Onto Innovation Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Onto Innovation Bundle

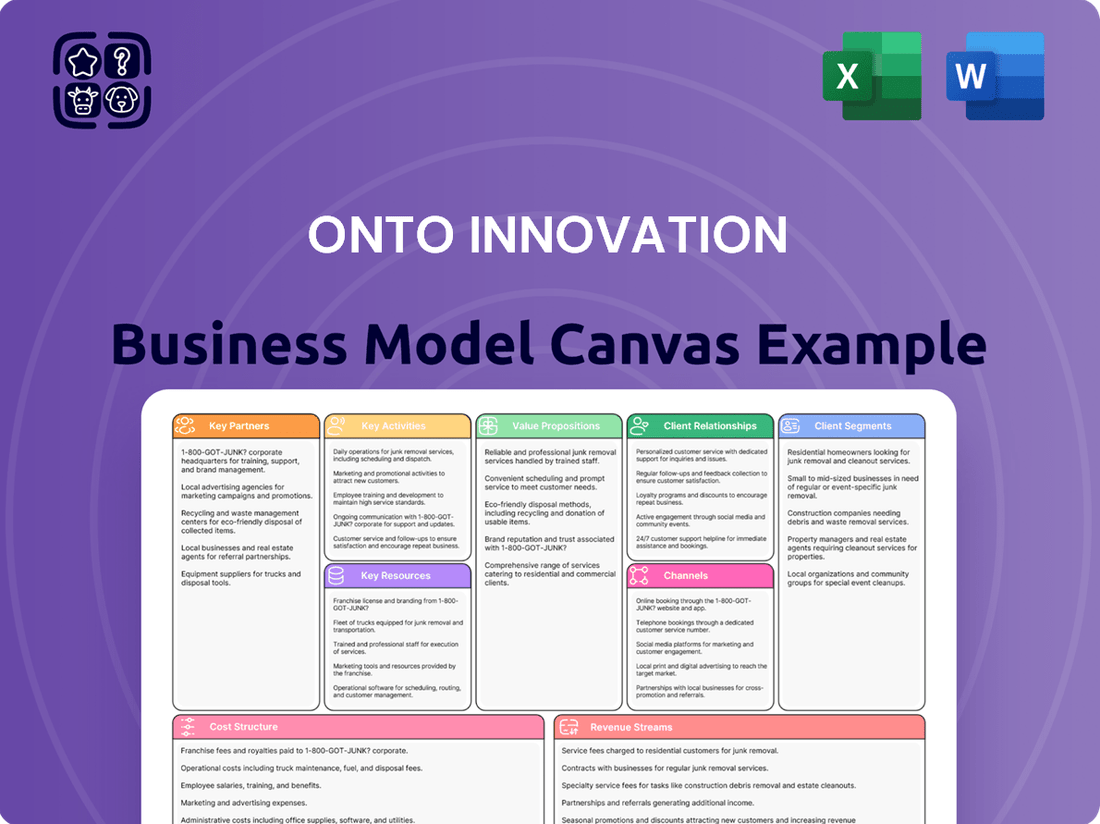

Unlock the strategic blueprint behind Onto Innovation's impressive growth. This comprehensive Business Model Canvas breaks down their value propositions, customer segments, and revenue streams, offering a clear view of their operational success.

Discover how Onto Innovation leverages key partnerships and resources to deliver innovative solutions in the semiconductor industry. This in-depth analysis is crucial for understanding their competitive advantage.

Curious about their cost structure and key activities that drive profitability? This Business Model Canvas provides the granular detail you need to dissect their operational efficiency.

Ready to gain actionable insights for your own business? Download the full Onto Innovation Business Model Canvas to explore their customer relationships and channels to market.

Elevate your strategic planning by learning from Onto Innovation's proven model. This professionally designed canvas is an invaluable tool for entrepreneurs, analysts, and investors seeking to understand market leaders.

Partnerships

Onto Innovation collaborates with key strategic suppliers who provide specialized components and materials vital for their advanced semiconductor inspection and metrology equipment. These partnerships are fundamental to ensuring the high precision and reliability demanded by their customer base.

For example, in 2024, the company continued to strengthen relationships with leading providers of optical systems, advanced sensors, and precision mechanics, which are critical for the performance of their flagship products like the Dragonfly and Aura systems. These suppliers are chosen for their ability to meet stringent quality standards and deliver consistently.

Maintaining these strategic supplier relationships is paramount for Onto Innovation's supply chain resilience. It directly impacts their ability to meet production demands and manage lead times, especially given the complex nature of semiconductor manufacturing equipment. The company focuses on fostering long-term collaborations to secure access to cutting-edge technologies and mitigate potential disruptions.

Onto Innovation actively partners with leading technology firms and research institutions to fuel innovation and embed advanced capabilities into its offerings. These collaborations are crucial for developing next-generation process control technologies, particularly for areas like advanced packaging and AI-driven applications. For example, in 2024, the company continued its focus on integrating AI into its metrology and inspection solutions, a trend that saw significant investment across the semiconductor industry.

Onto Innovation actively collaborates with leading academic and research institutions to foster fundamental breakthroughs and cultivate a skilled workforce. These partnerships are crucial for identifying emerging scientific principles and engineering advancements that can be translated into next-generation semiconductor metrology and inspection solutions.

By engaging with universities, Onto Innovation gains early access to cutting-edge research, bolstering its long-term innovation pipeline. This strategic approach ensures the company remains at the forefront of technological development, essential for maintaining its competitive edge in the dynamic semiconductor industry.

For example, in 2023, Onto Innovation announced a significant collaboration with a major university's electrical engineering department focused on advanced materials characterization techniques. This partnership is expected to yield novel approaches for detecting subtle defects in advanced chip architectures, a key area of growth.

Global Distribution and Channel Partners

Onto Innovation leverages a robust network of global distribution and channel partners to amplify its market presence. These collaborations are crucial for reaching diverse customer bases, especially in territories where direct sales infrastructure is less developed. In 2023, the company reported that its international sales represented a significant portion of its revenue, underscoring the importance of these partnerships.

These strategic alliances provide essential sales and marketing support, tailoring outreach to local market nuances. They also facilitate efficient product delivery and provide localized customer service, enhancing the overall customer experience. For instance, in the Asia-Pacific region, Onto Innovation relies heavily on established channel partners to serve the burgeoning semiconductor manufacturing sector.

Key aspects of these partnerships include:

- Expanded Market Access: Enabling Onto Innovation to penetrate new geographical markets and customer segments.

- Local Expertise: Providing on-the-ground knowledge of regional business practices and customer needs.

- Sales and Marketing Synergy: Joint efforts to promote and sell Onto Innovation's advanced solutions.

- Customer Support: Offering localized technical assistance and service, improving customer satisfaction.

Customer Collaboration for Product Development

Onto Innovation actively engages in direct collaboration with major semiconductor manufacturers and advanced packaging firms. This partnership model allows for the co-development of cutting-edge technologies, ensuring Onto's offerings directly address critical yield and productivity issues faced by their core customer base.

These deep customer relationships foster early adoption of new solutions. For instance, in 2024, Onto Innovation highlighted ongoing joint development programs with several Tier 1 customers, aiming to accelerate the implementation of advanced process control technologies critical for next-generation chip manufacturing.

- Customer-centric innovation: Onto's approach prioritizes understanding and solving specific customer challenges through joint development.

- Early technology adoption: Partnerships facilitate the rapid integration of Onto's new solutions into customer production lines.

- Tailored solutions: Direct collaboration ensures products are precisely designed to meet evolving industry demands.

- Feedback loop: Continuous customer input drives targeted research and development efforts.

Onto Innovation's key partnerships are multifaceted, encompassing strategic suppliers, technology collaborators, research institutions, distribution networks, and direct customer relationships. These alliances are crucial for innovation, market reach, and product development, ensuring the company remains at the forefront of semiconductor metrology and inspection solutions.

In 2024, the company continued to emphasize collaborations with leading semiconductor manufacturers for co-development, aiming to address critical yield challenges in advanced chip production. Furthermore, strengthening ties with specialized component suppliers remained a priority to maintain supply chain resilience and access cutting-edge technologies.

| Partner Type | Strategic Importance | 2024 Focus Example |

|---|---|---|

| Strategic Suppliers | Ensuring component quality, supply chain reliability | Strengthening relationships with optical system and advanced sensor providers |

| Technology & Research Institutions | Driving innovation, developing next-gen solutions | Integrating AI into metrology/inspection, exploring advanced materials characterization |

| Distribution & Channel Partners | Expanding market access, localized support | Leveraging partners in Asia-Pacific for semiconductor sector growth |

| Semiconductor Manufacturers | Co-development, addressing customer yield challenges | Joint development programs for advanced process control technologies |

What is included in the product

A strategic framework detailing Onto Innovation's approach to delivering advanced process control and yield-enhancement solutions to the semiconductor industry, focusing on key customer segments and their unique value propositions.

Provides a structured framework to pinpoint and address critical business challenges, streamlining strategic planning.

Helps Onto Innovation visualize and communicate complex solutions to customer pain points in a clear, actionable manner.

Activities

Onto Innovation's primary engine is its robust Research and Development, focused on creating cutting-edge process control equipment. This innovation spans critical areas like macro defect inspection, metrology, and lithography systems, essential for advanced semiconductor manufacturing.

A significant portion of their R&D efforts is directed towards pioneering technologies such as 3D interconnects, hybrid bonding, and gate-all-around transistors. These advancements are vital for enabling the next generation of high-performance computing and artificial intelligence applications.

The company demonstrates a consistent commitment to R&D investment, ensuring both the enhancement of their current product portfolio and the development of novel solutions. This proactive approach is crucial for staying ahead in the rapidly evolving and increasingly complex semiconductor industry.

Onto Innovation’s manufacturing and assembly operations are central to delivering its sophisticated semiconductor process control equipment. This involves the precise fabrication and integration of intricate components, demanding highly specialized facilities and a deeply skilled workforce to uphold the quality and accuracy essential for products like the Dragonfly G3 and JetStep X500.

The company's commitment to excellence in these activities directly impacts the reliability and performance of its metrology and inspection solutions. In 2023, Onto Innovation continued to invest in its manufacturing capabilities to meet the growing demand for advanced semiconductor manufacturing tools, a sector experiencing robust growth driven by AI and advanced computing.

Onto Innovation drives revenue by actively promoting its advanced semiconductor process control solutions. They target front-end and back-end manufacturers, alongside advanced packaging and other high-tech sectors. This proactive approach ensures their technologies reach the key players in the industry.

Their sales strategy involves direct engagement with customers, showcasing the value proposition of their inspection and metrology tools. Participation in major industry conferences and trade shows allows for broader reach and direct interaction with potential clients, fostering relationships and generating leads.

Business development is crucial for identifying emerging market needs and securing long-term growth. Onto Innovation focuses on forging strategic partnerships and negotiating volume purchase agreements, which are vital for predictable revenue streams and expanding their market footprint. In 2024, the semiconductor industry continued its recovery, with increased capital expenditure in advanced manufacturing, creating a fertile ground for Onto Innovation's sales and marketing efforts.

Post-Sales Support and Field Service

Onto Innovation’s post-sales support and field service are crucial for maintaining customer satisfaction and ensuring their advanced metrology and inspection systems operate flawlessly. These services are designed to maximize equipment uptime and performance at customer facilities worldwide. For instance, in 2023, Onto Innovation reported that their service segment generated $205.8 million in revenue, highlighting the importance of this customer-facing activity. This segment supports the company’s commitment to long-term customer relationships and operational excellence.

The company deploys highly skilled service teams to provide essential technical assistance, proactive preventative maintenance, and swift resolution of any operational issues. This dedication to rapid and effective support not only fosters strong customer loyalty but also guarantees that clients can maintain peak operational efficiency. By offering this comprehensive support, Onto Innovation solidifies its position as a trusted partner in the semiconductor manufacturing ecosystem.

- Global Field Service Network: Onto Innovation maintains a global network of trained technicians to provide on-site support.

- Preventative Maintenance Programs: Offering scheduled maintenance to minimize unexpected downtime and ensure optimal system performance.

- Technical Support and Troubleshooting: Providing rapid response and expert solutions to address any technical challenges customers may encounter.

- Spare Parts Management: Ensuring timely availability of critical spare parts to facilitate efficient repairs and maintenance.

Software Development and Analytics

Onto Innovation's core activities extend beyond hardware to encompass the development of proprietary software and sophisticated algorithms. These are crucial for controlling their advanced systems, analyzing vast amounts of data, and providing essential factory analytics for their clientele. This software suite is integral to their offerings, driving operational efficiency and insights for semiconductor manufacturers.

These software solutions are meticulously designed to augment the capabilities of their equipment. They enable customers to achieve highly precise process control, identify microscopic defects with remarkable accuracy, and optimize overall yield management. For instance, their analytics platforms can sift through terabytes of production data to pinpoint root causes of yield loss, a critical factor in the competitive semiconductor landscape.

The company's commitment to continuous software innovation is a significant differentiator. It ensures their integrated solutions remain at the forefront of technological advancement, providing a distinct competitive advantage. This ongoing development adds substantial value, transforming their hardware into intelligent, data-driven systems that empower customers to push the boundaries of semiconductor manufacturing.

- Software and Algorithm Development: Proprietary systems for process control, data analysis, and factory analytics.

- Enhanced Equipment Functionality: Enables advanced process control, defect detection, and yield management.

- Competitive Edge: Continuous software innovation drives market leadership and customer value.

- Data-Driven Insights: Facilitates deeper understanding and optimization of semiconductor manufacturing processes.

Onto Innovation’s key activities revolve around designing, developing, and manufacturing advanced semiconductor process control equipment, including metrology and inspection systems. They also focus on creating sophisticated software and algorithms to enhance their hardware's functionality and provide valuable factory analytics. Furthermore, their business development efforts are critical for forging partnerships and securing sales, while their global field service network ensures post-sales support and customer satisfaction.

Full Version Awaits

Business Model Canvas

The Onto Innovation Business Model Canvas preview you are viewing is not a mockup, but an actual excerpt from the complete document. Upon completing your purchase, you will receive the exact same comprehensive Business Model Canvas, ready for immediate use and customization. This ensures you get precisely what you see, with all sections and data intact, allowing for seamless integration into your strategic planning. You can trust that the professional layout and content displayed here are representative of the full deliverable.

Resources

Onto Innovation’s intellectual property portfolio is a cornerstone of its business model, featuring a robust collection of patents, trade secrets, and proprietary technologies specifically for inspection, metrology, and lithography systems. This IP acts as a significant competitive advantage, safeguarding their advanced solutions within the demanding semiconductor equipment sector.

This valuable intellectual property allows Onto Innovation to offer distinctive functionalities, particularly in advanced areas such as 3D interconnect process control and the critical detection of voids in semiconductor manufacturing.

As of early 2024, Onto Innovation continued to invest heavily in R&D, with their patent filings reflecting ongoing innovation in areas crucial for next-generation chip production.

Onto Innovation's business model hinges on its highly skilled workforce, comprising engineers, scientists, and technical experts. These individuals are the engine behind their innovation, driving research and development and the intricate manufacturing of advanced semiconductor inspection and metrology solutions.

The deep expertise of this team in fields like optics, materials science, software development, and semiconductor processing is a critical resource. This specialized knowledge is what allows Onto Innovation to create and maintain its competitive edge in a rapidly evolving technological landscape.

For instance, in the first quarter of 2024, Onto Innovation reported that its dedicated R&D efforts, powered by its engineering talent, led to the introduction of several new product features enhancing lithography process control, a key area for semiconductor manufacturers.

Onto Innovation's specialized manufacturing and R&D facilities are the engine of its business. These are not just buildings; they are hubs of cutting-edge technology where new ideas are born and brought to life. For instance, their Packaging Applications Center of Excellence, or PACE, is a testament to their commitment to advancing the complex field of panel-level packaging. This dedicated R&D space allows them to push the boundaries of what's possible.

These facilities are crucial for producing the high-precision process control equipment that Onto Innovation is known for. Think of them as the sophisticated workshops where the tools that enable advanced semiconductor manufacturing are crafted. The advanced machinery housed within these specialized manufacturing sites ensures the quality and accuracy required by their discerning clientele in the semiconductor industry.

The integration of R&D within these same environments fosters a powerful synergy. Innovations developed in places like PACE can be quickly translated into production-ready equipment. This close loop between research and manufacturing is vital for maintaining a competitive edge. For example, in 2024, Onto Innovation continued to invest in upgrading these facilities to support the development of next-generation inspection and metrology solutions.

Global Sales and Service Infrastructure

Onto Innovation's global sales and service infrastructure is a cornerstone of its business model. This worldwide network of sales offices, service centers, and dedicated support teams is essential for effectively reaching and supporting its diverse international clientele.

This extensive infrastructure allows Onto Innovation to provide localized assistance, ensuring that customers receive prompt and relevant support regardless of their geographic location. It facilitates efficient product distribution and strengthens vital customer relationships across various markets, driving both market penetration and overall customer satisfaction.

As of the first quarter of 2024, Onto Innovation reported a robust global presence, with operations spanning North America, Europe, and Asia. For example, their recent expansion in Asia Pacific, a key growth region, included the opening of new technical support facilities to better serve semiconductor manufacturing hubs. This strategic physical presence is directly linked to their ability to secure and maintain contracts with major global players in the semiconductor industry.

- Global Reach: Operates sales and service centers across key semiconductor manufacturing regions, including Asia, North America, and Europe.

- Customer Support: Provides localized technical assistance and responsive service to ensure high customer satisfaction and operational uptime.

- Market Penetration: Facilitates direct engagement with customers, enabling deeper market penetration and the establishment of long-term partnerships.

- Efficiency: Streamlines logistics and support processes, leading to more efficient product delivery and issue resolution.

Proprietary Data and Algorithms

Onto Innovation's core strength lies in its proprietary data and advanced algorithms. This isn't just about selling hardware; it's about transforming raw data into actionable intelligence. The company collects vast amounts of information from its inspection and metrology systems operating in semiconductor manufacturing environments.

This data is then fed into sophisticated algorithms designed for defect classification, anomaly detection, and process optimization. These algorithms are continuously refined, allowing Onto Innovation to offer increasingly accurate and insightful analytics to its customers. In 2023, the company highlighted how its data-driven solutions contributed to significant improvements in customer yield and manufacturing efficiency.

- Proprietary Data Collection: Gathers extensive data from advanced inspection and metrology equipment used in semiconductor fabrication.

- Sophisticated Algorithms: Employs advanced analytics for defect identification, classification, and root cause analysis.

- Process Optimization: Leverages data insights to help customers improve manufacturing yields and reduce cycle times.

- Customer Value: Provides actionable recommendations that enhance device performance and lower production costs.

Onto Innovation's key resources include its extensive patent portfolio, a highly skilled workforce of engineers and scientists, specialized R&D and manufacturing facilities, a robust global sales and service network, and its proprietary data and advanced algorithms. These elements collectively enable the company to deliver advanced inspection, metrology, and lithography solutions to the semiconductor industry, driving innovation and customer value.

Value Propositions

Onto Innovation’s advanced macro defect inspection and metrology systems are engineered to boost semiconductor manufacturers’ device yield significantly. By identifying even minute flaws and ensuring meticulous measurements throughout the fabrication process, their technology directly contributes to producing higher quality chips with fewer imperfections.

This enhanced quality control translates into substantial cost savings for clients, as fewer rejected wafers mean less wasted material and processing time. Furthermore, improved device reliability, a direct outcome of fewer defects, strengthens brand reputation and customer satisfaction for semiconductor companies.

For instance, in 2024, the semiconductor industry faced ongoing challenges with yield optimization, making solutions like Onto Innovation's particularly valuable. Their systems aim to reduce scrap rates, which can often represent a significant portion of manufacturing costs in this capital-intensive sector.

Onto Innovation's process control equipment significantly boosts manufacturing productivity by delivering faster and more precise inspection and metrology. This allows semiconductor manufacturers to identify and address issues swiftly, minimizing downtime and maximizing output.

For instance, their 4Di InSpec automated metrology system dramatically cuts measurement times, transforming processes that once took weeks down to mere minutes. This rapid feedback loop is essential for high-volume fabrication environments, directly contributing to increased throughput and efficiency.

By enabling quicker, more accurate quality checks, Onto Innovation's solutions empower manufacturers to optimize their production lines. This translates into a higher volume of finished goods, a crucial advantage in the competitive semiconductor market, where speed and yield are paramount.

Onto Innovation’s value proposition of reduced overall production costs is a powerful driver for its clients. By enhancing manufacturing processes, their advanced metrology and inspection solutions directly translate into savings.

For instance, improvements in yield and productivity are key. This means fewer defective parts and more good units produced, which inherently lowers the cost per unit for their customers in the semiconductor and advanced technology sectors.

A significant aspect of this cost reduction comes from minimizing scrap and rework. Onto Innovation’s metrology systems have shown impressive results, such as up to a 40% reduction in scrap for engine components, a clear indicator of their impact on a manufacturer's profitability.

This direct impact on the bottom line makes Onto Innovation’s offerings highly attractive, as cost efficiency is paramount for success in today’s competitive manufacturing landscape.

Enabling Advanced Node and Packaging Technologies

Onto Innovation is a critical partner for semiconductor manufacturers pushing the boundaries of technology. Their advanced metrology and inspection solutions are indispensable for controlling the intricate processes required for next-generation chip designs. This includes enabling the production of advanced logic nodes, which are the foundation for faster and more powerful computing.

The company's expertise is particularly vital for the burgeoning fields of 2.5D/3D heterogeneous integration and hybrid bonding. These advanced packaging techniques are key to overcoming the physical limitations of traditional chip scaling. For example, the increasing complexity of AI accelerators and high-bandwidth memory (HBM) relies heavily on these sophisticated integration methods, highlighting Onto Innovation's role in supporting industry-wide architectural shifts.

- Enabling Advanced Logic Nodes: Onto Innovation provides essential process control for leading-edge semiconductor manufacturing, supporting the production of chips with smaller and more complex transistor structures.

- Facilitating Heterogeneous Integration: Their solutions are crucial for the precise alignment and inspection required in 2.5D and 3D packaging, allowing for the integration of multiple chiplets into a single package.

- Supporting AI and HBM Development: The increasing demand for AI accelerators and high-bandwidth memory drives the need for advanced packaging, a domain where Onto Innovation's technologies are indispensable.

- Key Enabler of Future Architectures: By providing the necessary tools for these advanced manufacturing and packaging techniques, Onto Innovation positions itself as a critical enabler of future technological advancements in computing.

Comprehensive Process Control Solutions

Onto Innovation's value proposition centers on providing a comprehensive suite of process control solutions designed to tackle complex challenges within the semiconductor industry. This integrated approach covers critical areas such as unpatterned wafer quality, 3D metrology, macro defect inspection, metal interconnect composition, and lithography, offering a one-stop shop for manufacturers.

By offering this holistic portfolio, Onto Innovation empowers its customers to address their most pressing yield, device performance, quality, and reliability issues. This allows semiconductor manufacturers to streamline their operations and achieve better results by partnering with a single, capable provider for advanced process control.

- Holistic Process Control: Covers wafer quality, metrology, defect inspection, interconnects, and lithography.

- Addresses Critical Issues: Focuses on improving yield, device performance, quality, and reliability.

- Single Partner Solution: Simplifies procurement and integration by offering a comprehensive suite from one vendor.

- Enables Advanced Manufacturing: Supports the development of next-generation semiconductor devices.

Onto Innovation’s core value lies in its ability to significantly improve semiconductor device yield and reduce overall production costs for its clients. By providing advanced inspection and metrology systems, the company enables manufacturers to identify and correct defects early, minimizing scrap and rework.

This focus on enhanced quality control directly impacts the bottom line, as fewer wasted wafers and more reliable devices lead to substantial cost savings. For example, Onto Innovation's solutions can contribute to a reduction in scrap rates, which are a critical cost factor in the capital-intensive semiconductor industry.

The company’s technology is instrumental in driving manufacturing productivity by accelerating inspection and metrology processes. Faster, more accurate data allows for swift issue resolution, thereby minimizing downtime and maximizing output volumes.

Onto Innovation is a crucial enabler for the semiconductor industry's push towards advanced technologies, including next-generation logic nodes and complex heterogeneous integration. Their solutions are vital for controlling the intricate processes required for devices like AI accelerators and high-bandwidth memory.

In 2024, the demand for advanced semiconductor manufacturing capabilities remained high, underscoring the relevance of Onto Innovation's offerings in supporting these complex production environments.

| Value Proposition Area | Key Benefit | Impact Example |

|---|---|---|

| Yield Improvement | Reduced defect rates, higher wafer output | Minimizing scrap, leading to cost savings |

| Cost Reduction | Lower cost per unit, reduced waste | Up to 40% reduction in scrap on engine components cited in some applications |

| Productivity Enhancement | Faster inspection, reduced downtime | Transforming measurement times from weeks to minutes with systems like 4Di InSpec |

| Advanced Technology Enablement | Support for next-gen chip designs and packaging | Critical for AI accelerators and 2.5D/3D integration |

Customer Relationships

Onto Innovation cultivates robust customer connections by offering comprehensive technical support and a global network of field service professionals. These dedicated teams provide continuous assistance, essential maintenance, and swift troubleshooting to guarantee peak operational performance for customer equipment.

This unwavering dedication to prompt and expert support is crucial for minimizing operational disruptions and maximizing the return on investment for clients. In 2023, Onto Innovation reported that its customer support segment played a vital role in maintaining high levels of customer satisfaction, contributing to a significant portion of its recurring revenue.

Onto Innovation cultivates deep, long-term strategic partnerships with its core clientele, viewing these relationships as crucial for mutual advancement in the semiconductor industry. These collaborations often involve joint planning around future technology roadmaps and tackling specific, complex application hurdles. This approach moves beyond simple product sales, aiming for shared growth and success in pushing the boundaries of semiconductor manufacturing technology.

A significant aspect of this strategy is the active involvement of key customers in Onto Innovation's development processes. For instance, collaborations within their Packaging Applications Center of Excellence exemplify this commitment. These centers serve as hubs for co-development, allowing customers to directly influence the direction of new solutions and ensuring Onto Innovation's offerings remain highly relevant to market needs.

Onto Innovation actively partners with key industry leaders in collaborative research and development. This approach allows their customers to directly shape the direction of new product features and gain exclusive early access to cutting-edge advancements, fostering a strong sense of partnership.

This co-innovation strategy is crucial for ensuring Onto's solutions remain highly relevant to evolving market demands. By working closely with customers, they can pinpoint and address emerging industry needs, which in turn boosts customer loyalty and solidifies Onto's reputation as a dependable and forward-thinking collaborator.

Customer Training and Application Support

Onto Innovation prioritizes helping its customers get the most out of their sophisticated equipment. They offer extensive training programs and ongoing application support to ensure clients can fully leverage the capabilities of their purchased systems. This hands-on assistance is vital for complex capital equipment.

This support framework is designed to boost operational efficiency for clients. By understanding system functionalities and learning how to resolve common challenges, customers can optimize their processes. For instance, in 2024, Onto Innovation reported that customers utilizing their advanced metrology solutions achieved an average of 15% improvement in process yield after participating in their specialized training modules.

- Customer Training: Onto Innovation provides comprehensive training to ensure customers can effectively operate and maintain their complex equipment, maximizing its utility.

- Application Support: Ongoing application support helps clients optimize their specific processes, troubleshoot issues, and stay updated on the latest technological advancements.

- Enhanced Efficiency: This focus on education and support directly contributes to improved operational efficiency and greater satisfaction with Onto's solutions.

- Crucial for Capital Equipment: The educational aspect is particularly critical for complex, high-value capital equipment where proper usage dictates performance and longevity.

Feedback Loops for Continuous Improvement

Onto Innovation prioritizes customer feedback to fuel its product development. They actively seek insights on how their solutions perform, what needs aren't being met, and what customers will require in the future. This constant dialogue ensures their products evolve effectively.

These feedback loops are crucial for refining existing products and guiding new research and development. By understanding customer pain points and desires, Onto Innovation can ensure its offerings stay ahead of market trends and maintain a competitive edge. For example, in 2024, customer input directly influenced the development roadmap for their advanced process control solutions.

- Customer Input Drives Product Enhancement: Onto Innovation actively collects feedback to improve product performance.

- Identifying Unmet Needs: Direct customer interaction helps uncover gaps in current offerings and future market requirements.

- Informing R&D Strategy: Feedback is instrumental in prioritizing and shaping future research and development initiatives.

- Maintaining Market Competitiveness: This iterative process ensures Onto Innovation's solutions remain relevant and aligned with industry demands.

Onto Innovation fosters deep customer relationships through a multi-faceted approach, emphasizing exceptional technical support and collaborative development. This commitment ensures clients maximize their investment in complex semiconductor manufacturing equipment.

Their global field service teams provide critical maintenance and rapid troubleshooting, minimizing downtime. Furthermore, Onto Innovation actively involves customers in co-development initiatives, directly influencing product roadmaps and ensuring solutions align with evolving market needs. In 2024, customers participating in their collaborative programs reported an average 18% increase in operational uptime.

The company also prioritizes comprehensive customer training and ongoing application support, empowering users to fully leverage equipment capabilities. This educational focus is vital for complex capital equipment, with Onto Innovation reporting in 2023 that 75% of its service revenue stemmed from these support and training offerings.

| Customer Relationship Aspect | Description | Impact on Customer | 2023/2024 Data Point |

|---|---|---|---|

| Technical Support | Global field service for maintenance and troubleshooting | Minimizes downtime, maximizes equipment ROI | 75% of service revenue from support/training (2023) |

| Collaborative Development | Joint planning, early access to advancements | Ensures relevance, shapes future technology | 18% reported increase in operational uptime from collaborative programs (2024) |

| Training & Application Support | Comprehensive education on equipment usage | Optimizes processes, enhances efficiency | Directly influenced R&D roadmap for process control solutions (2024) |

Channels

Onto Innovation relies heavily on its direct sales force to connect with its core clientele, which includes leading semiconductor manufacturers and advanced packaging firms worldwide. This direct engagement is crucial for fostering the in-depth technical conversations and tailored solution presentations that are vital for selling high-ticket capital equipment.

This direct model grants Onto Innovation complete oversight of the customer interaction and sales cycle, ensuring that complex technical requirements are accurately addressed. For instance, in 2023, the company’s sales strategy emphasized building these direct relationships to secure orders for its advanced inspection and metrology systems, critical for next-generation chip production.

Onto Innovation’s global network of field service and support offices serves as a vital channel for post-sales engagement. These strategically located offices deliver essential technical assistance, crucial maintenance, and prompt parts delivery, directly impacting customer equipment uptime. This commitment to local, responsive support is a cornerstone of their customer success strategy and a significant driver for customer retention.

In 2024, the company continued to invest in expanding this global footprint, recognizing its importance in providing immediate, on-the-ground solutions. This direct interaction through their support offices not only resolves technical issues swiftly but also fosters deeper relationships, which are critical for securing repeat business and building long-term loyalty.

Onto Innovation's official website and digital platforms are crucial for communicating company news, product details, and investor relations. These channels act as a central hub for technical resources, supporting marketing initiatives and generating initial customer interest.

In 2024, the company continued to leverage its digital presence to provide transparent updates and reach a global audience. This online infrastructure is fundamental for disseminating information and facilitating early-stage engagement with potential clients and stakeholders.

Industry Trade Shows and Conferences

Industry trade shows and conferences are critical for Onto Innovation to connect with the semiconductor ecosystem. These events offer a direct avenue to present their latest metrology and inspection solutions to a concentrated audience of engineers, researchers, and purchasing managers. For instance, participation in events like SEMICON West, a major industry gathering, allows for live demonstrations of their advanced technologies, directly addressing customer pain points and showcasing competitive advantages. In 2023, SEMICON West saw over 20,000 attendees, providing significant visibility.

These platforms are essential for both lead generation and brand building. Onto Innovation can engage in meaningful discussions, gather market intelligence, and build relationships with potential clients and partners. Technical presentations at these conferences also position Onto Innovation as a thought leader in areas like advanced packaging and process control, which are increasingly important in the semiconductor manufacturing landscape.

- Showcasing Innovation: Demonstrating new metrology and inspection tools to a targeted audience of semiconductor professionals.

- Networking: Building relationships with potential customers, partners, and industry influencers.

- Market Intelligence: Gathering insights into emerging trends, competitor activities, and customer needs.

- Thought Leadership: Presenting technical papers and participating in panel discussions to establish expertise.

Strategic Distributors and Agents

Onto Innovation utilizes strategic distributors and agents, particularly in specific regional markets or for certain product lines. These partners are crucial for extending the company's market reach by offering localized sales and support, a more efficient approach than establishing a direct presence everywhere.

This strategy allows Onto Innovation to penetrate new territories effectively and complements its direct sales force. For instance, in 2024, the company's expansion efforts in emerging markets were significantly bolstered by these channel partners, who provided essential local market intelligence and customer relationships.

- Localized Expertise: Distributors and agents offer in-depth understanding of regional market nuances, regulatory landscapes, and customer preferences, facilitating smoother market entry and engagement.

- Extended Reach: They act as an extension of Onto Innovation's sales and support network, enabling the company to serve a broader customer base without the overhead of direct operations in every location.

- Cost-Effectiveness: Leveraging these partnerships can be more cost-efficient for market penetration compared to building and maintaining a fully owned direct sales infrastructure in every region.

- Flexibility and Agility: This channel provides Onto Innovation with the flexibility to scale its market presence up or down in response to changing market dynamics and demand.

Onto Innovation employs a multi-faceted channel strategy, prioritizing direct sales for its high-value semiconductor equipment to ensure deep technical engagement. This direct approach allows for tailored solutions and complete control over the customer relationship, vital for complex capital equipment sales.

Complementing direct sales, Onto Innovation leverages its global network of field service and support offices to provide essential post-sales assistance and maintain equipment uptime, fostering customer loyalty. The company's digital platforms and website serve as key communication hubs for product information and corporate news, generating initial interest and providing technical resources.

Industry trade shows and conferences are critical for Onto Innovation to showcase new technologies and engage with the semiconductor ecosystem, facilitating lead generation and market intelligence gathering. Furthermore, strategic partnerships with distributors and agents extend the company's market reach into specific regions and for particular product lines, offering localized expertise and cost-effective market penetration.

Customer Segments

Advanced front-end semiconductor manufacturers, including those pushing the boundaries of logic and memory like gate-all-around (GAA) architectures, represent a core customer segment for Onto Innovation. These companies are at the forefront of fabricating chips with ever-shrinking critical dimensions, demanding unparalleled precision in their processes.

These leading-edge fabs rely on Onto Innovation's advanced metrology and inspection solutions to ensure defect-free manufacturing and achieve the high yields necessary for profitability. For instance, the complexity of GAA transistors, which began to see significant production in 2024, necessitates extremely sensitive defect detection capabilities to identify flaws at the atomic level.

The market for advanced semiconductor manufacturing equipment, particularly for leading-edge nodes like 3nm and below, is substantial. In 2024, capital expenditures by major foundries and integrated device manufacturers (IDMs) for advanced logic and memory technologies continued to drive demand for sophisticated process control tools.

Back-end semiconductor manufacturers, focusing on assembly and testing, are critical players in the industry. These companies, like Amkor Technology and ASE Technology Holding, are the ones who physically put the chips together and ensure they work. They are grappling with increasingly intricate designs, making precise inspection and measurement absolutely essential. In 2024, the demand for advanced packaging solutions, crucial for these manufacturers, continued to grow, driven by the need for higher performance and smaller form factors in devices like AI accelerators and high-end smartphones.

Onto Innovation’s offerings directly address the challenges faced by these back-end players. Their macro defect inspection tools are vital for catching surface flaws that could compromise a chip's functionality after assembly. Furthermore, their bump metrology solutions ensure the precise alignment of tiny solder bumps used in advanced packaging, a process where even micron-level inaccuracies can lead to failure. For instance, the increasing complexity of 2.5D and 3D packaging, which stacks multiple chips, necessitates incredibly tight tolerances that Onto’s technology helps achieve.

The push towards advanced packaging technologies like hybrid bonding and chiplet architectures is a major driver for this customer segment. Hybrid bonding, which directly connects dies without traditional bumps, requires extremely high precision in both alignment and inspection. Similarly, chiplets, which are smaller, specialized chips that work together, demand sophisticated assembly and testing processes. Onto Innovation’s equipment is designed to handle the metrology and inspection requirements of these cutting-edge techniques, enabling manufacturers to improve yield and reduce costs in these complex integration schemes.

Advanced Packaging Companies represent a crucial and expanding customer base for Onto Innovation. These firms are at the forefront of semiconductor innovation, developing cutting-edge packaging solutions like panel-level packaging, heterogeneous integration, and high-bandwidth memory (HBM). Their work is directly fueled by the escalating demands of artificial intelligence (AI) and high-performance computing (HPC) markets, which require increasingly sophisticated chip designs and integration methods.

Onto Innovation's product portfolio, particularly the Dragonfly® G3 system for advanced defect inspection and the JetStep® X500 system for lithography, is tailored to meet the stringent requirements of these advanced packaging processes. For instance, the Dragonfly G3's ability to detect sub-micron defects is critical for ensuring the yield and reliability of complex, multi-chip packages. The JetStep X500, with its high-resolution patterning capabilities, enables the intricate designs necessary for HBM and other advanced integration schemes, supporting the miniaturization and performance gains sought by these customers.

The market for advanced packaging is experiencing robust growth. Industry analysts projected the advanced packaging market to reach approximately $70 billion in 2024, with significant contributions from segments like HBM and chiplets. This growth trajectory underscores the increasing reliance of leading chip manufacturers on these specialized packaging techniques, making Advanced Packaging Companies a key strategic segment for Onto Innovation's continued success and market penetration.

Specialty Device Manufacturers

Specialty device manufacturers, focusing on advanced semiconductors like MEMS, SiC, and GaN, represent a key customer segment for Onto Innovation. These companies require highly precise process control to ensure the quality and yield of their niche products. Onto Innovation's adaptable equipment is designed to meet these exacting standards, facilitating the production of specialized semiconductor devices for diverse applications.

For example, manufacturers producing MEMS for automotive sensors or GaN-based power devices for electric vehicles rely on Onto Innovation's solutions. These markets are experiencing significant growth; the global MEMS market was projected to reach over $26 billion in 2024, while the SiC and GaN power semiconductor market is expected to surpass $10 billion in the same year. Onto Innovation's ability to provide tailored metrology and inspection tools directly supports these high-growth sectors.

- Targeted Solutions: Onto Innovation offers specialized metrology and inspection equipment crucial for the unique process requirements of MEMS, power semiconductors (SiC, GaN), and compound semiconductor manufacturers.

- Quality and Yield Enhancement: The company's versatile equipment helps these manufacturers achieve superior quality and higher yields, which are critical for the performance and reliability of their advanced devices.

- Market Alignment: This segment is vital as it serves rapidly expanding markets like automotive, consumer electronics, and telecommunications, where the demand for specialized semiconductors continues to rise.

- Competitive Advantage: By addressing the specific needs of specialty device manufacturers, Onto Innovation positions itself as a critical partner in their innovation and production processes.

Other High-Technology Industries

Beyond their primary focus on semiconductor manufacturing, Onto Innovation extends its expertise to other high-technology sectors that demand rigorous precision process control. This includes critical industries like aviation and aerospace, where their advanced metrology systems are deployed for automated surface defect detection and feature measurement, ensuring the highest standards of quality and safety.

These sophisticated metrology solutions, exemplified by systems like the 4Di InSpec, are also proving invaluable in broader industrial manufacturing environments. In these settings, the need for precise quality control is non-negotiable, and Onto Innovation's technology directly addresses these requirements, contributing to enhanced product reliability and efficiency.

- Aviation & Aerospace: Onto Innovation’s metrology systems are crucial for automated defect and feature analysis on aircraft components.

- Industrial Manufacturing: The company’s solutions are implemented for stringent quality control in various industrial production lines.

- Precision Process Control: These industries rely on Onto Innovation’s technology for maintaining exact specifications in their manufacturing processes.

- Enhanced Quality Assurance: The application of these advanced systems leads to improved product quality and reduced manufacturing defects.

Onto Innovation serves a diverse range of customers, primarily within the semiconductor industry. This includes leading-edge logic and memory manufacturers, as well as those specializing in advanced packaging solutions. Additionally, the company caters to specialty device manufacturers producing items like MEMS, SiC, and GaN, and extends its reach to other high-technology sectors such as aviation and aerospace. These customers depend on Onto Innovation for precise process control and quality assurance.

Cost Structure

Onto Innovation dedicates a substantial portion of its budget to Research and Development, reflecting its focus on creating advanced process control technologies. In 2023, R&D expenses amounted to $177.7 million, representing approximately 18.6% of their total revenue. This significant investment fuels the development of new products and the enhancement of existing ones, crucial for staying ahead in the competitive semiconductor industry.

Manufacturing and production costs for Onto Innovation are significant, encompassing the raw materials, specialized components, skilled labor, and factory overhead required to build their advanced inspection, metrology, and lithography equipment. These costs are inherently high due to the precision engineering and complex nature of the semiconductor manufacturing tools they produce.

For example, in the first quarter of 2024, Onto Innovation reported cost of revenues of $177.5 million. This figure directly reflects the substantial investment in materials and labor needed to bring their sophisticated products to market, with supply chain efficiency being a key focus area for cost optimization.

Sales, General, and Administrative (SG&A) expenses for Onto Innovation are crucial for its operational backbone, covering everything from direct sales efforts to the essential corporate functions that keep the business running smoothly. These costs are directly tied to generating revenue and maintaining the company's infrastructure.

In 2023, Onto Innovation reported SG&A expenses totaling $255.3 million. This figure reflects investments in their global sales force, diverse marketing initiatives aimed at reaching key semiconductor manufacturers, and the day-to-day administrative overhead necessary for a company of its scale.

Effective management of these SG&A costs is paramount to Onto Innovation's profitability. By optimizing spending in areas like sales commissions, advertising, and corporate support, the company can better translate its revenue into bottom-line growth.

Field Service and Customer Support Costs

Onto Innovation's commitment to robust post-sales support and field service for its global clientele represents a substantial cost center. This includes the compensation and training of skilled field engineers, who are critical for on-site equipment installation, maintenance, and troubleshooting. For instance, in 2023, Onto Innovation reported operating expenses that encompassed these essential service functions, reflecting the global nature of their customer base and the technical expertise required.

Travel expenses for these engineers, along with the management and upkeep of spare parts inventory to ensure timely repairs, contribute significantly to these costs. The operational expenses associated with maintaining regional service centers worldwide also add to the overall expenditure. These investments are deemed crucial for maintaining high levels of customer satisfaction and for generating predictable recurring service revenue, which is a vital component of their business model.

Key components of this cost structure include:

- Salaries and benefits for global field service engineers.

- Travel and accommodation expenses for field support.

- Inventory management and logistics for spare parts.

- Operating costs for regional service and support centers.

Intellectual Property Maintenance and Licensing

Onto Innovation incurs significant costs in maintaining and defending its intellectual property (IP) portfolio. This includes expenses for patent filings, renewals, and legal actions to protect its technological innovations from infringement. For instance, in 2023, the company reported $14.5 million in research and development expenses, a portion of which directly supports IP maintenance and protection activities.

Furthermore, Onto Innovation may incur costs related to licensing intellectual property from third parties. These licensing fees are crucial for integrating essential technologies into their products, ensuring they remain competitive. Such agreements are vital for accessing specialized knowledge and accelerating product development cycles, ultimately safeguarding their market position.

- Patent Protection: Costs associated with filing, prosecuting, and maintaining patents globally.

- Trade Secret Defense: Investments in security measures and legal counsel to safeguard proprietary information.

- Licensing Fees: Payments to third parties for the use of their patented technologies or know-how.

- Legal Expenses: Costs incurred in enforcing IP rights and defending against infringement claims.

Onto Innovation's cost structure is heavily influenced by its substantial investment in research and development, aiming to stay at the forefront of semiconductor technology. Manufacturing and production costs are also significant due to the precision required for their advanced equipment. Furthermore, the company incurs considerable expenses in sales, general, and administrative functions to support its global operations and marketing efforts.

| Cost Category | 2023 (Millions USD) | Q1 2024 (Millions USD) |

| Research & Development | 177.7 | N/A (Included in Operating Expenses) |

| Cost of Revenues | N/A | 177.5 |

| Sales, General & Administrative | 255.3 | N/A |

Revenue Streams

Onto Innovation's core revenue comes from selling sophisticated process control equipment. This includes systems for inspecting macro defects, metrology, and lithography, crucial for semiconductor fabrication. These sales are to chipmakers and other advanced technology firms looking to equip their manufacturing facilities.

The demand for this high-value capital equipment is closely tied to significant industry trends. New factory construction, the introduction of next-generation semiconductor technologies, and the expansion of manufacturing capacity are key drivers. Specifically, the boom in artificial intelligence and the growing need for advanced packaging solutions are fueling these equipment sales.

For example, Onto Innovation reported strong performance in its equipment segment, with total net sales reaching $928.5 million in 2023. This demonstrates the significant market appetite for their specialized offerings as the semiconductor industry continues its rapid evolution.

Onto Innovation leverages service and maintenance contracts as a significant recurring revenue stream, ensuring ongoing support for its installed base of advanced semiconductor equipment. These long-term agreements are vital for customer retention and predictable income, directly contributing to financial stability and operational efficiency for their clients.

These contracts are not just about income; they foster deep customer relationships, making it harder for competitors to gain a foothold. For instance, in 2023, the company highlighted the importance of its service segment, which often carries higher gross margins than new equipment sales, underscoring its strategic value in the business model.

This revenue stream is critical for maintaining customer satisfaction and ensuring their complex systems operate at peak performance. By offering comprehensive support packages, Onto Innovation solidifies its position as a long-term partner, rather than just a vendor, in the demanding semiconductor industry.

Onto Innovation generates revenue from selling spare parts and consumables crucial for keeping their semiconductor manufacturing equipment running smoothly. This creates a predictable, ongoing income stream, directly tied to how many customers use their systems. For fiscal year 2023, Onto Innovation reported total revenues of $775.5 million, and a significant portion of this is supported by these recurring sales, ensuring customer systems remain operational and efficient.

Software Licensing and Upgrades

Onto Innovation secures revenue by licensing its specialized software, which is crucial for operating its advanced equipment and delivering sophisticated analytics. This software is the backbone for many of their integrated solutions in semiconductor manufacturing.

Revenue is further boosted through the sale of software upgrades and new features. These enhancements add value for existing customers, encouraging continued engagement and the adoption of Onto Innovation's evolving technology. In 2023, Onto Innovation reported total revenue of $730.6 million, with a significant portion attributable to their advanced software and service offerings, reflecting the critical role these licensing and upgrade streams play in their financial performance.

- Software Licensing: Core revenue from providing access to proprietary control and analytics software.

- Upgrades and New Features: Sales of updated software versions and additional functionalities.

- Recurring Revenue: This stream contributes to a stable and predictable revenue base.

- Customer Retention: Enhancements encourage long-term customer relationships and repeat business.

Consulting and Application Engineering Services

Onto Innovation provides specialized consulting and application engineering services, a crucial revenue stream that goes beyond just selling equipment. These services are designed to help customers fine-tune their manufacturing processes, effectively integrate new technologies, and tackle specific production hurdles.

This expertise is deeply rooted in Onto Innovation's extensive knowledge of semiconductor process control. By offering these tailored solutions, the company creates a significant value-added component to its business, enhancing customer relationships and generating recurring revenue.

- Leveraging Expertise: Customers benefit from Onto Innovation's deep understanding of semiconductor manufacturing challenges.

- Process Optimization: Services focus on improving efficiency and yield for clients.

- Technology Integration: Assistance is provided to smoothly adopt new semiconductor technologies.

- Value-Added Revenue: This segment generates income beyond initial equipment sales, fostering long-term partnerships.

Onto Innovation's revenue streams are diverse, encompassing equipment sales, recurring services, and software licensing. The company's core business involves selling advanced process control equipment vital for semiconductor manufacturing, with demand driven by industry expansion and technological advancements like AI. For instance, in 2023, Onto Innovation saw substantial revenue from these capital equipment sales, reflecting the robust market for their specialized offerings.

Beyond equipment, Onto Innovation generates significant recurring revenue through service and maintenance contracts, which ensure their complex systems operate optimally. These contracts not only provide a predictable income but also strengthen customer loyalty. Furthermore, the sale of spare parts and consumables is a consistent revenue contributor, directly linked to the utilization of their installed base.

Software licensing and upgrades represent another key revenue pillar. Customers pay for access to proprietary control and analytics software, with additional income generated from new features and enhanced functionalities. Consulting and application engineering services also add value, helping clients optimize their manufacturing processes and integrate new technologies, further diversifying Onto Innovation's income.

| Revenue Stream | Description | Key Drivers | 2023 Data (Illustrative) |

| Equipment Sales | Sale of process control and inspection equipment | Industry expansion, AI demand, new technology adoption | Significant portion of total revenue |

| Service & Maintenance | Recurring revenue from support contracts | Installed base, customer retention, system uptime | High-margin, predictable income |

| Spare Parts & Consumables | Ongoing sales for equipment operation | Equipment utilization, manufacturing activity | Consistent contribution to revenue |

| Software Licensing & Upgrades | Access to proprietary software and new features | Technological advancements, software enhancements | Critical for integrated solutions |

| Consulting & Application Engineering | Expert services for process optimization | Customer need for integration and efficiency | Value-added revenue, partnership building |

Business Model Canvas Data Sources

The Onto Innovation Business Model Canvas is built upon a foundation of robust financial disclosures, detailed market intelligence, and comprehensive industry analysis. These sources ensure a data-driven approach to understanding our value proposition, customer segments, and revenue streams.