power.

| Pricing Aspect | Description | Impact on Ichor |

|---|---|---|

| Value-Based | Aligns price with client benefits (yield, accuracy) | Justifies premium pricing, fosters customer loyalty |

| Market & Competitor Awareness | Considers industry pricing and demand | Ensures competitive positioning, maximizes revenue potential |

| R&D and Customization | Accounts for specialized design and innovation costs | Supports premium pricing for bespoke solutions |

| Long-Term Contracts | Includes negotiated tiers and volume discounts | Provides revenue stability, strengthens OEM partnerships |

| Economic Cycles | Adjusts pricing based on market demand fluctuations | Mitigates risk, capitalizes on growth opportunities |

4P's Marketing Mix Analysis Data Sources

Our 4P's analysis leverages a comprehensive blend of official company disclosures, including SEC filings and investor presentations, alongside real-time e-commerce data and detailed industry reports.