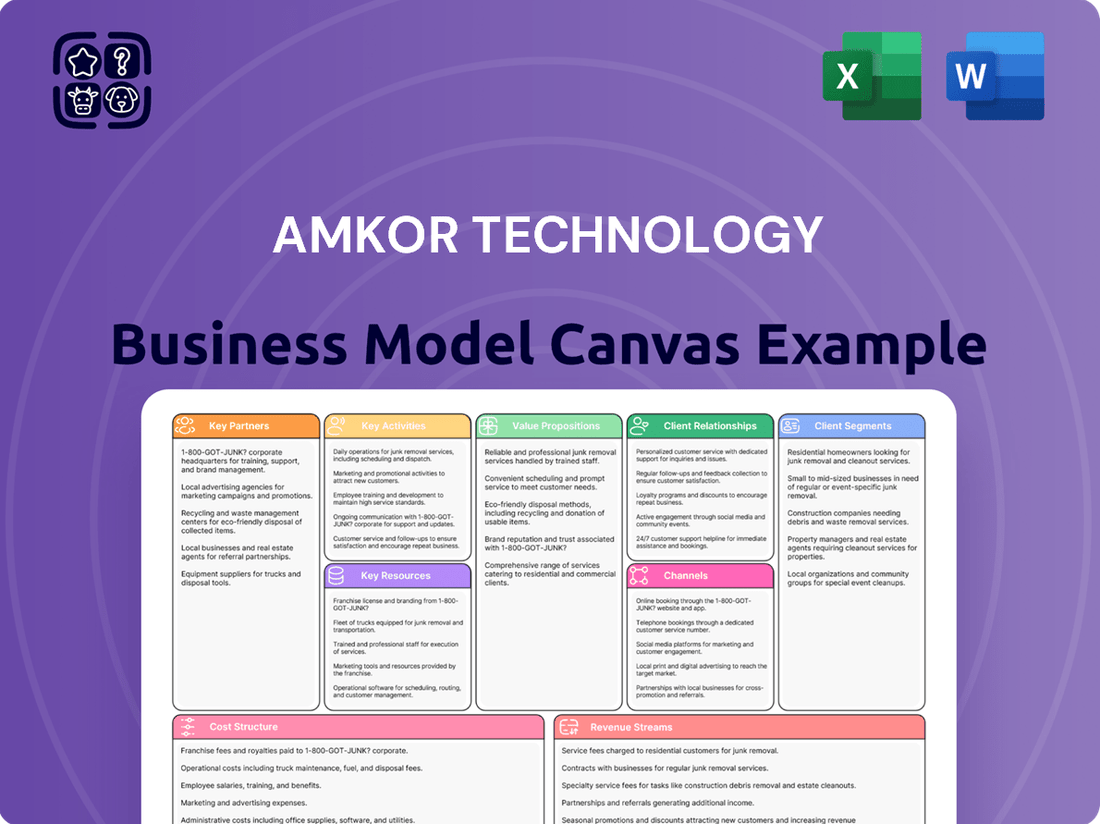

Amkor Technology Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Amkor Technology Bundle

Unlock the strategic blueprint behind Amkor Technology's success with our comprehensive Business Model Canvas. This detailed analysis reveals how Amkor leverages its key partnerships and value propositions to serve diverse customer segments in the semiconductor industry. Understand their revenue streams and cost structure to gain critical insights.

Partnerships

Amkor Technology's key partnerships with semiconductor design houses, also known as fabless companies, are foundational to its business. These collaborations are crucial because fabless firms conceptualize and design advanced chips but outsource the complex manufacturing and testing processes. Amkor steps in to provide these essential assembly and test services, acting as a vital link that allows these innovative companies to launch their products without the immense capital expenditure of building their own fabrication plants.

These relationships are typically more than transactional; they are often strategic and long-term. Amkor frequently engages in collaborative development with its fabless partners, working together to pioneer new packaging technologies that can enhance chip performance, reduce size, or improve reliability. For instance, in 2024, Amkor continued to invest heavily in advanced packaging solutions like fan-out wafer-level packaging (FOWLP) and advanced substrate technologies, directly supporting the evolving needs of its fabless clientele for next-generation applications.

Amkor Technology's key partnerships include Integrated Device Manufacturers (IDMs) who often outsource assembly and test functions. This collaboration allows IDMs to tap into Amkor's specialized skills and advanced packaging technologies, freeing them to concentrate on their core competency: wafer fabrication. For instance, Amkor's role in supporting the burgeoning advanced packaging market, which is projected to grow significantly in the coming years, directly benefits IDMs seeking to enhance their product performance and miniaturization.

Amkor Technology relies heavily on its key partnerships with suppliers of critical assembly equipment, testing apparatus, and essential raw materials like substrates and leadframes. These relationships are foundational to maintaining operational excellence and driving technological innovation in the semiconductor packaging industry.

Strong ties with these suppliers, including those providing molding compounds, grant Amkor access to cutting-edge technology and high-quality inputs. This ensures Amkor can meet demanding customer specifications and maintain a competitive edge in a rapidly evolving market.

In 2024, Amkor continued to foster these strategic alliances to secure consistent supply chains and competitive pricing. For instance, the company's commitment to advanced packaging solutions necessitates ongoing collaboration with equipment manufacturers to integrate novel processes and materials.

Technology and R&D Collaborators

Amkor actively partners with leading research institutions and universities to drive innovation in semiconductor packaging. These collaborations are crucial for developing cutting-edge technologies that address evolving industry needs. For instance, in 2024, Amkor continued its engagement with academic bodies to explore advanced materials and miniaturization techniques.

These R&D collaborations allow Amkor to access specialized expertise and share the costs of developing next-generation packaging and test solutions. By working with technology consortiums, Amkor stays ahead of the curve, ensuring its offerings meet the future demands of the semiconductor market. This strategic approach solidifies Amkor's position as an industry leader.

- Research Institutions: Collaborations focused on fundamental material science and novel packaging architectures.

- Universities: Partnerships for talent development and exploration of emerging technologies.

- Technology Consortiums: Joint efforts to define industry standards and accelerate technology adoption.

Logistics and Supply Chain Partners

Amkor's ability to deliver its semiconductor packaging and testing services hinges on a robust network of logistics and supply chain partners. These collaborations are critical for the seamless, secure, and timely movement of delicate components across international borders. For instance, Amkor's reliance on specialized carriers ensures that sensitive materials are handled with the utmost care, minimizing damage and loss during transit. In 2023, Amkor reported significant investments in optimizing its supply chain, aiming to reduce transit times by an average of 15% for key customer segments.

These partnerships directly impact Amkor's operational efficiency and customer satisfaction. By minimizing lead times and ensuring the integrity of the supply chain, Amkor can meet demanding production schedules and maintain high service levels. The company actively fosters relationships with partners who demonstrate a commitment to reliability and innovation in logistics solutions. This focus is particularly important given the global nature of semiconductor manufacturing, where disruptions can have substantial ripple effects.

Key aspects of these logistics and supply chain partnerships include:

- Global Reach and Reliability: Securing partnerships with carriers and freight forwarders that offer extensive global networks and a proven track record of on-time deliveries, essential for Amkor's worldwide customer base.

- Specialized Handling and Security: Collaborating with logistics providers equipped to handle sensitive electronic components, including temperature-controlled transport and advanced tracking systems to ensure component integrity and security.

- Efficiency and Cost Optimization: Working with partners to streamline shipping processes, reduce transit times, and manage transportation costs effectively, thereby enhancing overall competitiveness and customer value.

- Risk Mitigation: Developing contingency plans and diversifying logistics partners to mitigate potential disruptions caused by geopolitical events, natural disasters, or other unforeseen circumstances affecting global trade routes.

Amkor's key partnerships extend to equipment manufacturers and material suppliers, forming the backbone of its production capabilities. These relationships are vital for ensuring access to the latest advancements in assembly machinery, testing equipment, and high-quality raw materials like substrates and leadframes. For instance, in 2024, Amkor continued to integrate advanced manufacturing technologies sourced from these partners to enhance its offerings in areas like 2.5D and 3D packaging.

These collaborations are not merely transactional; they often involve joint development efforts to push the boundaries of semiconductor packaging technology. By working closely with suppliers, Amkor can co-develop solutions tailored to specific customer needs, thereby accelerating innovation and maintaining a competitive edge. This symbiotic relationship ensures Amkor remains at the forefront of technological evolution in the semiconductor industry.

| Partner Type | Focus Area | 2024 Impact/Example |

|---|---|---|

| Equipment Manufacturers | Advanced Assembly & Test Machinery | Integration of next-gen wafer-level packaging equipment to support high-density interconnects. |

| Material Suppliers | Substrates, Leadframes, Molding Compounds | Securing supply of specialized materials for high-performance computing and automotive applications. |

| Technology Developers | Novel Packaging Architectures & Processes | Collaborative R&D on emerging materials and miniaturization techniques for advanced semiconductor nodes. |

What is included in the product

Amkor Technology's Business Model Canvas focuses on providing advanced semiconductor packaging and test services to a diverse range of electronics manufacturers, leveraging its global manufacturing footprint and technological expertise.

This model emphasizes strong customer relationships, efficient supply chain management, and continuous innovation in packaging solutions to address the evolving needs of the semiconductor industry.

Amkor Technology's Business Model Canvas acts as a pain point reliever by offering a clear, one-page snapshot of their complex operations, simplifying understanding for stakeholders.

This structured approach helps Amkor Technology address pain points related to communication and strategic alignment by providing a shared, digestible framework for their diverse business units.

Activities

Amkor Technology's key activities revolve around the intricate design and development of semiconductor packages. This core function involves extensive research and development to create cutting-edge packaging solutions tailored to precise performance, miniaturization, and cost targets for a wide array of electronic devices.

The company actively innovates to address the evolving needs of the semiconductor industry, particularly for advanced chips and emerging market demands. In 2024, Amkor continued to invest heavily in R&D, with a focus on enabling next-generation technologies like AI and 5G, which require increasingly sophisticated packaging designs.

Amkor Technology's core activity revolves around the physical assembly of integrated circuits, transforming bare silicon chips into the finished products consumers and businesses use. This intricate process includes critical steps like die attach, where the chip is secured to a substrate, wire bonding to create electrical connections, molding to protect the chip, and singulation to separate individual units. These operations demand extreme precision and rigorous quality assurance to ensure the reliability and performance of the final semiconductor packages.

In 2023, Amkor reported approximately $6.2 billion in revenue, underscoring the significant scale of its assembly operations. The company's expertise in these manufacturing processes is crucial for a vast array of electronic devices, from smartphones and automotive systems to advanced computing and networking equipment. Amkor's commitment to high-volume, high-quality manufacturing makes it a vital partner for semiconductor manufacturers worldwide.

Semiconductor test services are fundamental to Amkor Technology's operations, ensuring that packaged semiconductors meet stringent quality and performance standards. This involves a multi-faceted approach, including rigorous electrical testing to verify functionality and adherence to specifications, functional testing to confirm the integrated circuit operates as designed under various conditions, and environmental testing to assess reliability under different temperature and humidity levels. These activities are crucial for preventing costly field failures and maintaining customer trust.

In 2024, the semiconductor testing market continued its robust growth, driven by increasing chip complexity and the demand for higher reliability across sectors like automotive, AI, and high-performance computing. Amkor, as a leading provider, plays a vital role in this ecosystem by offering comprehensive test solutions that validate the performance and durability of advanced semiconductor packages. This commitment to quality is a cornerstone of their value proposition.

Quality Assurance and Reliability Management

Amkor Technology places immense importance on maintaining stringent quality control across its entire assembly and testing operations. This commitment is fundamental to ensuring the reliability and performance of the semiconductor packages it provides to its diverse customer base. The company actively implements comprehensive quality management systems, such as ISO 9001, to govern its processes.

Reliability testing is a cornerstone of Amkor's quality assurance strategy. This involves subjecting products to various stress conditions to predict their long-term performance and identify potential failure modes. Ensuring compliance with critical industry standards and customer-specific requirements is also a non-negotiable aspect of their operations.

- Rigorous Quality Control: Amkor employs extensive checks at every stage of assembly and testing to guarantee product integrity.

- Robust Quality Management Systems: Adherence to internationally recognized standards like ISO 9001 underpins their operational framework.

- Comprehensive Reliability Testing: Products undergo demanding tests to ensure they meet performance expectations under various environmental conditions.

- Industry Standard Compliance: Amkor ensures all its processes and products meet or exceed relevant semiconductor industry regulations and customer specifications.

Global Supply Chain and Operations Management

Amkor Technology's core operations revolve around expertly navigating a complex global supply chain. This involves strategically sourcing essential raw materials, meticulously coordinating intricate manufacturing processes across its numerous international facilities, and ensuring the timely delivery of finished semiconductor packages to customers worldwide. In 2024, Amkor continued to emphasize optimizing these processes for both speed and cost efficiency, a critical factor in the highly competitive semiconductor industry.

Efficient management of this extensive supply chain is paramount to Amkor's success. It directly impacts the company's ability to respond swiftly to market demands and maintain competitive pricing for its advanced packaging solutions. For instance, in Q1 2024, Amkor reported a revenue of $1.43 billion, demonstrating the scale of operations managed through their supply chain capabilities.

- Sourcing and Procurement: Securing reliable and cost-effective access to specialized materials like leadframes, molding compounds, and substrates.

- Manufacturing Coordination: Orchestrating production across diverse manufacturing sites in Asia, Europe, and North America, ensuring quality and throughput.

- Logistics and Distribution: Managing the intricate movement of components and finished goods globally to meet customer delivery schedules.

- Inventory Management: Balancing inventory levels to avoid stockouts while minimizing holding costs, a crucial aspect of operational efficiency.

Amkor Technology's key activities encompass the intricate design and development of advanced semiconductor packaging solutions, crucial for enabling next-generation technologies. The company's manufacturing operations involve the precise physical assembly of integrated circuits, including die attach, wire bonding, molding, and singulation, all performed with meticulous quality control. Furthermore, Amkor provides comprehensive semiconductor test services to ensure the reliability and performance of its packaged products.

In 2024, Amkor continued its strategic focus on research and development, particularly in areas like artificial intelligence and 5G, which demand increasingly sophisticated packaging. The company's manufacturing prowess is evident in its ability to handle high-volume production with rigorous quality assurance. For example, in the first quarter of 2024, Amkor reported a revenue of $1.43 billion, reflecting the substantial scale of its operations.

The company's commitment to quality is reinforced by robust quality management systems and comprehensive reliability testing, ensuring products meet stringent industry standards and customer specifications. Amkor also excels in managing a complex global supply chain, from sourcing raw materials to coordinating production and ensuring timely delivery of finished semiconductor packages, a critical factor in its ability to respond to market demands efficiently.

Delivered as Displayed

Business Model Canvas

The Amkor Technology Business Model Canvas preview you are currently viewing is an exact replica of the document you will receive upon purchase. This means you're seeing the actual, complete Business Model Canvas, not a sample or mockup, ensuring full transparency and no surprises. Once your order is processed, you will gain immediate access to this comprehensive and professionally formatted document, ready for your immediate use and analysis.

Resources

Amkor Technology's advanced manufacturing facilities and equipment are the backbone of its operations, featuring state-of-the-art assembly and test capabilities across its global network. These facilities are outfitted with highly specialized machinery and sophisticated automation systems, enabling the company to handle complex semiconductor packaging and testing requirements with precision and efficiency.

These physical assets are crucial for Amkor's capacity to deliver high-volume, high-quality semiconductor services, directly impacting its ability to meet the demanding needs of its clientele in the rapidly evolving tech industry. For instance, in 2023, Amkor continued to invest in its manufacturing infrastructure to support advanced packaging technologies, essential for next-generation semiconductors.

Amkor Technology's robust intellectual property portfolio, featuring a significant number of patents and proprietary process technologies in semiconductor packaging, assembly, and testing, forms a cornerstone of its competitive advantage. This deep well of innovation allows Amkor to offer advanced solutions that meet the evolving demands of the electronics industry.

This protected knowledge base is not just a collection of patents; it's the engine driving Amkor's ability to develop cutting-edge packaging technologies. For instance, their advancements in areas like wafer-level packaging and advanced substrate technologies are directly attributable to their R&D investments and the resulting intellectual property, enabling them to secure premium market positions.

Amkor Technology's skilled engineering and technical workforce is a cornerstone of its operations. This team, comprising experts in semiconductor physics, materials science, and advanced manufacturing, is essential for developing and implementing cutting-edge packaging and test solutions.

In 2024, Amkor continued to invest in its talent pool, recognizing that human capital is as vital as its advanced manufacturing facilities. The company's commitment to research and development, fueled by these skilled professionals, allows it to stay at the forefront of the rapidly evolving semiconductor industry.

Global Customer Base and Relationships

Amkor Technology's global customer base and the relationships built with them are a cornerstone of its business. These aren't just transactions; they are deep, established partnerships with some of the biggest names in the semiconductor industry.

This diverse global clientele, including leading fabless semiconductor companies and integrated device manufacturers, represents a significant intangible asset. These long-standing connections translate into predictable revenue streams and a solid foundation for future expansion. For instance, Amkor's customer concentration highlights this strength, with its top customers often representing a substantial portion of its revenue, demonstrating the depth of these relationships.

- Established Partnerships: Amkor maintains strong ties with major semiconductor players, fostering loyalty and repeat business.

- Revenue Stability: These deep relationships contribute to a consistent and reliable revenue base, crucial for financial planning.

- Collaborative Growth: Working closely with clients allows for joint development and innovation, driving mutual growth opportunities.

- Market Access: Serving a global customer base provides Amkor with broad market reach and insights into diverse regional demands.

Financial Capital and Investment Capacity

Amkor Technology's business model relies heavily on substantial financial capital to fuel its operations and growth. This financial strength is crucial for continuous investment in cutting-edge technologies, essential for maintaining its competitive edge in the semiconductor packaging and test industry. For instance, in 2023, Amkor invested $732.4 million in capital expenditures, a significant portion of which was directed towards advanced packaging solutions and capacity expansion to meet evolving customer needs.

This robust investment capacity allows Amkor to not only keep pace with technological advancements but also to lead in areas like advanced semiconductor packaging. The company's commitment to research and development, backed by its financial resources, ensures it can develop and offer innovative solutions that address the increasing complexity and performance demands of the electronics market. By prioritizing these investments, Amkor solidifies its position as a key player capable of supporting the rapid growth and innovation seen across various tech sectors.

- Financial Capital for Innovation: Amkor's significant financial resources are channeled into R&D and the adoption of new technologies, such as advanced wafer-level packaging and heterogeneous integration.

- Investment in Facilities: Capital expenditures, like the $732.4 million in 2023, are allocated to expanding and upgrading manufacturing facilities to increase capacity and efficiency.

- Technological Leadership: Financial strength enables Amkor to invest in proprietary technologies and processes, ensuring it remains at the forefront of the semiconductor packaging industry.

- Market Demand Responsiveness: Amkor's investment capacity allows it to scale operations and adapt to the dynamic and growing demands of the global electronics market.

Amkor Technology's proprietary manufacturing processes and deep expertise in semiconductor packaging are critical intangible assets. These allow them to offer specialized solutions that competitors find difficult to replicate, driving value for their customers.

Their intellectual property, including numerous patents, underpins their ability to develop and implement advanced packaging techniques. This innovation directly supports the performance and miniaturization demands of modern electronics.

Amkor's commitment to R&D, evidenced by ongoing investments, ensures they remain at the forefront of packaging technology. This focus on innovation is key to their sustained competitive advantage in a rapidly evolving market.

Value Propositions

Amkor Technology provides a complete range of outsourced semiconductor assembly and test (OSAT) solutions, acting as a single point of contact for all post-fabrication requirements. This integrated approach streamlines the semiconductor supply chain, making it easier for clients to manage their operations.

This comprehensive service model simplifies logistics and ensures a smooth transition from wafer fabrication to finished product. For instance, Amkor's extensive portfolio covers advanced packaging technologies, critical for high-performance applications, and robust testing capabilities to guarantee product reliability.

In 2024, the global OSAT market was valued at approximately $40 billion, with companies like Amkor playing a pivotal role in meeting the growing demand for sophisticated semiconductor packaging and testing services. Amkor's ability to offer end-to-end solutions is a key differentiator in this competitive landscape.

Amkor Technology's value proposition of enabling customer focus on core competencies allows semiconductor companies to offload the complexities of assembly and test. This strategic outsourcing frees up valuable internal resources, enabling clients to concentrate on their strengths in chip design, research, and market development. In 2024, the semiconductor industry continued its rapid innovation cycle, making this focus crucial for competitive advantage.

By partnering with Amkor, companies can avoid the significant capital expenditures typically required for advanced manufacturing facilities. This financial flexibility is particularly important as the cost of cutting-edge semiconductor fabrication equipment continues to rise. Amkor's expertise in these areas helps clients accelerate their time-to-market for new products, a critical factor in the fast-paced technology sector.

Amkor offers access to sophisticated packaging and testing solutions, enabling clients to leverage advanced technologies without the substantial R&D investment. This specialized knowledge is crucial for achieving peak product performance and unwavering reliability.

For instance, Amkor's commitment to innovation is evident in their continuous development of advanced packaging, such as 2.5D/3D integration, which is vital for high-performance computing and AI applications. In 2023, the semiconductor packaging market, a key area for Amkor, was valued at approximately $25 billion, demonstrating the significant demand for such advanced services.

Cost Efficiency and Scalability

Amkor Technology's extensive global footprint and highly specialized manufacturing facilities are key to delivering substantial cost savings for clients. By outsourcing to Amkor, businesses can avoid the massive capital expenditures and operational overhead associated with building and maintaining their own advanced semiconductor manufacturing capabilities. For example, in 2023, Amkor reported net sales of $5.7 billion, demonstrating the scale at which they operate and the efficiencies they can pass on to customers.

The company's infrastructure is designed for flexibility, allowing clients to adjust production volumes seamlessly. This adaptability is crucial in the volatile semiconductor market, where demand can fluctuate rapidly. Amkor's ability to scale production up or down ensures that customers are not burdened with excess capacity during downturns or unable to meet demand during surges. This agility directly translates into improved cost management and market responsiveness for their partners.

- Global Scale: Amkor operates advanced manufacturing facilities across Asia, Europe, and North America, enabling localized support and supply chain optimization for its global customer base.

- Specialized Infrastructure: Investment in state-of-the-art equipment and processes for advanced packaging technologies reduces the need for individual companies to make these significant capital outlays.

- Flexible Capacity: Amkor's manufacturing network is designed to accommodate varying production volumes, allowing clients to efficiently manage inventory and respond to market dynamics.

- Cost Efficiencies: By leveraging Amkor's scale and expertise, customers can achieve lower per-unit costs for semiconductor packaging and testing compared to in-house operations.

Accelerated Time-to-Market

Amkor's streamlined manufacturing and supply chain operations, bolstered by its extensive global footprint, significantly reduce lead times for new semiconductor products. This efficiency is a cornerstone of their value proposition, enabling clients to navigate the fast-paced tech landscape with greater agility.

The company's advanced rapid prototyping services are a critical component in accelerating development cycles. By offering quick turnaround on complex designs, Amkor empowers its customers to test and iterate faster, a vital advantage in a market where speed to innovation directly impacts market share.

In 2024, the semiconductor industry continued its rapid evolution, with many new product introductions requiring expedited manufacturing. Amkor's ability to consistently deliver on accelerated timelines, as demonstrated by their support for numerous high-volume product launches throughout the year, underscores this value proposition.

- Efficient Processes: Amkor's optimized workflows and integrated supply chain reduce manufacturing bottlenecks.

- Global Footprint: Strategic placement of facilities worldwide allows for localized support and reduced transit times.

- Rapid Prototyping: Advanced capabilities enable quick creation and validation of new semiconductor designs.

- Competitive Edge: Faster time-to-market allows customers to capture market share in dynamic technology sectors.

Amkor Technology's value proposition centers on providing comprehensive, end-to-end outsourced semiconductor assembly and test (OSAT) solutions. This allows clients to focus on their core competencies like chip design and R&D, while Amkor handles the complexities of post-fabrication processes.

By leveraging Amkor's global scale and specialized infrastructure, customers avoid significant capital expenditures associated with advanced manufacturing facilities. This strategic outsourcing enhances financial flexibility and accelerates time-to-market for new products in the rapidly evolving semiconductor industry. In 2023, Amkor's net sales reached $5.7 billion, highlighting their operational capacity and efficiency.

Amkor's optimized processes and global footprint significantly reduce lead times, supported by advanced rapid prototyping services. This agility is crucial for customers needing to quickly iterate designs and respond to market demands, a key factor in the competitive technology sector.

| Value Proposition Aspect | Description | 2023/2024 Relevance |

|---|---|---|

| End-to-End OSAT Solutions | Single point of contact for all post-fabrication needs, simplifying the supply chain. | The global OSAT market was valued at approximately $40 billion in 2024, underscoring the demand for integrated services. |

| Focus on Core Competencies | Enables clients to concentrate on chip design and innovation by outsourcing assembly and test. | The semiconductor industry's rapid innovation cycle in 2024 makes this focus critical for competitive advantage. |

| Reduced Capital Expenditure | Provides access to advanced manufacturing without requiring clients to invest in costly facilities. | Rising costs of cutting-edge semiconductor equipment make this a significant financial benefit. |

| Accelerated Time-to-Market | Streamlined operations and rapid prototyping help clients launch new products faster. | Amkor supported numerous high-volume product launches in 2024, demonstrating this capability. |

Customer Relationships

Amkor Technology emphasizes dedicated account management to foster strong, personalized relationships with its clients. These account managers act as primary points of contact, ensuring a deep understanding of each customer's unique requirements and project timelines. This approach is crucial for navigating the complexities of semiconductor packaging and testing services, where tailored solutions are paramount.

Complementing account management, Amkor provides robust technical support throughout the product lifecycle. This technical expertise ensures that customers receive timely assistance with design, process integration, and troubleshooting. In 2024, Amkor continued to invest in its support infrastructure, aiming to reduce customer ramp times and enhance overall product performance, a critical factor in the fast-paced electronics industry.

Amkor Technology actively partners with clients throughout the package design and development lifecycle. This involves providing crucial design-for-manufacturability feedback and jointly creating bespoke solutions tailored to specific needs.

This intensive technical collaboration builds significant trust and drives innovation, as evidenced by Amkor's consistent customer retention rates, which have historically remained strong, reflecting the value placed on these partnerships.

For instance, in 2024, Amkor continued to highlight its customer-centric approach, emphasizing how co-development projects directly contribute to accelerated product roadmaps for its semiconductor partners.

Amkor Technology cultivates long-term, strategic partnerships, often embedding itself deeply within its key customers' supply chains. These relationships are foundational, built on a bedrock of mutual trust and shared objectives, fostering a collaborative environment for ongoing innovation and mutual success.

Performance-Based Contracts and Service Level Agreements

Amkor Technology solidifies customer relationships through robust performance-based contracts and Service Level Agreements (SLAs). These agreements are crucial for ensuring that Amkor consistently meets or exceeds customer expectations in terms of quality, turnaround time, and reliability.

These formal agreements are designed to foster transparency and accountability. They clearly define the expected performance standards, giving customers confidence in Amkor's ability to deliver. For instance, Amkor's commitment to quality is often reflected in metrics like defect rates and yield percentages, which are closely monitored and reported.

- Performance Metrics: Contracts often specify key performance indicators (KPIs) such as on-time delivery rates, yield percentages, and defect rates, directly linking Amkor's compensation or incentives to achieving these targets.

- Service Level Agreements (SLAs): SLAs detail the expected service quality, response times for issues, and uptime guarantees for critical manufacturing processes, ensuring predictable and reliable operations for clients.

- Customer Satisfaction: These structured relationships aim to enhance customer satisfaction by providing clear expectations and a framework for continuous improvement, often leading to long-term partnerships.

- Accountability: The contractual nature of these relationships ensures that Amkor is accountable for its service delivery, with clear recourse mechanisms if agreed-upon standards are not met.

Global Customer Service and Regional Presence

Amkor Technology maintains a global operational footprint, ensuring localized customer service and support to meet the diverse logistical and communication needs of its international clientele. This regional presence is key to their strategy, enhancing responsiveness and accessibility for customers worldwide.

For instance, Amkor's commitment to regional support is evident in its numerous facilities strategically located across Asia, Europe, and North America. This allows for direct engagement and tailored solutions, fostering stronger client relationships.

- Global Network: Amkor operates manufacturing and service facilities in over 10 countries, providing proximity to key customer hubs.

- Localized Support Teams: Dedicated regional teams offer specialized technical and logistical assistance, understanding local market dynamics.

- Enhanced Responsiveness: A distributed service model reduces communication delays and improves issue resolution times for international partners.

- Accessibility: Customers benefit from readily available support channels, facilitating smoother collaboration and project execution.

Amkor Technology prioritizes deep customer engagement through dedicated account management and extensive technical support, ensuring tailored solutions for semiconductor packaging and testing. This collaborative approach, extending from initial design to product lifecycle support, fosters strong, long-term partnerships built on trust and mutual innovation.

In 2024, Amkor's focus on customer-centricity was underscored by its co-development initiatives, which aim to accelerate product roadmaps for its semiconductor partners, demonstrating a commitment to shared success and continuous improvement in a dynamic industry.

Performance-based contracts and SLAs are central to Amkor's customer relationship strategy, guaranteeing quality, timely delivery, and reliability through clearly defined metrics like yield percentages and on-time delivery rates, fostering accountability and client confidence.

Amkor's global operational footprint, with facilities in over 10 countries, ensures localized support and enhanced responsiveness, allowing for direct engagement and tailored solutions that meet the diverse logistical and communication needs of its international clientele.

| Customer Relationship Aspect | Description | Key Benefit | 2024 Focus/Example |

|---|---|---|---|

| Dedicated Account Management | Primary point of contact ensuring understanding of client needs. | Personalized service, efficient communication. | Strengthening relationships with top-tier semiconductor manufacturers. |

| Technical Support | Expert assistance throughout the product lifecycle. | Faster ramp times, improved product performance. | Investment in advanced simulation tools for design support. |

| Collaborative Development | Joint creation of bespoke solutions with design feedback. | Innovation, tailored solutions, manufacturability. | Co-development projects accelerating partner product roadmaps. |

| Performance-Based Contracts & SLAs | Formal agreements defining service quality and metrics. | Transparency, accountability, reliability. | Emphasis on achieving industry-leading yield and on-time delivery metrics. |

| Global Operational Footprint | Localized support and service facilities worldwide. | Enhanced responsiveness, accessibility, understanding of regional needs. | Expansion of support capabilities in emerging semiconductor markets. |

Channels

Amkor Technology leverages a dedicated direct sales force and proactive business development teams to cultivate relationships with semiconductor manufacturers. These teams are instrumental in identifying and engaging prospective clients, deeply understanding their unique product development needs and technical specifications.

These client-facing units are responsible for the critical initial outreach, the meticulous gathering of customer requirements, and the complex negotiation of service agreements and contracts. In 2024, Amkor’s sales and marketing expenses represented approximately 3.4% of its total revenue, underscoring the significant investment in these crucial customer engagement functions.

Amkor's extensive network of manufacturing and test facilities across Asia, Europe, and North America are its primary channels for delivering advanced semiconductor packaging and testing services. This global footprint ensures close proximity to key semiconductor manufacturers, facilitating streamlined logistics and responsive customer support. For instance, Amkor operates over 30 facilities strategically located in countries like South Korea, Taiwan, China, Malaysia, Vietnam, and the United States, enabling efficient global supply chain management.

These facilities are not just production hubs but also critical touchpoints for customer engagement. Clients have the opportunity to visit these sites, observe operations firsthand, and collaborate directly with Amkor's experienced engineering and operational teams. This direct interaction fosters transparency and allows for tailored solutions, reinforcing Amkor's commitment to customer satisfaction and partnership. In 2023, Amkor reported over $6.4 billion in revenue, underscoring the scale and importance of its global operational channels.

Technical support and engineering teams are vital channels for Amkor Technology, offering customers ongoing communication and problem-solving expertise. They provide crucial technical consultation throughout the design, assembly, and testing phases of semiconductor packaging. In 2024, Amkor’s dedicated engineering workforce, comprising thousands of skilled professionals, directly engages with clients to ensure seamless integration and optimal performance of their advanced packaging solutions.

Customer Portals and Communication Platforms

Amkor Technology leverages secure online customer portals and dedicated communication platforms to streamline interactions. These digital channels are crucial for sharing vital project updates, detailed technical data, comprehensive quality reports, and essential logistical information directly with clients.

These platforms foster greater transparency and significantly boost operational efficiency by providing a centralized hub for all client-related communications and documentation. For instance, Amkor's commitment to clear communication is reflected in its proactive approach to sharing manufacturing progress and quality assurance metrics.

- Enhanced Transparency: Real-time access to project status and quality data reduces queries and builds trust.

- Improved Efficiency: Digital document sharing and communication channels cut down on manual processes and delivery times.

- Data Accessibility: Customers can easily retrieve technical specifications, quality reports, and shipment tracking information.

- Direct Feedback Loop: Platforms can facilitate direct communication for quicker issue resolution and feedback incorporation.

Industry Conferences and Trade Shows

Amkor Technology actively participates in key industry events like SEMICON West and productronica. These platforms are crucial for demonstrating their advanced packaging solutions and fostering relationships with potential customers in the semiconductor ecosystem. In 2023, Amkor reported significant engagement at these shows, highlighting their commitment to industry visibility and lead generation.

These gatherings allow Amkor to directly engage with a broad spectrum of stakeholders, from engineers to procurement managers, showcasing their technological prowess and understanding of market needs. The company leverages these opportunities to gather competitive intelligence and identify emerging trends, which is vital for their ongoing innovation strategy.

- Showcasing Capabilities: Amkor uses conferences to exhibit its latest advancements in advanced packaging technologies, such as 2.5D/3D integration and heterogeneous integration.

- Networking and Lead Generation: These events are vital for connecting with current and prospective clients, driving new business opportunities and strengthening partnerships.

- Market Intelligence: Participation provides Amkor with direct insights into market trends, competitor activities, and customer demands, informing strategic decisions.

- Brand Building: Consistent presence at major industry forums reinforces Amkor's position as a leader in the semiconductor packaging sector.

Amkor's channels are multifaceted, encompassing direct sales, a global network of manufacturing facilities, technical support teams, digital portals, and industry events. These diverse touchpoints ensure comprehensive customer engagement and service delivery across the semiconductor value chain.

The direct sales force and business development teams act as the initial interface, building relationships and understanding client needs, while the extensive manufacturing and testing facilities serve as the core delivery channels. Digital platforms and industry events further enhance communication, transparency, and market presence.

In 2024, Amkor's sales and marketing expenses were about 3.4% of revenue, highlighting the investment in these customer-facing channels. The company's global operational footprint, with over 30 facilities, underpins its ability to serve clients efficiently, a scale reflected in its $6.4 billion revenue in 2023.

| Channel Type | Description | Key Activities | 2023 Revenue (Approx.) | 2024 Sales & Marketing Expense (Approx.) |

| Direct Sales/BD | Dedicated teams engaging clients | Relationship building, requirement gathering, negotiation | N/A | 3.4% of Revenue |

| Manufacturing Facilities | Global network of production sites | Packaging and testing services delivery | $6.4 Billion | N/A |

| Technical Support/Engineering | Expert consultation and problem-solving | Design, assembly, and testing support | N/A | Thousands of professionals |

| Digital Portals | Online platforms for communication | Project updates, data sharing, reports | N/A | N/A |

| Industry Events | Conferences and trade shows | Showcasing solutions, networking, market intelligence | N/A | N/A |

Customer Segments

Fabless semiconductor companies, a cornerstone for Amkor Technology, design the brains of modern electronics but leave the physical creation to partners. These entities, from nimble startups to industry giants, depend on specialized services like Amkor's for crucial assembly and testing. In 2024, the global fabless semiconductor market continued its robust growth, with revenues projected to reach over $250 billion, underscoring the vital role Amkor plays in enabling these innovators.

Integrated Device Manufacturers (IDMs) are crucial customers for Amkor Technology. These companies, like Intel or Texas Instruments, handle the entire semiconductor process from design to fabrication. However, they often rely on Amkor for specialized assembly and testing services, especially to manage fluctuating production needs or to leverage Amkor's advanced packaging capabilities. In 2024, the semiconductor industry saw continued demand for sophisticated packaging solutions, a key area where Amkor supports IDMs.

Amkor Technology serves key players in the communications sector, including manufacturers of chips for smartphones, sophisticated networking gear, and vital 5G infrastructure. These companies rely on advanced packaging solutions to achieve the high performance and compact designs demanded by today's communication devices.

The demand for advanced packaging in this segment is driven by the relentless pursuit of speed and efficiency. For instance, the global semiconductor market, which heavily influences the communications sector, saw significant growth, with revenues projected to reach over $600 billion in 2024, underscoring the critical role of packaging in enabling these advanced technologies.

Consumer Electronics Market

This segment focuses on companies creating semiconductors for a vast range of consumer electronics. Think about the chips that power your personal computers, tablets, smartwatches, and even your smart home gadgets. Gaming consoles also fall under this umbrella, relying heavily on advanced semiconductor technology.

For these companies, getting the best bang for their buck is crucial. They need chips that are not only high-performing but also affordable to produce in massive quantities. This cost-effectiveness is a major factor in making consumer electronics accessible to a broad market. In 2024, the global consumer electronics market was projected to reach over $1 trillion, highlighting the sheer volume and value of this segment.

- High-Volume Production: Manufacturers in this segment require partners capable of producing millions of semiconductor units efficiently.

- Cost Sensitivity: The price of components directly impacts the final retail price of consumer devices, making cost-effectiveness paramount.

- Product Diversity: This segment covers a broad spectrum of devices, from low-power wearables to high-performance gaming hardware.

Automotive and Industrial Market

Amkor Technology is a key supplier for the automotive market, offering essential packaging and testing solutions for semiconductors. These chips are critical for technologies like advanced driver-assistance systems (ADAS), in-car infotainment, and robust power management systems, all vital for modern vehicles.

The industrial sector also represents a significant customer base for Amkor. This segment relies on Amkor for chips used in demanding applications such as factory automation, sophisticated medical devices, and the ever-expanding Internet of Things (IoT). These applications inherently require exceptionally high reliability and extended operational lifecycles, areas where Amkor's expertise is crucial.

- Automotive: Packaging and testing for ADAS, infotainment, and power management chips.

- Industrial: Solutions for factory automation, medical devices, and IoT applications.

- Key Requirements: High reliability and long product lifecycles are paramount for both segments.

- Market Growth: The automotive semiconductor market, particularly for ADAS, is projected for substantial growth, with some estimates suggesting a compound annual growth rate (CAGR) exceeding 15% in the coming years, directly benefiting Amkor's offerings.

Amkor Technology serves a diverse range of customers, including fabless semiconductor companies and Integrated Device Manufacturers (IDMs). These clients rely on Amkor for essential assembly and testing services, particularly for advanced packaging solutions. In 2024, the semiconductor industry's continued growth, with global revenues projected to exceed $600 billion, highlights Amkor's critical role in enabling technological advancements across various sectors.

Cost Structure

Amkor Technology's manufacturing and operational costs are heavily influenced by direct expenses like raw materials, which include substrates, leadframes, and molding compounds essential for their semiconductor packaging. These material costs are a substantial part of their overall spending, directly impacting profitability.

Utilities and consumables used throughout the assembly and testing phases also form a significant chunk of Amkor's cost structure. Efficient management of these operational expenses is paramount for maintaining a competitive edge and ensuring healthy profit margins in the semiconductor industry.

For instance, in 2023, Amkor reported cost of goods sold amounting to approximately $4.7 billion, highlighting the scale of their manufacturing and operational expenditures. Optimizing these direct costs through supply chain efficiencies and process improvements remains a key strategic focus for the company.

Amkor Technology's business model hinges on significant and continuous capital expenditure for advanced assembly and test equipment. This investment is crucial for staying competitive in the rapidly evolving semiconductor industry.

In 2023, Amkor reported capital expenditures of $625 million. This substantial outlay reflects the ongoing need to upgrade existing facilities and acquire cutting-edge technology to meet the demands of their global customer base.

These expenditures are not just for new equipment but also for the expansion and upkeep of their extensive network of manufacturing sites worldwide. Maintaining technological leadership and sufficient production capacity requires this sustained financial commitment.

Amkor Technology's cost structure is significantly influenced by labor expenses, encompassing both direct and indirect roles. In 2024, wages and benefits for their highly skilled direct labor, crucial for intricate manufacturing processes, represent a substantial outlay. Similarly, the costs associated with indirect labor, including vital R&D, engineering, quality control, and administrative teams, are major components. Attracting and retaining this specialized talent remains paramount to their operational success and innovation.

Research and Development (R&D) Expenses

Amkor Technology's commitment to innovation is reflected in its substantial Research and Development (R&D) expenses. These costs are crucial for developing cutting-edge packaging solutions and refining existing manufacturing processes to meet evolving industry demands. In 2023, Amkor reported R&D expenses of $366.5 million, representing a significant portion of its operational budget, underscoring the importance of technological advancement for maintaining its market leadership.

These investments fuel the creation of new packaging technologies, such as advanced substrate materials and miniaturization techniques, which are vital for the semiconductor industry's progress. Furthermore, ongoing R&D efforts enhance testing methodologies, ensuring the reliability and performance of Amkor's products in increasingly complex electronic devices.

- Innovation Driver: R&D expenses are the engine for developing next-generation semiconductor packaging, including advanced materials and assembly techniques.

- Competitive Edge: Significant investment in R&D helps Amkor maintain its competitive advantage by offering differentiated and high-performance solutions.

- Process Improvement: A portion of R&D is dedicated to optimizing existing manufacturing processes, leading to increased efficiency and reduced costs.

- Future Growth: These expenditures are directly linked to Amkor's ability to capture future market share and drive long-term revenue growth.

Sales, General, and Administrative (SG&A) Expenses

Amkor Technology's Sales, General, and Administrative (SG&A) expenses encompass the costs tied to selling and marketing its advanced semiconductor packaging and testing services, alongside the essential functions of corporate administration, legal, and finance. These overheads are crucial for supporting the business operations and driving revenue growth.

For the first quarter of 2024, Amkor Technology reported SG&A expenses of $145.2 million. This figure reflects the investment in sales teams, marketing initiatives to promote their diverse portfolio of solutions, and the operational costs of managing a global enterprise. Effective control over these expenditures is vital for maintaining profitability and enhancing shareholder value.

- Sales and Marketing: Costs associated with customer acquisition, brand building, and promotional activities.

- General and Administrative: Expenses related to corporate functions like executive management, human resources, IT, and legal services.

- Financial Performance Impact: Efficient management of SG&A directly influences Amkor's operating margins and overall financial health.

- 2024 Q1 Data: SG&A expenses stood at $145.2 million, highlighting the scale of these operational investments.

Amkor Technology’s cost structure is a complex interplay of direct manufacturing expenses, significant capital investments, labor, research and development, and overheads. Direct costs, like raw materials and consumables, form a substantial portion, as seen in their $4.7 billion cost of goods sold in 2023. Continuous capital expenditure, totaling $625 million in 2023, is essential for maintaining technological leadership and production capacity.

| Cost Category | 2023 (Approx.) | Significance |

|---|---|---|

| Cost of Goods Sold | $4.7 billion | Includes raw materials (substrates, leadframes) and consumables. |

| Capital Expenditures | $625 million | Investment in advanced assembly and test equipment, facility upgrades. |

| R&D Expenses | $366.5 million | Drives innovation in packaging solutions and process improvements. |

| SG&A Expenses (Q1 2024) | $145.2 million | Covers sales, marketing, administration, and corporate functions. |

Revenue Streams

Amkor Technology's primary revenue stream is generated through fees for its comprehensive semiconductor assembly services. These services encompass critical processes such as die attach, wire bonding, flip chip, and increasingly sophisticated advanced packaging solutions.

Pricing for these services is predominantly determined by the volume of units processed and the inherent complexity of the required packaging technology. For instance, in 2023, Amkor's revenue was approximately $5.3 billion, with assembly and test services forming the core of this figure.

Amkor Technology generates revenue through its Test Services Fees by offering a wide array of integrated circuit testing. This includes crucial electrical, functional, and environmental testing, vital for ensuring product quality and performance.

These fees are typically structured on a per-unit basis or are calculated based on the intricate nature and time commitment required for specific test protocols. For instance, in 2023, Amkor reported significant revenue from its assembly and test services, demonstrating the substantial contribution of these fee-based offerings to its overall financial performance.

Amkor Technology generates revenue by offering specialized package design and development services. This caters to clients needing bespoke solutions, leveraging Amkor's engineering prowess and charging fees for the application of its intellectual property.

Value-Added Services and Consulting

Amkor Technology diversifies its revenue through value-added services beyond core manufacturing. These include sophisticated supply chain management and logistics coordination, ensuring seamless delivery for clients. For the fiscal year 2023, Amkor reported that its services segment contributed significantly to its overall revenue, demonstrating the growing importance of these offerings.

Furthermore, Amkor provides specialized services like burn-in testing, a critical step in qualifying semiconductor devices for reliability. They also offer valuable technical consulting focused on optimizing packaging and testing processes. This consultative approach not only generates additional income but also strengthens customer relationships by providing tailored solutions and expertise.

- Supply Chain Management and Logistics: Ensuring efficient and reliable movement of goods.

- Burn-in Services: Enhancing semiconductor reliability through accelerated testing.

- Technical Consulting: Expert advice on packaging and test process optimization.

Licensing of Intellectual Property

While Amkor Technology's core business revolves around manufacturing and services, it does have a revenue stream from licensing its intellectual property. This involves allowing other companies to use Amkor's patented packaging and testing technologies in exchange for fees.

This strategy effectively monetizes Amkor's significant investments in research and development, turning innovative designs into additional income. For instance, in 2023, Amkor reported substantial R&D expenditures, indicating a continuous effort to build its IP portfolio.

- Intellectual Property Licensing: Amkor may license its proprietary packaging and testing innovations.

- R&D Monetization: This stream capitalizes on Amkor's research and development investments.

- Strategic Partnerships: Licensing can foster collaborations with other industry players.

Amkor Technology's revenue is primarily driven by fees for semiconductor assembly and test services, with pricing influenced by volume and complexity. For the fiscal year 2023, Amkor reported approximately $5.3 billion in revenue, with these core services forming the bulk of this figure.

Additional revenue is generated from specialized services like burn-in testing and technical consulting, alongside fees for package design and development, and intellectual property licensing. The company's commitment to R&D, evidenced by significant 2023 expenditures, supports this IP monetization strategy.

| Revenue Stream | Description | 2023 Data (Approx.) |

| Assembly & Test Services | Core semiconductor packaging and testing | $5.3 billion (Total Revenue) |

| Specialized Services | Burn-in, consulting, design & development | Contributes to overall revenue |

| IP Licensing | Monetizing proprietary technologies | Supports R&D investment |

Business Model Canvas Data Sources

Amkor Technology's Business Model Canvas is informed by a blend of internal financial reports, customer feedback, and operational data. This multi-faceted approach ensures a comprehensive understanding of the company's strategic positioning and market engagement.