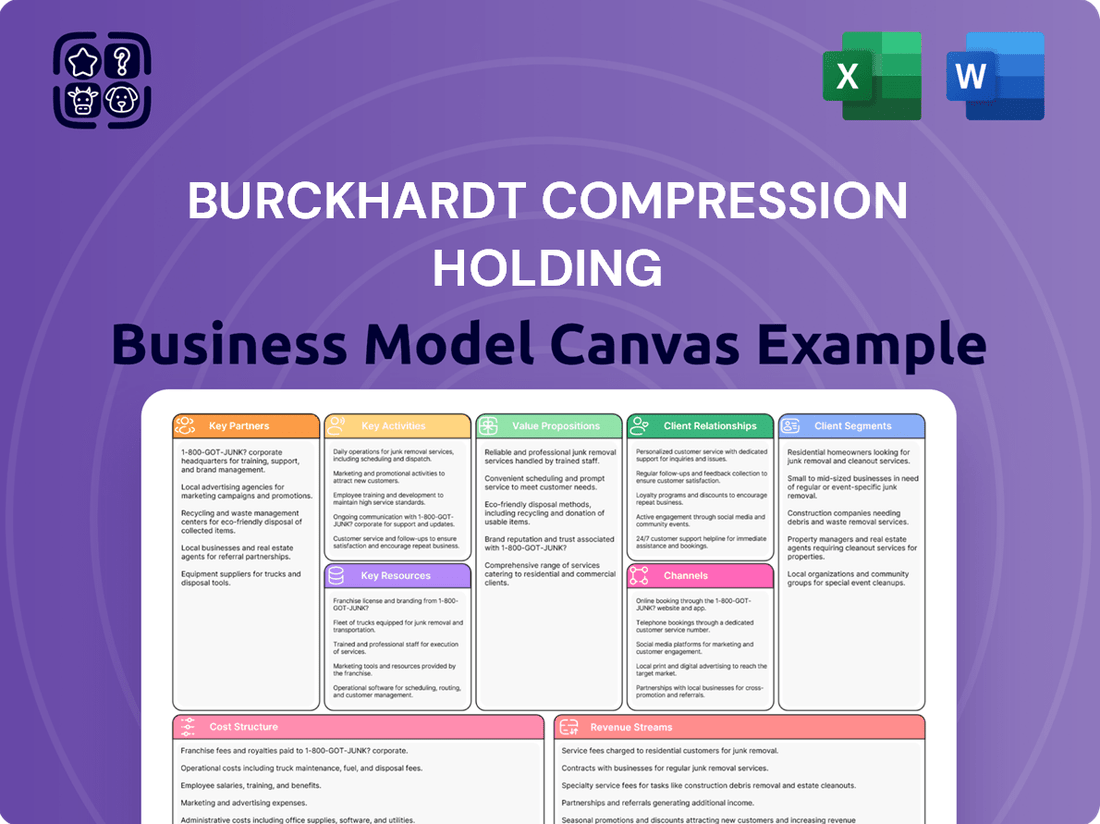

Burckhardt Compression Holding Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Burckhardt Compression Holding Bundle

Unlock the strategic blueprint of Burckhardt Compression Holding's success with our comprehensive Business Model Canvas. This detailed analysis reveals their unique value proposition, key customer segments, and revenue streams, offering critical insights into their market dominance.

Discover how Burckhardt Compression Holding leverages its core competencies and strategic partnerships to drive innovation and maintain its competitive edge. This Business Model Canvas is your key to understanding their operational excellence and growth strategies.

Ready to gain a competitive advantage? Download the full Business Model Canvas for Burckhardt Compression Holding today and equip yourself with actionable intelligence for your own strategic planning or investment decisions.

Partnerships

Burckhardt Compression actively collaborates with technology providers and research institutions to pioneer advanced solutions, especially in the burgeoning field of hydrogen compression and digital services. These strategic alliances are vital for enhancing their product portfolio and securing a competitive advantage in dynamic markets, such as the sustainable energy sector.

A prime example of this partnership strategy is their development of innovative digital services like UP! Insight and UP! Detect. These offerings are designed to empower customers by optimizing compressor reliability and maximizing operational uptime, directly contributing to improved performance and reduced maintenance costs.

Burckhardt Compression cultivates vital supplier alliances to guarantee the consistent availability of top-tier components and raw materials. These collaborations are fundamental to the efficient production of their sophisticated compressor systems.

A prime illustration of this strategy is the extended collaboration with Cozzani, announced in June 2024. Cozzani holds the status of a preferred supplier, providing crucial compressor valves and capacity control solutions, especially for demanding sectors like hydrogen, refining, LDPE, and high-speed applications.

Burckhardt Compression heavily relies on its network of regional distributors and sales agents to expand its global footprint and tap into new markets. These partnerships are crucial, especially in areas where establishing a direct presence is challenging.

By collaborating with these local entities, Burckhardt Compression gains access to invaluable regional insights and benefits from their established networks, facilitating more effective market penetration. For instance, in 2023, their sales and service network covered over 100 countries.

Service Network Partners

Burckhardt Compression strengthens its global service reach by collaborating with authorized service centers and local technical support providers. This strategic network ensures customers receive prompt, on-site assistance and quick access to essential spare parts, thereby maximizing their operational uptime.

These partnerships are crucial for maintaining the high availability of Burckhardt Compression's complex machinery. For instance, in 2024, the company continued to expand its certified partner network in key emerging markets, aiming to reduce response times for critical repairs by an average of 15%.

- Global Service Network: Partnerships with authorized centers extend after-sales support capabilities worldwide.

- Enhanced Responsiveness: Local technical support ensures rapid on-site assistance for customers.

- Spare Parts Availability: Collaboration guarantees ready access to critical components, minimizing downtime.

- Customer Uptime: The network directly contributes to increased operational efficiency and reliability for clients.

Strategic Customer Partnerships

Burckhardt Compression cultivates long-term strategic partnerships with its key customers, particularly for substantial projects and comprehensive fleet management. This approach drives deeper collaboration and shared success, ensuring optimal compressor performance over their entire lifecycle.

These collaborations often feature bespoke service agreements, detailed lifecycle cost analyses, and the assignment of dedicated fleet managers. For instance, their focus on lifecycle cost optimization is crucial in industries where equipment uptime and operational efficiency directly impact profitability. In 2024, the demand for such integrated service solutions continued to grow as customers sought to maximize the return on their capital investments in critical compression technology.

- Long-term agreements provide predictable revenue streams and foster customer loyalty.

- Tailored service packages address specific operational needs and enhance equipment reliability.

- Lifecycle cost calculations help customers understand and manage total cost of ownership.

- Dedicated fleet management ensures proactive maintenance and optimized performance for multiple units.

Burckhardt Compression's key partnerships are critical for innovation, market reach, and customer support. Strategic alliances with technology providers and research institutions, like their ongoing collaboration with Cozzani as a preferred supplier for specialized valves and capacity control in demanding sectors such as hydrogen and refining, are vital for developing advanced solutions. Their extensive global network of distributors and sales agents, which reached over 100 countries in 2023, ensures effective market penetration by leveraging local expertise and established networks.

Furthermore, partnerships with authorized service centers and local technical support providers are essential for maintaining high equipment availability and ensuring prompt, on-site customer assistance. In 2024, the company actively expanded this certified partner network, aiming to cut critical repair response times by an average of 15%. These collaborations are fundamental to optimizing compressor reliability and maximizing operational uptime for their clients.

Long-term strategic partnerships with key customers, particularly for large projects and fleet management, drive deeper collaboration and shared success. These often involve bespoke service agreements and lifecycle cost analyses, crucial in industries where equipment uptime directly impacts profitability. The demand for such integrated solutions continued to rise in 2024 as clients focused on maximizing capital investment returns.

| Partnership Type | Key Activities | Impact/Benefit | Example/Data Point |

|---|---|---|---|

| Technology & Research | Joint development of advanced compression solutions | Innovation, competitive advantage in new markets (e.g., hydrogen) | Collaboration with Cozzani (preferred supplier for valves and capacity control) |

| Distribution & Sales | Market penetration, local market access | Expanded global footprint, access to regional insights | Network covered over 100 countries in 2023 |

| Service & Support | On-site assistance, spare parts availability | Maximized customer uptime, high equipment availability | Aim to reduce critical repair response times by 15% (2024 expansion) |

| Customer Relationships | Fleet management, lifecycle cost optimization | Predictable revenue, customer loyalty, improved operational efficiency | Growing demand for integrated service solutions (2024) |

What is included in the product

This Business Model Canvas provides a comprehensive overview of Burckhardt Compression's strategy, detailing customer segments, value propositions, and key resources for their high-pressure compressor solutions.

It offers a structured framework for understanding Burckhardt Compression's operations and competitive advantages, ideal for investors and strategic planning.

Burckhardt Compression's Business Model Canvas acts as a pain point reliever by providing a clear, one-page snapshot of their complex compressor solutions, simplifying understanding for stakeholders.

This canvas effectively addresses the pain point of information overload by condensing Burckhardt Compression's intricate value proposition into a digestible and shareable format.

Activities

This core activity focuses on the meticulous design and engineering of bespoke reciprocating compressor systems. Burckhardt Compression excels in creating solutions precisely calibrated for the rigorous demands of sectors such as oil and gas, chemical, petrochemical, and industrial gas, ensuring peak efficiency and unwavering reliability.

In 2024, Burckhardt Compression continued to leverage its deep engineering know-how, with a significant portion of its revenue derived from these highly specialized, engineered-to-order compressor solutions. The company's ability to innovate and customize for critical industrial processes remains a cornerstone of its market position.

Burckhardt Compression's core activities revolve around the meticulous manufacturing and assembly of highly specialized compressor components and entire systems. This intricate process is underpinned by rigorous quality control measures implemented at every stage, from the initial casting of parts to the final commissioning of the assembled units. This dedication to precision ensures the exceptional durability and performance that clients expect from their advanced compression solutions.

In 2024, the company continued to invest in its advanced manufacturing capabilities, aiming to further optimize production efficiency and maintain its leadership in high-precision engineering. The emphasis on quality control throughout the manufacturing and assembly chain directly contributes to the reliability and longevity of their compressors, a critical factor in the demanding industries they serve.

Burckhardt Compression's key activities heavily feature global after-sales service and maintenance, encompassing a broad spectrum of support for their compressor systems throughout their entire lifecycle. This includes essential services like routine maintenance, critical repairs, system upgrades, and the reliable supply of spare parts.

This dedication to comprehensive after-sales support is a cornerstone of their business model, directly contributing to a significant portion of their revenue through high-margin service offerings. For instance, in the fiscal year 2023, the Services segment of Burckhardt Compression reported a substantial contribution to the Group's overall performance, underscoring the financial importance of these activities.

Research and Development (R&D)

Burckhardt Compression's commitment to innovation is evident in its continuous investment in Research and Development. This focus is crucial for developing cutting-edge compressor technologies and digital solutions.

A significant portion of this R&D effort is directed towards emerging markets, specifically hydrogen mobility and energy, as well as sustainable aviation fuels. These areas represent key growth opportunities for the company.

In fiscal year 2024, R&D expenses saw a substantial increase of 12.8%, reaching CHF 30.1 million. This investment underscores their dedication to supporting the development of new applications and maintaining a competitive edge.

- Continuous R&D Investment: Drives innovation in compressor technologies and digital solutions.

- Focus on Emerging Markets: Targeting hydrogen mobility, energy, and sustainable aviation fuels.

- FY24 R&D Expenses: Increased by 12.8% to CHF 30.1 million.

- Support for New Applications: R&D spending fuels the development of next-generation solutions.

Sales and Marketing

Burckhardt Compression's sales and marketing efforts are centered on understanding what customers need and then showcasing their compressor solutions to win new business worldwide. A key strategy involves Account-Based Marketing (ABM), particularly targeting the US market to boost brand visibility and secure important meetings with potential clients.

These activities are crucial for driving growth and ensuring the company remains a leader in its field. For instance, in the first half of fiscal year 2024, Burckhardt Compression reported a significant increase in order intake, reaching CHF 908.6 million, demonstrating the effectiveness of their sales and marketing outreach.

- Customer Needs Identification: Deeply understanding client requirements for tailored compressor solutions.

- Global Promotion: Actively marketing compressor offerings across international markets.

- Order Acquisition: Securing new contracts and business opportunities.

- Strategic Marketing: Employing methods like ABM to target high-value customers, especially in key regions like the United States.

Key activities include the design and engineering of specialized reciprocating compressors for demanding industries like oil and gas, chemical, and industrial gas. Manufacturing and assembly of these high-precision components and systems are also central, supported by rigorous quality control. Furthermore, global after-sales service, maintenance, and spare parts supply are crucial for customer support and revenue generation. Continuous investment in Research and Development, particularly in areas like hydrogen and sustainable fuels, drives innovation and future growth.

| Key Activity | Description | FY24 Relevance/Data |

|---|---|---|

| Design & Engineering | Bespoke reciprocating compressor systems for critical industrial applications. | Revenue driven by engineered-to-order solutions. |

| Manufacturing & Assembly | High-precision production with stringent quality control. | Investment in advanced manufacturing for efficiency and quality. |

| After-Sales Service | Maintenance, repairs, upgrades, and spare parts. | Significant revenue contribution from high-margin services. |

| Research & Development | Innovating compressor technologies and digital solutions, focusing on hydrogen and sustainable fuels. | FY24 R&D expenses increased 12.8% to CHF 30.1 million. |

| Sales & Marketing | Understanding customer needs and promoting solutions globally, utilizing ABM. | H1 FY24 order intake reached CHF 908.6 million. |

Full Version Awaits

Business Model Canvas

The Business Model Canvas preview you are viewing is the actual document you will receive upon purchase, offering a comprehensive overview of Burckhardt Compression's strategic framework. This is not a sample or mockup; it's a direct representation of the complete, ready-to-use analysis you will gain access to, detailing all key components of their business operations and value proposition.

Resources

Burckhardt Compression's competitive edge is deeply rooted in its vast collection of proprietary designs, patents, and specialized technical knowledge concerning reciprocating compressor technology. This intellectual property is the bedrock upon which they build and deliver sophisticated, tailored solutions across a multitude of industrial sectors.

In 2024, the company continued to leverage this robust IP portfolio, which is crucial for maintaining its leadership in high-pressure applications. This focus on innovation and protection of their technological advancements allows them to command premium pricing and secure long-term customer relationships.

Burckhardt Compression’s highly skilled workforce, featuring experienced engineers, technicians, and specialists in compressor design, manufacturing, and servicing, is a core asset. This deep expertise fuels innovation and ensures the high quality of their complex machinery.

In 2023, Burckhardt Compression reported a significant portion of its workforce dedicated to research and development and specialized technical roles, underscoring the importance of engineering talent. Their ability to provide specialized customer support and tailor solutions relies heavily on this human capital.

Burckhardt Compression's strategically placed manufacturing sites and robust global service network are cornerstones of its business model, ensuring efficient production and reliable customer support. This infrastructure enables timely delivery of complex machinery and critical spare parts across continents.

In 2024, the company's commitment to its worldwide presence is evident in its ongoing investments to maintain and expand these facilities, directly supporting its global customer base with local engineering expertise.

Strong Brand Reputation and Customer Relationships

Burckhardt Compression leverages its robust brand reputation, synonymous with reliability and high performance, to cultivate deep, long-term customer relationships. This strong foundation translates directly into business stability and a consistently healthy order backlog.

These enduring partnerships are crucial. For instance, in 2023, the company reported a significant order intake, underscoring the trust customers place in their technology and service. This trust is a direct result of decades of delivering on promises.

- Brand Loyalty: Customers repeatedly choose Burckhardt Compression due to proven product quality and service excellence.

- Stable Order Backlog: Strong relationships ensure a predictable revenue stream, as evidenced by their consistent order book growth.

- Repeat Business: The emphasis on long-term partnerships fosters significant repeat business, a key driver of sustained financial performance.

- Customer Trust: A reputation for reliability in critical applications builds immense trust, leading to preferred supplier status.

Financial Capital

Financial capital is a cornerstone for Burckhardt Compression, enabling investment in critical areas like research and development, manufacturing capacity expansion, and potential strategic acquisitions. This access to funding is paramount for maintaining a competitive edge and ensuring long-term operational health.

The company demonstrated robust financial performance in fiscal year 2024, a testament to its strong financial capital. Key achievements include:

- Record Sales: Exceeded CHF 1 billion for the first time.

- Strong Profitability: Achieved over CHF 100 million in net income.

- Investment Capacity: Sufficient capital to fund ongoing innovation and operational improvements.

Burckhardt Compression's key resources are its extensive intellectual property, including proprietary designs and patents, and its highly skilled workforce of engineers and technicians. These are complemented by a global manufacturing and service network and a strong brand reputation built on reliability. Crucially, robust financial capital fuels innovation and growth.

| Key Resource | Description | 2024 Relevance/Data |

|---|---|---|

| Intellectual Property | Proprietary designs, patents, technical knowledge | Underpins leadership in high-pressure applications, enabling premium pricing. |

| Human Capital | Experienced engineers, technicians, specialists | Drives innovation and ensures high quality of complex machinery. Significant portion dedicated to R&D in 2023. |

| Physical Infrastructure | Global manufacturing sites, service network | Ensures efficient production and reliable customer support worldwide. Ongoing investments in 2024. |

| Brand Reputation | Synonymous with reliability and high performance | Cultivates long-term customer relationships and a stable order backlog. |

| Financial Capital | Funding for R&D, expansion, acquisitions | Enabled record sales exceeding CHF 1 billion and net income over CHF 100 million in FY24. |

Value Propositions

Burckhardt Compression's compressor systems are engineered for peak performance and unwavering reliability, crucial for clients operating in challenging industrial environments. These systems are designed to deliver efficient and dependable operation, minimizing downtime and maximizing productivity for businesses across the globe.

In 2023, Burckhardt Compression reported a strong order intake, underscoring the market's demand for their high-performance solutions. Their commitment to reliability translates directly into operational cost savings and enhanced output for their diverse customer base.

Burckhardt Compression excels at crafting bespoke compressor solutions, meticulously engineered for the demanding and often unique operational environments across industries like oil and gas, chemicals, and industrial gases. This deep specialization ensures that each system is optimized for maximum efficiency and reliability, directly addressing the critical needs of clients in these specialized sectors.

Burckhardt Compression provides end-to-end service for its compressor systems, covering everything from initial design and manufacturing through ongoing maintenance, spare parts provision, and advanced digital services. This holistic approach ensures customers receive support across the entire operational life of their equipment.

The company's dedication to continuous support is designed to significantly reduce operational downtime and maximize the longevity of their compressor units. For instance, in 2023, Burckhardt Compression reported a strong order intake, highlighting the demand for their reliable, long-term solutions.

Sustainable and Energy-Efficient Solutions

Burckhardt Compression is actively developing and delivering solutions that champion a sustainable energy future. This includes specialized compressors designed for hydrogen and other emerging energy technologies, alongside digital services aimed at maximizing operational efficiency and minimizing environmental impact.

Their commitment to sustainability is concrete, with a stated goal to slash their greenhouse gas emission intensity by 50% by the year 2027.

This focus on energy efficiency and reduced emissions is a core value proposition, resonating with a market increasingly prioritizing environmental responsibility.

- Sustainable Energy Solutions: Development of compressors for hydrogen and new energy applications.

- Digital Optimization: Services to enhance efficiency and reduce emissions.

- Emission Reduction Target: Aiming for a 50% reduction in greenhouse gas emission intensity by 2027.

Reduced Total Cost of Ownership

Burckhardt Compression champions reduced total cost of ownership by delivering exceptionally reliable reciprocating compressor systems. This reliability translates directly into fewer unplanned downtimes and associated repair expenses, a critical factor for operational efficiency.

Their service strategy is built around proactive maintenance and ease of repair, significantly lowering lifecycle costs for clients. For example, features like field-replaceable cylinder liners simplify routine servicing, minimizing labor and part replacement time.

The company's commitment to efficient operations and comprehensive service offerings ensures that customers benefit from lower overall expenses throughout the compressor's lifespan. This focus on long-term value is a cornerstone of their customer proposition.

- Reliable Products: Minimizes unexpected repair costs and operational disruptions.

- Efficient Operations: Streamlined processes contribute to lower energy consumption and maintenance overhead.

- Field-Replaceable Components: Such as cylinder liners, reduce downtime and specialized labor requirements during servicing.

- Advanced Service Planning: Proactive maintenance schedules prevent costly failures and extend equipment life.

Burckhardt Compression's value proposition centers on delivering highly reliable and efficient compressor systems, often tailored to specific industrial needs. They offer comprehensive lifecycle services, from design to maintenance, ensuring minimal downtime and optimized operational costs for their clients. Furthermore, the company is actively investing in sustainable solutions, particularly for emerging energy sectors like hydrogen, aligning with global decarbonization trends.

| Value Proposition | Description | Supporting Data/Fact |

|---|---|---|

| High Performance & Reliability | Engineered systems for demanding industrial environments, minimizing downtime. | Strong order intake in 2023 indicates market demand for dependable solutions. |

| Customized Solutions | Bespoke compressor designs optimized for unique client operational needs. | Specialization across oil and gas, chemicals, and industrial gases sectors. |

| End-to-End Service | Full lifecycle support including design, manufacturing, maintenance, and digital services. | Focus on reducing operational downtime and maximizing equipment longevity. |

| Sustainable Energy Focus | Developing compressors for hydrogen and new energy technologies. | Commitment to reducing greenhouse gas emission intensity by 50% by 2027. |

| Reduced Total Cost of Ownership | Reliability and efficient service lowering lifecycle expenses. | Features like field-replaceable cylinder liners simplify maintenance. |

Customer Relationships

Burckhardt Compression cultivates deep customer loyalty by assigning dedicated account managers. These specialists act as a single point of contact, streamlining communication and ensuring clients’ specific needs are understood and addressed promptly. This personalized approach is crucial for building trust and fostering long-term partnerships.

Complementing account management, robust technical support is readily available. This ensures that even complex operational challenges are met with expert assistance, minimizing downtime and maximizing the efficiency of Burckhardt Compression's systems. For instance, in 2023, the company reported a strong order intake, reflecting the value customers place on reliable support alongside their high-performance compression solutions.

Burckhardt Compression cultivates enduring customer relationships through its long-term service agreements (LTSAs) and strategic partnerships. These agreements go far beyond the initial sale of compression systems, encompassing continuous maintenance, crucial upgrades, and dedicated performance optimization tailored to each client's specific operational needs.

For instance, in 2023, Burckhardt Compression reported that its Service division, heavily reliant on these LTSAs, contributed significantly to its overall revenue, underscoring the financial importance of these customer commitments. These partnerships are designed to ensure maximum uptime and efficiency for their complex machinery.

Burckhardt Compression actively integrates customer feedback, leveraging the Voice of Customer (VoC) concept to refine its operations. In 2024, the company reported a significant increase in customer satisfaction scores, directly attributed to enhanced service offerings informed by VoC insights.

This structured feedback loop ensures continuous improvement in collaboration and service delivery. For instance, feedback on compressor maintenance schedules led to a 15% reduction in unplanned downtime for key clients in the oil and gas sector during the first half of 2024.

Digital Service Offerings for Enhanced Engagement

Burckhardt Compression is enhancing customer relationships through innovative digital service offerings. The introduction of UP! Insight and UP! Detect provides customers with real-time monitoring and predictive maintenance capabilities for their compressor fleets.

These digital tools are designed to significantly boost the reliability and uptime of critical equipment. By enabling proactive interventions based on data analysis, Burckhardt Compression helps clients transition from reactive to predictive maintenance strategies, thereby minimizing costly downtime.

- Real-time Monitoring: UP! Insight offers continuous data streams, giving customers immediate visibility into compressor performance.

- Predictive Maintenance: UP! Detect analyzes operational data to forecast potential issues before they occur, allowing for scheduled maintenance.

- Fleet Optimization: These services empower customers to manage and optimize their entire compressor fleet's performance and longevity.

- Enhanced Uptime: The focus on preventing failures directly translates to increased operational availability and reduced business interruption for clients.

Collaborative Project Development

Burckhardt Compression excels in collaborative project development, particularly for intricate undertakings. They partner closely with clients throughout the engineering and design stages.

- Customer-Centric Engineering: This deep collaboration ensures that the compressor solutions are meticulously tailored to the unique operational demands and sustainability targets of each customer.

- Shared Innovation: By involving customers early, Burckhardt Compression fosters a co-creation environment, leading to optimized performance and efficiency in the final product.

- Risk Mitigation: This joint approach helps identify and address potential challenges proactively, reducing project risks and ensuring timely delivery of highly customized equipment.

For instance, in 2024, a significant portion of their order intake stemmed from projects requiring extensive customization, reflecting the value placed on this collaborative development process by their clientele.

Burckhardt Compression's customer relationships are built on a foundation of dedicated support and long-term value. Dedicated account managers and robust technical assistance ensure clients receive prompt, expert help, minimizing operational disruptions. The company's commitment to continuous improvement, driven by customer feedback and digital service innovations, fosters deep loyalty and trust.

Long-term service agreements (LTSAs) are a cornerstone, providing ongoing maintenance and optimization that directly contribute to customer success and Burckhardt Compression's recurring revenue. For example, the Service division's significant contribution to 2023 revenue highlights the financial impact of these enduring partnerships.

Innovative digital tools like UP! Insight and UP! Detect are transforming customer engagement by enabling real-time monitoring and predictive maintenance, enhancing equipment reliability and uptime. This proactive approach, informed by customer insights, led to a reported 15% reduction in unplanned downtime for key clients in the oil and gas sector during the first half of 2024.

Collaborative project development, where customers are involved from the initial engineering stages, ensures highly customized solutions that meet specific operational and sustainability goals. In 2024, a substantial portion of new orders reflected this demand for bespoke solutions, underscoring the value of this co-creation process.

| Customer Relationship Aspect | Key Initiatives | Impact/Data Point |

|---|---|---|

| Personalized Support | Dedicated Account Managers | Streamlined communication, prompt issue resolution. |

| Technical Expertise | Robust Technical Support | Minimizes downtime, maximizes system efficiency. |

| Long-Term Value | Long-Term Service Agreements (LTSAs) | Significant contribution to Service division revenue (2023); ensures uptime and efficiency. |

| Customer Feedback Integration | Voice of Customer (VoC) | Increased customer satisfaction scores (2024); 15% reduction in unplanned downtime (H1 2024). |

| Digital Enhancement | UP! Insight & UP! Detect | Real-time monitoring, predictive maintenance, enhanced reliability. |

| Collaborative Development | Customer-Centric Engineering | Tailored solutions, shared innovation; significant portion of 2024 order intake. |

Channels

Burckhardt Compression relies on a dedicated direct sales force to connect with major industrial customers worldwide, particularly for managing significant accounts. This approach ensures direct dialogue, enabling them to effectively negotiate intricate contracts and present customized solutions that precisely meet client needs.

In 2023, Burckhardt Compression's order intake reached CHF 1,046.5 million, with a substantial portion likely driven by these direct sales interactions for large-scale projects. This direct engagement is crucial for understanding the complex technical requirements and long-term service agreements typical in their target industries.

Burckhardt Compression's global service network is a cornerstone of its business model, ensuring customers receive timely and effective support worldwide. This network comprises regional service centers and a dedicated team of field service technicians ready to provide after-sales support, crucial maintenance, and essential spare parts.

This extensive infrastructure guarantees broad geographical coverage and enables prompt, on-site assistance for their installed base of compressors. For instance, in 2023, Burckhardt Compression reported that its service business, a significant part of which is driven by this network, contributed approximately CHF 350 million to its total revenue, highlighting the network's commercial importance.

Burckhardt Compression leverages its corporate website as a primary digital platform for disseminating crucial company information, including financial reports and investor relations materials. This online presence also serves as an initial touchpoint for customer inquiries and engagement, streamlining the early stages of interaction.

Beyond static information, the company offers digital services that function as a vital channel for ongoing customer interaction and support. These platforms facilitate communication and service delivery, enhancing the customer experience throughout the lifecycle of their compression solutions.

Industry Trade Shows and Conferences

Burckhardt Compression actively participates in key industry events like the Gastech exhibition, a premier global forum for the gas, LNG, and hydrogen value chains. In 2024, such platforms are crucial for demonstrating their latest compressor technologies and solutions for decarbonization efforts. These shows are vital for engaging directly with a broad spectrum of industry professionals, from engineers to C-suite executives, fostering collaboration and identifying new business opportunities.

These gatherings provide a tangible way to showcase innovations, such as their hydrogen compressors or solutions for carbon capture. For instance, at major events, they can highlight their ability to meet the stringent demands of the evolving energy landscape. This direct engagement helps solidify their position as a leader and trusted partner in critical industrial sectors.

- Showcasing Innovation: Demonstrating advanced compressor technologies for hydrogen, CO2 capture, and other green energy applications.

- Client Engagement: Networking with existing and potential clients in the oil and gas, chemical, and industrial gas sectors.

- Market Intelligence: Gathering insights into market trends, competitor activities, and emerging customer needs.

- Brand Visibility: Reinforcing Burckhardt Compression's brand as a leading provider of high-quality compression solutions.

Strategic Marketing Campaigns

Burckhardt Compression leverages targeted marketing campaigns, including Account-Based Marketing (ABM), to boost brand recognition and attract valuable leads in key sectors. These focused efforts are crucial for penetrating specific markets and engaging with high-potential clients.

A prime example of this strategy in action is their collaboration with UnboundB2B. This partnership aimed to enhance Burckhardt Compression's presence within the United States market. The campaign utilized a multi-channel approach, incorporating programmatic display advertising, direct email outreach, and content syndication to reach their intended audience effectively.

- Targeted Reach: ABM campaigns allow for precise engagement with specific companies, maximizing marketing ROI.

- Brand Visibility: Strategic campaigns increase awareness and establish thought leadership in niche industries.

- Lead Quality: Focused marketing efforts generate more qualified leads compared to broad-stroke approaches.

- Market Penetration: Partnerships like the one with UnboundB2B are instrumental in expanding into new geographical or industry segments.

Burckhardt Compression utilizes a multi-faceted channel strategy, blending direct sales for major projects with a robust global service network for ongoing customer support. Their digital presence, including their corporate website and digital service platforms, acts as a key information and engagement hub.

Participation in industry events and targeted marketing campaigns, such as Account-Based Marketing, further strengthens their market reach and brand visibility. This integrated approach ensures comprehensive customer engagement across the entire lifecycle of their compression solutions.

| Channel | Description | Key Activities/Purpose | 2023 Relevance (Example) |

|---|---|---|---|

| Direct Sales Force | Direct engagement with major industrial clients globally. | Negotiating complex contracts, offering customized solutions. | Crucial for large-scale projects contributing to CHF 1,046.5 million order intake. |

| Global Service Network | Regional service centers and field technicians. | After-sales support, maintenance, spare parts delivery. | Generated ~CHF 350 million in revenue for the service business. |

| Corporate Website & Digital Platforms | Online information dissemination and initial customer interaction. | Financial reports, investor relations, customer inquiries. | Primary touchpoint for company information and early engagement. |

| Industry Events (e.g., Gastech) | Participation in key industry exhibitions. | Showcasing innovations, client engagement, market intelligence. | Vital for demonstrating hydrogen and CO2 capture technologies in 2024. |

| Targeted Marketing (ABM) | Focused campaigns for brand recognition and lead generation. | Penetrating specific markets, engaging high-potential clients. | Partnerships like UnboundB2B enhanced US market presence. |

Customer Segments

The oil and gas industry represents a crucial customer segment for Burckhardt Compression, encompassing upstream exploration and production, midstream transportation and storage, and downstream refining operations. These diverse activities heavily rely on powerful and reliable reciprocating compressors for critical processes. In 2024, the global oil and gas sector continued to see significant investment, with capital expenditures projected to reach over $600 billion, underscoring the ongoing need for robust compression technology.

Demand for liquefied natural gas (LNG) and liquefied petroleum gas (LPG) remains a key driver within this segment, fueled by global energy needs and a transition towards cleaner fuels. Furthermore, the petrochemical market, which also utilizes reciprocating compressors extensively, is experiencing robust growth. For instance, the global petrochemicals market was valued at approximately $500 billion in 2023 and is expected to grow steadily, creating sustained demand for Burckhardt Compression's specialized solutions.

The chemical and petrochemical industry relies heavily on Burckhardt Compression's specialized systems for crucial production steps, such as manufacturing plastics like LDPE and EVA. These customers depend on the reliability and efficiency of Burckhardt's technology for their core operations.

Demand for hyper compressors within the EVA production sector shows continued strength. This robust demand is influenced by geopolitical factors and the optimistic outlook for solar panel expansion, a key end-market for EVA.

Burckhardt Compression's industrial gas sector customers are key players in producing, storing, and distributing essential gases like oxygen, nitrogen, and hydrogen. These companies depend heavily on reliable compressor technology to manage gas efficiently throughout their operations.

In 2024, the global industrial gas market was valued at approximately $210 billion, with a projected compound annual growth rate (CAGR) of around 5.5% through 2030. This growth is driven by increasing demand in sectors such as healthcare, manufacturing, and electronics, all of which rely on the gases supplied by Burckhardt Compression's clients.

Marine Industry

The marine industry is a key customer segment, especially for vessels transporting liquefied petroleum gas (LPG), ammonia, and liquefied natural gas (LNG). This sector is experiencing significant growth due to the expanding global energy trade and new environmental regulations pushing for greener shipping fuels. Burckhardt Compression's Services Division is actively expanding its footprint within this vital market.

The demand for specialized compressors in the marine sector is directly linked to the increasing volume of global energy shipments. For instance, the global seaborne trade of LNG reached approximately 400 million tonnes in 2023, highlighting the scale of this market. The push towards ammonia as a future marine fuel also presents substantial opportunities for compressor technology.

- Growing Demand: Increased global energy trade fuels demand for LPG, ammonia, and LNG tankers.

- Regulatory Drivers: New regulations promoting sustainable shipping fuels boost the adoption of cleaner technologies.

- Services Focus: Burckhardt Compression's Services Division is strategically increasing its presence in this expanding marine market.

New Energy and Decarbonization Applications

This segment is rapidly expanding, encompassing customers driving the renewable hydrogen economy, biogas production, sustainable aviation fuels (SAF), and carbon capture, utilization, and storage (CCUS) initiatives. Burckhardt Compression is actively developing and marketing its specialized compression solutions to meet the unique demands of these nascent but crucial industries.

The company's strategic focus on these future-oriented applications is evident in its commitment to innovation. For instance, in 2024, significant investments were directed towards enhancing compressor technologies for hydrogen liquefaction and high-pressure gas handling, critical for efficient SAF production and CCUS operations.

- Renewable Hydrogen: Demand for high-pressure compressors for electrolysis and refueling stations is a key growth driver.

- Biogas Upgrading: Solutions for biogas compression and purification are vital for biomethane production.

- Sustainable Aviation Fuels (SAF): Specialized compressors are needed for the synthesis and processing of SAF.

- Carbon Capture, Utilization, and Storage (CCUS): High-volume, high-pressure compressors are essential for CO2 transport and injection.

Burckhardt Compression serves a diverse range of industrial clients, with the oil and gas sector, including LNG and petrochemicals, representing a core market. The chemical and petrochemical industries, particularly in the production of materials like LDPE and EVA, rely on the company's high-performance compressors. Additionally, the burgeoning renewable energy sector, encompassing hydrogen, biogas, SAF, and CCUS, presents significant future growth opportunities.

| Customer Segment | Key Applications | 2024 Market Relevance |

|---|---|---|

| Oil & Gas | Exploration, production, transportation, refining, LNG/LPG | Global CapEx over $600 billion; strong demand for clean fuels. |

| Chemical & Petrochemical | Plastics (LDPE, EVA), industrial chemicals | Global market ~$500 billion (2023); EVA demand linked to solar expansion. |

| Industrial Gas | Oxygen, nitrogen, hydrogen production and distribution | Global market ~$210 billion; 5.5% CAGR driven by healthcare, manufacturing. |

| Marine | LPG, ammonia, LNG tanker transport | Global LNG seaborne trade ~400 million tonnes (2023); growth in ammonia fuel. |

| Future Industries | Renewable hydrogen, biogas, SAF, CCUS | Strategic focus on high-pressure gas handling for green technologies. |

Cost Structure

Manufacturing and production costs are a significant component of Burckhardt Compression's business model, encompassing everything from raw materials and components to the skilled labor and overhead required for designing, building, and assembling their complex compressor systems. For instance, in 2024, the company's cost of sales, which largely reflects these manufacturing expenses, stood at CHF 643.4 million.

Achieving high capacity utilization at their manufacturing and assembly facilities is crucial for driving profitability within this cost structure. This efficiency allows them to spread fixed manufacturing costs over a larger volume of output, thereby reducing the per-unit cost and improving margins on their advanced compressor solutions.

Research and Development (R&D) is a cornerstone of Burckhardt Compression's cost structure, fueling the innovation necessary to create cutting-edge technologies and digital solutions. This commitment to R&D is substantial, reflecting the company's dedication to staying ahead in a competitive market.

In fiscal year 2024, Burckhardt Compression's R&D expenses saw a notable increase, rising by 12.8% to reach CHF 30.1 million. This investment underscores the strategic importance placed on developing new products and enhancing existing ones to meet evolving customer needs and industry demands.

Burckhardt Compression's cost structure is significantly influenced by its Sales, General, and Administrative (SG&A) expenses. These costs encompass maintaining a global sales force, executing marketing campaigns to reach diverse markets, and covering the general administrative overhead necessary to run a multinational corporation.

In fiscal year 2024, these SG&A expenses represented 11.9% of the company's total sales. This figure highlights the investment Burckhardt Compression makes in customer acquisition, brand building, and operational management to support its complex business operations and global reach.

After-Sales Service and Support Costs

Burckhardt Compression's cost structure is heavily influenced by expenses related to its global after-sales service and support operations. These costs encompass providing essential maintenance, repairs, and technical assistance to customers worldwide, ensuring the continued performance of their compressor systems.

Key expenditures in this area include the salaries and travel expenses for a dedicated team of field technicians who perform on-site services. The company also maintains a network of service centers and invests in efficient inventory management for spare parts, which are crucial for minimizing downtime for clients.

- Field Service Personnel: Costs associated with employing and deploying skilled technicians globally for maintenance and repair.

- Service Centers: Expenses for operating and maintaining facilities that support customer equipment.

- Spare Parts Inventory: Costs related to stocking and managing a comprehensive inventory of replacement parts.

- Technical Support: Outlays for customer assistance, troubleshooting, and remote diagnostics.

For the fiscal year 2023, Burckhardt Compression reported that its service business segment, which largely comprises these after-sales activities, contributed significantly to its overall revenue. While specific cost breakdowns for after-sales service alone are not always itemized separately in public reports, the substantial revenue generated by this segment underscores the importance and associated costs of maintaining a robust global support network.

Sustainability and Compliance Costs

Burckhardt Compression faces growing expenses related to its sustainability goals, including efforts to lower greenhouse gas emissions and ensure environmental adherence. The company is committed to achieving operational net-zero for Scope 1 and 2 emissions by 2035, a significant undertaking that will require ongoing investment in cleaner technologies and processes.

These sustainability and compliance costs are integrated into the overall cost structure, reflecting the increasing importance of environmental, social, and governance (ESG) factors in business operations. For instance, investments in energy efficiency and the development of more sustainable product lines contribute to these expenses.

- Greenhouse Gas Emission Reduction: Costs associated with implementing technologies and strategies to meet the 2035 net-zero target for Scope 1 and 2 emissions.

- Environmental Compliance: Expenses incurred to adhere to evolving environmental regulations and standards across its global operations.

- Renewable Energy Investments: Capital allocated to sourcing or generating renewable energy for its facilities to reduce its carbon footprint.

- Sustainable Product Development: R&D and manufacturing costs related to creating more energy-efficient and environmentally friendly compressor solutions.

Burckhardt Compression's cost structure is dominated by manufacturing and production expenses, as evidenced by its 2024 cost of sales reaching CHF 643.4 million. This includes raw materials, skilled labor, and overhead for their complex compressor systems. High capacity utilization is key to managing these costs efficiently.

Research and Development (R&D) is another significant cost, with CHF 30.1 million spent in 2024, a 12.8% increase, highlighting their focus on innovation. Sales, General, and Administrative (SG&A) expenses accounted for 11.9% of total sales in 2024, covering global operations and customer outreach.

After-sales service and support represent a substantial cost area, involving field technicians, service centers, and spare parts inventory to ensure customer satisfaction and equipment uptime. Additionally, sustainability initiatives, such as achieving net-zero emissions by 2035, are increasingly influencing their cost structure through investments in cleaner technologies and compliance.

| Cost Category | FY 2024 (CHF million) | % of Sales (FY 2024) | Key Drivers |

|---|---|---|---|

| Cost of Sales | 643.4 | N/A | Raw materials, labor, manufacturing overhead |

| R&D Expenses | 30.1 | N/A | Innovation, new product development |

| SG&A Expenses | N/A | 11.9% | Global sales, marketing, administration |

| Sustainability Initiatives | Ongoing Investment | Integrated | Emission reduction, compliance, green tech |

Revenue Streams

Burckhardt Compression generates significant revenue through the design, manufacture, and sale of new reciprocating compressor systems. These advanced systems cater to a broad range of industrial clients across the globe. This core business segment is crucial for the company's financial performance.

In fiscal year 2024, the Systems Division demonstrated strong growth, with sales reaching CHF 748.8 million. This represents a substantial 18.2% increase compared to the previous year, highlighting robust demand for their new compressor solutions.

After-sales service and maintenance contracts represent a significant and expanding revenue source for Burckhardt Compression. These comprehensive offerings include long-term service agreements, crucial maintenance, essential repairs, and complete overhauls for their installed compressor base. This focus on existing installations ensures ongoing customer relationships and predictable income.

The Services Division is strategically positioned to deliver high-margin products and increasingly sophisticated digital solutions. This segment is vital for maximizing profitability and leveraging technological advancements to enhance customer support and operational efficiency.

For instance, in fiscal year 2023, Burckhardt Compression reported that its Services segment achieved a notable CHF 346 million in revenue, underscoring the substantial contribution of these after-sales activities to the company's overall financial performance.

Burckhardt Compression generates revenue by selling original spare parts and essential components needed for compressor upkeep and repair over their operational life. This ensures their machinery continues to function optimally.

With a robust US service network, the company guarantees that these critical parts are readily accessible to customers, minimizing downtime and supporting the longevity of their compressor systems.

In 2023, Burckhardt Compression reported a significant portion of its revenue came from services and spare parts, indicating the vital role this segment plays in their overall financial performance.

Digital Services and Software Subscriptions

Burckhardt Compression is expanding its revenue through digital services and software subscriptions, notably with offerings like UP! Insight and UP! Detect. These services provide customers with real-time monitoring and predictive analytics for their compressor equipment, significantly boosting operational efficiency and offering a valuable recurring revenue stream.

These digital solutions are designed to enhance customer value by offering proactive maintenance insights and performance optimization, thereby strengthening customer relationships and creating new avenues for consistent income. For instance, UP! Insight leverages data to provide operational intelligence, while UP! Detect focuses on early fault detection.

- Digital Services: UP! Insight and UP! Detect offer real-time monitoring and predictive analytics.

- Recurring Revenue: These digital offerings create a predictable income stream for Burckhardt Compression.

- Customer Value Enhancement: Proactive insights and performance optimization improve customer operations.

Upgrades and Modernization Projects

Burckhardt Compression generates significant revenue by offering upgrades and modernization services for existing compressor systems. This revenue stream focuses on enhancing the efficiency, performance, and lifespan of installed equipment, ensuring clients benefit from the latest technological advancements. For instance, upgrades for hyper and booster compressors are a key component of this offering.

These modernization projects are crucial for clients looking to adapt to evolving industry standards and operational demands. The company's ability to service and improve its installed base, rather than solely relying on new sales, provides a stable and recurring revenue component. In 2024, this segment continued to be a vital contributor to overall financial performance.

- Revenue from upgrades and modernization projects

- Enhances efficiency, performance, and operational life of existing compressor systems

- Includes specific upgrades for hyper and booster compressors

- Supports long-term customer relationships and recurring revenue

Burckhardt Compression's revenue is diversified across several key areas, including new compressor systems, after-sales services, spare parts, digital solutions, and modernization projects. This multi-faceted approach ensures resilience and consistent income generation.

| Revenue Stream | FY 2024 (CHF million) | FY 2023 (CHF million) | Key Aspects |

|---|---|---|---|

| New Compressor Systems (Systems Division) | 748.8 | 612.8 | Design, manufacture, and sale of reciprocating compressor systems; 18.2% YoY growth in FY24. |

| After-Sales Service & Maintenance | 346 (FY23 Services Segment) | N/A | Long-term service agreements, maintenance, repairs, overhauls; high-margin offerings. |

| Spare Parts & Components | N/A | Significant portion of revenue | Essential for compressor upkeep and longevity; supported by a robust US service network. |

| Digital Services (e.g., UP! Insight/Detect) | Growing | Growing | Real-time monitoring, predictive analytics, recurring revenue stream. |

| Upgrades & Modernization | Vital contributor | Vital contributor | Enhances efficiency and performance of existing systems, including hyper and booster compressors. |

Business Model Canvas Data Sources

The Burckhardt Compression Holding Business Model Canvas is built upon a foundation of extensive market research, internal financial disclosures, and expert strategic analysis. These diverse data sources ensure each component of the canvas accurately reflects the company's operational realities and market positioning.