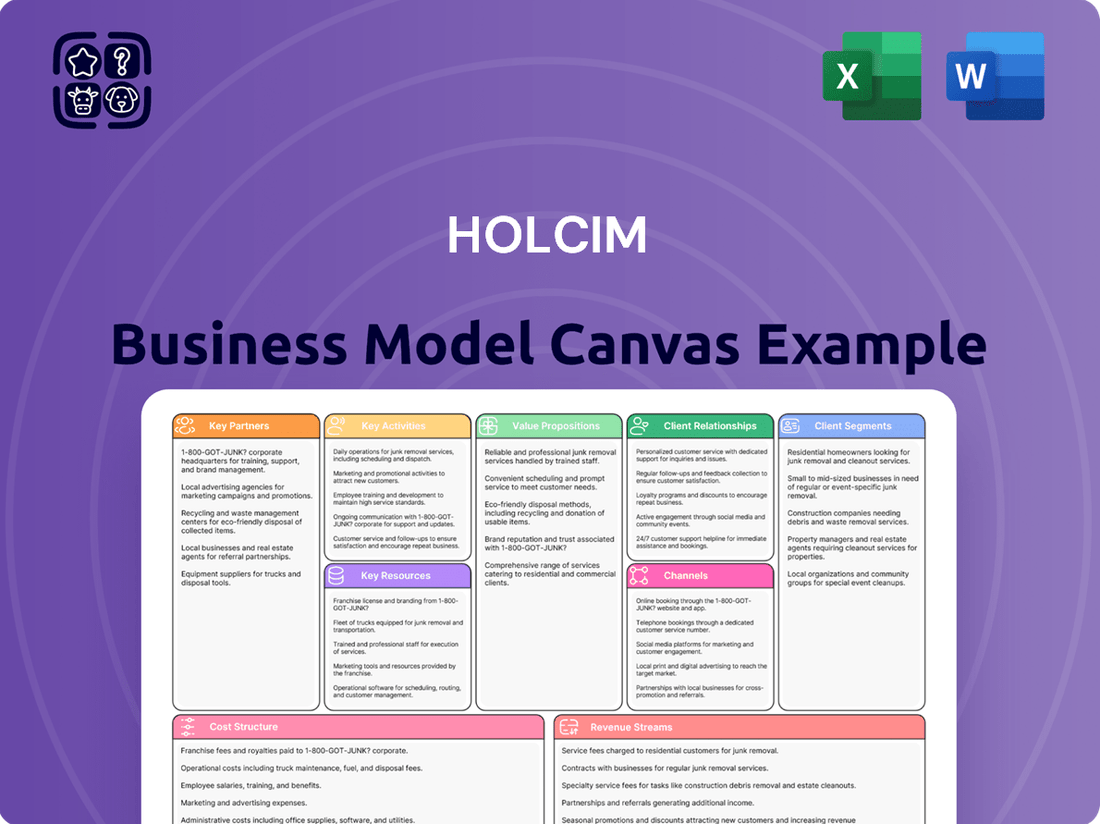

Holcim Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Holcim Bundle

Discover the strategic backbone of Holcim's success with our comprehensive Business Model Canvas. This detailed breakdown illuminates how they connect with customers, deliver value, and generate revenue in the competitive building materials sector. Ready to unlock actionable insights for your own venture?

Partnerships

Holcim actively partners with innovative startups and leading research institutions to pioneer sustainable building technologies. This includes advancements in 3D concrete printing and novel material science, pushing the boundaries of eco-friendly construction.

These collaborations are vital for accelerating the development of solutions that reduce carbon footprints and promote circularity in the building sector. A prime example is the development of OptiCEM, an AI-driven platform designed to refine cement formulations for improved sustainability and performance.

Holcim collaborates with waste management and recycling companies to secure construction and demolition materials (CDM) and other industrial by-products. This strategic alignment is crucial for advancing Holcim's circular economy goals, allowing them to integrate a higher percentage of recycled content into their product lines, such as their ECOPlanet cement range.

By leveraging these partnerships, Holcim aims to significantly boost the use of recycled materials in construction, contributing to a more sustainable built environment. For instance, in 2023, Holcim reported a 30% increase in the use of recycled materials across its operations, a testament to the effectiveness of these collaborations.

Holcim actively partners with universities and research institutions worldwide to drive innovation in sustainable construction. These collaborations focus on fundamental research, exploring novel building science concepts, and cultivating the next generation of talent in green building practices.

For instance, Holcim's research partnerships contribute to the scientific validation of its low-carbon cement and concrete technologies. In 2024, Holcim continued to invest in R&D, with a significant portion of its innovation pipeline stemming from these academic engagements, aiming to accelerate the transition to net-zero construction.

Industry Associations and Standardization Bodies

Holcim actively engages with industry associations and standardization bodies to influence the trajectory of sustainable construction. This involvement is crucial for shaping future practices and advocating for policies that favor low-carbon and circular economy principles in building materials.

By participating, Holcim contributes to the development of green building standards and certifications, ensuring these frameworks align with innovation and environmental goals. For instance, in 2024, Holcim continued its commitment to organizations like the World Green Building Council, aiming to drive widespread adoption of sustainable building practices.

- Industry Influence: Holcim's participation in bodies like the European Cement Association (CEMBUREAU) helps shape regulations and standards for cement production, promoting sustainability.

- Standard Setting: Collaboration on standards for recycled content in building materials, a key focus in 2024, directly impacts product development and market acceptance.

- Policy Advocacy: Engaging with policymakers through these associations allows Holcim to advocate for incentives supporting the circular economy and decarbonization in construction.

- Knowledge Sharing: These platforms facilitate the exchange of best practices, enabling Holcim to stay at the forefront of sustainable innovation and share its own advancements.

Architects, Engineers, and Developers

Holcim's strategic alliances with architects, engineers, and developers are crucial for embedding its sustainable building materials into significant construction ventures. These partnerships foster innovation through co-development, demonstrating novel uses for Holcim's offerings and accelerating their acceptance in the marketplace.

- Architectural Collaboration: Partnering with firms like SOM or Foster + Partners allows Holcim to showcase its low-carbon concrete and advanced building systems in landmark projects, influencing design trends.

- Engineering Integration: Working with engineering consultancies ensures Holcim's materials meet rigorous structural and performance standards, facilitating their specification in complex infrastructure and high-rise buildings.

- Developer Engagement: Collaborations with major real estate developers, such as Lendlease or Brookfield, are key to scaling the adoption of sustainable solutions across residential, commercial, and industrial portfolios.

- Market Influence: These partnerships are instrumental in driving demand for greener building practices, with Holcim's innovations often featured in high-profile developments that set new industry benchmarks.

Holcim's key partnerships extend to technology providers and digital innovators, aiming to enhance operational efficiency and product development. This includes collaborations on data analytics for optimizing supply chains and developing smart building solutions.

These partnerships are critical for integrating digital tools into the construction lifecycle, from design to maintenance. For instance, Holcim's work with software companies in 2024 focused on leveraging AI for predictive maintenance of its manufacturing facilities, aiming to reduce downtime and improve energy efficiency.

Holcim also forms strategic alliances with financial institutions and impact investors to fund sustainable projects and scale green innovations. These partnerships provide the necessary capital to drive large-scale transitions towards net-zero construction.

In 2024, Holcim secured significant funding for its circular economy initiatives, partly through these financial collaborations, enabling investments in new recycling technologies and low-carbon product lines.

| Type of Partner | Focus Area | Impact | Example (2023-2024) |

| Startups & Research Institutions | Sustainable Technologies (3D printing, new materials) | Accelerated innovation, eco-friendly solutions | OptiCEM platform development |

| Waste Management & Recycling Companies | Circular Economy, Recycled Content | Increased use of recycled materials | 30% increase in recycled material use (2023) |

| Universities & Academic Institutions | Fundamental Research, Talent Development | Validation of low-carbon technologies, R&D pipeline | Continued investment in R&D via academic partnerships (2024) |

| Industry Associations & Standardization Bodies | Policy, Standards, Knowledge Sharing | Shaping sustainable practices and regulations | Commitment to World Green Building Council (2024) |

| Architects, Engineers, Developers | Market Adoption, Co-development | Embedding sustainable materials in projects, market influence | Showcasing low-carbon concrete in landmark projects |

| Technology Providers & Digital Innovators | Operational Efficiency, Digital Solutions | Supply chain optimization, smart building integration | AI for predictive maintenance (2024 focus) |

| Financial Institutions & Impact Investors | Project Funding, Scaling Innovations | Capital for sustainable projects, green innovation scaling | Secured funding for circular economy initiatives |

What is included in the product

A detailed exploration of Holcim's business model, structured around the 9 classic Business Model Canvas blocks, offering insights into their customer segments, value propositions, and operational strategies.

Holcim's Business Model Canvas acts as a pain point reliever by providing a structured, visual framework that simplifies complex strategic planning.

It helps alleviate the pain of fragmented thinking by offering a comprehensive, one-page overview of all key business elements.

Activities

Holcim's manufacturing and production of building materials centers on the efficient, large-scale creation of cement, aggregates, and ready-mix concrete. This involves employing sophisticated processes and cutting-edge technologies to guarantee high quality and operational effectiveness. For instance, in 2023, Holcim reported a significant increase in its low-carbon product sales, which are a direct result of these advanced manufacturing capabilities.

A key aspect of Holcim's production strategy is the active integration of recycled materials into its product lines. This commitment to circularity not only reduces waste but also enhances the sustainability profile of its offerings. The company's efforts to lower CO2 emissions throughout its manufacturing operations are also paramount, aligning with global decarbonization goals and reflecting an investment in greener production methods.

Holcim dedicates substantial resources to research and development, focusing on creating a wide array of sustainable and circular building solutions. This commitment is evident in their development of low-carbon cement, such as ECOPlanet, and green concrete, like ECOPact, alongside energy-efficient building systems.

Their R&D efforts extend to exploring novel materials, advanced digital tools, and cutting-edge carbon capture technologies. In 2023, Holcim continued to advance its ECOPact concrete range, with sales growing by 38% globally, demonstrating strong market adoption of their sustainable innovations.

Holcim's distribution and logistics management is a critical activity, focusing on the efficient handling of its global supply chain. This involves managing transportation, warehousing, and the final delivery of building materials to a wide array of customers across the globe. For instance, in 2023, Holcim reported a significant portion of its €30.1 billion revenue was directly tied to the effective movement of its products, underscoring the importance of this operational pillar.

The company's approach ensures that products are available when and where customers need them, maintaining both timeliness and cost-effectiveness. This global network is essential for serving diverse markets, from large construction projects to smaller, regional demands, directly impacting Holcim's competitive edge and customer satisfaction.

Strategic Mergers, Acquisitions, and Divestments

Holcim strategically pursues mergers and acquisitions to bolster its offerings in sustainable building materials and enhance its market reach. For instance, in 2024, the company continued its focus on acquiring businesses that align with its decarbonization and circular economy goals, building on its 2023 acquisitions that significantly expanded its presence in the green building sector.

Divestments are also a key activity, allowing Holcim to streamline its operations and concentrate on high-growth, sustainable segments. This portfolio optimization ensures capital is allocated to areas with the greatest potential for value creation and market leadership.

- Portfolio Enhancement: Holcim actively seeks M&A targets that add sustainable solutions and geographic presence.

- Strategic Divestments: The company divests non-core assets to sharpen its focus on key growth areas.

- 2024 Focus: Continued emphasis on acquiring businesses in circular economy and decarbonization.

- Value Creation: M&A and divestments are driven by the goal of increasing shareholder value and market position.

Sustainability and Circular Economy Initiatives

Holcim is deeply committed to advancing the circular economy within the construction sector. A significant part of this involves boosting the incorporation of recycled construction and demolition waste into their products. They are also actively developing new circular product lines designed for longevity and recyclability.

The company's ECOCycle technology platform is central to these efforts, enabling the processing and reuse of construction materials. Holcim has set bold goals for reducing CO2 emissions and increasing waste recycling rates throughout its global operations, aiming to transform waste into valuable resources.

- Circular Economy Focus: Increasing the use of recycled construction and demolition materials.

- Product Development: Creating innovative circular products for sustainable construction.

- ECOCycle Platform: Utilizing advanced technology to process and reuse waste materials.

- Ambitious Targets: Setting clear goals for CO2 reduction and waste recycling across operations.

Holcim's key activities revolve around the production of building materials, with a strong emphasis on sustainability and circularity. They invest heavily in research and development to create innovative, low-carbon solutions like ECOPlanet cement and ECOPact concrete. Efficient global logistics and supply chain management are crucial for delivering these products effectively to customers worldwide.

Strategic mergers, acquisitions, and divestments are integral to Holcim's business model, allowing them to expand their sustainable offerings and market reach while optimizing their portfolio. The company is dedicated to advancing the circular economy by incorporating recycled materials through its ECOCycle technology platform, aiming to transform waste into valuable resources and reduce CO2 emissions.

| Key Activity | Description | Supporting Data/Focus |

|---|---|---|

| Manufacturing & Production | Efficient, large-scale creation of cement, aggregates, and ready-mix concrete using advanced processes. | Focus on low-carbon product sales growth. |

| Research & Development | Creating sustainable and circular building solutions, including low-carbon materials and energy-efficient systems. | ECOPact concrete sales grew 38% globally in 2023. |

| Distribution & Logistics | Efficient management of global supply chain for timely and cost-effective product delivery. | Effective product movement contributed significantly to €30.1 billion revenue in 2023. |

| Mergers, Acquisitions & Divestments | Strategic portfolio optimization to enhance sustainable offerings and market presence. | Continued focus on acquiring businesses in circular economy and decarbonization in 2024. |

| Circular Economy Advancement | Increasing use of recycled materials and developing circular product lines. | Utilizing ECOCycle technology platform to process and reuse construction waste. |

What You See Is What You Get

Business Model Canvas

The Holcim Business Model Canvas you are previewing is the authentic document you will receive upon purchase. This is not a sample or mockup; it's a direct representation of the comprehensive analysis that will be yours. Once your order is complete, you'll gain full access to this same, professionally structured Business Model Canvas, ready for your strategic insights.

Resources

Holcim operates a substantial global manufacturing and distribution network, encompassing numerous cement plants, aggregate quarries, and ready-mix concrete facilities. This extensive infrastructure allows for localized production and efficient supply chain management across diverse geographic regions.

In 2024, Holcim continued to leverage its vast operational footprint, which includes over 2,000 sites worldwide. This network is fundamental to its ability to meet regional demand for building materials, from essential infrastructure projects to residential construction.

The company's distribution capabilities are supported by a comprehensive logistics system, ensuring timely and cost-effective delivery of products. This global reach is a key competitive advantage, enabling Holcim to serve a broad customer base and adapt to varying market conditions.

Holcim's proprietary technology and innovation capabilities are anchored in its advanced R&D centers, which are crucial for developing next-generation building materials. These centers focus on areas like low-carbon cement and concrete, driving the company's sustainability agenda.

Intellectual property is a key resource, particularly patents and know-how related to circular economy solutions such as their ECOCycle technology. This technology allows for the recycling of construction and demolition waste into new building materials, significantly reducing environmental impact.

Digital tools are integral, enabling Holcim to optimize production processes and refine product formulations. In 2023, Holcim reported a 10% increase in sales for its sustainable solutions, a direct result of these innovation capabilities, highlighting their commercial impact.

Holcim's extensive reserves of high-quality raw materials, including limestone, clay, sand, and gravel, form the bedrock of its cement and aggregates production. These vast deposits are essential for maintaining consistent output and product quality across its global operations.

Securing sustainable access to these vital resources is a critical component of Holcim's business model, ensuring operational continuity and cost efficiency. In 2024, Holcim continued to focus on responsible quarrying and resource management, recognizing the long-term strategic importance of its raw material base.

Skilled Workforce and Expertise

Holcim's business model hinges on a highly skilled workforce. This includes engineers, material scientists, and operational specialists who drive innovation and ensure efficient production. In 2024, Holcim continued to invest in training and development, recognizing that their expertise is fundamental to delivering advanced building solutions and engaging effectively with clients on complex projects.

The company's sustainability experts are also a critical resource, guiding the development and implementation of eco-friendly building materials and practices. This expertise is increasingly vital as the construction industry, including Holcim, faces pressure to reduce its environmental footprint.

- Engineers and Material Scientists: Drive product innovation and quality control.

- Operational Specialists: Ensure efficient and safe manufacturing processes.

- Sustainability Experts: Lead the development of green building solutions.

- Client-Facing Professionals: Provide technical support and tailored solutions for complex projects.

Strong Brand Portfolio and Reputation

Holcim's robust brand portfolio, featuring recognized names like ECOPact and ECOPlanet, is a cornerstone of its business model. These brands are not just labels; they embody Holcim's commitment to sustainability, a critical differentiator in today's market. This strong reputation for quality and environmental stewardship attracts a growing segment of customers prioritizing green building solutions.

The company's leadership in sustainable building solutions is a significant intangible asset, fostering trust and loyalty. In 2023, Holcim reported a 13% increase in its sustainable solutions sales, demonstrating the market's positive reception to its eco-friendly offerings. This brand equity directly translates into a competitive advantage, allowing Holcim to command premium pricing and secure long-term customer relationships.

- Global Brand Recognition: Holcim operates under a suite of well-respected global brands that resonate with customers seeking reliable and innovative building materials.

- Sustainability Leadership: The company's proactive stance and investment in sustainable products, such as low-carbon concrete, have solidified its reputation as an industry leader in environmental responsibility.

- Customer Trust and Loyalty: The strong brand portfolio cultivates deep customer trust, leading to repeat business and a willingness to adopt new, sustainable product lines.

- Market Differentiation: Holcim's brands, particularly those focused on sustainability, clearly differentiate it from competitors, appealing to an increasingly environmentally conscious customer base.

Holcim's key resources include its extensive global manufacturing and distribution network, advanced proprietary technology, significant raw material reserves, and a highly skilled workforce. The company's strong brand portfolio, particularly in sustainable building solutions, is also a crucial asset, fostering customer trust and market differentiation.

In 2024, Holcim's operational footprint comprised over 2,000 sites worldwide, supporting its ability to meet diverse regional demands. The company's commitment to innovation is evident in its R&D centers focused on low-carbon materials, which contributed to a reported 10% increase in sustainable solutions sales in 2023.

Holcim's raw material reserves, including limestone and aggregates, are fundamental to its production capacity and cost efficiency. The company's workforce, comprising engineers, material scientists, and sustainability experts, drives product development and operational excellence, with ongoing investments in training and development throughout 2024.

| Key Resource Category | Specific Examples | 2023/2024 Relevance |

|---|---|---|

| Physical Assets | Global network of 2,000+ sites (cement plants, quarries, RMC facilities) | Ensured localized production and efficient supply chain in 2024. |

| Intellectual Property | ECOCycle technology, patents for circular economy solutions | Drives sustainability agenda and reduces environmental impact. |

| Raw Materials | Limestone, clay, sand, gravel reserves | Underpins consistent output and quality; focus on responsible management in 2024. |

| Human Capital | Engineers, material scientists, sustainability experts | Drove innovation and sustainability focus; ongoing training in 2024. |

| Brand Equity | ECOPact, ECOPlanet brands | Supported a 13% increase in sustainable solutions sales in 2023; market differentiation. |

Value Propositions

Holcim provides innovative building materials like ECOPact concrete and ECOPlanet cement, designed to drastically lower the carbon footprint of construction. This directly addresses the growing demand from clients aiming to achieve their environmental goals and build more sustainably.

By choosing Holcim's low-carbon solutions, customers can actively contribute to a greener built environment, aligning their projects with global sustainability efforts. For instance, ECOPact's carbon reduction can be as high as 30% compared to traditional concrete, making a tangible difference.

Holcim champions a circular economy by transforming construction and demolition debris, alongside other waste materials, into valuable resources. This approach significantly reduces the need for virgin materials, contributing to environmental stewardship and resource conservation. For instance, in 2023, Holcim's operations in Europe processed over 10 million tonnes of construction and demolition waste, diverting it from landfills and incorporating it into new building products.

Holcim offers advanced building materials like specialized concretes and roofing systems that boost performance and energy efficiency. This directly meets the growing need for stronger, longer-lasting infrastructure and buildings.

In 2024, Holcim continued to innovate, with its ECOPact concrete range, for example, significantly reducing the carbon footprint of construction projects, a key driver for sustainable development.

Comprehensive Building Solutions and Systems

Holcim moves beyond simply supplying cement and aggregates. They provide a full suite of integrated building solutions, covering everything from the ground up – foundations, structural elements, all the way to roofing and insulation systems. This comprehensive approach allows customers to achieve truly holistic and sustainable building outcomes.

This end-to-end offering significantly simplifies the procurement process for builders and developers. It also ensures that all the different components used in a construction project are designed to work together seamlessly, promoting greater efficiency and reliability.

- Holistic Sustainability: Holcim's integrated solutions are designed to enhance the overall sustainability of a building project, from material sourcing to energy efficiency in the finished structure.

- Simplified Procurement: Offering a broad range of building components under one roof streamlines the purchasing process for customers, saving time and reducing logistical complexities.

- System Compatibility: By providing a connected range of products, Holcim ensures that its solutions are compatible with each other, leading to better performance and fewer installation issues.

- Market Reach: In 2024, Holcim continued to expand its portfolio of sustainable building solutions, aiming to capture a larger share of the green building market, which is projected for significant growth.

Global Reach and Local Expertise

Holcim's unique blend of global reach and local expertise allows it to serve a vast array of construction needs. This dual capability ensures that whether a project is a massive infrastructure undertaking or a smaller residential build, Holcim can deliver precisely what's required.

The company's extensive international network means access to a broad range of resources and best practices. Simultaneously, its deep understanding of local markets, including specific regulations and material availability, enables the creation of highly tailored solutions. This adaptability is crucial for reliable supply chains, especially in diverse regional contexts.

For instance, in 2024, Holcim continued to leverage its global footprint to support major infrastructure projects worldwide. In Europe, its focus on sustainable building solutions, like low-carbon concrete, met stringent environmental regulations. Meanwhile, in emerging markets, Holcim adapted its product offerings to suit local construction methods and affordability requirements, demonstrating its commitment to providing relevant and reliable support across all scales of development.

- Global Network: Access to diverse resources and international best practices.

- Local Adaptation: Tailored solutions meeting specific regional needs and regulations.

- Scalability: Support for projects ranging from large infrastructure to residential construction.

- Reliable Supply: Consistent delivery of materials and expertise across varied markets.

Holcim offers a comprehensive suite of building solutions, simplifying procurement and ensuring system compatibility for clients. This end-to-end approach guarantees that all components work together seamlessly, leading to enhanced project efficiency and reliability.

Customer Relationships

Holcim fosters robust customer relationships by offering dedicated sales and technical support. Their teams provide expert guidance on everything from choosing the right products to applying them effectively, with a special focus on sustainable building solutions tailored to individual project needs.

This commitment ensures customers not only receive the best materials but also the knowledge to use them optimally, leading to greater project success and satisfaction. For instance, in 2024, Holcim's technical support teams engaged with over 50,000 construction projects globally, directly contributing to the successful implementation of their sustainable building materials.

Holcim cultivates enduring partnerships with major clients and for significant projects by employing dedicated key account managers. These teams provide tailored solutions and preferential services, fostering collaborative development of new construction methods. This approach is crucial for securing ongoing business and building strategic alliances.

In 2023, Holcim's commitment to key accounts contributed significantly to its commercial success, with a notable portion of its €30.5 billion revenue stemming from these long-term relationships. For instance, its work on major infrastructure projects, like the development of sustainable urban centers, exemplifies this strategy.

Holcim’s digital platforms, including its website and customer portals, offer extensive product catalogs, detailed technical specifications, and crucial sustainability data. This digital approach empowers customers by providing easy access to information, allowing them to make well-informed choices and simplify their purchasing journey.

In 2024, Holcim continued to invest in enhancing its online customer experience. For instance, their digital tools are designed to streamline the procurement process, reducing lead times and improving order accuracy. This focus on digital accessibility directly translates to increased customer convenience and transparency in transactions.

Sustainability Collaboration and Reporting

Holcim actively partners with its customers to advance their sustainability objectives. This includes providing guidance and support for achieving green building certifications, a critical aspect of modern construction. For instance, Holcim's ECOPact concrete range offers lower carbon footprints, aiding customers in meeting their environmental targets.

Transparent reporting on the environmental performance of its offerings is a cornerstone of Holcim's customer relationships. This data empowers clients to understand and communicate the reduced impact of their projects. By 2023, Holcim reported a 23% reduction in its Scope 1 and 2 CO2 emissions intensity compared to 1990, a figure that directly benefits customers seeking to lower their own environmental footprint.

- Customer Support for Green Certifications: Holcim assists clients in navigating and achieving certifications like LEED and BREEAM.

- Transparent Environmental Reporting: Providing clear data on product lifecycle impacts to aid customer ESG reporting.

- Shared Sustainability Goals: Aligning Holcim's efforts with customer commitments to climate action and circular economy principles.

Customer Training and Knowledge Sharing

Holcim actively engages in customer training and knowledge sharing, focusing on sustainable construction practices. These initiatives aim to educate clients on new product applications and the principles of the circular economy, thereby fostering the adoption of greener building methods.

By empowering customers with this knowledge, Holcim not only strengthens its relationships but also contributes to the broader advancement of the construction industry towards more environmentally conscious operations. For instance, in 2023, Holcim reported a 20% increase in participation in their sustainability workshops across Europe.

- Sustainable Practices Education: Holcim offers workshops and online resources detailing eco-friendly building techniques.

- Product Application Guidance: Training sessions cover the optimal use of Holcim's innovative and sustainable product lines.

- Circular Economy Principles: Knowledge sharing emphasizes material reuse and waste reduction in construction projects.

- Industry Advancement: Empowering customers drives wider adoption of sustainable solutions, benefiting the entire sector.

Holcim's customer relationships are built on a foundation of comprehensive support, from initial product selection to ongoing project success, with a strong emphasis on sustainable solutions. Their dedicated teams offer technical expertise, ensuring customers can effectively utilize materials, particularly those designed for reduced environmental impact.

Key account management is central to Holcim's strategy for major clients, providing tailored solutions and preferential services that foster long-term partnerships and collaborative innovation. This focus on strategic relationships was evident in 2023, where a significant portion of Holcim's €30.5 billion revenue was derived from these vital connections.

Digital platforms enhance customer engagement by offering accessible product information, technical specifications, and sustainability data, simplifying the purchasing process. Holcim's investment in these tools in 2024 aimed to streamline procurement and improve order accuracy, boosting customer convenience.

Furthermore, Holcim actively partners with customers to achieve their sustainability goals, offering guidance on green building certifications and transparently reporting on product environmental performance. This commitment is reflected in their 2023 report of a 23% reduction in Scope 1 and 2 CO2 emissions intensity compared to 1990, directly benefiting clients aiming to lower their own project footprints.

| Customer Relationship Aspect | Description | 2023/2024 Data/Example |

|---|---|---|

| Technical & Sales Support | Expert guidance on product selection and application, with a focus on sustainability. | In 2024, supported over 50,000 global construction projects with technical advice. |

| Key Account Management | Dedicated managers for major clients, offering tailored solutions and preferential services. | Contributed significantly to €30.5 billion revenue in 2023 through long-term relationships. |

| Digital Customer Experience | Online portals with product catalogs, technical data, and sustainability information. | Investment in 2024 to streamline procurement and enhance order accuracy. |

| Sustainability Partnership | Assistance with green certifications and transparent environmental reporting. | In 2023, reported a 23% reduction in CO2 emissions intensity (vs. 1990), aiding customer ESG goals. |

| Knowledge Sharing | Training on sustainable construction practices and circular economy principles. | 2023 saw a 20% increase in participation in sustainability workshops across Europe. |

Channels

Holcim's direct sales force is a critical channel for engaging major clients like large contractors, developers, and industrial customers. This approach allows for highly personalized service, offering technical expertise and customized product solutions essential for complex construction projects.

This direct engagement facilitates direct negotiation and fosters strong, long-term relationships. In 2024, Holcim continued to invest in its sales teams, recognizing that direct interaction is key to understanding and meeting the specific needs of its high-value clientele, thereby securing significant project wins.

Holcim reaches smaller contractors, individual builders, and DIY customers through a vast network of authorized distributors, building material retailers, and hardware stores. This strategy ensures widespread availability of its products across diverse geographic locations.

In 2024, Holcim continued to strengthen its retail partnerships, recognizing the crucial role these channels play in accessing the fragmented smaller customer segments. These partnerships are vital for maintaining broad market reach and ensuring product accessibility for a wide range of building needs.

Holcim is significantly expanding its digital footprint through online platforms and e-commerce. This strategy aims to make product discovery, ordering, and access to digital tools more convenient for a broader customer base, thereby increasing market reach.

In 2024, Holcim reported a substantial increase in digital sales, with online channels contributing a growing percentage to overall revenue. This digital shift is vital for enhancing customer engagement and streamlining the purchasing process for building materials.

Project-Specific Supply Chains

For substantial infrastructure and construction endeavors, Holcim crafts specialized, streamlined supply chains. This ensures that vast quantities of materials reach the project site precisely when and where needed, a critical factor for project success.

This tailored strategy is designed to meet the specific, often complex, logistical requirements of large-scale developments. It allows for greater control over material flow and reduces potential delays.

- Dedicated Logistics: Project-specific teams manage the entire supply chain, from sourcing to delivery, for major contracts.

- Just-in-Time Delivery: Holcim aims to deliver materials directly to the construction site as they are required, minimizing on-site storage needs and associated risks.

- Volume Optimization: These chains are built to handle the high-volume demands of projects like new airport terminals or high-speed rail lines.

- Cost Efficiency: By optimizing routes and minimizing handling, these project-specific chains contribute to overall project cost savings.

Innovation Hubs and Showrooms

Holcim's Innovation Hubs and showrooms act as vital touchpoints for demonstrating its cutting-edge sustainable building materials and technologies. These spaces are designed to actively engage key stakeholders like architects, engineers, and developers, fostering a collaborative environment for exploring new ideas. For instance, Holcim's commitment to innovation is reflected in its extensive R&D spending, which has consistently grown, with investments in sustainable solutions forming a significant portion of their 2024 capital expenditure plans.

These physical channels are instrumental in facilitating hands-on demonstrations of product performance and sustainability benefits. They also serve as platforms for co-creation workshops, allowing Holcim to directly incorporate feedback from industry professionals into the development of future offerings. By showcasing advancements such as low-carbon concrete formulations and circular economy principles in practice, these hubs accelerate the adoption of greener building practices across the industry.

- Showcasing Sustainable Solutions: Holcim's hubs display products like ECOPact concrete, which in 2024 saw increased adoption for projects aiming to reduce embodied carbon.

- Stakeholder Engagement: These spaces facilitate direct interaction with architects, engineers, and developers, promoting dialogue on sustainable construction.

- Fostering Co-creation: Collaborative sessions within the hubs help in the joint development of innovative building concepts and material applications.

- Demonstrating Performance: Physical demonstrations highlight the durability, efficiency, and environmental advantages of Holcim's advanced materials.

Holcim leverages a multi-channel strategy to reach diverse customer segments, from large-scale industrial clients to individual builders. This approach ensures broad market coverage and tailored engagement for specific needs.

The company's direct sales force is crucial for high-value clients, offering technical expertise and customized solutions. In 2024, Holcim's investment in these teams underscored their importance for securing major projects. Simultaneously, an extensive network of distributors and retailers serves smaller contractors and DIY customers, ensuring widespread product accessibility.

Holcim's digital channels are rapidly expanding, with online platforms and e-commerce simplifying product discovery and purchasing. This digital push in 2024 resulted in a notable rise in online sales, enhancing customer convenience and broadening market reach.

For large infrastructure projects, Holcim employs specialized, streamlined supply chains. These are designed for just-in-time delivery and volume optimization, critical for project timelines and cost efficiency. Innovation Hubs and showrooms further enhance engagement by showcasing sustainable materials and fostering co-creation with industry professionals, with R&D investments in green solutions a key focus in 2024.

| Channel | Target Customer | 2024 Focus/Activity | Key Benefit |

|---|---|---|---|

| Direct Sales Force | Major Contractors, Developers, Industrial Clients | Investment in sales teams for personalized service and technical expertise. | Securing large projects, fostering long-term relationships. |

| Distributors & Retailers | Smaller Contractors, Individual Builders, DIY Customers | Strengthening retail partnerships for broad market access. | Widespread availability, reaching fragmented customer segments. |

| Digital Platforms & E-commerce | Broad Customer Base | Substantial increase in digital sales and online contribution to revenue. | Enhanced convenience, streamlined purchasing, increased market reach. |

| Specialized Supply Chains | Large Infrastructure & Construction Projects | Tailored logistics for high-volume, just-in-time delivery. | Meeting complex logistical needs, reducing delays, cost efficiency. |

| Innovation Hubs & Showrooms | Architects, Engineers, Developers | Showcasing sustainable materials, fostering co-creation, R&D investment in green solutions. | Accelerating adoption of sustainable practices, co-developing future offerings. |

Customer Segments

Large-scale infrastructure developers, encompassing government bodies, public works departments, and private enterprises, are key customers for Holcim. These entities are engaged in significant projects like highways, bridges, airports, and dams, demanding substantial quantities of robust and long-lasting construction materials. For instance, the global infrastructure spending was projected to reach $15 trillion by 2040, with a significant portion dedicated to transportation and energy projects, highlighting the immense demand these developers represent.

Commercial and residential developers, including construction firms building offices, retail spaces, and housing, represent a key customer segment. They are actively looking for building materials that balance cost-effectiveness with environmental responsibility and visual appeal. In 2024, the global construction market was valued at approximately $13.2 trillion, with sustainability and innovation driving material choices.

Industrial clients, encompassing sectors like manufacturing, energy, and mining, represent a crucial segment for Holcim. These businesses often require highly specialized building materials tailored to demanding operational environments. Think of high-strength concrete for heavy machinery foundations or specialized aggregates for extreme weather resistance.

Their needs extend to durable roofing systems and materials that can withstand corrosive elements or extreme temperatures. For instance, in 2024, the global construction market for industrial facilities saw significant investment, particularly in renewable energy infrastructure, where materials with extended lifespans and specific performance characteristics are paramount.

Individual Builders and Small Contractors

Individual Builders and Small Contractors represent a vital customer segment for Holcim. This group encompasses independent contractors, smaller construction companies, and even individual homeowners tackling renovation or smaller building endeavors. Their purchasing habits often lean towards retail channels where they seek accessible and adaptable building materials.

For these customers, product availability and ease of use are paramount. They often operate with tighter budgets and timelines, making reliable sourcing and straightforward application of materials crucial for project success. Holcim's ability to cater to these needs through its retail network and product innovation directly impacts its engagement with this segment.

- Key Needs: Readily available, versatile building materials.

- Purchasing Behavior: Primarily through retail channels.

- Project Scope: Renovation and small-scale building projects.

- Value Proposition: Accessibility, ease of use, and reliable product performance.

Public Sector and Government Bodies

Public sector entities, including government bodies and municipalities, are significant customers for Holcim, particularly in infrastructure and urban development projects. These organizations often have procurement policies that favor sustainable and environmentally certified materials. For instance, in 2024, many governments worldwide have intensified their focus on green building standards, influencing material choices for public works.

Holcim's offerings align with these demands by providing low-carbon concrete solutions and recycled aggregates. These products help public sector clients meet their sustainability targets and comply with stringent environmental regulations. The company's commitment to reducing embodied carbon in its materials is a key differentiator for these customers.

- Infrastructure Projects: Government bodies frequently commission large-scale infrastructure projects such as roads, bridges, and public transportation systems, where Holcim's advanced and sustainable building materials are essential.

- Urban Planning and Development: Municipalities involved in urban renewal and smart city initiatives seek durable, eco-friendly materials for public buildings, parks, and residential developments.

- Sustainable Procurement Policies: Many public sector organizations in 2024 are mandated to prioritize suppliers and materials that adhere to strict environmental performance criteria, including carbon footprint reduction.

- Regulatory Compliance: Holcim's products help government entities meet evolving building codes and environmental regulations, ensuring compliance and long-term project viability.

Holcim serves a broad customer base, from massive infrastructure developers and commercial builders to industrial clients and individual contractors. Each segment has distinct needs regarding material performance, cost, and sustainability. Public sector entities, in particular, are increasingly prioritizing eco-friendly and certified materials for their projects.

| Customer Segment | Key Needs | Purchasing Behavior | Project Focus | Market Relevance (2024 Data) |

|---|---|---|---|---|

| Large-scale Infrastructure Developers | Robust, long-lasting materials, high volume | Direct procurement, long-term contracts | Roads, bridges, airports, dams | Global infrastructure spending projected to reach $15 trillion by 2040. |

| Commercial & Residential Developers | Cost-effectiveness, sustainability, aesthetics | Contractors, distributors, direct sales | Offices, retail, housing | Global construction market valued at ~$13.2 trillion in 2024. |

| Industrial Clients | Specialized, high-performance materials for demanding environments | Direct sales, specialized distributors | Manufacturing, energy, mining facilities | Significant investment in industrial facilities, especially renewable energy infrastructure. |

| Individual Builders & Small Contractors | Accessibility, versatility, ease of use | Retail channels, local suppliers | Renovations, small-scale construction | Reliable sourcing and product availability are crucial. |

| Public Sector Entities | Sustainable, environmentally certified materials, regulatory compliance | Government tenders, procurement portals | Public infrastructure, urban development | Intensified focus on green building standards by governments worldwide. |

Cost Structure

Holcim's cost structure heavily relies on procuring essential raw materials such as limestone, clay, sand, and gravel. These natural resources are the bedrock of cement production. In 2024, the company continued to manage these procurement expenses, which form a substantial part of its operational outlay.

Beyond traditional materials, Holcim also incurs costs for alternative raw materials and fuels, crucial for optimizing its production processes and sustainability efforts. The global price volatility of these commodities directly influences the company's profitability, making efficient sourcing a key strategic imperative.

Energy consumption is a significant cost for Holcim, as producing cement, aggregates, and concrete demands substantial electricity and fuel. In 2023, Holcim reported that its energy costs represented a notable portion of its operating expenses, though specific percentages vary by region and production method.

To combat these rising energy expenses and environmental concerns, Holcim is actively pursuing energy efficiency initiatives across its operations. For instance, the company is increasing its use of alternative fuels, such as biomass and waste-derived fuels, which can offer cost savings compared to traditional fossil fuels and contribute to a lower carbon footprint.

Holcim's extensive global presence and the inherently heavy, bulky nature of its building materials mean that logistics and transportation costs are a significant component of its overall cost structure. These expenses encompass freight charges for moving raw materials to production sites and finished goods to customers, ongoing fleet maintenance for its vast transportation network, and the strategic management of its distribution channels worldwide.

For instance, in 2023, Holcim reported that its cost of sales, which includes significant logistics components, stood at CHF 22.0 billion. This highlights the substantial investment required to ensure timely and efficient delivery of its products across diverse markets, impacting overall profitability and operational efficiency.

Research and Development Expenses

Holcim's cost structure heavily features investments in Research and Development (R&D) to drive innovation in sustainable building materials and circular economy solutions. These R&D expenditures are fundamental to developing next-generation products and decarbonization technologies, ensuring Holcim remains at the forefront of the industry. For instance, in 2023, Holcim reported R&D expenses of CHF 250 million, a significant portion allocated to advancing its low-carbon product portfolio and digital solutions.

These R&D outlays are critical for maintaining Holcim's competitive edge and addressing global sustainability challenges. The company actively pursues innovations in areas such as alternative fuels, advanced cementitious materials, and construction waste recycling technologies. This commitment to innovation is reflected in their ongoing projects and partnerships aimed at reducing the environmental footprint of construction.

- Investment in Sustainable Product Development: Holcim dedicates substantial resources to creating new products with lower environmental impact, such as ECOPact concrete.

- Circular Technology Advancements: Costs are incurred in developing and implementing technologies for recycling construction and demolition waste, turning it into valuable resources.

- Decarbonization Solutions: Significant R&D spending targets innovations for reducing CO2 emissions across the value chain, including new binders and carbon capture technologies.

- Innovation Leadership: These R&D expenses are a strategic cost to maintain and enhance Holcim's position as a leader in sustainable construction innovation.

Operational and Labor Costs

Holcim's operational and labor costs are substantial, encompassing the upkeep of its extensive network of manufacturing plants and the maintenance of sophisticated machinery. These expenses are critical for ensuring efficient production and product quality across its global operations. For instance, in 2024, Holcim continued to invest in upgrading its facilities to enhance energy efficiency and reduce its environmental footprint, a significant portion of which falls under operational expenditure.

The company's workforce, spread across manufacturing, sales, and administrative roles worldwide, represents a major cost component. This includes salaries, wages, health benefits, and other employee-related expenses. Holcim's commitment to its employees involves ongoing training and development programs, which also contribute to these labor costs, aiming to maintain a skilled and motivated global team to support its strategic objectives.

- Plant Operations & Maintenance: Expenses for running and servicing Holcim's global manufacturing facilities and equipment.

- Labor Expenses: Costs associated with salaries, benefits, and training for Holcim's worldwide workforce.

- 2024 Focus: Investments in facility upgrades for energy efficiency and environmental improvements were a key operational cost driver.

Holcim's cost structure is significantly influenced by raw material procurement, with limestone, clay, and aggregates forming the base. Energy consumption is another major expense, as cement production is energy-intensive. In 2023, energy costs were a notable portion of operating expenses, with ongoing efforts in 2024 to optimize this through alternative fuels.

Logistics and transportation represent a substantial cost due to the heavy nature of building materials. In 2023, Holcim's cost of sales, including logistics, was CHF 22.0 billion. Investments in R&D for sustainable products and decarbonization technologies, totaling CHF 250 million in 2023, are also key cost drivers.

| Cost Category | Key Components | 2023 Data (if available) | 2024 Focus |

| Raw Materials | Limestone, clay, sand, gravel, alternative fuels | Substantial portion of procurement | Efficient sourcing, managing price volatility |

| Energy | Electricity, fuels for production | Notable portion of operating expenses | Energy efficiency initiatives, increased alternative fuel use |

| Logistics & Transportation | Freight, fleet maintenance, distribution | Included in CHF 22.0 billion cost of sales | Optimizing global supply chains |

| Research & Development | Sustainable product innovation, decarbonization tech | CHF 250 million | Advancing low-carbon products and digital solutions |

| Operations & Labor | Plant upkeep, machinery maintenance, workforce salaries & benefits | Ongoing investment in facility upgrades | Maintaining skilled workforce, operational efficiency |

Revenue Streams

Holcim's primary revenue stream comes from the sale of cement, a fundamental building material. This includes a broad portfolio of cement types, catering to various construction needs, from residential projects to large-scale infrastructure. In 2023, Holcim's net sales reached CHF 30.1 billion, with the cement business being a substantial contributor to this figure.

Holcim generates significant revenue from the sale of aggregates, which are fundamental building materials. This income stream comes from quarrying, processing, and distributing essential components like crushed stone, sand, and gravel used in concrete, asphalt, and various construction applications.

In 2024, the aggregates segment remained a cornerstone of Holcim's financial performance. The company's extensive network of quarries and production facilities ensures a consistent supply, meeting the high demand from infrastructure projects and the broader construction industry globally.

Holcim generates revenue by producing and delivering ready-mix concrete, a fundamental building material for numerous construction projects. This includes a growing portfolio of sustainable concrete options, such as their ECOPact range, which caters to environmentally conscious developers and builders.

In 2023, Holcim's sales of ready-mix concrete, alongside other building materials, contributed significantly to their overall net sales, which reached CHF 30.1 billion. The company's strategic focus on sustainable solutions like ECOPact is a key driver for future revenue growth in this segment.

Sales of Advanced Building Solutions and Products

Holcim generates significant revenue from its advanced building solutions and products. This includes earnings from a diverse and expanding range of high-value offerings such as precast concrete, asphalt, and roofing systems under its Elevate brand. The company is also seeing growth in insulation and other specialized construction materials.

This segment represents a crucial avenue for Holcim's strategic development and future growth. For instance, in 2023, Holcim's High-Performance Solutions & Products segment saw strong performance, contributing to the company's overall financial results.

- Precast Concrete: Revenue from customized concrete elements for various construction projects.

- Asphalt: Earnings from high-quality asphalt for road construction and maintenance.

- Roofing Systems (Elevate): Sales of advanced roofing solutions, contributing to a growing market segment.

- Insulation and Specialized Products: Income from energy-efficient insulation materials and other niche building products.

Services and Value-Added Offerings

Holcim generates revenue through a variety of services that enhance its core product offerings. These include expert technical consulting, guiding customers through complex construction projects, and specialized sustainable construction advisory, helping clients meet environmental goals.

Waste co-processing also contributes significantly, turning waste materials into valuable resources for cement production. This not only diversifies revenue but also strengthens customer relationships by providing comprehensive solutions.

- Technical Consulting: Holcim's experts offer guidance on product application, project planning, and on-site support, ensuring optimal performance and efficiency for customers.

- Sustainable Construction Advisory: This service helps clients navigate green building certifications, material selection for reduced environmental impact, and life cycle assessments, aligning with global sustainability trends.

- Waste Co-processing: Holcim leverages its industrial infrastructure to process various waste streams, converting them into alternative fuels and raw materials for its cement kilns, creating a circular economy revenue stream.

Holcim's revenue streams are diverse, encompassing core building materials, advanced solutions, and value-added services. The sale of cement, aggregates, and ready-mix concrete forms the bedrock of their income, supported by a growing portfolio of specialized products and sustainable offerings.

In 2024, the company continued to focus on these segments, leveraging its global presence and commitment to innovation. Holcim's strategic acquisitions and investments in sustainable technologies are designed to bolster these revenue channels and drive future growth.

The company's advanced building solutions, including precast concrete, asphalt, and roofing systems, represent a significant and expanding revenue area. Services like technical consulting and waste co-processing further diversify income and strengthen customer partnerships.

| Revenue Stream | Description | 2023 Contribution (Illustrative) |

|---|---|---|

| Cement | Sale of various cement types for construction. | Significant portion of CHF 30.1 billion net sales. |

| Aggregates | Quarrying, processing, and distribution of stone, sand, gravel. | Key contributor to overall sales performance. |

| Ready-Mix Concrete | Production and delivery of concrete, including sustainable options. | Substantial contributor to net sales. |

| Advanced Building Solutions | Precast concrete, asphalt, roofing, insulation, specialized products. | Strong performance and strategic growth area. |

| Services | Technical consulting, sustainable advisory, waste co-processing. | Diversifies revenue and enhances customer relationships. |

Business Model Canvas Data Sources

The Holcim Business Model Canvas is informed by a blend of internal financial data, extensive market research reports, and strategic insights derived from operational performance. This comprehensive data approach ensures each component of the canvas is grounded in factual information.