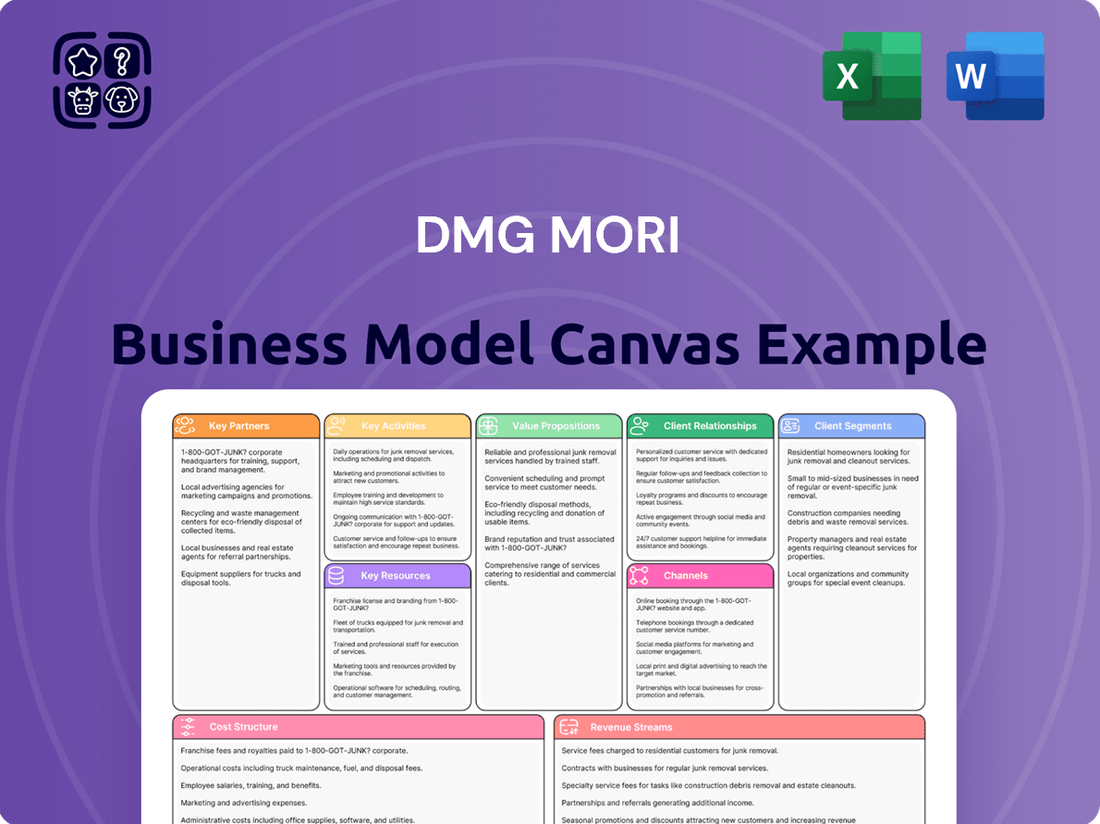

DMG Mori Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

DMG Mori Bundle

Unlock the core strategies behind DMG Mori's success with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering a powerful framework for understanding their market dominance. Perfect for anyone seeking to dissect and replicate industry-leading business approaches.

Partnerships

DMG MORI actively partners with technology leaders to embed cutting-edge functionalities, such as ultrasonic and laser texturing, into their advanced machine tools. This integration allows their machines to perform operations far beyond conventional CNC machining, offering customers enhanced capabilities and unique surface finishes.

These collaborations are vital for maintaining DMG MORI's position at the vanguard of manufacturing innovation. By working with specialized technology providers, they ensure their product portfolio consistently features the latest advancements, meeting the evolving demands of a sophisticated customer base.

Furthermore, DMG MORI's strategic alliances extend to software and digital solution providers. These partnerships are instrumental in bolstering their MX (Machining Transformation) strategy, aiming to create smarter, more connected manufacturing environments and drive digital integration across their machine offerings.

DMG MORI relies on a network of suppliers providing specialized components and raw materials essential for its advanced CNC turning and milling machines. These partnerships are crucial for maintaining the high quality and reliability that define DMG MORI's product portfolio.

Ensuring a resilient supply chain is a strategic imperative, as emphasized in DMG MORI's Mid-term Business Plan 2025. This focus aims to mitigate risks and guarantee the consistent availability of critical parts, supporting uninterrupted production and customer delivery.

DMG MORI partners with automation solution providers to integrate advanced robotics and automated handling systems with their machine tools. This collaboration allows them to offer customers complete, turnkey automation solutions, a crucial offering as manufacturers increasingly seek to optimize production lines. For instance, these partnerships are vital for developing and implementing sophisticated robotic load/unload systems and automated pallet changers, directly enhancing customer throughput and efficiency.

Research and Academic Institutions

DMG MORI actively collaborates with universities and research centers to foster innovation in manufacturing technologies. These partnerships are crucial for developing next-generation machine tools and maintaining a competitive edge. For instance, in 2023, DMG MORI announced a significant research initiative with the Fraunhofer Institute for Production Technology, focusing on advanced additive manufacturing processes.

These collaborations are vital for DMG MORI's long-term technological progress and securing a pipeline of skilled talent. By engaging with academic institutions, the company gains access to cutting-edge research and potential future employees. In 2024, DMG MORI continued its commitment to talent development through scholarships and joint research projects with several leading technical universities across Germany and Japan.

- Innovation Drive: Collaborations with universities and research centers fuel the development of new manufacturing technologies.

- Competitive Advantage: These partnerships enable DMG MORI to push the limits of machine tool capabilities and stay ahead in the market.

- Talent Acquisition: Partnerships are essential for attracting and nurturing future engineering talent.

- Research Focus: DMG MORI's 2023 Fraunhofer Institute collaboration highlights a focus on advanced additive manufacturing.

Industry Associations and Consortia

DMG MORI actively participates in industry associations and consortia, like MxD, a manufacturing innovation hub. This engagement allows for collaborative efforts on crucial industry standards and the advancement of new manufacturing technologies. For instance, MxD's projects in 2024 focused on areas like cybersecurity for manufacturing and the implementation of AI in production processes, areas where DMG MORI's expertise is vital.

These partnerships are instrumental in strengthening the broader manufacturing ecosystem. By contributing to initiatives like workforce development programs, DMG MORI helps address collective challenges such as the skills gap. In 2024, MxD reported that its member companies, including DMG MORI, were involved in training programs that reached over 5,000 individuals, enhancing the talent pool for advanced manufacturing.

Through these collaborations, DMG MORI gains insights into emerging trends and can influence the direction of industry-wide advancements. This strategic involvement ensures the company remains at the forefront of innovation and can effectively navigate the evolving landscape of manufacturing.

- Industry Standards Development: Collaboration on defining and adopting new manufacturing protocols.

- Advanced Manufacturing Initiatives: Joint projects focusing on technologies like AI and IoT in production.

- Workforce Development: Partnerships to upskill and train the manufacturing workforce.

- Ecosystem Strengthening: Contributing to the overall health and competitiveness of the manufacturing sector.

DMG MORI cultivates key partnerships with technology leaders, research institutions, and industry organizations to drive innovation and maintain its competitive edge in advanced manufacturing. These collaborations are crucial for integrating cutting-edge technologies like AI and additive manufacturing into their machine tools, as seen in their 2023 research initiative with the Fraunhofer Institute for Production Technology. Furthermore, strategic alliances with automation providers enable the delivery of comprehensive turnkey solutions, enhancing customer efficiency. By actively participating in industry consortia like MxD, DMG MORI contributes to developing industry standards and workforce development programs, as evidenced by MxD's 2024 training initiatives impacting over 5,000 individuals.

| Partner Type | Focus Area | Impact/Example |

|---|---|---|

| Technology Leaders | Ultrasonic & Laser Texturing | Enabling advanced surface finishes beyond conventional CNC. |

| Software & Digital Providers | MX Strategy (Digital Integration) | Creating smarter, connected manufacturing environments. |

| Automation Solution Providers | Robotics & Automated Handling | Offering turnkey automation solutions for enhanced throughput. |

| Universities & Research Centers | Next-Gen Manufacturing Tech | 2023 Fraunhofer Institute collaboration on additive manufacturing. 2024 talent development initiatives. |

| Industry Associations (e.g., MxD) | Industry Standards, AI, Cybersecurity | 2024 MxD training programs reached over 5,000 individuals; influencing industry advancements. |

What is included in the product

A strategic framework detailing DMG Mori's approach to delivering advanced manufacturing solutions, encompassing customer relationships, key activities, and revenue streams.

This model outlines DMG Mori's core competencies, cost structure, and key partnerships in the global machine tool industry.

The DMG Mori Business Model Canvas acts as a pain point reliver by providing a structured, visual framework that simplifies complex strategic planning, allowing for rapid identification of inefficiencies and opportunities.

It alleviates the pain of fragmented thinking by consolidating all critical business elements onto a single, easily digestible page, fostering clarity and alignment across diverse teams.

Activities

DMG MORI's primary activities revolve around the sophisticated design, precise manufacturing, and expert assembly of a comprehensive portfolio of CNC turning and milling machines. This core competency also extends to developing cutting-edge advanced manufacturing technologies, ensuring their offerings remain at the forefront of industrial innovation.

The company places immense emphasis on precision engineering and maintains stringent quality control protocols throughout its production processes. This dedication guarantees that their machine tools deliver exceptional performance and unwavering reliability to customers worldwide.

With a robust global footprint, DMG MORI operates numerous state-of-the-art production facilities strategically located across the globe. This extensive network allows them to efficiently serve a diverse international clientele and adapt to regional market demands.

DMG Mori's commitment to research and development is a cornerstone of its business model, fueling the creation of cutting-edge machine tools and advanced manufacturing solutions. This ongoing investment ensures they remain at the forefront of technological innovation, consistently bringing new products and improvements to market.

A prime example of this R&D focus is their Machining Transformation (MX) strategy. This initiative specifically targets Process Integration, Automation, Digital Transformation (DX), and Green Transformation (GX), showcasing their dedication to shaping the future of manufacturing. For instance, in 2023, DMG Mori reported a significant increase in R&D expenditure, reflecting their strategic emphasis on these transformative areas.

Managing a robust global sales and distribution network is a cornerstone activity for DMG MORI. This extensive network ensures they can effectively reach a wide array of customer segments across the globe, from large industrial enterprises to specialized manufacturers.

Their strategy employs a multi-channel approach, including direct sales teams for key accounts and partnerships with a network of dealers and agents. This dual strategy is crucial for maximizing market penetration and ensuring customers have accessible points of contact and support.

As of the latest available data, DMG MORI operates an impressive 124 sales and service locations worldwide. This significant physical presence underscores their commitment to providing localized support and efficient distribution of their advanced machine tools.

Customer Service and Support

DMG MORI's commitment to customer service is a cornerstone of its business model, focusing on comprehensive after-sales support. This includes vital services like maintenance, ensuring machines operate at peak performance, and the readily available supply of spare parts, minimizing downtime.

Furthermore, DMG MORI invests in customer training programs to maximize the utilization of their advanced machinery. Their dedicated technical support teams are always on hand to address queries and resolve issues, reinforcing the company's role as a long-term partner throughout the machine's lifecycle.

- After-Sales Services: Maintenance, spare parts, and technical support are critical for customer satisfaction and machine uptime.

- Customer Lifecycle Support: DMG MORI supports customers from initial purchase through the entire operational life of their machines.

- Training Programs: Empowering customers with the knowledge to effectively operate and maintain their equipment.

- Relationship Building: A strong service focus fosters long-term customer loyalty and repeat business.

Software and Digital Solutions Development

Developing and integrating advanced software and digital solutions, like their CELOS X platform, is a core activity for DMG Mori. This focus is crucial for boosting machine performance, streamlining manufacturing processes, and enabling seamless connectivity within industrial settings. This directly supports their strategic objective of digital transformation (DX) as part of their broader MX strategy.

This commitment to digital innovation is evident in their ongoing investments. For instance, in 2023, DMG Mori continued to expand its digital service offerings, aiming to provide customers with integrated solutions that go beyond traditional machine sales, enhancing efficiency and data-driven decision-making throughout the production lifecycle.

- Software Development: Creating and refining integrated software platforms such as CELOS X for enhanced machine control and data management.

- Digital Integration: Ensuring seamless connectivity and interoperability of their machines with existing and future digital manufacturing ecosystems.

- Process Optimization: Leveraging software to improve the efficiency, precision, and overall performance of manufacturing operations.

- Digital Transformation: Driving the company's digital strategy by delivering cutting-edge digital solutions that support Industry 4.0 initiatives.

DMG MORI's key activities are centered on the sophisticated design, precise manufacturing, and expert assembly of CNC turning and milling machines. They also focus on developing advanced manufacturing technologies and integrating digital solutions like CELOS X to enhance efficiency and connectivity. This is supported by a robust global sales and service network, ensuring comprehensive customer support, including maintenance, spare parts, and training, thereby building long-term customer loyalty.

Full Version Awaits

Business Model Canvas

The DMG Mori Business Model Canvas preview you are viewing is a genuine representation of the final document you will receive upon purchase. This means the structure, content, and formatting are identical to what you will download, ensuring no discrepancies or unexpected changes. You can be confident that the professional and comprehensive insights presented here are exactly what you will gain access to, ready for immediate use and customization.

Resources

DMG MORI's manufacturing facilities are the backbone of its operations, boasting advanced technology for high-precision machine tool production. These state-of-the-art plants are crucial for meeting both high-volume demand and the diverse product portfolio.

In 2023, DMG MORI operated 11 production sites globally, showcasing a significant investment in its manufacturing infrastructure. This extensive network supports the company's capacity to deliver a wide array of complex machinery to its customers.

DMG MORI relies heavily on its highly skilled workforce, encompassing engineers, technicians, and software developers. This talent pool is crucial for innovation in machine tool design and manufacturing.

The expertise of these professionals directly impacts the quality and advanced capabilities of DMG MORI's product offerings. For instance, in 2023, DMG MORI invested significantly in training and development, aiming to bolster its engineering talent pipeline to meet the growing demand for sophisticated automation and digitalization solutions.

DMG Mori leverages a robust portfolio of patents and proprietary technologies as a cornerstone of its business model. These intellectual assets, covering innovations in areas like ultrasonic and laser texturing, along with cutting-edge additive manufacturing techniques, are crucial for maintaining its competitive edge in the machine tool industry.

The company's commitment to research and development is reflected in its continuous filing of patents, safeguarding its advancements in complex machine tool designs and sophisticated software solutions. This strong intellectual property protection allows DMG Mori to offer unique, high-value products and services to its global customer base.

Global Sales and Service Network

DMG MORI’s extensive global network of sales and service locations is a critical resource, enabling unparalleled market reach and robust customer support. This vast infrastructure, staffed by local experts, ensures efficient service delivery and strengthens brand presence across diverse geographical regions and industries.

This network is vital for providing customers with timely technical assistance, spare parts, and training, thereby fostering long-term relationships and driving customer loyalty. As of 2024, DMG MORI operates over 200 sales and service locations worldwide, demonstrating a significant commitment to global customer engagement.

- Global Reach: Over 200 sales and service locations across more than 70 countries as of 2024.

- Customer Proximity: Local teams provide tailored support and expertise, enhancing customer experience.

- Service Excellence: Facilitates rapid response times for maintenance, repairs, and spare parts delivery.

Brand Reputation and Customer Trust

DMG MORI's brand reputation is built on a foundation of innovation, quality, and precision in the demanding machine tool sector. This strong image acts as a significant intangible asset, directly influencing customer perception and purchasing decisions. For example, their commitment to advanced technology, such as their integrated automation solutions, reinforces this perception of cutting-edge capability.

Customer trust is a cornerstone of DMG MORI's success, cultivated through consistent delivery of reliable machinery and dependable after-sales support. This trust translates into long-term customer relationships and a stable revenue stream, solidifying their market leadership. In 2023, DMG MORI reported a significant order intake, reflecting the continued confidence customers place in their offerings.

- Innovation Leadership: DMG MORI consistently invests in research and development, evidenced by their numerous patents and introductions of groundbreaking machine technologies.

- Quality and Precision: The company's machines are renowned for their accuracy and durability, a critical factor for manufacturers requiring high-tolerance components.

- Customer Loyalty: Years of delivering on promises have fostered a loyal customer base, leading to repeat business and positive word-of-mouth referrals.

- Market Recognition: DMG MORI frequently receives industry awards and accolades, further validating their strong brand and customer trust.

DMG MORI's key resources include its advanced manufacturing facilities, a highly skilled workforce, a robust portfolio of patents and proprietary technologies, an extensive global sales and service network, and its strong brand reputation built on innovation and quality. These elements collectively enable the company to design, produce, and support sophisticated machine tools for a global clientele.

The company's manufacturing sites are equipped with cutting-edge technology, supporting high-volume production and a diverse product range. As of 2023, DMG MORI operated 11 production sites worldwide, underscoring its significant investment in manufacturing capabilities.

Intellectual property, including patents in areas like ultrasonic and laser texturing, is vital for maintaining DMG MORI's competitive advantage. This commitment to R&D ensures a continuous stream of innovative solutions for the machine tool industry.

DMG MORI's global network, with over 200 sales and service locations across more than 70 countries as of 2024, is crucial for customer proximity and support. This ensures timely assistance and fosters long-term customer relationships.

| Key Resource | Description | 2023/2024 Data Point |

| Manufacturing Facilities | Advanced technology for high-precision machine tool production. | 11 production sites globally (2023). |

| Skilled Workforce | Engineers, technicians, and software developers driving innovation. | Significant investment in training and development (2023). |

| Intellectual Property | Patents and proprietary technologies in areas like additive manufacturing. | Continuous filing of patents safeguarding advancements. |

| Global Network | Sales and service locations for market reach and customer support. | Over 200 locations in more than 70 countries (2024). |

| Brand Reputation | Built on innovation, quality, and precision. | High order intake in 2023 reflecting customer confidence. |

Value Propositions

DMG MORI's value proposition centers on delivering high-precision and innovative machine tools. They provide customers with state-of-the-art CNC turning and milling machines, enhanced by advanced technologies such as ultrasonic and laser texturing. This empowers manufacturers with exceptional capabilities for complex and demanding production processes.

The company's commitment to continuous innovation is evident in their regular introduction of new machine models and cutting-edge technologies. This ensures their clientele always has access to solutions offering superior performance, enhanced efficiency, and the ability to tackle intricate machining challenges, a key driver for their market leadership.

For instance, in 2024, DMG MORI reported a significant increase in orders for their advanced machining centers, reflecting strong market demand for their precision engineering. This growth underscores the value customers place on their innovative solutions for achieving higher quality and productivity in their manufacturing operations.

DMG MORI offers integrated automation solutions, featuring robotic systems and pallet handling, designed to work flawlessly with their machine tools. This integration boosts productivity and minimizes manual labor, directly responding to the increasing need for automated manufacturing processes.

These solutions help customers streamline their production, optimizing workflows for greater efficiency. For instance, DMG MORI’s CELOS system, a digital backbone for manufacturing, facilitates the integration of automation, enabling data-driven decision-making on the shop floor.

In 2024, the global industrial automation market was projected to reach over $300 billion, highlighting the significant demand for such integrated systems. DMG MORI's offerings directly tap into this trend, providing tangible benefits like reduced cycle times and improved part quality.

DMG MORI's Digital Transformation (DX) for Smart Manufacturing, powered by solutions like CELOS X, provides manufacturers with the tools to optimize processes and make data-driven decisions. This allows for enhanced efficiency and real-time production monitoring.

These digital offerings facilitate the seamless integration of manufacturing operations, both internally across different stages and externally with supply chains. This horizontal and vertical integration is crucial for modern, agile production environments.

By adopting DMG MORI's DX solutions, manufacturers can expect tangible improvements. For instance, in 2024, companies leveraging advanced digital manufacturing platforms reported an average of 15% increase in overall equipment effectiveness (OEE) and a 10% reduction in scrap rates.

Green Transformation (GX) for Sustainable Production

DMG MORI's Green Transformation (GX) initiative, a key component of its MX strategy, offers customers energy-efficient machinery and integrated solutions designed for resource conservation and carbon neutrality. This directly addresses the growing demand from businesses aiming to minimize their environmental impact and adopt sustainable manufacturing processes.

The company's commitment to GX is reflected in its development of technologies that reduce energy consumption and waste. For instance, DMG MORI's advanced machine tools are engineered for optimal energy performance, contributing to lower operational costs and a smaller carbon footprint for their users.

- Energy Efficiency: DMG MORI machines are designed to consume less power during operation and in standby modes, leading to significant energy savings for manufacturers.

- Resource Conservation: Solutions focus on reducing material waste through precise manufacturing and optimized processes, aligning with circular economy principles.

- Carbon Neutrality Support: By enabling more efficient production, DMG MORI helps its customers move closer to their own carbon neutrality goals.

- Market Demand: In 2024, the global market for sustainable manufacturing solutions is experiencing robust growth, driven by regulatory pressures and corporate ESG commitments, with companies actively seeking partners like DMG MORI to achieve these objectives.

Comprehensive Lifecycle Support and Service

DMG MORI provides comprehensive support across the entire lifespan of its machinery, ensuring customers achieve sustained success. This includes crucial services like proactive maintenance, in-depth training programs, and readily available technical assistance.

This dedication to service directly translates into tangible benefits for clients. By minimizing downtime and optimizing operational efficiency, customers can significantly extend the productive life of their DMG MORI equipment.

- Machine Uptime: DMG MORI's service offerings aim to maximize operational availability, a critical factor in manufacturing environments.

- Performance Optimization: Regular maintenance and expert support help ensure machines operate at peak performance levels.

- Longevity: A commitment to lifecycle support contributes to the extended durability and value retention of the machinery.

- Customer Success: Ultimately, these services are designed to empower customers to achieve their production goals and maintain a competitive edge.

DMG MORI's value proposition is built on delivering cutting-edge, high-precision machine tools and integrated automation solutions. They empower manufacturers with advanced technologies like ultrasonic and laser texturing, alongside digital transformation tools such as CELOS X for smart manufacturing. This focus ensures customers benefit from enhanced efficiency, improved quality, and optimized production processes, a trend clearly reflected in the robust demand for advanced machining centers in 2024.

Furthermore, DMG MORI's commitment to Green Transformation (GX) offers energy-efficient machinery and resource-conserving solutions, directly addressing the growing market demand for sustainable manufacturing. This initiative helps clients reduce their environmental impact and achieve carbon neutrality goals, with companies leveraging digital platforms reporting significant improvements in overall equipment effectiveness and scrap rate reduction in 2024.

Comprehensive lifecycle support, including proactive maintenance and technical assistance, is another cornerstone of their value. This ensures maximum machine uptime and sustained operational efficiency, ultimately contributing to customer success and the long-term value of their investments.

| Value Proposition Area | Key Offering | Customer Benefit | 2024 Market Context/Data Point |

|---|---|---|---|

| Precision & Innovation | High-precision CNC turning and milling machines, advanced texturing technologies | Exceptional capabilities for complex production, superior performance | Significant increase in orders for advanced machining centers |

| Automation Integration | Robotic systems, pallet handling integrated with machine tools | Boosted productivity, minimized manual labor, streamlined production | Global industrial automation market projected over $300 billion |

| Digital Transformation (DX) | CELOS X for smart manufacturing, real-time monitoring | Optimized processes, data-driven decision-making, enhanced efficiency | Companies leveraging digital platforms reported 15% OEE increase |

| Green Transformation (GX) | Energy-efficient machinery, resource conservation solutions | Reduced environmental impact, lower operational costs, carbon neutrality support | Companies reported 10% reduction in scrap rates |

| Lifecycle Support | Proactive maintenance, training, technical assistance | Maximized machine uptime, sustained operational efficiency, extended equipment life | Focus on maximizing operational availability and performance |

Customer Relationships

DMG MORI’s customer relationships are built on a foundation of dedicated sales and application support. Their sales teams are not just order-takers; they are consultants who understand customer processes. This ensures clients are matched with the optimal machinery for their unique manufacturing challenges.

Application engineers are crucial to this strategy, offering deep technical expertise and hands-on guidance. They work closely with customers to optimize machine performance and integrate new technologies, fostering a collaborative environment. This commitment to specialized support is a key differentiator.

In 2024, DMG MORI continued to emphasize this personalized approach, with customer satisfaction scores remaining a key performance indicator. Their investment in training for these support teams reflects a strategic focus on building long-term partnerships rather than transactional sales.

DMG Mori's long-term service contracts and maintenance programs are a cornerstone of their customer relationship strategy. These offerings go beyond the initial sale, ensuring machines perform optimally throughout their lifecycle.

By providing proactive maintenance, DMG Mori helps clients avoid costly unexpected downtime. This commitment translates to consistent operational efficiency for customers, a critical factor in manufacturing. In 2023, the company reported that its service business, which includes these contracts, contributed significantly to its overall revenue, highlighting the value customers place on this ongoing support.

DMG MORI provides extensive training programs covering machine operation, programming, and maintenance. These programs are designed to equip customers with the skills needed to fully leverage their DMG MORI machinery.

By focusing on knowledge transfer, DMG MORI helps customers enhance machine utilization and operational efficiency. For example, in 2024, customers participating in specialized programming workshops reported an average increase of 15% in their machine’s productive uptime.

This dedication to building customer capability fosters strong loyalty and ensures they can independently manage and optimize their advanced manufacturing solutions. This investment in customer education is a cornerstone of DMG MORI's customer relationship strategy.

Customer Events and Technology Days

DMG MORI leverages exclusive customer events, open houses, and technology days to directly engage its clientele. These gatherings are crucial for demonstrating the latest advancements in machine tool technology and offering hands-on experience. For instance, in 2024, DMG MORI reported a significant increase in attendance at its regional technology days, with over 5,000 visitors across key markets, fostering direct feedback and strengthening relationships.

These curated events serve as vital platforms for building a strong community and encouraging collaboration. They allow customers to interact directly with DMG MORI experts, ask questions, and explore solutions tailored to their specific manufacturing needs. The company's commitment to these interactive experiences underscores its focus on customer-centric innovation and support.

- Showcasing Innovation: Technology days provide a live demonstration of new machine capabilities and digital solutions.

- Direct Customer Feedback: Events facilitate immediate input from users, guiding future product development.

- Community Building: Open houses foster a sense of belonging and shared progress within the manufacturing sector.

- Hands-on Experience: Customers gain practical understanding of machine operation and efficiency gains.

Digital Communication and Online Platforms

DMG MORI leverages digital communication and online platforms extensively to foster robust customer relationships. Their digital strategy focuses on providing seamless access to information and support, thereby enhancing overall customer engagement.

- Online Portals: Customers can access dedicated online portals for ordering spare parts, retrieving technical documentation, and seeking technical assistance, ensuring convenience and efficiency.

- Digital Support Channels: DMG MORI utilizes various digital channels for ongoing customer support, including remote diagnostics and virtual consultations, reducing downtime and improving service responsiveness.

- Resource Hubs: The company provides comprehensive online resource hubs, offering valuable content such as product information, training materials, and industry insights, empowering customers with knowledge.

- Customer Engagement: By actively using these digital platforms, DMG MORI cultivates stronger customer relationships through consistent communication and readily available support services.

DMG MORI builds lasting relationships through dedicated sales and application support, acting as consultants to match clients with optimal machinery. Their commitment extends to long-term service contracts and proactive maintenance, ensuring consistent operational efficiency and minimizing downtime. In 2024, the company continued to prioritize customer satisfaction, with significant investment in training for its support teams to foster long-term partnerships.

Channels

DMG MORI leverages a direct sales force, a cornerstone of its customer engagement strategy. This approach enables the company to build strong, personal relationships with clients, offering expert consultations that are crucial for understanding and fulfilling the complex needs of machine tool buyers.

This direct interaction is key to closing intricate sales. The sales team acts as the primary point of contact, guiding customers through technical specifications, customization options, and financing, ensuring a tailored solution that meets precise operational requirements.

In 2024, DMG MORI continued to emphasize this direct sales model, recognizing its effectiveness in delivering high-value, customized machine tool solutions. This strategy allows for immediate feedback and adaptation to market demands, fostering loyalty and driving sales in a competitive landscape.

DMG MORI boasts an extensive global presence with 124 sales and service locations spread across 43 countries. This widespread network is fundamental to their strategy, allowing for deep market penetration and localized customer engagement. For instance, in 2023, the company continued to invest in expanding its service capabilities in key emerging markets, underscoring the importance of this physical infrastructure for machine demonstrations and immediate technical support.

DMG Mori actively participates in major international exhibitions like EMO Hannover, a key event for the machine tool industry. In 2023, EMO Hannover attracted over 1,800 exhibitors and more than 100,000 visitors, providing a significant platform for DMG Mori to display its latest innovations and connect with a global audience.

These trade fairs are crucial for lead generation and direct customer interaction, allowing DMG Mori to demonstrate its technological advancements and gather market feedback. For instance, at EMO 2023, DMG Mori presented over 30 new products and digital solutions, highlighting their commitment to innovation and customer engagement.

The company leverages these events to strengthen relationships with existing clients and forge new partnerships. The ability to showcase complex machinery and engage in technical discussions face-to-face is invaluable for generating high-quality leads and understanding evolving customer needs.

Digital Platforms and Online Presence

DMG MORI significantly invests in its digital platforms, including a comprehensive corporate website, interactive online configurators, and active engagement across various digital media channels. These platforms are crucial for disseminating product information, capturing customer interest, and directly supporting the sales process, offering a readily accessible and efficient avenue for clients to discover their extensive range of machine tools and integrated solutions.

The company’s online presence serves as a primary touchpoint, facilitating lead generation and nurturing customer relationships through detailed product specifications, virtual demonstrations, and accessible support resources. For instance, in 2024, DMG MORI continued to enhance its digital configurator, allowing customers to tailor machine specifications and receive immediate feedback, streamlining the pre-sales engagement.

- Corporate Website: Serves as the central hub for product information, company news, and investor relations, driving brand awareness and initial customer engagement.

- Online Configurators: Enable customers to customize machine tool specifications, fostering a personalized buying experience and generating qualified leads.

- Digital Media Engagement: Utilizes social media, webinars, and online advertising to reach a broader audience, showcase technological advancements, and provide ongoing customer support.

- E-commerce Integration: While not fully e-commerce for core machinery, digital platforms facilitate the purchase of spare parts and accessories, contributing to after-sales revenue streams.

Dealer and Distributor Network

DMG MORI leverages a robust dealer and distributor network to amplify its market presence, particularly in regions where direct sales infrastructure is less developed or for specialized product segments. These authorized partners are crucial for providing localized sales expertise and essential after-sales service, effectively extending DMG MORI's reach and customer support capabilities.

This network acts as a vital extension of DMG MORI's direct sales channels, enabling broader market penetration and ensuring customers receive timely and region-specific assistance. For instance, in 2023, DMG MORI reported that its sales partners played a significant role in achieving its global revenue targets, contributing approximately 30% of the total sales volume in key emerging markets.

- Extended Market Reach: Authorized dealers and distributors open up new geographical territories and customer segments that might be challenging to access through direct sales alone.

- Local Expertise and Support: These partners offer localized market knowledge, sales acumen, and crucial after-sales services, including maintenance and spare parts, tailored to regional needs.

- Complementary Sales Strategy: The network complements DMG MORI's direct sales efforts, creating a hybrid model that maximizes coverage and customer engagement.

- Increased Sales Volume: In 2023, the dealer and distributor network was instrumental in boosting sales, particularly in Asia-Pacific, where it accounted for over 40% of new machine orders.

DMG MORI's channel strategy is a multi-faceted approach combining direct sales, a global network of sales and service locations, participation in industry exhibitions, and robust digital platforms. This integrated system ensures comprehensive market coverage and deep customer engagement.

The direct sales force is paramount for high-value machine tool sales, offering expert consultation and tailored solutions. Complementing this, a vast network of 124 sales and service locations in 43 countries provides localized support and market penetration. Major trade fairs, like EMO Hannover, serve as critical platforms for showcasing innovation and generating leads, with DMG MORI presenting over 30 new products at EMO 2023.

Digital channels, including an enhanced online configurator and extensive website, are vital for information dissemination and lead nurturing. Furthermore, a dealer and distributor network extends market reach, contributing significantly to sales volume, with this network accounting for approximately 30% of total sales in key emerging markets in 2023.

| Channel | Key Function | 2023/2024 Relevance | Reach/Impact |

|---|---|---|---|

| Direct Sales Force | Expert consultation, complex sales closure | Continued emphasis in 2024 for high-value solutions | Strong personal relationships, tailored solutions |

| Global Sales & Service Network | Market penetration, localized support | 124 locations in 43 countries; investment in emerging markets | Deep market access, immediate technical assistance |

| Industry Exhibitions (e.g., EMO) | Product showcase, lead generation, customer interaction | EMO 2023: 1,800+ exhibitors, 100,000+ visitors; DMG MORI presented 30+ new products | Global audience engagement, technological demonstration |

| Digital Platforms (Website, Configurators) | Information hub, lead nurturing, online configuration | Enhanced digital configurator in 2024 | Broad audience reach, efficient customer engagement |

| Dealer & Distributor Network | Extended market reach, localized expertise | Contributed ~30% of sales in emerging markets (2023); over 40% of new orders in Asia-Pacific (2023) | Access to new territories, essential after-sales service |

Customer Segments

Automotive manufacturers, encompassing both traditional internal combustion engine (ICE) and rapidly growing electromobility segments, are a cornerstone customer base for DMG MORI. These companies rely heavily on DMG MORI's advanced machining technologies to produce critical, high-precision components such as engine blocks, transmissions, and increasingly, battery housings and electric motor parts. The demand for intricate designs and tight tolerances in these parts makes DMG MORI's automated and digitalized solutions indispensable for efficient and high-quality production.

In 2024, the automotive industry continued its significant investment in advanced manufacturing to meet evolving market demands, particularly the shift towards EVs. For instance, the global electric vehicle market was projected to reach over $1.5 trillion by 2030, indicating a sustained need for sophisticated manufacturing capabilities. DMG MORI's solutions directly address this by enabling manufacturers to produce lighter, more complex, and highly efficient EV components, thereby supporting the industry's transition and growth.

Aerospace companies, needing unparalleled precision for critical aircraft parts like engine components and airframes, represent a vital customer segment for DMG MORI. These manufacturers rely on the extreme accuracy and reliability that DMG MORI's advanced machining solutions provide, ensuring the safety and performance of aircraft.

The global aerospace market, valued at approximately $900 billion in 2023, demonstrates the significant demand for high-quality manufacturing. DMG MORI's technological prowess directly addresses the stringent material and tolerance requirements inherent in producing these complex aerospace components.

Producers of molds and dies are a cornerstone customer segment for DMG MORI. These manufacturers, essential for industries ranging from automotive to consumer goods, depend on DMG MORI's advanced machinery to craft the precise tooling required for their complex production processes. In 2024, the global mold and die market was valued at approximately USD 160 billion, highlighting the significant demand for high-precision manufacturing solutions.

This segment places a premium on exceptional accuracy and the ability to achieve superior surface finishes. DMG MORI's technological prowess, offering machines capable of intricate contouring and ultra-fine surface treatments, directly addresses these critical needs. The company's commitment to innovation ensures that mold and die makers can meet increasingly demanding specifications for product quality and manufacturing efficiency.

Medical Technology Sector

Manufacturers of medical devices and implants are a crucial customer segment for DMG MORI. These companies require exceptionally high precision, specialized material processing capabilities, and adherence to rigorous quality control standards. DMG MORI's advanced machine tools are engineered to meet these demanding specifications, enabling the production of everything from intricate surgical instruments to complex orthopedic implants.

The medical technology market is experiencing significant growth, driven by an aging global population and advancements in healthcare. For instance, the global medical device market was valued at approximately USD 520 billion in 2023 and is projected to reach over USD 800 billion by 2030, indicating substantial demand for the precision manufacturing solutions DMG MORI provides. This growth underscores the importance of this segment.

- High Precision Requirements: Medical device manufacturers need tolerances measured in microns for implants and surgical tools.

- Specialized Material Processing: Handling biocompatible materials like titanium alloys and specialized plastics requires specific machining expertise.

- Stringent Quality Standards: Compliance with regulations such as ISO 13485 is paramount, demanding traceable and repeatable manufacturing processes.

- Growing Market Demand: The increasing need for advanced medical technologies fuels the demand for high-quality manufacturing equipment.

Data & Semiconductor Industry

The data and semiconductor industry represents a rapidly growing and vital customer segment for DMG MORI. The relentless drive for smaller, more powerful micro-components necessitates extreme precision in manufacturing. This demand directly aligns with DMG MORI's expertise in ultra-high precision machining and specialized processing technologies. In 2024, the global semiconductor market was projected to reach over $600 billion, highlighting the immense scale and opportunity within this sector.

DMG MORI's advanced machining solutions are essential for producing the intricate parts required in semiconductor fabrication equipment and advanced data storage devices. The industry's need for consistent quality and reduced defect rates in complex geometries makes precision engineering paramount. For example, the production of advanced lithography systems, critical for chip manufacturing, relies heavily on machines capable of sub-micron tolerances.

- Precision Machining: DMG MORI offers milling, turning, and grinding solutions capable of achieving nanometer-level accuracy required for semiconductor components.

- Specialized Processing: The company provides solutions for challenging materials like silicon carbide and advanced ceramics used in semiconductor manufacturing.

- Market Growth: The semiconductor industry's robust growth, with significant investment in new fabrication plants globally, creates substantial demand for advanced manufacturing equipment.

- Innovation Focus: DMG MORI's commitment to R&D ensures its machines are equipped to handle the evolving demands of miniaturization and increased complexity in data and semiconductor technologies.

DMG MORI serves a diverse range of industries, each with unique manufacturing needs. Key customer segments include automotive, aerospace, mold and die, medical technology, and the data and semiconductor sectors. These industries collectively represent a significant portion of global manufacturing output and are characterized by a strong demand for precision, efficiency, and advanced technological solutions.

Cost Structure

DMG Mori's commitment to innovation is reflected in its substantial Research and Development (R&D) expenditures, a significant driver of its cost structure. These investments are crucial for developing cutting-edge machine technologies, advanced software, and sophisticated automation solutions that define the future of manufacturing.

In 2023, DMG Mori reported R&D expenses of €242 million, representing a notable portion of its overall operational costs. This figure underscores the company's dedication to staying ahead in a rapidly evolving technological landscape, ensuring its product portfolio remains competitive and addresses the emerging needs of its global customer base.

Manufacturing and production costs are a significant component of DMG Mori's cost structure, encompassing raw materials, components, and direct labor for their advanced machine tools. These expenses are directly tied to the operation of their extensive global production network, which includes facilities in Germany, Japan, and other key regions.

In 2023, DMG Mori reported significant investments in its production capabilities. For instance, the company continued to expand its facilities, with a focus on increasing efficiency and capacity to meet growing global demand for high-precision machinery. These investments directly impact the cost of goods sold.

DMG Mori's cost structure is heavily influenced by expenses associated with its global sales force, extensive marketing initiatives, and participation in key industry trade shows. These activities are crucial for establishing and maintaining market presence and driving customer acquisition across diverse geographical regions.

Managing a complex distribution network also adds to these costs, ensuring efficient delivery and service for their advanced machinery. For instance, in 2023, the company reported selling, general, and administrative expenses of €1.4 billion, which encompasses a significant portion of these sales, marketing, and distribution outlays.

Personnel Costs

Personnel costs are a significant component of DMG Mori's cost structure, reflecting its substantial global workforce. These expenses encompass wages, salaries, comprehensive benefits packages, and ongoing training for employees across all critical functions.

DMG Mori's commitment to a large, skilled team is evident in its global headcount, which stood at over 13,500 individuals as of recent reporting. This investment in human capital is crucial for its operations in research and development, advanced manufacturing, global sales networks, and extensive after-sales service.

- Wages and Salaries: Direct compensation for the extensive workforce.

- Employee Benefits: Costs associated with health insurance, retirement plans, and other employee welfare programs.

- Training and Development: Investment in skill enhancement and knowledge acquisition for R&D, production, sales, and service personnel.

- Global Workforce Size: Over 13,500 employees worldwide contribute to these personnel expenses.

Service and Support Infrastructure Costs

DMG Mori invests heavily in its global service and support infrastructure, a crucial element for customer retention and revenue generation. These costs encompass maintaining a vast network of field technicians, ensuring readily available spare parts inventories across various regions, and operating training centers to keep technical staff proficient.

The company's commitment to comprehensive after-sales support translates into significant operational expenses. For instance, in 2023, DMG Mori reported that its service business segment contributed substantially to overall revenue, underscoring the importance of this cost center. These expenditures are vital for delivering timely repairs, preventative maintenance, and technical assistance, thereby enhancing customer satisfaction and equipment uptime.

Furthermore, the development and upkeep of digital service platforms are increasingly becoming a core component of this cost structure. These platforms facilitate remote diagnostics, predictive maintenance, and efficient communication with customers, streamlining support operations and potentially reducing on-site intervention costs over time. Such investments are critical for staying competitive in the evolving landscape of industrial machinery support.

- Global Service Network: Costs for field technicians, travel, and local support centers.

- Spare Parts Inventory: Expenses related to stocking and managing a comprehensive range of replacement parts worldwide.

- Training Centers: Investment in facilities and programs to train service personnel.

- Digital Service Platforms: Outlays for developing and maintaining online support tools and remote diagnostic capabilities.

DMG Mori's cost structure is significantly shaped by its substantial investments in research and development, aiming to maintain its technological edge in advanced machine tools. These R&D expenditures, which reached €242 million in 2023, are critical for developing new innovations.

Manufacturing and production expenses, including raw materials and labor across its global network, form another core cost. Additionally, extensive global sales, marketing, and distribution efforts contribute significantly, with Selling, General, and Administrative expenses totaling €1.4 billion in 2023.

Personnel costs, supporting a workforce of over 13,500 employees worldwide, are substantial, covering wages, benefits, and training. The company also incurs significant costs for its global service and support infrastructure, including field technicians, spare parts, and digital service platforms, essential for customer retention.

| Cost Category | 2023 Financial Impact (EUR Million) | Key Drivers |

|---|---|---|

| Research & Development | 242 | New technology development, software, automation |

| Sales, General & Administrative | 1,400 | Global sales force, marketing, distribution network |

| Personnel Costs | (Estimated based on workforce size) | Wages, benefits, training for 13,500+ employees |

| Service & Support | (Significant operational costs) | Field technicians, spare parts, training centers, digital platforms |

Revenue Streams

DMG Mori's core revenue generation stems from the direct sale of its advanced CNC turning and milling machines. This encompasses a broad portfolio, including highly specialized equipment that integrates cutting-edge ultrasonic and laser technologies to meet diverse manufacturing demands.

In 2024, DMG Mori reported significant sales figures, with its Machine Tools segment being a primary driver of its financial performance. The company's commitment to innovation and a wide product offering, from standard machines to highly customized solutions, continues to attract a global customer base, underscoring the strength of this revenue stream.

DMG Mori generates significant revenue from selling sophisticated automation solutions. These aren't just standalone products; they're often integrated with their core machine tools, offering customers a complete, optimized manufacturing workflow. Think robotic cells, efficient pallet handling systems, and automated guided vehicles (AGVs) that streamline production.

In 2024, the demand for such integrated automation continues to surge, driven by the need for increased efficiency and reduced labor costs across manufacturing sectors. Companies are investing heavily to stay competitive, making these solutions a vital revenue stream for DMG Mori.

DMG Mori generates recurring revenue through service and maintenance contracts, along with spare parts sales. These agreements provide ongoing support for their installed machinery, ensuring optimal uptime for customers.

This segment has been a consistent performer, demonstrating steady growth and significantly contributing to the stabilization of DMG Mori's overall sales revenue. For instance, in 2023, the company reported a substantial increase in its service business, highlighting its importance.

Software and Digital Solutions Licensing/Sales

DMG Mori is increasingly generating revenue from licensing and selling software and digital solutions. These offerings are designed to boost machine performance, enable better connectivity, and optimize manufacturing processes, directly supporting their digital transformation initiatives.

This strategic shift reflects the growing demand for integrated digital tools in the manufacturing sector. For instance, in 2023, the company highlighted its progress in digitalization, with a significant portion of new machine orders including digital components and services.

- Software Licensing: Recurring revenue from subscriptions or perpetual licenses for advanced machine control software, predictive maintenance modules, and process simulation tools.

- Digital Solutions Sales: One-time sales of integrated digital packages, such as IoT platforms for factory-wide data analysis or customized automation software.

- Data-Driven Services: Revenue generated from providing insights and analytics derived from machine data, enabling customers to improve efficiency and reduce downtime.

- Connectivity Platforms: Income from providing and maintaining the digital infrastructure that connects machines, systems, and personnel within a manufacturing environment.

Training and Consulting Services

DMG MORI leverages its expertise to generate revenue through comprehensive training and consulting services. These offerings are designed to empower customers with the skills needed to maximize the performance of their DMG MORI machinery.

The company provides specialized training programs covering machine operation, maintenance, and advanced programming techniques. Beyond training, DMG MORI offers consulting services focused on optimizing manufacturing processes, improving efficiency, and implementing digital solutions. For instance, in 2023, DMG MORI reported a significant increase in demand for digital services and automation solutions, indicating a growing market for their consulting expertise.

- Specialized Training: Programs for machine operation, maintenance, and programming.

- Consulting Services: Process optimization, efficiency improvements, and digital integration.

- Value Addition: Enhances customer utilization of DMG MORI equipment.

- Revenue Diversification: Creates additional income streams beyond machine sales.

Beyond machine sales, DMG Mori also generates substantial revenue from the sale and integration of sophisticated automation solutions. These are often bundled with their core machine tools, creating complete manufacturing workflows for clients.

The company's service and maintenance contracts, alongside spare parts sales, form a crucial recurring revenue stream. These offerings ensure customer satisfaction and continued operational efficiency of their machinery.

DMG Mori's digital transformation strategy is also a growing revenue contributor, with income derived from software licensing and the sale of digital solutions designed to enhance machine performance and connectivity.

Furthermore, DMG Mori capitalizes on its expertise by offering specialized training and consulting services, aiding customers in optimizing their manufacturing processes and maximizing equipment utilization.

| Revenue Stream | Description | 2023 Data/Trend |

|---|---|---|

| Machine Sales | Direct sale of CNC turning and milling machines. | Primary revenue driver; strong global demand. |

| Automation Solutions | Integrated robotic cells, pallet handling, AGVs. | Increasing demand due to efficiency needs. |

| Service & Maintenance | Contracts, spare parts, ongoing support. | Consistent performance with steady growth. |

| Software & Digital Solutions | Licensing, IoT platforms, data analytics. | Growing contribution, reflecting digitalization trend. |

| Training & Consulting | Machine operation, process optimization. | Increased demand for digital and automation expertise. |

Business Model Canvas Data Sources

The DMG Mori Business Model Canvas is informed by a blend of internal financial reports, extensive market research on machine tool trends, and strategic insights from customer feedback and sales data. These diverse sources ensure a comprehensive and accurate representation of the company's operations and market position.