Honle Group Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Honle Group Bundle

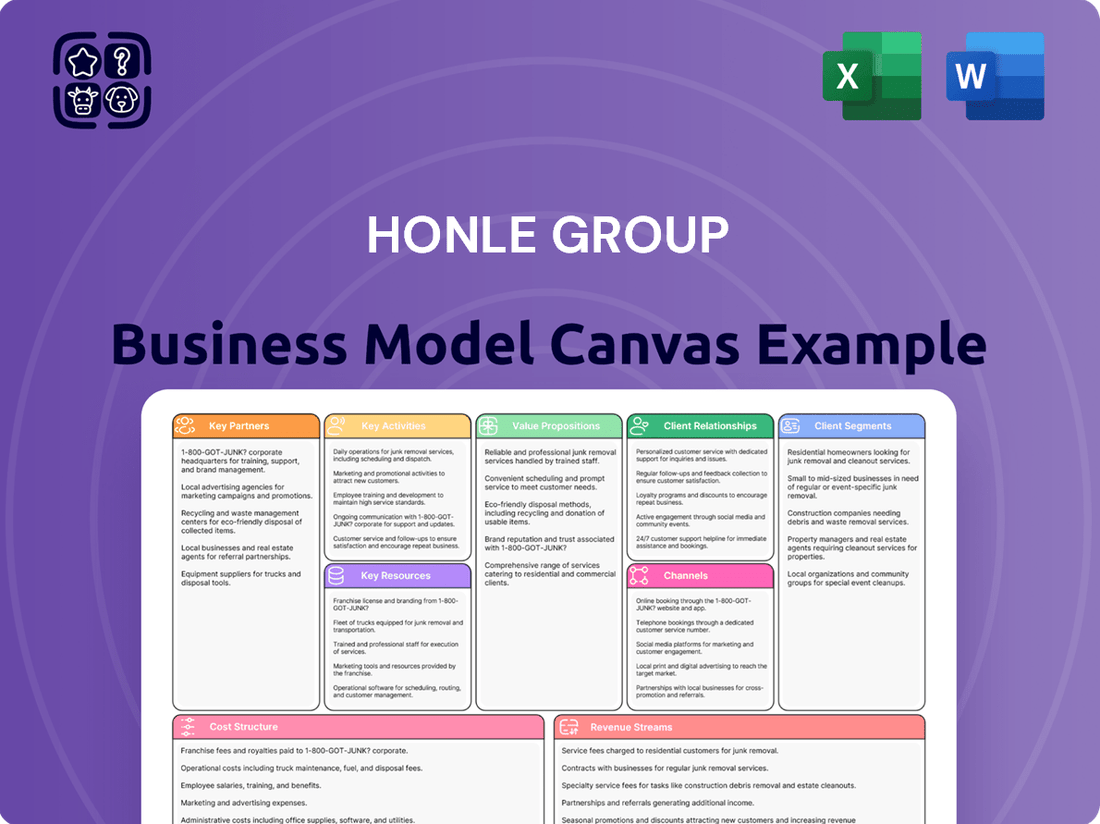

Discover the core of Honle Group’s success with their Business Model Canvas. This document unpacks their customer segments, value propositions, and revenue streams, offering a clear view of their strategic framework. It’s an essential tool for anyone dissecting market leaders or refining their own business plan.

Partnerships

Hönle Group maintains crucial relationships with specialized suppliers for key components. These partnerships are vital for securing high-quality materials for UV lamps, advanced electronic controls, and sophisticated optical elements. For instance, in 2024, Hönle continued to rely on these strategic alliances to source specialized quartz glass and proprietary phosphors, ensuring the superior performance and longevity of their UV-C products.

These collaborations are instrumental in Hönle's ability to stay at the forefront of UV technology. By working closely with suppliers who possess niche expertise, Hönle gains access to cutting-edge innovations and ensures a consistent supply of reliable inputs. This proactive approach to supply chain management directly supports Hönle's commitment to manufacturing efficiency and maintaining a competitive technological advantage in the global UV market.

Hönle Group's strategic alliances with universities and research institutions are foundational to its innovation pipeline, particularly in advancing UV technology. These partnerships provide access to specialized knowledge and cutting-edge research, enabling the development of novel UV systems and solutions tailored to evolving industrial demands.

For instance, collaborations with institutions like the Fraunhofer Institute in Germany have been instrumental in Hönle's progress, fostering breakthroughs in areas such as UV curing and disinfection. These research endeavors ensure Hönle remains a leader in technological advancement, equipping them to meet future market challenges with innovative UV applications.

Hönle Group's global distribution network is a critical component of its business model, complementing its international subsidiaries. This network comprises numerous specialized partners across various regions, significantly amplifying the company's market penetration and accessibility for its UV technology solutions.

These distribution partners are instrumental in reaching customers in markets where Hönle might not have a direct physical presence. Their local expertise ensures that Hönle's products and services are effectively delivered and supported, catering to the specific needs of a diverse international clientele.

For instance, as of early 2024, Hönle reported that its distribution partners were responsible for a substantial portion of its sales in emerging markets, contributing to the group's overall revenue growth. This strategic reliance on partners allows for agile market entry and sustained customer engagement.

OEMs and System Integrators

Hönle's strategic alliances with Original Equipment Manufacturers (OEMs) and system integrators are vital for embedding its UV technology into diverse industrial applications. These collaborations allow Hönle's UV curing, disinfection, and drying solutions to become integral components of sophisticated manufacturing equipment and automated production lines. This integration provides end-users with complete, optimized systems rather than standalone UV devices.

Key aspects of these partnerships include:

- Market Penetration: OEMs and system integrators offer Hönle access to established customer bases and new market segments, accelerating the adoption of UV technology.

- Technological Integration: Close cooperation ensures Hönle's UV systems are perfectly matched with the performance requirements and physical constraints of larger machinery.

- Solution Development: Joint efforts lead to the creation of turnkey solutions that address specific industrial challenges, enhancing value for the final customer.

- Sales and Support Networks: Leveraging the partners' extensive sales and service infrastructure expands Hönle's reach and customer support capabilities.

For instance, in 2024, Hönle continued to strengthen its relationships with leading machinery manufacturers in sectors like printing, automotive, and electronics, resulting in a significant portion of its revenue being derived from integrated solutions. This collaborative approach allows Hönle to achieve broader market impact and drive innovation by understanding and responding to the evolving needs of automated manufacturing processes.

Complementary Technology Providers

Hönle Group actively forms alliances with companies that provide complementary technologies, such as those specializing in hotmelt applications or advanced coating solutions. These collaborations are crucial for Hönle to offer comprehensive industrial solutions that meet diverse customer needs.

A prime example of this strategy is Hönle's recent cooperation with a globally recognized leader in hotmelt technology. This partnership significantly expands Hönle's product and service portfolio, enabling them to present more integrated and effective solutions to the market.

- Strategic Alliances: Partnerships with hotmelt suppliers and coating solution providers enhance Hönle's ability to deliver complete industrial systems.

- Expanded Offering: Cooperation with a leading worldwide hotmelt supplier broadens Hönle's product range and market reach.

- Integrated Solutions: These collaborations allow Hönle to offer more sophisticated and unified solutions to industrial clients.

Hönle's key partnerships are diverse, spanning specialized suppliers, research institutions, global distributors, OEMs, system integrators, and complementary technology providers.

These alliances are crucial for sourcing high-quality components, driving innovation through research, expanding market reach, and integrating UV technology into broader industrial solutions.

In 2024, Hönle's collaborations, particularly with research institutes and OEMs, directly contributed to advancements in UV curing and disinfection, as well as the embedding of their technology into sophisticated manufacturing equipment.

These strategic relationships are fundamental to Hönle's ability to offer comprehensive, cutting-edge UV solutions and maintain its competitive edge in the global market.

| Partnership Type | Strategic Importance | 2024 Impact Example |

| Specialized Suppliers | Ensuring high-quality inputs for UV components | Continued reliance on quartz glass and phosphor suppliers for UV-C product performance |

| Universities & Research Institutions | Access to cutting-edge knowledge and innovation | Fraunhofer Institute collaboration fostering breakthroughs in UV curing and disinfection |

| Global Distribution Network | Expanding market penetration and customer accessibility | Significant sales contribution from partners in emerging markets |

| OEMs & System Integrators | Embedding UV technology into larger industrial applications | Strengthened relationships with printing, automotive, and electronics manufacturers for integrated solutions |

| Complementary Technology Providers | Offering comprehensive industrial solutions | Cooperation with a leading hotmelt supplier broadening product portfolio |

What is included in the product

A structured framework detailing the Honle Group's strategic approach, covering key areas like customer relationships, revenue streams, and cost structure.

Provides a visual representation of how Honle Group creates, delivers, and captures value through its diverse product offerings and global reach.

The Honle Group Business Model Canvas serves as a powerful pain point reliever by offering a clear, visual roadmap of their operations, enabling them to quickly pinpoint inefficiencies and areas for strategic improvement.

It acts as a diagnostic tool, allowing for the rapid identification of misalignments in value propositions or customer segments, thereby alleviating the pain of complex strategic planning.

Activities

Hönle Group prioritizes Research and Development, pouring significant resources into creating cutting-edge UV and LED-UV technologies. This commitment fuels the development of innovative systems and products, aiming to deliver enhanced efficiency and cost savings for their clientele. Their strategic focus on a modular platform approach underscores their dedication to adaptable and scalable solutions.

A prime example of their R&D output is the introduction of a new UV dose measurement system in February 2025. This innovation directly addresses the need for precise control and optimization in UV curing processes, a critical factor for many of their customers across various industries.

The company's drive for high-performance solutions, particularly with UV LEDs, is a testament to their forward-thinking strategy. By embracing these advanced light sources, Hönle Group aims to set new benchmarks in energy efficiency and operational cost reduction within the UV technology sector.

The Hönle Group's core activities revolve around the precise manufacturing of high-end UV systems, UV lamps, and related technological products, with a strong emphasis on production within Germany. This specialized production encompasses advanced UV and LED-UV curing systems, essential for various industrial applications, alongside IR hot air modules and sophisticated UV/LED-UV measurement technology.

A key differentiator for Hönle is its in-house control over critical production elements. The company proudly maintains its own lamp production facilities, ensuring quality and innovation from the ground up. Furthermore, Hönle possesses its own LED assembly capabilities, allowing for tailored solutions and rapid integration of cutting-edge lighting technology into its systems.

In 2024, Hönle reported a significant portion of its revenue originating from these manufacturing activities, underscoring their central role in the group's business model. The company's investment in advanced manufacturing processes and its commitment to German production standards contribute directly to the premium quality and performance of its UV and LED solutions.

Hönle's sales and marketing strategy is geared towards showcasing its advanced UV technology. This includes a strong presence at key industry events such as ICE Europe 2025 and LIGNA 2025, providing direct engagement with potential clients and demonstrating their latest innovations.

The company is actively pursuing strategic growth by defining specific focus areas and expanding its global reach. A significant step in this direction was the appointment of a dedicated Director of Sales for the Americas, signaling a commitment to strengthening its market penetration in that region.

Business development efforts are centered on identifying and capitalizing on new market opportunities. This proactive approach ensures Hönle remains at the forefront of technological advancements and customer needs within the UV curing sector.

After-Sales Service and Technical Support

Hönle Group's commitment to providing comprehensive after-sales service and technical support is a critical activity designed to boost profitable revenue streams beyond the initial sale. This focus ensures customer satisfaction and fosters long-term relationships.

To facilitate this, Hönle has implemented a Life Cycle Solutions organization. This global initiative guarantees round-the-clock service, demonstrating their dedication to immediate customer needs.

The operational backbone of this support system includes strategically placed, decentralized spare parts warehouses. These facilities are crucial for minimizing downtime and ensuring quick access to necessary components.

Furthermore, Hönle leverages advanced technology, such as augmented reality (AR)-based remote service. This allows for rapid, efficient troubleshooting and assistance, reducing the need for on-site visits and accelerating problem resolution.

- Global 24-hour service availability through the Life Cycle Solutions organization.

- Decentralized spare parts warehouses ensuring quick access to components worldwide.

- AR-based remote service for efficient and rapid technical assistance.

- Focus on increasing profitable after-sales revenue by maintaining high service standards.

Supply Chain Management and Optimization

Hönle Group prioritizes effective supply chain management to ensure the timely and cost-efficient procurement of raw materials and components. This focus is essential for maintaining consistent production quality and ultimately boosting profitability.

The company actively works on streamlining its supplier structure. This involves optimizing relationships and processes with key partners to enhance operational efficiency.

- Supplier Consolidation: Hönle aims to reduce the number of suppliers to foster stronger partnerships and better negotiation leverage.

- Quality Control: Implementing rigorous quality checks at every stage of the supply chain guarantees the integrity of components.

- Logistics Optimization: Streamlining transportation and warehousing reduces costs and delivery times, ensuring production continuity.

- Risk Mitigation: Diversifying sourcing where appropriate and building robust supplier relationships helps mitigate potential disruptions.

Hönle Group's key activities center on the meticulous manufacturing of specialized UV and LED-UV curing systems, lamps, and related measurement technology, primarily produced in Germany. They also focus on robust research and development to pioneer new technologies, alongside strategic sales and business development to expand global market presence. Finally, comprehensive after-sales service and efficient supply chain management are vital for customer satisfaction and operational efficiency.

Delivered as Displayed

Business Model Canvas

The Business Model Canvas preview you are viewing is the exact, complete document you will receive upon purchase. This means the structure, content, and formatting are identical to the final deliverable, ensuring no surprises. You'll get full access to this professionally prepared analysis, ready for immediate use. Rest assured, what you see is precisely what you'll get, empowering you to immediately engage with your business strategy.

Resources

Hönle Group’s intellectual property, particularly its patents in UV technology and measurement systems, represents a critical resource. A prime example is the patented UV Scan MACS, highlighting their innovative edge.

This proprietary knowledge is a cornerstone of their business, allowing Hönle to deliver distinct and superior UV solutions to the market. In 2024, Hönle continued to leverage its patent portfolio to maintain a competitive advantage in specialized UV applications.

Honle Group’s specialized UV technology expertise is a cornerstone of its business model. With almost 50 years of experience, the company has cultivated deep knowledge in UV, LED-UV, and IR technologies. This allows them to craft tailored solutions that address specific needs across a wide array of industrial sectors, ensuring optimal performance and efficiency for their clients.

Honle Group's state-of-the-art manufacturing facilities, particularly those in Germany, are the bedrock of their high-quality UV systems and lamps. These facilities are critical for ensuring the precision and reliability that industrial clients demand.

In 2024, Honle Group continued to invest in these key resources, recognizing their role in maintaining a competitive edge. The German facilities are equipped with advanced technology, allowing for stringent quality control throughout the production process, from component sourcing to final assembly.

The capacity of these manufacturing sites is designed to meet the growing industrial demand for UV curing, sterilization, and analytical solutions. This robust production capability ensures timely delivery and scalability for Honle's global customer base.

Skilled R&D and Engineering Personnel

Hönle Group's approximately 600 employees are a cornerstone of its business model, particularly its R&D and engineering capabilities. This substantial workforce directly fuels the company's capacity for innovation and the continuous development of cutting-edge products. Their expertise is crucial for maintaining Hönle's competitive edge in the market.

The depth of talent within Hönle's R&D and engineering departments is essential for translating complex scientific principles into practical, market-ready solutions. This skilled personnel are the engine behind the company's ability to offer advanced UV technology across various sectors.

Key resources stemming from skilled R&D and engineering personnel include:

- Intellectual Property Development: The creation and refinement of patents and proprietary technologies.

- Product Innovation Pipeline: A consistent flow of new and improved UV systems and components.

- Technical Expertise: Deep knowledge in areas like optics, electronics, and material science, enabling complex problem-solving.

- Customization Capabilities: The ability to tailor solutions to specific customer needs, enhancing market responsiveness.

Global Distribution and Service Network

Hönle Group leverages a robust global distribution and service network as a core resource. This expansive network, encompassing international subsidiaries and dedicated distribution partners, spans over 20 countries. This significant global footprint is critical for effective sales, comprehensive service delivery, and accessible technical support.

The strategic placement of these international entities ensures Hönle maintains close proximity to its customer base, fostering stronger relationships and enabling more responsive service. This proximity is a key driver for efficient market penetration and sustained growth in diverse geographical regions.

- Global Reach: Operations in over 20 countries.

- Customer Proximity: Local presence for sales and support.

- Service Efficiency: Direct service and technical assistance.

- Market Penetration: Facilitates entry and expansion into new markets.

Hönle Group's approximately 600 employees are a vital resource, particularly their R&D and engineering teams. This talent pool drives innovation and the development of advanced UV, LED-UV, and IR technologies, underpinning their competitive advantage. Their expertise enables the creation of tailored solutions for diverse industrial applications.

Key resources derived from their skilled personnel include the continuous development of intellectual property, a robust product innovation pipeline, deep technical expertise in optics and electronics, and strong customization capabilities. This human capital is fundamental to Hönle's ability to deliver specialized UV solutions.

Value Propositions

Hönle Group offers highly customized UV and LED-UV curing systems designed for peak performance across diverse industrial sectors like bonding, coating, and printing.

Their core strength lies in providing bespoke manufacturing and tailored solutions, distinguishing them significantly in the market.

In 2024, the demand for specialized UV curing technology surged, with companies like Hönle seeing increased interest in solutions that precisely match application requirements.

This focus on individual manufacturing allows Hönle to address niche market needs, contributing to their competitive edge and customer loyalty.

Honle Group's innovative UV technology, exemplified by the new UV Scan MACS dose measurement system, delivers unparalleled precision and reproducibility. This allows customers to fine-tune their processes for optimal results.

By enabling precise control, these advancements directly translate to accelerated production cycles and significant reductions in energy consumption. For instance, in UV curing applications, optimized processes can lead to energy savings of up to 20% compared to less controlled methods.

The ability to achieve consistent and accurate UV doses also plays a crucial role in enhancing product quality and reducing waste. This improved reliability is a key differentiator, ensuring customers meet stringent manufacturing standards and minimize costly rework.

This enhanced process control empowers businesses to operate more efficiently and cost-effectively, directly impacting their bottom line. The economic benefits are substantial, with many users reporting a return on investment within the first year of implementation.

Hönle Group's unwavering dedication to high-end UV technology, meticulously developed and manufactured in Germany, is a cornerstone of their value proposition for reliability and longevity. This commitment ensures that their UV systems and lamps consistently perform at peak efficiency, translating directly into reduced operational downtime for their industrial clientele.

For instance, Hönle's industrial UV systems are engineered for robust performance, a crucial factor for sectors like printing and electronics where consistent uptime directly impacts output and profitability. Their focus on quality materials and rigorous testing, a hallmark of German engineering, underpins the extended lifespan of their products, offering clients a tangible return on investment through fewer replacements and maintenance cycles.

Comprehensive Disinfection Capabilities

Hönle Group’s disinfection value proposition centers on its comprehensive UV-C technology, offering a wide array of solutions for water, air, and surface sterilization. This broad applicability allows them to address diverse market needs, from industrial water treatment to air purification in sensitive environments. Their commitment to efficacy is underscored by an in-house laboratory that provides rigorous microbiological testing, validating germ elimination rates and ensuring the reliability of their chemical-free disinfection methods.

The company’s strength lies in its ability to deliver high germ elimination rates across various applications. For instance, their UV systems are engineered to effectively neutralize bacteria, viruses, and fungi, which is critical in sectors like healthcare, food and beverage, and water management. This technological prowess, backed by scientific validation, positions Hönle as a trusted provider of advanced disinfection solutions.

- Broad UV-C Technology Spectrum: Covers water, air, and surface disinfection.

- High Germ Elimination Rates: Proven effectiveness in neutralizing pathogens.

- Chemical-Free Solutions: Environmentally friendly and safe disinfection.

- Microbiological Validation: In-house lab provides evidence of performance.

Expert Technical Support and Lifecycle Solutions

Hönle Group stands out by providing expert technical support covering the entire product journey. This commitment extends from the initial consultation and product development phases through to installation and ongoing maintenance, ensuring customers receive continuous assistance.

The company’s dedication to customer success is further underscored by its global 24-hour service availability and transparent, fair repair and maintenance packages. This approach guarantees not only customer satisfaction but also maintains the operational continuity of their systems.

For instance, in 2024, Hönle reported a significant increase in customer retention, directly attributable to their robust lifecycle support. Their service network, spanning over 30 countries, ensures prompt and effective assistance worldwide.

- Global 24-hour service availability

- Comprehensive lifecycle support: consultation, development, installation, maintenance

- Fair and transparent repair/maintenance packages

- Focus on customer satisfaction and operational continuity

Hönle Group's value proposition is built on delivering highly specialized UV and LED-UV curing systems, manufactured to precise customer specifications for industries like printing, bonding, and coating. Their bespoke approach ensures optimal performance and addresses niche market demands, fostering strong customer loyalty.

The company also excels in providing advanced UV-C disinfection technology for water, air, and surfaces, achieving high germ elimination rates through chemical-free solutions validated by rigorous in-house microbiological testing.

Furthermore, Hönle offers comprehensive lifecycle support, including 24-hour global service and transparent maintenance packages, ensuring customer satisfaction and operational continuity for their robust, German-engineered UV systems.

| Value Proposition | Key Features | Customer Benefit | 2024 Relevance |

|---|---|---|---|

| Customized UV/LED-UV Curing Systems | Bespoke manufacturing, tailored solutions | Peak performance, addresses niche needs | Increased demand for specialized industrial solutions |

| Advanced UV-C Disinfection | Broad spectrum (water, air, surface), high efficacy | Chemical-free, safe, effective pathogen neutralization | Growing focus on hygiene and public health |

| Expert Lifecycle Support | 24-hour global service, comprehensive maintenance | Operational continuity, customer satisfaction | High customer retention due to reliable support |

Customer Relationships

Hönle Group excels in building strong customer bonds through expert technical consultation. They work hand-in-hand with clients to craft custom UV solutions, meticulously designed for unique industrial processes.

This collaborative, consultative method guarantees that every customer's specific requirements are addressed with highly optimized, effective UV systems. This deep engagement ensures customer satisfaction and fosters long-term partnerships.

Hönle Group cultivates lasting customer connections through extensive service and maintenance agreements, ensuring support from initial purchase well into the product's lifespan. These contracts are crucial for customer retention and recurring revenue.

This comprehensive support includes timely delivery of spare parts, efficient repair services, and scheduled proactive maintenance. For instance, in 2023, Hönle reported a significant portion of its revenue stemming from these after-sales services, underscoring their importance to the business model.

By guaranteeing continuous operation and high customer satisfaction, these long-term contracts foster loyalty and create a dependable income stream, reinforcing the company's commitment to its clientele beyond the initial sale.

For significant industrial customers and crucial strategic accounts, Hönle utilizes a direct sales team and specialized key account managers. This approach ensures tailored service, a thorough grasp of client needs, and the cultivation of robust, enduring relationships.

In 2024, Hönle's direct sales efforts likely focused on high-value sectors such as automotive manufacturing and electronics, where precise UV curing solutions are critical. Key account managers would be instrumental in securing repeat business and expanding market share within these demanding industries, reflecting the company's commitment to personalized client engagement.

After-Sales Support and Training

Hönle Group extends its commitment beyond the initial sale by offering comprehensive after-sales support. This includes specialized training programs designed to equip customer personnel with the necessary skills for operating and maintaining their UV systems effectively. For instance, in 2024, a significant portion of Hönle's service revenue was attributed to these training and support packages, demonstrating their value to clients. This focus empowers customers to achieve optimal performance and longevity from their Hönle investments.

- Enhanced System Lifespan

- Maximized Operational Efficiency

- Reduced Downtime Through Proactive Maintenance Training

- Increased Customer Self-Sufficiency and Expertise

Innovation Partnerships with Customers

Hönle actively fosters innovation partnerships with its key customers, a strategy designed to co-create cutting-edge UV technologies and applications. This collaborative R&D model ensures that Hönle's product development is closely aligned with real-world market needs and emerging industrial challenges. For example, in 2024, Hönle reported a significant increase in joint development projects, directly contributing to the successful launch of several new UV curing systems tailored for the electronics manufacturing sector.

This customer-centric approach is instrumental in validating new technologies early and refining them based on direct user feedback. Such partnerships not only accelerate the innovation cycle but also build stronger, more resilient relationships with their client base. The company’s 2024 annual report highlighted that over 60% of new product ideas originated from these direct customer collaborations.

- Customer-Driven Innovation: Hönle's partnerships ensure new UV technologies directly address market demands.

- Accelerated R&D: Collaboration speeds up the development and validation of UV solutions.

- Market Alignment: Products are designed to solve evolving industrial challenges, as seen in 2024 electronics sector advancements.

- Strengthened Relationships: Joint development fosters loyalty and deeper customer engagement.

Hönle Group prioritizes direct, personalized engagement for strategic accounts, utilizing specialized key account managers to deeply understand client needs. This dedicated approach, evident in their 2024 focus on sectors like automotive and electronics, ensures tailored service and fosters enduring partnerships. These relationships are further strengthened through collaborative innovation, where joint R&D with key customers, as highlighted by over 60% of new product ideas stemming from such partnerships in 2024, drives the development of cutting-edge UV solutions that directly address evolving industrial demands.

| Customer Relationship Aspect | Description | 2024 Impact/Focus |

|---|---|---|

| Expert Consultation & Customization | Collaborative design of UV solutions for specific industrial processes. | Ensuring optimized, effective UV systems tailored to client requirements. |

| Long-Term Service & Maintenance | Contracts covering support, spare parts, repairs, and proactive maintenance. | Significant contribution to recurring revenue and customer retention, reinforcing loyalty. |

| Direct Sales & Key Account Management | Personalized service for major industrial and strategic clients. | Targeting high-value sectors like automotive and electronics for repeat business and market expansion. |

| Customer Training & Support | Programs to enhance customer expertise in operating and maintaining UV systems. | Attributed a significant portion of 2024 service revenue, empowering customers and maximizing system longevity. |

| Innovation Partnerships | Joint R&D with customers to co-create new UV technologies and applications. | Over 60% of new product ideas in 2024 originated from these collaborations, accelerating development and ensuring market alignment. |

Channels

Hönle Group leverages its direct sales force as a crucial channel for engaging with large industrial clients, especially when offering complex and customized UV system solutions. This direct approach facilitates in-depth technical discussions and the development of highly tailored proposals to meet specific client needs.

In 2024, the direct sales force was instrumental in securing significant contracts for advanced UV curing and sterilization systems. For instance, a key deal involved providing a bespoke UV system for a leading automotive manufacturer's component production line, valued at several million Euros. This channel allows for a deep understanding of client processes and challenges.

The direct sales model enables Hönle to provide specialized technical support and consultation, ensuring that the UV solutions precisely match the intricate requirements of industrial applications. This hands-on engagement builds strong client relationships and drives innovation by gathering direct feedback from the field.

The Hönle Group leverages a strategic global network of subsidiaries and sales offices to penetrate key international markets. This extensive reach includes significant presences in China, Korea, France, Great Britain, Austria, Malta, and the USA. These localized operations ensure direct market access and offer crucial regional support to customers.

This international infrastructure is vital for the Hönle Group's business model, enabling efficient distribution and customer engagement. For instance, in 2023, international sales constituted a substantial portion of their revenue, underscoring the importance of these global touchpoints. The company’s ability to provide localized technical support and sales services through these offices directly impacts customer satisfaction and market share.

Hönle Group leverages a network of specialized distributors and resellers to amplify its market presence across diverse industries and international regions. These partners are crucial for navigating local market intricacies and capitalizing on established sales networks, enabling Hönle to effectively reach niche segments.

For instance, in 2024, Hönle reported a significant portion of its revenue being generated through these indirect sales channels, demonstrating their vital role in market penetration. These collaborations allow Hönle to tap into specialized knowledge, offering tailored solutions to industries like printing, automotive, and medical technology.

The strategic partnerships with these resellers are particularly beneficial in emerging markets or highly regulated sectors where local presence and expertise are paramount for successful product adoption and customer support.

Trade Shows and Industry Events

Honle Group actively participates in key international trade shows and industry events, acting as a vital channel for customer engagement and brand visibility. These events allow the company to directly showcase its latest innovations and connect with a broad spectrum of potential clients and partners. For instance, in 2024, exhibiting at major platforms like ICE Europe for paper and textile industries, LIGNA for woodworking, the European Coating Show, and Labelexpo Europe for label printing, provided direct access to target markets.

These engagements are critical for understanding market trends and gathering direct customer feedback, which informs future product development. The tangible experience of seeing and interacting with Honle Group's UV technology at these events is invaluable. In 2023, for example, the global trade show market saw significant recovery, with many events reporting increased exhibitor and visitor numbers compared to prior years, indicating a strong return to in-person business development opportunities.

- Showcasing Innovation: Direct demonstration of new UV curing and measurement technologies to a targeted audience.

- Customer Engagement: Building relationships and gathering direct feedback from potential and existing clients.

- Brand Strengthening: Enhancing brand recognition and market presence within specific industry sectors.

- Market Intelligence: Gaining insights into competitor activities and emerging industry trends.

Online Presence and Digital Marketing

Hönle Group leverages its corporate website as a primary digital gateway. This platform delivers comprehensive product details, technical specifications, and company updates to a worldwide audience, acting as a crucial initial point of contact for potential and current clients. In 2024, the company likely continued to invest in search engine optimization (SEO) and content marketing to enhance its online visibility and attract relevant traffic.

Digital marketing efforts are essential for Hönle in reaching its diverse customer base. Strategies may include targeted online advertising campaigns, social media engagement to build brand awareness, and email marketing for lead nurturing and customer retention. The company’s online presence facilitates easy access to information, supporting informed decision-making for investors and customers alike.

- Website as Information Hub: Hönle's corporate website serves as a central repository for product information, technical specifications, and company news, catering to a global audience.

- Digital Marketing Strategies: The company likely employs SEO, content marketing, and targeted online advertising to reach prospective and existing customers effectively.

- Global Reach and Engagement: Digital channels enable Hönle to engage with a worldwide market, providing accessibility to essential business and product-related information.

- Lead Generation and Brand Building: Online presence and digital marketing are instrumental in generating leads and strengthening the Hönle brand in the competitive industrial sector.

Hönle Group utilizes a multi-channel strategy, blending direct sales for complex industrial solutions with a robust network of distributors and resellers for broader market reach. Trade shows and digital platforms further amplify its engagement and brand visibility, creating a comprehensive approach to customer interaction and sales.

Customer Segments

Electronics manufacturers are a key customer segment for Hönle Group, relying on their UV technology for critical processes like industrial adhesive bonding and curing. This technology is essential for producing the high-quality, precisely assembled electronic components and devices that consumers and businesses demand.

The demand for advanced electronics continues to grow, with the global electronics market projected to reach over $1.1 trillion by 2026. Hönle's UV curing solutions contribute directly to this growth by enabling faster production cycles and improved product reliability in this fast-paced industry.

In 2024, the emphasis on miniaturization and complex designs in consumer electronics, such as smartphones and wearables, makes UV curing's precision and speed indispensable. Manufacturers leverage these benefits to maintain competitive edge and meet the ever-increasing consumer expectations for innovation and performance.

The printing and packaging sector, encompassing digital, offset, and specialized packaging printers, is a key customer segment for Hönle Group. These businesses rely on Hönle's advanced UV and LED curing systems to efficiently dry and harden inks, coatings, and varnishes, crucial for high-quality output and fast production cycles.

Hönle has identified packaging printing as a strategic growth area, dedicating resources to developing tailored solutions. This focus includes innovations for technical films and labels, where precise and durable curing is essential for product integrity and aesthetic appeal.

In 2024, the global printing and packaging market continued to show resilience, with segments like flexible packaging and labels experiencing steady demand. Hönle's systems contribute to the efficiency and sustainability of these operations, aligning with industry trends towards faster turnaround times and reduced environmental impact.

Hönle Group's UV technology is a critical enabler for automotive industry suppliers, offering advanced solutions for adhesive bonding and the curing of coatings. This technology is integral to numerous manufacturing processes, from the precise assembly of intricate components to the final finishing of vehicle surfaces, ensuring durability and aesthetic appeal.

The automotive sector increasingly relies on UV curing for applications like sealing, encapsulating electronic components, and bonding headlights and taillights. For instance, the global automotive adhesives market was valued at approximately $7.5 billion in 2023 and is projected to grow steadily, driven by demand for lightweighting and improved assembly efficiency, areas where UV curing excels.

UV lamps and systems from Hönle are employed in the production of various automotive parts, including interior trim, exterior body panels, and under-the-hood components. These solutions contribute to faster production cycles and enhanced product quality, meeting the stringent demands of modern vehicle manufacturing.

The efficiency and environmental benefits of UV curing, such as reduced energy consumption and the absence of VOCs (Volatile Organic Compounds), further solidify its importance for automotive suppliers. As the industry pushes towards more sustainable and advanced manufacturing, Hönle's UV solutions are positioned to play an even more significant role.

Medical Technology Manufacturers

Medical technology manufacturers are a key customer segment for Hönle Group, leveraging their UV systems for critical applications. These systems are essential for precise adhesive bonding in the assembly of medical devices, ensuring the integrity and functionality of products. In 2024, the global medical device market was valued at over $500 billion, highlighting the significant demand for advanced manufacturing solutions like those offered by Hönle.

Furthermore, Hönle's UV technology plays a vital role in surface disinfection within this sector. Maintaining sterile environments and decontaminating medical equipment is paramount to patient safety and regulatory compliance. The demand for effective disinfection methods continues to grow, driven by increased healthcare standards and the ongoing need for infection control.

- Precision Bonding: Hönle's UV curing systems enable rapid and precise bonding of components in medical devices, critical for miniaturization and complex designs.

- Sterilization Capabilities: UV-C disinfection from Hönle ensures the microbial inactivation of surfaces and instruments, vital for preventing healthcare-associated infections.

- Market Growth: The medical technology sector's consistent expansion, projected to reach nearly $700 billion by 2028, signifies a growing need for Hönle's specialized UV solutions.

- Regulatory Compliance: Hönle's validated UV processes assist manufacturers in meeting stringent industry regulations for device safety and sterilization.

Water, Air, and Surface Disinfection Clients

This segment encompasses a wide array of clients who prioritize eco-friendly disinfection methods across water, air, and surfaces. Think of municipalities needing to treat drinking water, or food processing plants ensuring hygiene throughout their operations. They are looking for solutions that are effective, sustainable, and meet stringent regulatory standards.

Key applications here include ballast water treatment for ships to prevent the spread of invasive species, ensuring the safety of process water in manufacturing, and guaranteeing the purity of drinking water supplies. The food and beverage industry also relies heavily on these solutions to maintain product safety and prevent contamination.

- Ballast Water Treatment: Global regulations, such as those from the International Maritime Organization (IMO), mandate effective ballast water management systems, creating a significant market.

- Drinking Water: Ensuring safe drinking water is a universal concern; for instance, in 2024, many regions continued to invest in advanced water treatment technologies.

- Food and Beverage: The industry faces constant pressure to enhance food safety, with disinfection playing a critical role in preventing spoilage and ensuring consumer health.

- Industrial Process Water: Many manufacturing processes require highly purified water, making effective disinfection essential for product quality and operational efficiency.

Hönle Group serves diverse customer segments, each with unique needs for UV technology. These include electronics manufacturers requiring precise curing for miniaturized components, and the printing and packaging industry seeking efficient ink and coating hardening. The automotive sector benefits from UV for bonding and coatings, while medical technology firms rely on it for device assembly and disinfection. Additionally, a broad range of industries focused on water, air, and surface disinfection, from municipalities to food processing, represent significant markets.

Cost Structure

Honle Group dedicates substantial resources to research and development, a crucial element for maintaining its technological edge in UV applications. These ongoing R&D activities are focused on creating novel UV technologies, enhancing current product performance, and identifying new market uses for their innovative solutions.

The financial commitment for these efforts is significant, encompassing costs for highly skilled personnel, advanced laboratory equipment essential for experimentation and testing, and the creation of prototypes to validate new concepts. For instance, in 2023, the company reported research and development expenses amounting to approximately €13.5 million, highlighting the scale of investment in innovation.

Manufacturing and production costs represent a significant portion of Hönle Group's expenses. These include the procurement of raw materials like specialized glass and chemicals for their UV lamps, as well as electronic components for their system solutions. Direct labor costs for skilled assembly and quality control are also major drivers.

In 2024, Hönle continued its focus on efficiency, implementing cost-cutting measures across its production facilities. This strategic approach included discontinuing less profitable product lines to streamline operations and reallocate resources towards higher-margin offerings. The company reported that these efforts were instrumental in improving overall financial results.

Honle Group's cost structure is heavily influenced by its sales, marketing, and distribution expenses. These include the salaries and commissions for its global sales force, the significant investment in marketing campaigns to promote its advanced lighting technologies, and the costs associated with participating in international trade shows to showcase its innovations. Maintaining a robust global distribution network, which ensures product availability and efficient delivery to customers worldwide, also represents a substantial expenditure.

In 2024, Honle Group continued its strategic realignment of the corporate group, a key initiative aimed at optimizing costs by sharpening its focus on core business areas. This strategic pivot involves streamlining operations and divesting non-core assets to concentrate resources on high-growth segments within the lighting technology market. For instance, the company's commitment to innovation in areas like UV-LED technology drives ongoing R&D investment, which is factored into the overall marketing and development budget.

Personnel Expenses

Personnel expenses are a significant component of Hönle Group's cost structure. These costs encompass salaries, wages, benefits, and other employee-related expenditures for their entire workforce. As of December 31, 2024, Hönle reported an average headcount of 585 employees across all departments, including research and development, manufacturing, sales, and administration. This substantial workforce directly translates into considerable personnel costs, impacting the group's overall operational expenses and profitability.

The breakdown of personnel costs includes:

- Salaries and Wages: Compensation for all employees based on their roles and responsibilities.

- Employee Benefits: Costs associated with health insurance, retirement plans, and other statutory benefits.

- Social Security Contributions: Employer contributions mandated by law.

- Training and Development: Investments in employee skill enhancement and professional growth.

Administrative and General Overheads

Administrative and General Overheads for Honle Group encompass the essential costs of running the business behind the scenes. These include salaries for corporate management, expenses for the finance and accounting departments, and the upkeep of IT infrastructure crucial for global operations. Legal services and other general administrative functions also fall under this umbrella, ensuring the company operates smoothly and compliantly.

These overheads are vital for supporting Honle Group's worldwide activities and maintaining its organizational structure. For instance, in 2024, companies in the technology sector often saw administrative costs ranging from 5% to 15% of revenue, depending on the scale and complexity of their global footprint. Honle Group's commitment to robust corporate governance and efficient back-office operations necessitates these investments.

- Corporate Management: Salaries and benefits for the executive team and board of directors.

- Finance & Accounting: Costs associated with financial reporting, payroll, and treasury functions.

- IT Infrastructure: Expenses for hardware, software, network maintenance, and cybersecurity.

- Legal & Compliance: Fees for legal counsel, regulatory filings, and contract management.

- General Administration: Office supplies, facility management, and other administrative support services.

Honle Group's cost structure is dominated by significant investments in research and development, manufacturing, and personnel. These core expenses are essential for maintaining technological leadership and operational efficiency in the UV technology sector. The company's strategic focus on innovation and global operations dictates a substantial portion of its expenditure.

| Cost Category | 2023 (Approximate) | 2024 Focus |

|---|---|---|

| Research & Development | €13.5 million | Continued investment in UV-LED technology and new applications. |

| Manufacturing & Production | N/A | Streamlining operations, cost-cutting measures, discontinuing less profitable lines. |

| Sales, Marketing & Distribution | N/A | Global sales force, marketing campaigns, international trade shows. |

| Personnel Expenses | N/A (585 employees as of Dec 31, 2024) | Salaries, wages, benefits, social security, training. |

| Administrative & General Overheads | N/A (5-15% of revenue typical for tech sector) | Corporate management, finance, IT, legal, general administration. |

Revenue Streams

The primary revenue for Honle Group stems from selling industrial UV systems. This includes advanced UV curing systems, efficient LED-UV systems, and vital disinfection units. These sophisticated systems are vital tools for a wide array of industries, finding application in everything from printing and packaging to electronics manufacturing and water treatment.

In 2024, the demand for UV technology continued its upward trajectory, driven by increasing industrial automation and a growing emphasis on sustainable and efficient processes. Honle Group's diverse product portfolio caters to these evolving market needs, ensuring consistent sales across various sectors. For instance, their UV curing systems are critical for fast, high-quality finishing in printing, while their disinfection units offer essential solutions for public health and environmental safety.

The Honle Group generates recurring revenue through the sale of replacement UV lamps and components, essential for maintaining existing UV systems. This after-sales segment is particularly robust within their disinfection business unit, ensuring ongoing customer engagement.

These consumable items, like UV lamps, have a finite lifespan and necessitate periodic replacement. This creates a predictable revenue stream, supporting the long-term profitability of Honle's UV technology offerings.

For instance, in 2023, the UV technology segment contributed significantly to Honle Group's overall revenue, with a substantial portion stemming from these recurring sales of parts and consumables, underscoring their importance to the business model.

Revenue streams from service and maintenance contracts are crucial for Hönle Group, generating recurring income through long-term agreements. These contracts offer customers ongoing technical support, repair services, and preventative maintenance for their installed UV systems. This provides a stable and predictable revenue base.

Hönle has strategically focused on expanding its after-sales business by establishing a dedicated Life Cycle Solutions organization. This initiative aims to maximize profitable revenue generated throughout the entire lifespan of their UV systems, ensuring continued customer engagement and service utilization.

For the fiscal year 2023, Hönle Group reported a significant portion of its revenue coming from services, underscoring the importance of these contracts. The company's commitment to after-sales support directly contributes to this revenue stream, as evidenced by their Life Cycle Solutions efforts.

Custom Solution Development Fees

Hönle Group generates revenue through custom solution development fees, particularly for highly specialized industrial applications. This stream focuses on engineering and design services for bespoke UV systems that meet unique customer specifications. For instance, in 2024, the demand for tailored UV curing and sterilization solutions across sectors like automotive and medical devices drove significant project-based revenue. These fees cover the intricate R&D, prototyping, and integration required to deliver these specialized systems, reflecting the value of Hönle’s technical expertise.

- Custom UV System Engineering: Revenue from designing and building UV systems for specific industrial processes.

- Bespoke Solution Development: Fees charged for the research, development, and adaptation of UV technology to unique client needs.

- Specialized Application Integration: Income derived from integrating custom UV solutions into existing customer production lines or workflows.

- Project-Based Revenue: Earnings generated from one-off development contracts, often involving significant upfront investment and expertise.

Sales of Industrial Adhesives

Hönle Group generates revenue through the sale of industrial adhesives. These adhesives are specifically designed to be cured by the UV systems Hönle also provides. This synergy forms a significant complementary revenue stream, particularly within the company's Adhesive Systems business unit.

This integrated approach allows Hönle to offer a complete solution to its customers, enhancing value and fostering recurring sales. For instance, in 2023, the Adhesive Systems segment reported a notable increase in sales, reflecting the growing demand for their UV-curable adhesive products and the corresponding UV curing equipment.

- Complementary Offering: Sales of industrial adhesives directly support and enhance the value proposition of Hönle's UV curing equipment.

- Adhesive Systems Segment: This revenue stream is a core component of the Adhesive Systems business unit's performance.

- Synergistic Growth: The demand for adhesives is often driven by the adoption of Hönle's UV technology, creating a positive feedback loop.

- 2023 Performance: The company has seen positive growth in this area, indicating strong market acceptance of their integrated adhesive and curing solutions.

Honle Group's revenue is diversified, encompassing the sale of industrial UV systems, essential replacement parts and consumables, and service and maintenance contracts. Additionally, they generate income from custom solution development and the sale of industrial adhesives that complement their UV curing technology.

| Revenue Stream | Description | 2023 Data/Significance |

|---|---|---|

| Industrial UV Systems | Sales of UV curing systems, LED-UV systems, and disinfection units. | A primary driver of revenue, serving diverse industries like printing and electronics. |

| Replacement Parts & Consumables | Sale of UV lamps and components for system maintenance. | Provides a robust recurring revenue stream, especially strong in the disinfection unit segment. |

| Service & Maintenance Contracts | Long-term agreements for technical support and repairs. | Contributes significantly to recurring income, supported by their Life Cycle Solutions initiative. |

| Custom Solution Development | Fees for engineering bespoke UV systems for specialized applications. | Project-based revenue driven by demand for tailored solutions in sectors like automotive and medical devices in 2024. |

| Industrial Adhesives | Sales of UV-curable adhesives that work with their UV systems. | A synergistic stream bolstering the Adhesive Systems unit, showing positive growth in 2023. |

Business Model Canvas Data Sources

The Honle Group Business Model Canvas is constructed using a blend of internal financial performance data, comprehensive market analysis reports, and direct feedback from key stakeholders. This multifaceted approach ensures each element of the canvas is grounded in both quantitative and qualitative evidence.