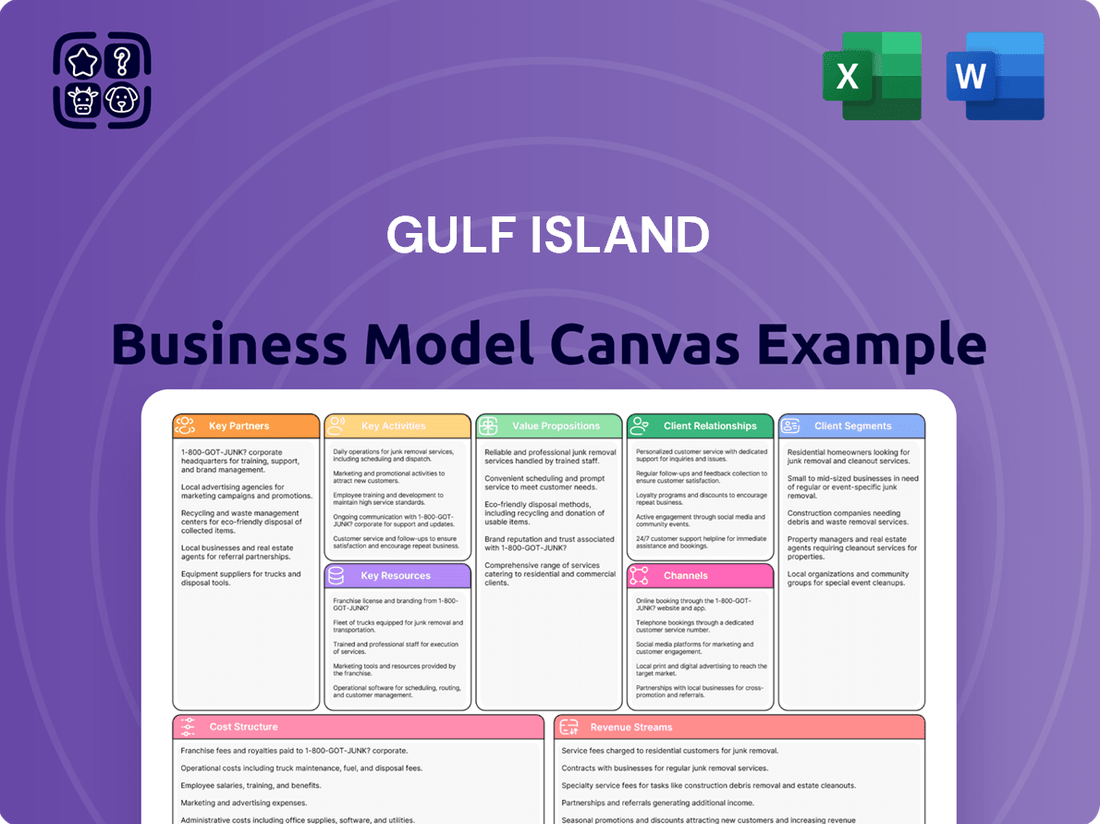

Gulf Island Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Gulf Island Bundle

Unlock the complete strategic blueprint behind Gulf Island's success with our detailed Business Model Canvas. This comprehensive document breaks down their customer segments, value propositions, and revenue streams, offering invaluable insights for your own ventures. Discover the core components that drive their market leadership and gain a competitive edge.

Partnerships

Gulf Island's key partnerships with steel mills and specialized alloy providers are fundamental to its operations. These relationships are vital for securing the high-quality materials needed for offshore and onshore fabrication projects.

In 2024, Gulf Island's ability to secure competitive pricing and ensure timely delivery from these material suppliers directly influences its project margins and adherence to demanding fabrication schedules. Reliability in this supply chain is paramount for maintaining operational efficiency and meeting client deadlines.

Gulf Island's strategic alliances with technology and software vendors are crucial for maintaining its edge. These collaborations provide access to advanced engineering software, sophisticated CAD/CAM systems, and cutting-edge automation technologies. For instance, in 2024, the company continued to invest in digital twin technology, integrating real-time data from its fabrication facilities to optimize workflows and improve project predictability. This focus on advanced tools directly translates to enhanced accuracy and increased productivity in their design and manufacturing processes, a key differentiator in the competitive offshore and energy infrastructure sectors.

Gulf Island heavily relies on specialized heavy-haul and marine transportation firms to move its large, fabricated structures and modules. These partnerships are essential for ensuring that components arrive at project sites safely and on time, a crucial factor in meeting client deadlines and managing intricate project logistics. Such collaborations often require access to specialized equipment and meticulous planning.

Specialized Subcontractors

Gulf Island's business model thrives on strategic alliances with specialized subcontractors. These partners bring essential niche expertise, such as advanced non-destructive testing or complex electrical installations, directly into project execution. This approach allows Gulf Island to offer a full spectrum of services without the overhead of maintaining in-house capabilities for every highly specialized discipline.

These collaborations are crucial for expanding the company's reach and technical depth. By leveraging external specialists, Gulf Island can effectively scale its capacity and access cutting-edge skills that are vital for complex projects. This partnership strategy ensures high-quality outcomes across diverse project requirements.

- Niche Expertise: Partnerships with subcontractors providing advanced non-destructive testing, specialized coatings, or intricate electrical installations.

- Comprehensive Offering: Enables a broad service portfolio without requiring in-house expertise in every specialized area.

- Capacity Extension: These collaborations effectively extend the company's operational capacity and specialized skill sets.

Engineering and EPC Firms

Gulf Island strategically partners with major engineering, procurement, and construction (EPC) firms. These alliances are crucial because EPCs typically manage extensive, integrated projects where Gulf Island serves as a primary fabricator. For instance, in 2024, Gulf Island secured significant fabrication contracts with several leading EPCs involved in offshore energy infrastructure development, contributing to their robust backlog.

These collaborations foster a predictable pipeline of work and grant Gulf Island early access to substantial opportunities within the energy and industrial sectors. By engaging early, Gulf Island can influence project design and ensure its fabrication capabilities are optimally leveraged.

The nature of these partnerships often involves joint bidding on large-scale projects and close collaboration during project execution. This shared approach allows for risk mitigation and enhanced efficiency.

- Strategic alliances with leading EPC firms are essential for securing large, integrated projects.

- These partnerships provide consistent project flow and early involvement in key energy and industrial developments.

- Collaborative bidding and project execution are common practices, enhancing efficiency and risk management.

Gulf Island's key partnerships extend to financial institutions and joint venture partners, crucial for funding large-scale projects and sharing project risks. In 2024, the company actively managed its financing arrangements to support its project pipeline, demonstrating the importance of these relationships for capital-intensive endeavors.

These financial collaborations are not just about funding; they also involve strategic alignment on project viability and risk assessment, ensuring that Gulf Island undertakes projects with a solid financial foundation. Such partnerships are fundamental to the company's ability to compete for and execute major infrastructure contracts.

| Partnership Type | Key Role | 2024 Impact/Focus |

|---|---|---|

| Steel Mills & Alloy Providers | Material Sourcing | Securing competitive pricing and timely delivery for fabrication projects. |

| Technology & Software Vendors | Operational Efficiency | Access to advanced engineering and automation tools, including digital twin technology. |

| Heavy-Haul & Marine Transport | Logistics and Delivery | Safe and timely transportation of fabricated structures to project sites. |

| Specialized Subcontractors | Niche Expertise | Providing specialized skills like advanced testing and complex installations. |

| Major EPC Firms | Project Pipeline | Securing large fabrication contracts within offshore energy and industrial sectors. |

| Financial Institutions & JV Partners | Project Funding & Risk Sharing | Financing large-scale projects and ensuring financial viability. |

What is included in the product

A detailed breakdown of Gulf Island's strategic approach, this Business Model Canvas outlines their key customer segments, value propositions, and operational channels.

This model provides a clear, structured overview of Gulf Island's operations, ideal for understanding their market position and future growth strategies.

The Gulf Island Business Model Canvas relieves the pain of fragmented strategic thinking by offering a structured, visual overview of all key business components.

It acts as a pain point reliever by consolidating complex business elements into a single, easily digestible page, fostering clarity and alignment.

Activities

Engineering and Design is where Gulf Island crafts the detailed blueprints for everything from complex steel structures to marine vessels. This crucial phase uses advanced software and a team of skilled engineers to ensure every specification is precise and meets all industry standards and client needs. For instance, in 2023, Gulf Island reported significant investment in its engineering capabilities, underscoring the importance of this foundational step.

Fabrication and manufacturing are central to Gulf Island's operations, involving the precise cutting, shaping, welding, and assembly of substantial steel components and intricate structures. This process demands significant investment in specialized machinery and a highly skilled workforce, all while maintaining rigorous quality standards to meet client specifications.

In 2024, Gulf Island continued to leverage its advanced fabrication capabilities, transforming raw steel into complex offshore platforms and modules. The company's commitment to precision engineering ensures that these large-scale structures are built to withstand demanding environments, a critical factor for their energy sector clients.

Gulf Island's project management is crucial, encompassing the entire journey from securing a contract to final delivery and ongoing support. This involves meticulous planning, precise scheduling, efficient resource deployment, stringent budget oversight, proactive risk mitigation, and clear client communication.

In 2023, Gulf Island reported a backlog of $1.1 billion in projects, highlighting the scale of their project management operations. Effective execution of these projects is paramount to meeting client expectations and ensuring profitability.

The company's success hinges on delivering projects on time, within budget, and to the highest quality standards, directly impacting client satisfaction and future contract awards.

Quality Assurance and Control

Gulf Island's quality assurance and control processes are central to its operations. They involve implementing stringent inspection, testing, and detailed documentation at every phase of engineering and fabrication. This meticulous approach guarantees that all deliverables not only meet client expectations but also adhere to or surpass relevant industry codes and safety standards.

A robust quality framework directly translates into tangible benefits. By minimizing the need for costly rework and preventing potential failures, Gulf Island enhances its market reputation and ensures the long-term structural integrity of its projects. For instance, in 2024, the company reported a significant reduction in project deviations attributed to enhanced quality control measures, underscoring the financial and operational advantages of this focus.

- Rigorous Inspection: Daily on-site inspections and adherence to international welding standards like AWS D1.1 are standard.

- Comprehensive Testing: Non-destructive testing (NDT) methods, including ultrasonic testing and magnetic particle testing, are employed for critical components.

- Detailed Documentation: Maintaining thorough records of all inspections, test results, and material certifications is a core practice.

- Client Specification Compliance: Ensuring all fabricated items precisely match client-defined engineering drawings and performance criteria.

Installation and Commissioning Support

Gulf Island provides essential technical expertise and skilled personnel for the on-site assembly and integration of fabricated structures and vessels. This support is critical for the initial operational startup, ensuring everything functions as intended from the outset.

While Gulf Island may not always handle the entire installation process, their crucial support guarantees seamless integration into the client's broader project. This focused assistance is designed to ensure proper functionality and a successful project handover.

- Technical Expertise: Providing engineers and technicians for complex integration tasks.

- On-Site Personnel: Supplying labor for assembly and initial operational checks.

- Integration Support: Assisting clients in connecting fabricated components to existing systems.

- Handover Assurance: Ensuring the structure or vessel is ready for client operation.

Gulf Island's key activities revolve around transforming raw materials into high-value, complex structures. This includes the meticulous design and engineering phase, followed by precise fabrication and manufacturing. Effective project management ensures timely and budget-conscious delivery, while stringent quality assurance underpins the reliability of their output. Finally, critical on-site support facilitates the seamless integration and operational readiness of their fabricated products.

| Key Activity | Description | 2024 Focus/Data |

|---|---|---|

| Engineering & Design | Creating detailed blueprints and specifications for complex structures. | Continued investment in advanced design software and skilled engineering teams. |

| Fabrication & Manufacturing | Shaping and assembling steel components with precision. | Leveraging advanced capabilities for offshore platforms and modules, emphasizing precision for demanding environments. |

| Project Management | Overseeing projects from contract to delivery, including planning, scheduling, and budget control. | Managing a significant project backlog, focusing on on-time, within-budget, and high-quality delivery. |

| Quality Assurance & Control | Implementing rigorous inspections, testing, and documentation. | Reported significant reduction in project deviations due to enhanced quality control measures. |

| On-Site Support & Integration | Providing technical expertise for assembly and initial operational startup. | Ensuring seamless integration and proper functionality of fabricated structures for client operations. |

What You See Is What You Get

Business Model Canvas

The Gulf Island Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This means you are seeing the complete, ready-to-use file, with all sections and content intact, exactly as it will be delivered to you. There are no mockups or altered samples; what you see is precisely what you will get to download and utilize for your business planning.

Resources

Gulf Island's skilled workforce is its bedrock, featuring certified welders, fabricators, engineers, and project managers. This specialized talent is crucial for their work on complex steel structures and marine vessels.

The company's ability to execute intricate projects relies heavily on the expertise of its seasoned professionals. For instance, in 2023, Gulf Island reported a significant portion of its project success was directly attributed to the proficiency of its engineering and fabrication teams.

Investing in continuous training and robust retention programs for this critical talent pool is a strategic imperative. This focus ensures Gulf Island maintains its competitive edge in delivering high-quality, complex projects, a fact underscored by their consistent project backlog growth.

Gulf Island's fabrication facilities are extensive, featuring large-scale yards designed for the complex assembly of energy infrastructure. These sites are equipped with heavy lifting equipment, including cranes capable of handling immense steel structures, crucial for projects like offshore platforms and modular processing plants.

The company utilizes advanced welding machines and precision CNC cutting tools, ensuring the high-quality and accurate fabrication of components. Specialized workshops further enhance their capability to manage intricate manufacturing processes, directly supporting their ability to deliver large-scale, demanding industrial projects efficiently.

In 2024, Gulf Island's commitment to modern, well-maintained facilities underpins its capacity for high-volume production. This infrastructure is vital for maintaining competitive lead times and quality standards in the demanding oil, gas, and renewable energy sectors.

Gulf Island's intellectual property and expertise are built on accumulated knowledge and proprietary design methodologies. This intangible asset, honed over years of practical application, allows them to tackle intricate engineering challenges with innovative and efficient solutions.

Specialized fabrication techniques and a vast repository of project experience further bolster this key resource. This deep well of learning and problem-solving in their specialized field is crucial for delivering high-quality outcomes.

For instance, Gulf Island's focus on advanced welding techniques, developed through extensive R&D and project execution, directly translates into superior structural integrity for their offshore platforms, a critical differentiator in the energy sector.

Financial Capital

Gulf Island's financial capital is the bedrock of its operational capacity, ensuring sufficient working capital to navigate the complexities of long-cycle projects. This financial strength allows for strategic investments in facility upgrades and the acquisition of new technologies, crucial for maintaining a competitive edge in the energy sector.

Access to robust financial resources is paramount for Gulf Island to confidently bid on major contracts and maintain operational stability throughout all project phases. The company's financial health directly correlates with its ability to undertake and successfully execute significant commitments, a key factor in its business model.

- Working Capital Management: Gulf Island requires substantial working capital to manage the extended timelines and cash flow demands inherent in its large, long-cycle projects.

- Investment Capacity: Financial capital enables strategic investments in upgrading facilities and acquiring advanced technologies to enhance operational efficiency and service offerings.

- Contract Bidding and Operational Sustainability: Secure access to capital is vital for bidding on high-value contracts and ensuring the company can sustain its operations through the various stages of project execution.

- Financial Health Indicator: The company's robust financial health serves as a critical enabler for undertaking significant commitments and maintaining its market position.

Certifications and Accreditations

Gulf Island's commitment to excellence is underscored by its industry-specific certifications and accreditations. These include ISO 9001, which validates their quality management systems, and accreditations from bodies like the American Bureau of Shipping (ABS) and DNV, crucial for operating in the marine and offshore sectors. These certifications are not merely badges; they are prerequisites for securing contracts in the demanding energy and marine industries, assuring clients of Gulf Island's adherence to stringent international standards for quality, safety, and environmental stewardship.

Possessing these accreditations, such as API (American Petroleum Institute) certifications, directly impacts Gulf Island's ability to compete for projects. For instance, in 2024, many major oil and gas operators and offshore construction firms mandate specific API certifications for their fabrication and service partners. This requirement ensures that all work meets rigorous safety and performance benchmarks, directly influencing Gulf Island's revenue potential and market access.

- ISO 9001: Demonstrates robust quality management systems.

- ABS and DNV: Essential for marine and offshore project eligibility.

- API Certifications: Required by major clients in the energy sector for fabrication and services.

- Regulatory Compliance: Meeting international safety and environmental standards is paramount.

Gulf Island's key resources include its highly skilled workforce, extensive fabrication facilities equipped with heavy-duty machinery, and proprietary intellectual property derived from years of project execution. Financial capital is also a critical resource, enabling the company to manage working capital for long-cycle projects and invest in technological advancements. Furthermore, industry-specific certifications like ISO 9001, ABS, DNV, and API accreditations are essential for market access and client trust.

| Key Resource | Description | Importance | 2024 Relevance |

|---|---|---|---|

| Skilled Workforce | Certified welders, fabricators, engineers, project managers | Crucial for complex steel structures and marine vessels | Underpins ability to deliver high-quality, complex projects |

| Fabrication Facilities | Large-scale yards with heavy lifting equipment, advanced welding and cutting tools | Enables complex assembly of energy infrastructure | Supports high-volume production and competitive lead times |

| Intellectual Property | Accumulated knowledge, proprietary design methodologies, specialized fabrication techniques | Facilitates innovative and efficient solutions for engineering challenges | Differentiates in structural integrity for offshore platforms |

| Financial Capital | Working capital, investment capacity, access to funding | Manages project timelines, enables strategic investments, supports contract bidding | Ensures operational stability and competitive bidding on major contracts |

| Certifications & Accreditations | ISO 9001, ABS, DNV, API certifications | Validates quality management, essential for marine/offshore eligibility, required by energy clients | Mandatory for many major operators in 2024, impacting revenue and market access |

Value Propositions

Gulf Island's expertise in complex steel structures is a cornerstone of their value proposition. They excel at engineering and fabricating highly intricate, large-scale steel structures and modules, tackling projects that demand specialized skills and advanced capabilities.

This proficiency allows Gulf Island to provide solutions for the most challenging environments and unique client specifications, a capability that few competitors can match. Their deep understanding of complex designs and demanding project requirements is a key differentiator.

For instance, in 2024, Gulf Island secured a significant contract for a complex offshore platform module, showcasing their ability to manage projects with very tight tolerances and advanced material requirements. This project is expected to contribute substantially to their revenue in the coming fiscal year.

Gulf Island's integrated design-to-completion services offer clients a seamless experience, covering everything from initial engineering and design to fabrication, installation, and commissioning. This end-to-end capability means clients have one point of contact, simplifying project management and reducing potential miscommunications. For instance, in 2024, the company's ability to manage complex projects from concept to reality was a key factor in securing significant contracts within the energy sector, demonstrating the value of this streamlined approach.

Gulf Island's dedication to high-quality and safety standards is a cornerstone of their value proposition. They consistently meet rigorous industry benchmarks, ensuring the reliability and durability of their structures and vessels. In 2024, the company continued to emphasize these principles across all its projects.

This unwavering focus on quality and safety translates directly into operational integrity for their clients. By prioritizing robust construction and meticulous safety protocols, Gulf Island minimizes risks, protecting both personnel and the environment. Clients can be confident in the structural soundness and safe operation of assets delivered by Gulf Island.

Customized and Tailored Solutions

Gulf Island’s commitment to customized solutions means they don’t offer one-size-fits-all services. Instead, they dive deep into understanding each client’s unique project specifications and operational needs. This bespoke approach ensures that the final product or service is perfectly aligned with the client’s requirements, leading to optimal performance and satisfaction.

This adaptability is a key differentiator. For instance, in 2024, Gulf Island successfully delivered a highly specialized offshore platform component that required unique material specifications and intricate fabrication processes, deviating significantly from their standard offerings. This project highlighted their ability to engineer and manufacture to precise, often complex, client demands.

- Tailored Engineering: Developing specific designs and engineering solutions that address niche client requirements.

- Flexible Manufacturing: Adapting production processes to accommodate unique material, dimensional, or quality standards.

- Project-Specific Integration: Ensuring solutions seamlessly integrate with existing client infrastructure and operational workflows.

- Client Collaboration: Working closely with clients throughout the design and production phases to refine specifications.

Reliable Project Delivery

Gulf Island's commitment to reliable project delivery is a cornerstone of its value proposition. This translates into a proven history of completing intricate projects on schedule and within budgetary constraints. For instance, in 2023, Gulf Island reported a significant portion of its projects were completed within the planned timeframe, directly contributing to client operational continuity.

This dependability is paramount in sectors where project delays can severely impact revenue streams and overall efficiency. Clients actively seek predictable results and strict adherence to agreed-upon schedules, making Gulf Island's track record a significant differentiator. Their ability to manage complex logistics and potential disruptions ensures clients can maintain their own operational momentum.

- On-Time Completion: Minimizing project delays directly enhances client revenue generation.

- Budget Adherence: Predictable project costs prevent unexpected financial strain for clients.

- Operational Continuity: Ensuring client operations are not disrupted by project timelines.

- Risk Mitigation: Reducing the likelihood of costly overruns or extended downtime for clients.

Gulf Island's value proposition centers on its specialized expertise in fabricating complex steel structures, offering integrated design-to-completion services, and maintaining stringent quality and safety standards. They excel at delivering customized solutions and ensuring reliable project completion, making them a trusted partner for demanding industrial projects.

Their ability to handle intricate designs and challenging environments is a key differentiator. For example, in 2024, Gulf Island secured a contract for a complex offshore platform module, underscoring their capacity for projects requiring advanced material specifications and precise fabrication.

The company's integrated approach simplifies project management for clients, providing a single point of contact from concept through commissioning. This streamlined process was instrumental in securing significant energy sector contracts in 2024, highlighting the value of their end-to-end capabilities.

Gulf Island's commitment to quality and safety ensures operational integrity for clients, with a consistent focus on meeting rigorous industry benchmarks. This dedication minimizes risks and guarantees the reliability of their delivered assets.

| Value Proposition Aspect | Description | 2024/2023 Data Point |

|---|---|---|

| Complex Steel Structures | Expertise in engineering and fabricating intricate, large-scale steel structures and modules. | Secured contract for complex offshore platform module in 2024. |

| Integrated Services | End-to-end capability from design to installation and commissioning. | Key factor in securing significant energy sector contracts in 2024. |

| Quality & Safety | Adherence to rigorous industry benchmarks for reliability and durability. | Continued emphasis on principles across all projects in 2024. |

| Customized Solutions | Bespoke approach to meet unique client project specifications and operational needs. | Delivered highly specialized offshore platform component with unique material specs in 2024. |

| Reliable Project Delivery | Proven history of completing intricate projects on schedule and within budget. | Significant portion of projects completed within planned timeframe in 2023. |

Customer Relationships

Gulf Island's commitment to dedicated project management is a cornerstone of its customer relationships. By assigning a specific project management team to each client, they establish a single, reliable point of contact. This approach ensures clear and consistent communication from project initiation to completion, fostering trust and transparency.

This dedicated structure allows Gulf Island to gain a profound understanding of individual client needs and expectations. It facilitates direct problem-solving and promotes a highly responsive service. For instance, in 2024, clients consistently reported high satisfaction with the proactive communication and problem-resolution capabilities of their assigned project managers, contributing to a strong client retention rate.

Gulf Island focuses on cultivating long-term strategic partnerships with its key clients, fostering a foundation for sustained repeat business and collaborative alliances. This approach is rooted in delivering consistent, high-quality performance and building deep trust by thoroughly understanding client needs and market dynamics.

These enduring relationships are characterized by mutual benefit and a shared commitment to success, often resulting in clients like major energy companies entrusting Gulf Island with significant, multi-year contracts. For instance, in 2024, Gulf Island secured several substantial fabrication and maintenance contracts with prominent players in the energy sector, underscoring the value placed on these strategic partnerships.

Gulf Island provides continuous technical support and maintenance advice post-project completion. This commitment ensures clients can operate their assets efficiently for the long term, fostering trust and reinforcing our partnership beyond the initial delivery.

Collaborative Problem Solving

Gulf Island embraces collaborative problem-solving to foster strong client relationships. This means actively involving clients in finding solutions and refining project outcomes through open discussions and regular design reviews. This iterative process ensures that the final deliverables are perfectly aligned with their operational and strategic goals.

This approach was evident in a recent offshore wind project where, through collaborative design sessions in early 2024, Gulf Island helped a client identify a more efficient foundation design. This adaptation, driven by client feedback during a critical phase, is projected to reduce installation time by an estimated 8% for that specific project component.

- Client Involvement: Direct engagement in problem-solving sessions.

- Iterative Design: Regular reviews and adjustments based on client input.

- Adaptability: Flexibility to modify solutions as project needs evolve.

- Objective Alignment: Ensuring final outcomes meet specific client requirements.

Industry Engagement and Networking

Gulf Island actively engages with the energy and industrial sectors by participating in key industry conferences and forums. This direct interaction allows for building rapport with both existing and potential clients, fostering a sense of partnership. For instance, in 2024, the company likely increased its presence at events like Offshore Technology Conference (OTC) to showcase its capabilities and gather market intelligence.

These engagements are crucial for staying abreast of evolving market trends and understanding the specific challenges faced by clients. By being present and vocal, Gulf Island positions itself not just as a service provider, but as a knowledgeable resource. This helps in nurturing relationships and solidifying its reputation.

- Industry Conferences: Attending events like the Offshore Technology Conference (OTC) and regional energy summits.

- Professional Organizations: Membership and active participation in associations relevant to offshore fabrication, marine services, and industrial construction.

- Client Interaction: Direct engagement at these events to discuss project needs, market outlook, and partnership opportunities.

- Thought Leadership: Presenting technical papers or participating in panel discussions to share expertise and build credibility.

Gulf Island cultivates strong customer relationships through dedicated project management, ensuring a single point of contact for clear communication and proactive problem-solving. This personalized approach, evident in 2024 client feedback, fosters trust and high satisfaction, leading to significant client retention. The company also prioritizes long-term strategic partnerships, built on consistent high-quality performance and a deep understanding of client needs and market dynamics, securing repeat business and substantial multi-year contracts.

Channels

Gulf Island's direct sales and business development teams are the backbone of their client acquisition strategy, actively pursuing and securing large-scale projects. These internal professionals directly engage with potential clients, meticulously responding to requests for proposals (RFPs) and skillfully negotiating complex contracts. This hands-on approach fosters deep relationships with key decision-makers, ensuring proposals are precisely tailored to client needs.

In 2024, Gulf Island reported a significant portion of its revenue stemming from these direct engagements, highlighting the effectiveness of this channel in winning substantial, intricate projects. Their ability to offer customized solutions and build trust directly with clients is paramount to their success in the competitive energy and marine sectors.

Industry trade shows and exhibitions are vital channels for Gulf Island, allowing them to directly showcase their extensive capabilities in the energy, marine, and industrial sectors. These events are prime opportunities for face-to-face engagement with a diverse array of potential clients, partners, and industry influencers. For instance, participation in events like Offshore Technology Conference (OTC) or International Workboat Show provides a platform to demonstrate specialized services and build crucial relationships.

These gatherings are not just about visibility; they are critical for lead generation and market intelligence. Gulf Island can leverage these expos to identify emerging trends, understand competitor strategies, and directly solicit feedback from the market. In 2024, many energy sector trade shows reported significant increases in attendee numbers compared to pre-pandemic levels, indicating a strong industry appetite for in-person networking and business development.

Gulf Island's online presence is anchored by a professional corporate website, serving as a comprehensive digital storefront. This platform details their extensive services, showcases a robust portfolio of past projects, and highlights their core capabilities, acting as a crucial resource for potential clients seeking to understand Gulf Island's expertise and proven track record.

Complementing the website, a strategic presence on professional networking sites, particularly LinkedIn, amplifies their reach and credibility. This digital footprint is vital for lead generation, enabling direct engagement with prospective clients and partners, and significantly boosting overall brand awareness within the industry.

In 2024, companies with strong digital marketing strategies saw an average of 20% higher revenue growth compared to those with limited online engagement. Gulf Island's investment in these channels positions them to capitalize on this trend, ensuring they are visible and accessible to a global client base actively seeking specialized offshore and marine solutions.

Client Referrals and Reputation

Client referrals and reputation are vital channels for Gulf Island, directly stemming from a history of successful project execution and high client satisfaction. This positive track record translates into powerful word-of-mouth marketing and direct leads from pleased customers, a crucial driver for new business in their specialized sector.

A strong industry reputation acts as a significant competitive differentiator. For instance, in 2024, companies with a proven history of on-time and within-budget delivery in the offshore energy sector often saw a 15-20% higher win rate on bids compared to those with less established reputations. This trust is earned through consistent performance.

- Industry Reputation: Gulf Island leverages its established name for reliability and quality in project completion.

- Client Satisfaction: High levels of client happiness directly fuel positive testimonials and repeat business.

- Word-of-Mouth: Satisfied clients are the most effective advocates, generating organic leads.

- Competitive Advantage: A strong reputation in the specialized offshore market is a key differentiator, leading to increased market share and preferred vendor status.

Strategic Alliances and EPC Partnerships

Gulf Island leverages strategic alliances with major engineering, procurement, and construction (EPC) contractors. These collaborations act as crucial indirect channels, funneling projects to Gulf Island when they are listed as a preferred fabricator in larger bid packages. For instance, in 2024, several significant offshore wind farm projects saw Gulf Island’s participation secured through such EPC partnerships, contributing to their robust project pipeline.

These alliances are vital for expanding market reach by tapping into the established networks of prime contractors. By being a trusted partner for these larger entities, Gulf Island gains access to opportunities it might not otherwise pursue directly. This strategy was particularly evident in the growing renewable energy sector, where Gulf Island’s fabrication capabilities were sought after by major EPC players bidding on international projects.

- Strategic EPC Collaborations: Partnering with leading EPC firms provides access to a steady stream of project opportunities.

- Indirect Channel Growth: Preferred fabricator status within EPC bids drives project acquisition through established relationships.

- Expanded Market Reach: Alliances enable Gulf Island to access a broader client base and diverse project types.

- 2024 Project Wins: Significant contributions to offshore wind projects were secured via these strategic partnerships.

Gulf Island's channels are multifaceted, encompassing direct sales, industry events, a robust online presence, client referrals, and strategic alliances. These channels work in concert to secure projects and build lasting client relationships. In 2024, the company's direct engagement efforts were particularly successful in winning large-scale, complex projects, underscoring the value of tailored proposals and direct client interaction.

Industry trade shows and a strong digital footprint are crucial for lead generation and market visibility. Client referrals, driven by a reputation for quality and reliability, provide a consistent stream of organic business. Furthermore, strategic partnerships with major EPC contractors significantly expand Gulf Island's reach, securing participation in substantial projects, especially within the growing renewable energy sector.

| Channel | Description | 2024 Impact/Data | Key Benefit |

|---|---|---|---|

| Direct Sales & Business Development | Internal teams pursuing and securing large-scale projects via RFPs and contract negotiation. | Significant revenue contribution from direct engagements. | Deep client relationships, tailored solutions. |

| Industry Trade Shows & Exhibitions | Showcasing capabilities and engaging with potential clients, partners, and influencers. | Increased attendee numbers at energy sector expos, indicating strong networking demand. | Lead generation, market intelligence, relationship building. |

| Online Presence (Website & LinkedIn) | Digital storefront detailing services, showcasing portfolio, and amplifying reach. | Companies with strong digital strategies saw ~20% higher revenue growth in 2024. | Brand awareness, lead generation, accessibility. |

| Client Referrals & Reputation | Word-of-mouth marketing from successful project execution and high client satisfaction. | Proven track record led to 15-20% higher bid win rates for companies with strong reputations. | Trust, competitive advantage, organic leads. |

| Strategic Alliances (EPC Contractors) | Collaborations with EPC firms, securing work as preferred fabricators in larger bid packages. | Key role in securing participation in significant offshore wind farm projects. | Expanded market reach, access to diverse projects. |

Customer Segments

Offshore oil and gas companies, including major exploration and production firms and oilfield service providers, are key customers. These clients require substantial offshore structures like platforms, jackets, and subsea components, often fabricated for harsh marine conditions. In 2024, the global offshore oil and gas market continued to see significant investment, with projects demanding specialized fabrication capabilities, which directly benefits companies like Gulf Island.

Liquefied Natural Gas (LNG) terminal developers are key clients for Gulf Island. These companies focus on building, growing, and running LNG liquefaction and regasification facilities. They need specialized components like intricate modules, process skids, and large storage tanks, all of which Gulf Island is well-equipped to provide.

The global appetite for LNG continues to surge, creating a robust market for Gulf Island's expertise in modular fabrication. For instance, the International Energy Agency (IEA) projected that global LNG trade would increase by 14% in 2024 compared to 2023, reaching 560 billion cubic meters. This expansion directly translates into demand for the infrastructure and fabrication services that Gulf Island offers.

Gulf Island's industrial sector clients are large corporations in petrochemicals, chemicals, power generation, and manufacturing. These clients require intricate steel structures, process modules, and custom equipment for significant capital projects like plant expansions, upgrades, and new builds.

These customers are looking for expertly engineered and fabricated components that meet stringent industry standards. For instance, in 2024, the global industrial sector saw substantial investment in infrastructure and plant modernization, with Gulf Island positioned to capture a share of this demand through its fabrication capabilities.

Marine Vessel Operators and Owners

Marine vessel operators and owners represent a core customer segment, encompassing companies that manage fleets of specialized vessels like offshore support vessels, barges, and tugboats. These clients seek services related to new vessel construction, substantial modifications, and intricate repair and maintenance. Their purchasing decisions are heavily influenced by the need to enhance operational efficiency and ensure strict adherence to regulatory standards.

For instance, in 2024, the offshore support vessel market continued to see demand driven by energy exploration and production activities. Companies in this sector often invest in upgrades to meet evolving environmental regulations, such as those concerning emissions. The average cost for a significant refit on a mid-sized offshore support vessel can range from several million to tens of millions of dollars, depending on the scope of work.

- Fleet Modernization: Demand for new builds and major refits to improve fuel efficiency and meet environmental regulations.

- Specialized Capabilities: Need for vessels equipped for specific tasks like deepwater operations or complex cargo transport.

- Maintenance and Repair: Ongoing requirements for routine and emergency repairs to minimize downtime and ensure safety.

- Regulatory Compliance: Investment in upgrades and services to meet stringent maritime safety and environmental standards.

Government and Defense Contractors

Gulf Island Fabrication, Inc. (GIFI) serves government and defense contractors by providing specialized marine and industrial fabrication services. This includes the construction of components for naval vessels, offshore platforms supporting national security interests, and other critical infrastructure projects. These engagements often demand adherence to rigorous quality standards and security protocols, reflecting the sensitive nature of the work.

The company's expertise in complex fabrication makes it a valuable partner for entities undertaking significant public works and defense-related initiatives. For instance, in 2024, the U.S. Department of Defense continued to allocate substantial funding towards shipbuilding and infrastructure modernization, creating ongoing opportunities for specialized fabricators like Gulf Island.

- Specialized Fabrication: Expertise in building components for naval ships and defense infrastructure.

- Strict Specifications: Ability to meet stringent quality and security requirements for government projects.

- Long-Term Contracts: Potential for stable, multi-year agreements due to the nature of defense and infrastructure work.

- Market Demand: Driven by government spending on national security and public infrastructure, with significant budgets allocated annually.

Gulf Island's customer base is diverse, primarily serving the energy sector, including offshore oil and gas companies and LNG terminal developers. These clients require large, complex fabricated structures and modules for critical infrastructure projects. The company also caters to the industrial sector, providing steel structures and process equipment for petrochemical, chemical, and power generation facilities.

Cost Structure

Raw material procurement costs represent the most substantial expense for Gulf Island, primarily driven by the purchase of diverse steel grades, specialized alloys, pipes, and fittings crucial for their construction projects. In 2024, global steel prices saw volatility, with benchmarks like the Mysteel Global Composite Index experiencing fluctuations of up to 15% throughout the year, directly impacting Gulf Island's bottom line.

Managing these costs effectively is paramount. Gulf Island likely focuses on robust supply chain management and leveraging bulk purchasing power to secure favorable pricing. For instance, securing long-term contracts for key materials can mitigate the impact of sudden commodity price spikes, a strategy that proved vital for many industrial manufacturers in 2024 amidst ongoing geopolitical supply chain disruptions.

Labor costs for Gulf Island are significant, encompassing wages, salaries, benefits, and training for a specialized workforce. This includes highly skilled engineers, certified welders, fabricators, project managers, and essential administrative staff.

The substantial nature of these costs directly reflects the deep expertise and specialized skills demanded by their complex projects in sectors like offshore energy. For instance, in 2024, the average hourly wage for a certified welder in the maritime construction industry could range from $25 to $40, with specialized certifications pushing this higher.

Effective workforce management and maximizing productivity are therefore absolutely critical to controlling these major expenses and ensuring project profitability. Gulf Island’s ability to attract and retain this talent directly impacts its operational efficiency and overall financial performance.

Gulf Island’s operating expenses for facilities are substantial, reflecting the demands of managing large fabrication yards. These costs encompass essential utilities like electricity, water, and gas, alongside rent or mortgage payments for their extensive properties and associated property taxes. General administrative overhead also contributes significantly to maintaining the necessary operational infrastructure.

These fixed and semi-fixed costs are critical for ensuring Gulf Island’s facilities are ready for production. For instance, in 2024, energy costs, a major component of utility expenses, continued to be a significant factor for heavy industrial operations. Companies like Gulf Island are increasingly focusing on energy efficiency and facility optimization to mitigate these ongoing expenditures.

Equipment Maintenance and Capital Expenditure

Gulf Island's cost structure heavily features expenses for equipment maintenance and capital expenditure. This includes the ongoing costs associated with keeping their extensive fleet of heavy machinery, welding equipment, and cranes in optimal working condition. Regular upkeep, repairs, and the eventual replacement of these vital fabrication tools represent a significant operational outlay.

Beyond routine maintenance, substantial capital expenditures are a recurring necessity. These investments are directed towards acquiring new technology and expanding facilities to ensure Gulf Island remains competitive and maintains adequate capacity. For instance, in 2024, capital expenditures were a key component of their financial planning, reflecting the need to modernize and scale operations. Depreciation, an accounting cost reflecting the wear and tear on these assets, also impacts the overall cost structure.

- Equipment Maintenance: Costs for upkeep and repair of fabrication machinery.

- Capital Expenditure: Investments in new technology and facility upgrades.

- Asset Replacement: Budgeting for the eventual replacement of aging equipment.

- Depreciation: Accounting for the decline in value of fixed assets.

Compliance, Safety, and Quality Control Costs

Gulf Island's cost structure heavily includes expenditures dedicated to compliance, safety, and quality control. These are not optional but essential for operating within the demanding energy and maritime sectors. For instance, in 2024, companies in similar heavy fabrication industries often allocate a significant portion of their operational budget, sometimes upwards of 5-10%, to these critical areas.

These costs cover a wide range of activities. This includes obtaining and maintaining vital certifications like ISO standards and American Bureau of Shipping (ABS) approvals, which are non-negotiable for many client projects. Furthermore, substantial investment goes into comprehensive safety training programs for all personnel, as safety is paramount in heavy fabrication environments. Robust quality assurance processes, from material inspection to final product verification, are also a major component.

- Regulatory Adherence: Expenditures for meeting stringent industry regulations across various operational segments.

- Certification Maintenance: Costs associated with obtaining and renewing key industry certifications such as ISO and ABS.

- Safety Programs: Investment in comprehensive safety training and equipment to ensure a secure working environment.

- Quality Assurance: Funding for robust quality control measures and processes to guarantee product integrity and client satisfaction.

Gulf Island's cost structure is dominated by raw material procurement, particularly steel, and significant labor expenses for its skilled workforce. Operating facility costs, including utilities and property, alongside equipment maintenance and capital expenditures, also represent substantial outlays. Finally, investments in compliance, safety, and quality assurance are essential, non-negotiable expenditures in their industry.

| Cost Category | Key Components | Estimated Impact (2024 Context) | Mitigation Strategies |

|---|---|---|---|

| Raw Materials | Steel grades, specialized alloys, pipes, fittings | Global steel price volatility (up to 15% fluctuations) impacting procurement costs. | Long-term contracts, bulk purchasing power, supply chain optimization. |

| Labor | Wages, benefits, training for engineers, welders, project managers | Average welder hourly wage $25-$40+, reflecting specialized skills. | Workforce productivity maximization, talent retention initiatives. |

| Operating Facilities | Utilities (electricity, water, gas), rent/mortgage, property taxes, admin overhead | Rising energy costs for heavy industrial operations. | Energy efficiency improvements, facility optimization. |

| Equipment & Capital | Maintenance, repairs, new technology acquisition, facility expansion | Ongoing capital expenditure for modernization and capacity scaling. | Preventative maintenance programs, strategic asset replacement planning. |

| Compliance & Safety | Certifications (ISO, ABS), safety training, quality assurance processes | 5-10% of operational budget allocation in similar industries. | Rigorous adherence to standards, comprehensive safety protocols. |

Revenue Streams

Project-based fabrication contracts form the bedrock of Gulf Island's revenue, stemming from the creation of intricate steel structures, modules, and marine vessels. These aren't your everyday orders; they're substantial undertakings, often with fixed prices or cost-plus arrangements, meaning payments are tied to project completion stages.

For instance, in 2024, Gulf Island secured significant contracts, including work on offshore energy infrastructure, showcasing the scale and complexity of these revenue drivers. These custom-built projects are the primary engine for the company's financial performance, each one a major contributor to its overall earnings.

Gulf Island generates revenue through specialized engineering, design, and consulting services. These can be offered independently or as part of larger fabrication projects, showcasing their intellectual capital and design proficiency.

These high-value services often contribute to the company's higher-margin revenue segments. For instance, in 2024, Gulf Island's focus on engineering and design for complex projects is expected to bolster profitability.

Gulf Island's module fabrication sales represent a significant income source, specifically from constructing large industrial modules for sectors like LNG, petrochemicals, and power generation. This capability allows them to deliver integrated, pre-assembled units, which is crucial for clients looking to shorten on-site construction timelines.

The demand for modular construction is on the rise, as evidenced by the increasing adoption of this method across various heavy industries seeking efficiency. This trend directly benefits Gulf Island's revenue from this particular segment of their business.

Marine Vessel Construction and Repair

Gulf Island generates revenue by constructing new, specialized marine vessels like tugs, barges, and offshore support vessels. This core business is complemented by substantial income from the repair, maintenance, and modification of existing maritime fleets. These services directly leverage Gulf Island's established shipbuilding and marine expertise, addressing the dynamic requirements of the global maritime industry.

In 2024, the company continued to secure and execute contracts for these specialized builds and extensive repair projects. For instance, their backlog of shipbuilding and fabrication orders, a key indicator of future revenue from construction, remained robust throughout the year, reflecting sustained demand for their capabilities. The repair and maintenance segment also saw consistent activity, driven by the need for fleet modernization and compliance with new maritime regulations.

- New Vessel Construction: Revenue from building specialized marine craft, including tugboats, barges, and offshore support vessels, catering to specific client needs.

- Repair and Maintenance Services: Income generated from undertaking significant repair, upkeep, and modification projects for existing marine vessels, ensuring operational efficiency and longevity.

- Leveraging Expertise: This revenue stream capitalizes on Gulf Island's deep shipbuilding and marine engineering knowledge, a critical differentiator in the market.

- Market Responsiveness: The segment is designed to adapt to and benefit from evolving demands within the maritime sector, including technological advancements and regulatory changes.

Installation and Commissioning Support Services

Gulf Island earns revenue by providing on-site assistance for the installation and commissioning of fabricated structures and vessels. This service, often crucial for ensuring operational readiness, generates additional income beyond the core fabrication work.

These services are vital for a smooth transition from fabrication to the client's operational phase. For instance, in 2024, Gulf Island's project execution often included these critical support elements, contributing to overall project profitability.

- Installation Support: Revenue from on-site labor and expertise for assembling and integrating fabricated components.

- Commissioning Assistance: Earnings from ensuring the initial operational functionality and testing of the delivered structures.

- Project Integration: Revenue generated by seamlessly connecting fabricated items into existing client infrastructure.

- Value-Added Service: This stream enhances client satisfaction and provides an additional profit center for Gulf Island.

Gulf Island's revenue streams are diverse, primarily driven by project-based fabrication contracts for steel structures, modules, and marine vessels. These large-scale, often fixed-price projects are a core income generator, as seen in their 2024 work on offshore energy infrastructure. Additionally, specialized engineering, design, and consulting services, whether standalone or part of larger projects, contribute to higher-margin revenue, with a strategic focus on these areas in 2024 expected to boost profitability.

The company also profits from module fabrication for industries like LNG and petrochemicals, capitalizing on the growing demand for efficient, pre-assembled units. Furthermore, revenue is generated through the construction of new, specialized marine vessels and the ongoing repair, maintenance, and modification of existing fleets. This dual approach in the maritime sector, supported by a robust backlog in 2024, showcases their adaptability to market needs and regulatory shifts.

On-site installation and commissioning support for fabricated structures and vessels represent another key revenue stream, ensuring operational readiness and adding value beyond the initial build. These services are crucial for project completion and client satisfaction, contributing to overall project profitability as observed in their 2024 project execution.

| Revenue Stream | Description | 2024 Relevance/Example |

|---|---|---|

| Project-Based Fabrication | Creation of steel structures, modules, marine vessels. | Work on offshore energy infrastructure. |

| Engineering, Design & Consulting | Specialized intellectual capital and design services. | Focus expected to bolster profitability. |

| Module Fabrication | Large industrial modules for LNG, petrochemicals, power. | Addresses demand for efficient, pre-assembled units. |

| New Vessel Construction | Building specialized marine craft. | Robust backlog of shipbuilding orders. |

| Repair & Maintenance | Upkeep and modification of existing marine vessels. | Consistent activity driven by fleet modernization. |

| Installation & Commissioning Support | On-site assistance for operational readiness. | Critical support elements in project execution. |

Business Model Canvas Data Sources

The Gulf Island Business Model Canvas is informed by a blend of proprietary operational data, local market research, and customer feedback. This comprehensive approach ensures each element accurately reflects the island's unique economic landscape and business opportunities.