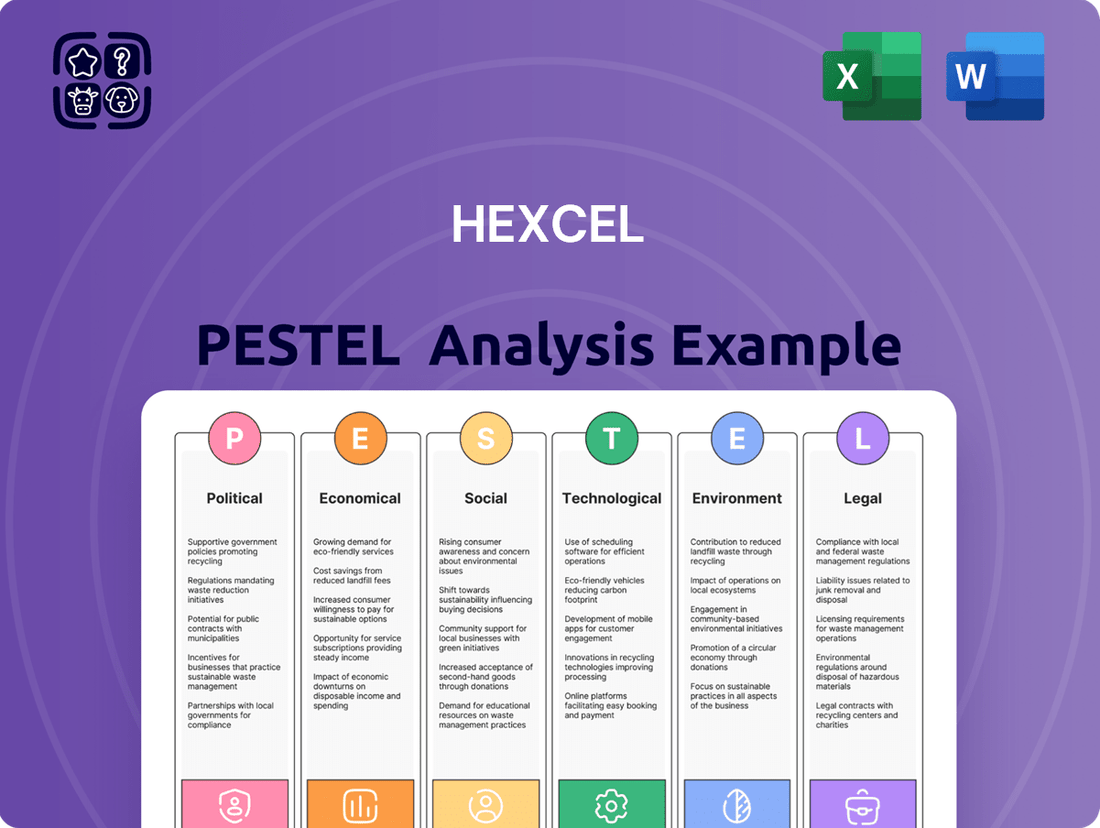

Hexcel PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Hexcel Bundle

Uncover the intricate web of political, economic, social, technological, environmental, and legal factors shaping Hexcel's trajectory. Our meticulously researched PESTLE analysis provides a crucial understanding of the external forces impacting this aerospace and defense giant. Equip yourself with actionable intelligence to anticipate challenges and capitalize on opportunities. Download the full PESTLE analysis now and gain a decisive competitive advantage.

Political factors

Government budgets for defense and space programs are a critical driver for Hexcel's revenue in these key sectors. For instance, the U.S. Department of Defense's budget for fiscal year 2025 is projected to be around $886 billion, reflecting ongoing investments in military modernization and readiness. This directly impacts demand for Hexcel's advanced composite materials used in fighter jets, helicopters, and other defense platforms.

Shifts in national security priorities and geopolitical events can also significantly alter the demand landscape. Increased global tensions or specific military modernization initiatives, such as the development of next-generation fighter aircraft or advanced missile systems, can spur greater investment in high-performance composites. Conversely, a reduction in defense spending or a de-escalation of international conflicts might temper this demand.

The aerospace industry operates under a highly regulated framework, with bodies like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) setting stringent material and manufacturing standards for commercial aircraft. These regulations directly influence Hexcel's product development and market entry, as compliance is paramount. For instance, the FAA's Part 25 regulations outline the airworthiness standards for transport category airplanes, impacting the types of advanced composite materials Hexcel can supply and the testing required.

Hexcel's reliance on a global supply chain makes it highly sensitive to international trade policies. Changes in global trade agreements, such as potential shifts in existing pacts or the negotiation of new ones, can significantly alter the cost and availability of its advanced composite materials. For instance, a disruption in a key trade route or the imposition of new tariffs could directly impact Hexcel's production costs and its ability to serve international markets efficiently.

Tariffs and export controls are critical considerations for Hexcel. In 2023, global trade faced ongoing adjustments, with some nations exploring more protectionist measures. These policies can lead to increased import duties on raw materials essential for Hexcel's manufacturing processes, thereby raising operational expenses. Conversely, export controls could restrict Hexcel's access to certain markets, limiting its sales potential and revenue growth opportunities in regions with stringent trade regulations.

Geopolitical Stability

Global geopolitical tensions and regional conflicts significantly impact Hexcel's operating environment. For instance, the ongoing conflict in Eastern Europe has disrupted supply chains for raw materials and components, affecting production schedules and increasing logistical costs for aerospace and defense manufacturers, including Hexcel's customers. This instability can also dampen demand for new aircraft and defense systems as governments reallocate resources.

Political instability in key regions where Hexcel has manufacturing facilities or significant customer bases presents a direct risk. For example, political unrest in the Middle East or North Africa could disrupt regional air travel, impacting airline customers and potentially delaying new aircraft deliveries. Hexcel's reliance on a global supply chain means that localized political instability can have ripple effects across its entire network.

- Supply Chain Vulnerability: Geopolitical events, such as trade disputes or sanctions, can restrict access to critical raw materials like carbon fiber precursors, impacting Hexcel's production capacity.

- Customer Demand Fluctuations: Regional conflicts can lead to increased defense spending, boosting demand for certain Hexcel products, but also divert government budgets away from commercial aerospace, affecting that segment.

- Operational Disruptions: Political instability in countries where Hexcel sources materials or has manufacturing presence can lead to temporary shutdowns or increased security costs.

Government Support for Advanced Manufacturing

Government initiatives aimed at bolstering domestic advanced manufacturing, including Hexcel's specialty materials, significantly influence the operating landscape. For instance, the U.S. government's renewed focus on reshoring critical supply chains and investing in high-tech industries, particularly in aerospace and defense, directly benefits companies like Hexcel. These efforts often translate into tangible support through R&D tax credits and subsidies for advanced materials and sustainable technologies.

These policies are designed to de-risk private sector investment in new facilities, cutting-edge research, and crucial workforce development programs. For example, the CHIPS and Science Act of 2022, while focused on semiconductors, signals a broader governmental commitment to nurturing domestic advanced manufacturing capabilities across various sectors, potentially creating spillover benefits for advanced materials suppliers. Such government backing can accelerate innovation and expand production capacity for companies like Hexcel.

- Government Investment in Aerospace: The U.S. Department of Defense's FY2025 budget request includes substantial funding for advanced aircraft programs, a key market for Hexcel's composite materials.

- R&D Tax Incentives: Ongoing tax credit programs in major industrial economies encourage companies to invest in research and development for new materials and manufacturing processes.

- Sustainable Technology Subsidies: Initiatives promoting greener manufacturing and lightweight materials, crucial for aerospace and automotive sectors, can provide financial incentives for Hexcel's sustainable product lines.

- Domestic Supply Chain Focus: Policies encouraging the onshoring of critical manufacturing components create opportunities for domestic advanced materials suppliers to secure new contracts and expand operations.

Government budgets for defense and space programs are a critical driver for Hexcel's revenue in these key sectors. For instance, the U.S. Department of Defense's budget for fiscal year 2025 is projected to be around $886 billion, reflecting ongoing investments in military modernization and readiness. This directly impacts demand for Hexcel's advanced composite materials used in fighter jets, helicopters, and other defense platforms.

Shifts in national security priorities and geopolitical events can also significantly alter the demand landscape. Increased global tensions or specific military modernization initiatives, such as the development of next-generation fighter aircraft or advanced missile systems, can spur greater investment in high-performance composites. Conversely, a reduction in defense spending or a de-escalation of international conflicts might temper this demand.

The aerospace industry operates under a highly regulated framework, with bodies like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) setting stringent material and manufacturing standards for commercial aircraft. These regulations directly influence Hexcel's product development and market entry, as compliance is paramount. For instance, the FAA's Part 25 regulations outline the airworthiness standards for transport category airplanes, impacting the types of advanced composite materials Hexcel can supply and the testing required.

Hexcel's reliance on a global supply chain makes it highly sensitive to international trade policies. Changes in global trade agreements, such as potential shifts in existing pacts or the negotiation of new ones, can significantly alter the cost and availability of its advanced composite materials. For instance, a disruption in a key trade route or the imposition of new tariffs could directly impact Hexcel's production costs and its ability to serve international markets efficiently.

What is included in the product

This Hexcel PESTLE analysis examines the Political, Economic, Social, Technological, Environmental, and Legal factors impacting the company, providing a comprehensive overview of the external landscape.

A clear, actionable summary of Hexcel's PESTLE factors, enabling swift identification of opportunities and threats to inform strategic decisions and mitigate potential risks.

Economic factors

Global economic growth is a critical driver for Hexcel. A healthy global economy, marked by strong GDP growth, directly fuels demand for commercial air travel and industrial products. For instance, the International Monetary Fund (IMF) projected global growth to be 3.2% in 2024, a slight slowdown from 2023, but expected to pick up to 3.5% in 2025. This expansion translates into more aircraft orders and increased industrial output, both of which are key markets for Hexcel's advanced composite materials.

When economies are expanding, airlines tend to order more new aircraft, and manufacturers increase production. This heightened activity directly benefits Hexcel, as its lightweight and high-strength composites are essential components in modern aircraft manufacturing and various industrial applications. The projected uptick in global growth for 2025 suggests a potentially more favorable environment for Hexcel's core business segments.

Commercial aerospace build rates are a huge deal for Hexcel, as they rely heavily on companies like Boeing and Airbus churning out new planes. For instance, in 2023, Airbus delivered 735 aircraft, while Boeing delivered 528. These numbers directly translate to Hexcel's material sales volumes.

Any hiccups in aircraft orders or production, like the ongoing supply chain issues impacting 2024 deliveries for both manufacturers, can really slow down Hexcel's business. A slowdown in build rates means less demand for Hexcel's advanced composite materials used in aircraft construction.

Hexcel Corporation, a leader in advanced composite materials, faces significant challenges from the volatility of raw material costs. The prices of essential inputs like carbon fiber precursors and specialty resins are heavily influenced by global commodity markets and geopolitical events. For instance, during 2024, the energy crisis and supply chain disruptions continued to exert upward pressure on the cost of petrochemicals, a key component in resin production, leading to an estimated 10-15% increase in some chemical feedstocks compared to 2023 levels.

These escalating raw material expenses, compounded by broader inflationary trends in 2024 and projected into 2025, directly impact Hexcel's profitability. If the company cannot fully pass these increased costs onto its customers through price adjustments, its profit margins are likely to be squeezed. Hexcel's ability to implement timely and effective pricing strategies will be crucial in mitigating these margin pressures and maintaining financial health amidst a dynamic cost environment.

Currency Exchange Rate Fluctuations

Hexcel, as a global manufacturer of advanced composite materials, is significantly influenced by currency exchange rate fluctuations. With operations and sales spread across various countries, the company faces risks from adverse currency movements that can affect its reported financial results and international pricing strategies. For instance, a stronger US dollar (USD) relative to other currencies could reduce the value of Hexcel's foreign earnings when translated back into USD, and potentially make its products more expensive for overseas customers.

These fluctuations directly impact Hexcel's reported revenues and costs. If the Euro weakens against the dollar, Hexcel's sales in Europe will translate into fewer dollars, impacting its top-line performance. Conversely, if its raw material costs are denominated in a strengthening currency, its cost of goods sold could rise. In the first quarter of 2024, Hexcel reported that foreign currency headwinds had a modest negative impact on its net sales, highlighting the ongoing sensitivity.

The competitiveness of Hexcel's advanced composites in international markets is also at stake. When the USD strengthens, Hexcel's products become relatively more expensive for buyers in countries with weaker currencies, potentially leading to a loss of market share to local competitors or those with cost bases in weaker currencies. For example, during periods of significant dollar appreciation, aerospace manufacturers in Europe might find it more economical to source materials from European suppliers if available.

- Impact on Revenue: A stronger USD can decrease the reported dollar value of sales made in weaker currencies.

- Cost Sensitivity: Fluctuations can increase or decrease the cost of imported raw materials or components.

- Competitive Positioning: Exchange rates affect the price competitiveness of Hexcel's products in global markets.

- 2024 Performance: Early 2024 data indicated a slight negative impact from currency exchange rate movements on Hexcel's net sales.

Interest Rates and Investment Climate

Fluctuations in global interest rates directly impact Hexcel's operating environment. When interest rates rise, the cost of borrowing increases for Hexcel's customers, such as aircraft manufacturers. This can lead to delayed or scaled-back investment in new aircraft programs, consequently reducing demand for Hexcel's advanced composite materials. For instance, the U.S. Federal Reserve maintained its benchmark interest rate in the 5.25%-5.50% range through early 2024, reflecting a higher cost of capital for many industries.

A higher interest rate scenario also affects Hexcel's own capital expenditure decisions. Financing expansions or new manufacturing facilities becomes more expensive, potentially slowing down growth initiatives. This environment can dampen overall investment across the aerospace and defense sectors, Hexcel's primary markets. In 2024, many central banks continued to grapple with inflation, keeping interest rates elevated compared to the preceding decade, which generally creates headwinds for capital-intensive industries.

The cost of capital is a critical factor in the long-term investment cycles typical of the aerospace industry. Higher rates can make large, multi-year aircraft development programs less attractive for airlines and manufacturers. This ripple effect can translate into reduced orders for Hexcel's high-performance materials. For example, the European Central Bank's policy rate remained at 4.50% in early 2024, contributing to a more cautious investment climate across Europe.

Conversely, periods of lower interest rates generally stimulate investment and economic activity, benefiting Hexcel. However, the prevailing trend in 2024 and into 2025 has been one of higher borrowing costs globally, aimed at controlling inflation. This suggests a continued need for Hexcel to manage its financial strategies carefully in response to the prevailing interest rate climate.

Global economic trends significantly shape Hexcel's market. Strong GDP growth, projected at 3.2% for 2024 and an anticipated 3.5% in 2025 by the IMF, directly boosts demand for commercial aerospace and industrial goods. This economic expansion encourages airlines to order more aircraft, driving Hexcel's material sales.

Increased aircraft production rates are vital for Hexcel, as seen in 2023 deliveries of 735 aircraft by Airbus and 528 by Boeing. However, supply chain disruptions in 2024 have impacted these build rates, potentially slowing demand for Hexcel's composites.

Raw material cost volatility, with some chemical feedstocks seeing 10-15% increases in 2024, directly pressures Hexcel's profit margins. Navigating these rising costs, influenced by energy prices and supply chain issues, is critical for maintaining profitability into 2025.

Currency fluctuations, particularly a stronger USD, can negatively impact Hexcel's reported sales and competitive pricing in international markets, as observed with modest headwinds in early 2024. High global interest rates, with the US Federal Reserve rate at 5.25%-5.50% through early 2024, also increase borrowing costs for customers, potentially dampening investment in new aircraft programs.

Same Document Delivered

Hexcel PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive Hexcel PESTLE analysis delves into the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the advanced composites industry. Gain valuable insights into market dynamics and strategic considerations.

Sociological factors

Societal pressure for sustainability is a major driver in the aerospace sector. Consumers and governments alike are demanding reduced environmental impact, pushing manufacturers to seek out lighter, more fuel-efficient materials. This directly plays into Hexcel's strengths, as their advanced composite materials are key to achieving these goals.

The demand for eco-conscious solutions is translating into tangible market shifts. For instance, the global aerospace composites market was valued at approximately $13.5 billion in 2023 and is projected to reach over $22 billion by 2030, showing a clear upward trend driven by these societal expectations. Hexcel's lightweight materials contribute significantly to lowering aircraft carbon footprints, making them increasingly sought after.

Hexcel's reliance on a highly skilled workforce in advanced materials, composites, and engineering is paramount for its ongoing innovation and manufacturing capabilities. The company needs access to talent proficient in areas like polymer chemistry and structural design to maintain its competitive edge.

Demographic trends, such as an aging workforce and increasing retirement rates in specialized technical fields, pose a significant challenge for Hexcel in maintaining its operational efficiency and driving future growth. For instance, the Society of Manufacturing Engineers reported in 2024 that a substantial portion of their experienced members are nearing retirement age, creating a potential talent gap.

The intense competition for specialized engineers and material scientists, particularly those with experience in aerospace and defense sectors, directly impacts Hexcel's ability to attract and retain the necessary expertise. In 2025, the U.S. Bureau of Labor Statistics projects continued strong demand for aerospace engineers, with an anticipated 7% growth through 2032, underscoring the competitive landscape for Hexcel.

Societal attitudes toward air travel are evolving, with growing concerns about environmental impact. A 2024 survey indicated that 65% of travelers are more conscious of aviation's carbon footprint than they were two years prior. This shift directly influences demand for aircraft, pushing manufacturers and their suppliers like Hexcel to prioritize sustainable solutions.

Conversely, positive public perception, often bolstered by technological advancements, fuels market growth. Hexcel's involvement in developing lighter, more fuel-efficient composite materials directly addresses these environmental concerns. For instance, the increasing adoption of advanced composites in new aircraft models, like the Boeing 787 and Airbus A350, has demonstrably improved fuel efficiency by up to 20%, enhancing air travel's appeal.

Demand for High-Performance Solutions

Societal shifts are increasingly prioritizing high-performance, durable, and energy-efficient solutions across many industries. This trend directly benefits Hexcel, as demand grows for its advanced composite materials in sectors like wind energy and automotive manufacturing, pushing beyond its traditional aerospace focus.

For instance, the global wind turbine blade market, a key area for Hexcel's materials, was valued at approximately $15.5 billion in 2023 and is projected to reach $25.7 billion by 2030, with a compound annual growth rate of around 7.5%. This expansion is driven by the need for lighter, stronger blades that can capture more wind energy efficiently.

- Growing Demand for Lightweight Materials: Consumers and industries are seeking products that offer better fuel economy and reduced environmental impact, favoring lightweight composites.

- Emphasis on Durability and Longevity: Societal preference for products with longer lifespans and lower maintenance requirements aligns with the inherent durability of Hexcel's advanced materials.

- Energy Efficiency as a Societal Imperative: The global push for sustainability and reduced carbon footprints makes energy-efficient solutions, enabled by lightweighting, highly desirable across transportation and power generation.

Corporate Social Responsibility (CSR) Expectations

Societal expectations around Corporate Social Responsibility (CSR) are intensifying, compelling companies like Hexcel to actively showcase ethical sourcing, fair labor, diversity, and community involvement. This heightened scrutiny comes from investors, customers, and the general public, all demanding greater accountability. For instance, in 2024, a significant majority of consumers reported that they would switch brands if they found a competitor with a better social responsibility record.

Meeting these elevated CSR standards is no longer just about compliance; it's a strategic imperative. Companies that excel in CSR often enjoy an enhanced brand reputation, making them more attractive to both customers and potential employees. This positive perception can translate into tangible benefits, such as increased market share and a stronger ability to attract and retain top talent, a critical factor in the competitive aerospace and defense industry.

- Growing Investor Demand: ESG (Environmental, Social, and Governance) funds saw substantial inflows in 2024, with many actively seeking companies with robust CSR frameworks.

- Consumer Preference: Surveys in early 2025 indicate that over 60% of consumers consider a company's social impact when making purchasing decisions.

- Talent Acquisition: A 2024 report highlighted that 70% of job seekers prioritize working for companies with strong CSR commitments.

- Reputational Benefits: Companies with high CSR ratings often experience lower volatility in their stock prices and greater resilience during economic downturns.

Societal pressure for sustainability is a major driver in the aerospace sector, pushing manufacturers towards lighter, fuel-efficient materials like Hexcel's composites. This trend is reflected in the global aerospace composites market, valued at approximately $13.5 billion in 2023 and projected to exceed $22 billion by 2030, demonstrating a clear market shift towards eco-conscious solutions.

Demographic shifts, particularly an aging workforce and retirement rates in specialized technical fields, present a challenge for Hexcel in maintaining operational efficiency and driving growth. The Society of Manufacturing Engineers reported in 2024 that a significant portion of experienced members are nearing retirement, indicating a potential talent gap.

The increasing consciousness of aviation's carbon footprint, with a 2024 survey showing 65% of travelers more aware of this issue, directly influences demand for aircraft and prioritizes sustainable solutions from suppliers like Hexcel. This societal shift is further amplified by the growing demand for energy-efficient solutions across various sectors, including wind energy and automotive manufacturing, where Hexcel's advanced materials are increasingly utilized.

Societal expectations around Corporate Social Responsibility (CSR) are intensifying, with investors and consumers demanding greater accountability. For instance, ESG funds saw substantial inflows in 2024, and over 60% of consumers in early 2025 considered a company's social impact in purchasing decisions, underscoring the strategic importance of robust CSR for Hexcel.

Technological factors

Hexcel's competitive edge hinges on continuous advancements in composite materials science, particularly in carbon fiber technology and resin systems. Ongoing research and development are crucial for creating materials that are not only stronger and lighter but also more cost-effective to produce.

Innovations in manufacturing processes, such as automated fiber placement and advanced curing techniques, are also key. These technological leaps directly impact Hexcel's ability to offer superior products, as seen in the aerospace sector's increasing demand for lightweight, high-performance composites.

Additive manufacturing, or 3D printing, is increasingly being used for complex aerospace and industrial components, creating new avenues for innovation. Hexcel can capitalize on this by using it for faster prototyping and producing highly specialized parts, potentially reducing lead times and material waste.

However, this technological shift also means Hexcel must adapt to evolving manufacturing methods, as additive manufacturing could disrupt traditional supply chains and production processes for certain materials and components.

Hexcel's commitment to Industry 4.0 principles is evident in its strategic investments in advanced automation and digital technologies. The company aims to leverage robotics, AI, and sophisticated data analytics to streamline its manufacturing operations. This focus is expected to yield significant improvements in production efficiency and product quality.

By integrating these technologies, Hexcel anticipates a reduction in operational costs and waste across its global network of facilities. For instance, the adoption of automated quality control systems can minimize defects, directly impacting profitability and customer satisfaction. Hexcel's financial reports for 2024 and projections for 2025 highlight ongoing capital expenditures dedicated to these modernization efforts.

New Application Development and Diversification

Technological advancements are significantly broadening the application of advanced composites, creating exciting new avenues for Hexcel. These breakthroughs are particularly impactful in emerging sectors like Urban Air Mobility (UAM), where lightweight yet strong materials are crucial.

Hexcel's expertise in composites is well-positioned to capitalize on these shifts. For instance, the demand for advanced materials in renewable energy, such as wind turbine blades, continues to grow. In 2023, the global wind energy market reached an installed capacity of over 1,000 GW, with composites playing a vital role in blade efficiency and durability.

Beyond aerospace, Hexcel is seeing diversification opportunities in areas like hydrogen storage tanks for transportation and industrial applications, and in the medical device sector, where biocompatible and high-strength composites are increasingly sought after. This diversification helps to stabilize revenue and reduce reliance on any single market.

- Urban Air Mobility (UAM): Composites are essential for the lightweight structures needed for eVTOL aircraft.

- Hydrogen Storage: Advanced composite tanks are critical for safe and efficient hydrogen transportation and storage.

- Renewable Energy: Composites are key to larger, more efficient wind turbine blades, with the global market showing robust growth.

- Medical Devices: Biocompatible and high-strength composites are finding new uses in prosthetics and surgical instruments.

Digital Design and Simulation Tools

Hexcel leverages advanced digital design and simulation tools, significantly speeding up its product development. These computational instruments enable precise material modeling and structural analysis, allowing for digital prototyping that optimizes composite structure performance. This sophisticated approach reduces reliance on costly and time-consuming physical testing, a crucial advantage in the fast-paced aerospace and industrial sectors.

These tools are instrumental in enhancing efficiency and innovation. For instance, by 2024, the aerospace industry's adoption of digital twins and advanced simulation software was projected to streamline design processes, potentially cutting development timelines by up to 30% for complex components. Hexcel's investment in these technologies directly supports this trend, ensuring they remain competitive.

- Accelerated Development: Digital simulation tools shorten the time from concept to market for new composite materials and structures.

- Performance Optimization: Advanced modeling allows for fine-tuning of material properties and structural designs for maximum efficiency and durability.

- Reduced Testing Costs: Virtual prototyping minimizes the need for expensive and lengthy physical testing phases.

- Enhanced Collaboration: Digital platforms facilitate seamless sharing and collaboration between Hexcel engineers and their customers on design projects.

Technological factors are pivotal for Hexcel, driving innovation in advanced composites. The company's investment in R&D, particularly in carbon fiber and resin systems, underpins its ability to deliver lighter, stronger, and more cost-effective materials. Innovations in manufacturing, like automated fiber placement, are key to meeting the aerospace sector's growing demand for high-performance composites.

Additive manufacturing presents new opportunities for Hexcel, enabling faster prototyping and the creation of specialized parts, though it also necessitates adaptation to evolving production methods. Hexcel's embrace of Industry 4.0, including AI and robotics, aims to boost manufacturing efficiency and product quality, with 2024/2025 financial reports indicating significant capital allocation for these upgrades.

Emerging applications like Urban Air Mobility (UAM) and hydrogen storage further highlight the expanding role of advanced composites. The renewable energy sector, particularly wind turbines, also represents a significant growth area, with the global market exceeding 1,000 GW of installed capacity in 2023, relying heavily on composite materials for blade efficiency.

Hexcel utilizes advanced digital design and simulation tools to accelerate product development, reducing reliance on physical testing. By 2024, the aerospace industry's adoption of digital twins was projected to cut development timelines for complex components by up to 30%, a trend Hexcel actively supports.

| Technology Area | Impact on Hexcel | Market Relevance (2024/2025 Data) |

|---|---|---|

| Advanced Composites R&D | Enhanced material properties (strength, weight, cost) | Aerospace, UAM, Renewable Energy, Medical Devices |

| Automated Manufacturing | Increased production efficiency, reduced waste | Aerospace component production, cost optimization |

| Additive Manufacturing (3D Printing) | Faster prototyping, specialized part production | Disruption of traditional supply chains, new product avenues |

| Industry 4.0 (AI, Robotics) | Streamlined operations, improved quality control | Operational cost reduction, enhanced competitiveness |

| Digital Design & Simulation | Accelerated product development, optimized performance | Aerospace development timelines (up to 30% reduction projected by 2024) |

Legal factors

Hexcel's advanced composite materials are subject to stringent certification processes by global aviation regulators like the FAA and EASA. For instance, achieving material qualification for new aerospace applications can take several years and significant investment, impacting product launch timelines.

Staying compliant with evolving safety regulations, such as those concerning fire, smoke, and toxicity (FST) standards, is critical. Failure to meet these requirements can prevent Hexcel's materials from being used in new aircraft designs, directly affecting market access and revenue potential in the commercial aerospace sector, which represented a significant portion of Hexcel's sales in recent years.

Hexcel Corporation operates within a robust legal environment that emphasizes intellectual property (IP) protection, crucial for safeguarding its advanced composite material technologies and proprietary manufacturing techniques. These strong legal frameworks, encompassing patents, trademarks, and trade secrets, are fundamental to maintaining Hexcel's competitive edge.

The company's reliance on innovation means that IP infringement litigation or disputes over licensing agreements for its specialized materials, such as those used in aerospace and defense, can significantly affect its financial performance and market position. For instance, in 2023, the global IP litigation market saw substantial activity, with significant damages awarded in patent disputes, underscoring the financial risks and rewards associated with IP protection.

Hexcel's operations, particularly in advanced composites for aerospace and defense, are heavily impacted by export control and trade compliance. Navigating regulations like the International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR) is crucial for market access and avoiding severe penalties.

Failure to comply with these stringent international rules can result in substantial fines, potentially reaching millions of dollars, and can jeopardize Hexcel's ability to conduct business in key global markets. For instance, a single violation could lead to debarment from exporting defense articles, significantly impacting revenue streams.

Product Liability and Safety Regulations

Hexcel, as a provider of advanced composite materials used in demanding applications like aerospace and defense, faces significant product liability risks. Should its materials fail and lead to structural issues or safety incidents, the company could be subject to substantial claims. For instance, in 2023, the aerospace industry continued to grapple with the aftermath of incidents that led to increased scrutiny on material integrity and supplier responsibility, impacting companies across the supply chain.

To counter this, Hexcel places a strong emphasis on rigorous quality assurance processes, including extensive testing and validation of its products. The company also utilizes comprehensive legal disclaimers and contractual agreements to define responsibilities and limit potential liabilities. These measures are crucial in the highly regulated aerospace sector, where material performance directly impacts passenger safety and aircraft airworthiness.

- Product Liability Exposure: Hexcel's advanced materials are integral to the structural integrity of aircraft and other high-performance systems, making product liability a key concern.

- Mitigation Strategies: Strict adherence to quality control, comprehensive testing protocols, and clear legal disclaimers are vital for managing product liability risks.

- Regulatory Environment: The aerospace and defense industries operate under stringent safety regulations, amplifying the importance of product reliability and supplier accountability.

- Industry Trends: Ongoing investigations and recalls in related sectors in 2023-2024 underscore the persistent need for robust safety and quality management in advanced material supply chains.

Labor and Employment Laws

Hexcel Corporation must navigate a complex web of labor and employment laws across its international locations. This includes adhering to varying regulations on minimum wage, workplace safety standards, and mandatory employee benefits, all of which significantly influence HR strategies and operational expenditures. For instance, in 2024, the ongoing discussions around fair wage policies and enhanced worker protections in key manufacturing regions could lead to increased labor costs if new mandates are implemented.

Adapting to evolving employment legislation is crucial for Hexcel. Potential shifts in regulations concerning collective bargaining rights or employee data privacy in 2025 could require substantial changes to Hexcel's existing HR frameworks and compliance procedures. Companies like Hexcel are increasingly focused on proactive compliance to mitigate risks associated with labor disputes and regulatory penalties.

- Global Compliance: Hexcel operates in numerous countries, each with distinct labor laws affecting wages, working conditions, and benefits.

- Impact on Costs: Adherence to these laws directly impacts operational expenses, particularly human resources management and employee compensation structures.

- Regulatory Changes: Anticipating and adapting to changes in labor legislation, such as those concerning union activities or benefits mandates, is essential for sustained operational efficiency.

- 2024/2025 Focus: Emerging trends in worker rights and fair compensation could necessitate strategic adjustments to employment practices in the near term.

Hexcel's commitment to intellectual property protection is paramount, as evidenced by its robust patent portfolio covering advanced composite materials and manufacturing processes. In 2023, the company continued to actively defend its IP, with legal expenses related to patent litigation being a notable factor in its operating costs. The global landscape for IP enforcement saw increased activity, with significant damage awards in patent disputes, underscoring the financial stakes involved for technology-driven companies like Hexcel.

The company's adherence to export control regulations, such as ITAR and EAR, is critical for its international business, particularly in the defense sector. Non-compliance can result in severe penalties, including substantial fines and potential debarment from exporting, which could significantly impact revenue streams. For instance, the U.S. Department of Commerce reported increased enforcement actions against companies violating export controls in the 2023-2024 period.

Product liability remains a significant legal consideration for Hexcel, given the critical nature of its materials in aerospace and defense applications. The company's rigorous quality assurance and testing protocols are designed to mitigate these risks. The aerospace industry's ongoing focus on material integrity, highlighted by investigations into component failures in 2023, reinforces the need for robust supplier accountability and risk management.

Navigating diverse international labor laws presents ongoing compliance challenges and impacts operational costs. In 2024, several key markets where Hexcel operates have seen proposed or enacted legislation aimed at increasing minimum wages and enhancing worker protections, potentially leading to higher labor expenses. Adapting to evolving employment legislation, such as changes in data privacy laws affecting employee records, requires continuous review of HR policies.

Environmental factors

Global efforts to curb carbon emissions are intensifying, with the aviation sector facing particular scrutiny. Regulations targeting greenhouse gas reductions are pushing airlines and aircraft manufacturers toward solutions that improve fuel efficiency. This trend directly supports Hexcel, as its lightweight composite materials are crucial for building more fuel-efficient aircraft, a key component in meeting these environmental mandates.

The drive for sustainability is translating into tangible market demand. For instance, by 2025, the International Civil Aviation Organization (ICAO) aims to achieve carbon-neutral growth for international aviation through its Corsia program. Hexcel's advanced composites offer significant weight savings compared to traditional aluminum, contributing to reduced fuel burn and lower emissions, making them indispensable for manufacturers like Boeing and Airbus as they strive to meet these stringent environmental targets.

The environmental challenge of managing and recycling composite materials, particularly thermosets, is a significant hurdle. As composite use grows, so does the need for effective end-of-life solutions.

Hexcel is actively addressing this by developing more recyclable materials and focusing on reducing manufacturing waste. Their involvement in end-of-life solutions is becoming crucial for long-term sustainability and market acceptance.

For instance, the European Composites Industry Association (EuCIA) reported that in 2023, efforts were intensifying to establish robust recycling infrastructure, with a focus on diverting composite waste from landfills.

The increasing global emphasis on sustainability is directly impacting Hexcel's operations. Consumers and regulators alike are demanding greater transparency and accountability in how raw materials are sourced and processed. This translates into a growing need for Hexcel to demonstrate robust, environmentally conscious supply chain practices.

Hexcel must actively verify that its suppliers meet stringent environmental standards. This includes scrutinizing their energy consumption, waste management, and emissions. For instance, in 2024, many aerospace and defense companies are setting targets for reducing Scope 3 emissions, which heavily rely on supplier performance.

Minimizing Hexcel's own ecological footprint across the material lifecycle is paramount. This involves optimizing manufacturing processes to reduce waste and energy usage, and considering the end-of-life implications for its advanced composite materials. The company's commitment to circular economy principles will be a key differentiator in the coming years.

Pollution Control and Hazardous Waste Regulations

Stricter environmental regulations, particularly concerning air and water pollution and hazardous waste management, directly influence Hexcel's manufacturing processes. These rules necessitate ongoing investment in advanced environmental compliance technologies to mitigate operational risks and ensure adherence to evolving standards.

Hexcel's commitment to environmental stewardship is reflected in its operational expenditures. For instance, in 2023, the company reported environmental compliance and sustainability initiatives as a key focus area, though specific figures for pollution control investments are embedded within broader operational costs. The global trend towards net-zero emissions by 2050, as emphasized by international agreements, will likely drive further regulatory tightening and capital allocation towards greener manufacturing practices for companies like Hexcel.

- Increased Capital Expenditures: Anticipated investments in advanced filtration systems and waste treatment facilities to meet stringent emission standards.

- Operational Cost Fluctuations: Potential for higher costs related to waste disposal and the use of more environmentally friendly, albeit potentially more expensive, raw materials.

- Technological Innovation: A push towards developing and adopting cleaner production technologies to reduce the environmental footprint and comply with regulations.

- Regulatory Compliance Burden: The need for robust monitoring, reporting, and auditing processes to demonstrate adherence to environmental laws.

Resource Depletion and Circular Economy Principles

Growing concerns over the depletion of natural resources are pushing industries worldwide to embrace circular economy principles. This shift emphasizes reducing consumption, maximizing reuse, and intensifying recycling efforts across all material streams. Hexcel's commitment to developing innovative, sustainable materials and more efficient manufacturing processes directly addresses these escalating environmental expectations, positioning the company favorably in a market increasingly prioritizing ecological responsibility.

The global demand for critical raw materials is projected to rise significantly. For instance, the International Energy Agency (IEA) reported in 2024 that demand for critical minerals like lithium and cobalt, essential for advanced materials, could increase by over 40 times by 2040 under net-zero emissions scenarios. Hexcel's focus on advanced composites, which often utilize lighter and more durable materials, can contribute to reducing the overall material footprint in sectors like aerospace and automotive, aligning with resource conservation goals.

- Resource Scarcity Impact: The increasing scarcity and price volatility of certain raw materials directly affect manufacturing costs and supply chain stability for companies like Hexcel.

- Circular Economy Adoption: By 2025, it's estimated that over 70% of companies will have integrated circular economy principles into their business models, according to various industry reports, signaling a strong market trend.

- Innovation in Sustainability: Hexcel's investment in R&D for recyclable composites and bio-based materials is crucial for meeting future regulatory demands and consumer preferences for environmentally friendly products.

Environmental pressures are a significant driver for Hexcel, pushing for lighter, more fuel-efficient aircraft. The aviation industry's commitment to carbon-neutral growth by 2025, as outlined by ICAO's Corsia program, directly benefits Hexcel, as its composite materials are key to reducing emissions.

The push for sustainability also means Hexcel must manage its own environmental footprint, from sourcing to end-of-life solutions for composites. By 2023, industry efforts were intensifying to build recycling infrastructure for composites, a crucial area for Hexcel's long-term strategy and market acceptance.

Stricter environmental regulations, particularly concerning pollution and waste, necessitate ongoing investment in compliance technologies. The global drive for net-zero emissions by 2050 will likely lead to further regulatory tightening, impacting Hexcel's manufacturing practices and capital allocation.

Resource scarcity is another key environmental factor, with demand for critical minerals expected to rise significantly by 2040. Hexcel's focus on advanced composites, which can reduce overall material usage, aligns with resource conservation goals and the growing adoption of circular economy principles.

PESTLE Analysis Data Sources

Our Hexcel PESTLE Analysis is grounded in comprehensive data from reputable sources, including government publications, international economic organizations, and leading industry analysis firms. We incorporate regulatory updates, market research, and technological trend reports to ensure a thorough understanding of the macro-environment.