Hexcel Marketing Mix

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Hexcel Bundle

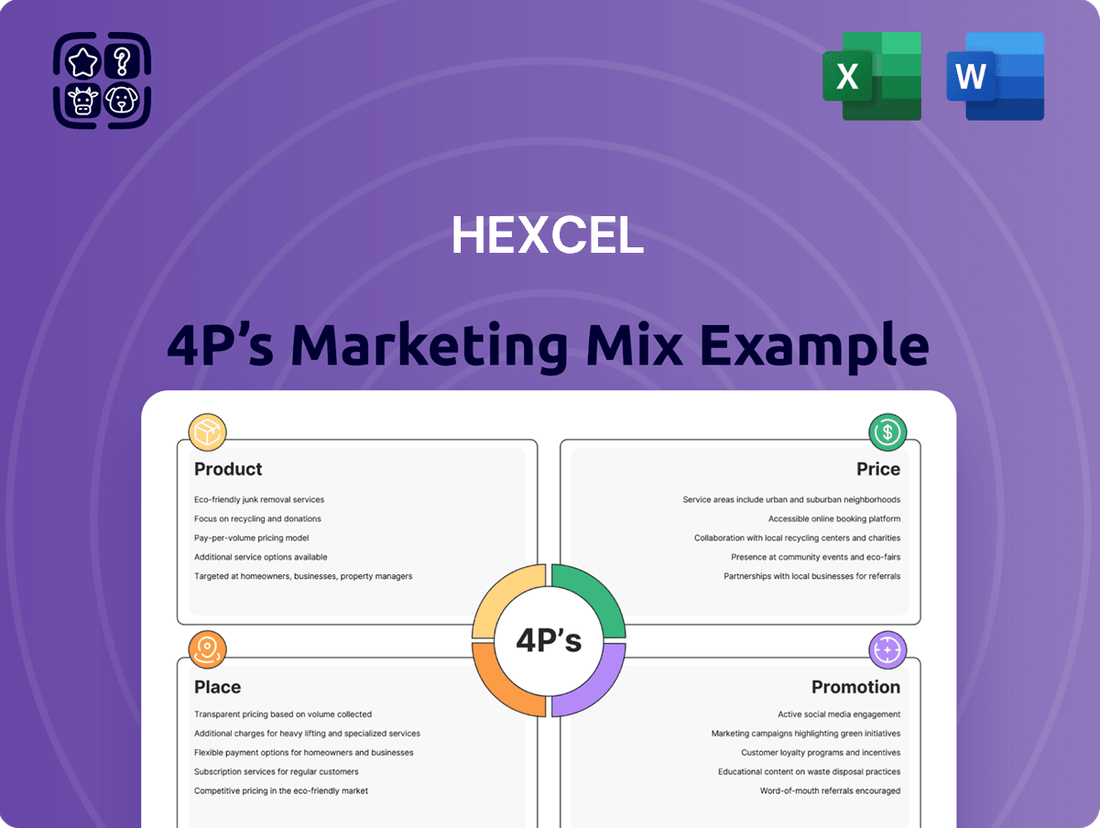

Hexcel's marketing prowess is built on a strategic foundation of Product, Price, Place, and Promotion. This analysis delves into how their advanced composite materials, premium pricing, specialized distribution, and targeted communication create a powerful market presence.

Unlock the full potential of this analysis with our comprehensive 4Ps report, offering actionable insights and real-world examples. Perfect for professionals, students, and consultants seeking to understand and replicate Hexcel's success.

Product

Hexcel's advanced composite materials, like carbon fibers and prepregs, are engineered for extreme performance, offering unparalleled strength-to-weight ratios. These materials are indispensable for sectors such as commercial aerospace, where fuel efficiency is paramount. For instance, the Boeing 787 Dreamliner utilizes over 50% composite materials by weight, significantly reducing its operational costs and environmental impact.

Hexcel's engineered core and composite structures go far beyond basic materials, offering advanced honeycomb and composite components. These are crucial for high-performance applications where strength and reliability are paramount, like in aerospace. For example, Hexcel's advanced composite materials are integral to the structure of aircraft like the Boeing 787 Dreamliner, contributing to its lightweight design and fuel efficiency.

These finished or semi-finished parts are engineered for complex challenges, providing exceptional structural integrity in tough conditions. Hexcel's commitment to vertical integration means they can develop custom composite solutions precisely matched to customer specifications, ensuring optimal performance for unique requirements.

Hexcel's HexBond® product line, encompassing structural film adhesives, foaming films, primers, and liquid shims, is a cornerstone of their offering. These materials are crucial for creating robust composite structures, with specialized formulations designed to meet the demanding performance standards of the aerospace industry. For instance, Hexcel's advanced adhesives are vital in aircraft manufacturing, contributing to lighter and stronger airframes.

The HexPly® brand complements this by providing a range of prepregs and resins, essential for the bonding and forming processes of composite materials. These systems are engineered for high performance, finding application not only in aerospace but also in various industrial sectors. The global market for advanced composites, where Hexcel operates, saw significant growth, with projections indicating continued expansion through 2025, driven by demand for lightweight and durable materials.

Tailored Solutions for Key Markets

Hexcel's product offerings are meticulously crafted to address the distinct needs of critical markets, including commercial aerospace, space and defense, and a range of industrial sectors. This specialization allows them to deliver advanced composite materials that enhance performance across these varied applications.

Their materials are integral to creating lighter, stronger, and more resilient end products. For instance, in aerospace, this translates to fuel efficiency and enhanced payload capacity in aircraft like the Boeing 787, which extensively uses Hexcel's carbon fiber composites. Similarly, in defense, their advanced materials contribute to the structural integrity and agility of platforms such as the F-35 fighter jet.

- Commercial Aerospace: Hexcel's lightweight composites are key to fuel efficiency and performance in new aircraft designs, contributing to reduced emissions.

- Space and Defense: Advanced materials provide critical strength and durability for demanding applications, from satellite structures to military aircraft components.

- Industrial Applications: Hexcel's solutions are adopted in sectors like automotive for weight reduction and in wind energy for stronger, more efficient turbine blades.

Innovation and Next-Generation Materials

Hexcel's commitment to innovation is central to its product strategy, driving the development of advanced composite materials. Their focus on next-generation carbon fibers and resin systems is crucial for enabling lighter, stronger, and more efficient aircraft, including the burgeoning advanced air mobility sector. This forward-looking approach ensures Hexcel remains at the forefront of material science for aerospace and defense applications.

Hexcel's research and technology investments are substantial, with a clear aim to push the boundaries of material performance and cost-effectiveness. Collaborations, such as the one with FIDAMC, underscore their dedication to shared innovation. These efforts are geared towards tangible outcomes like improved material properties and reduced manufacturing expenses, directly impacting the viability of future aerospace designs.

Sustainability is a key pillar of Hexcel's product innovation, particularly through advancements in bio-based resin systems and the development of recycled carbon fiber technologies. These initiatives not only address environmental concerns but also create new value streams and enhance the circularity of composite materials. Such focus is vital as the aerospace industry increasingly prioritizes sustainable solutions, with regulatory bodies and customers demanding greener alternatives.

- Innovation Focus: Development of next-generation carbon fibers, resin systems, and product forms.

- Key Collaborations: Partnerships like the one with FIDAMC to accelerate material advancements.

- Sustainability Initiatives: Investment in bio-based resins and recycled carbon fiber.

- Market Impact: Enabling future generations of aircraft and advanced air mobility vehicles.

Hexcel's product portfolio centers on advanced composite materials, including carbon fibers, prepregs, structural adhesives, and honeycomb core. These materials are engineered for high performance, offering exceptional strength-to-weight ratios crucial for industries like commercial aerospace, where fuel efficiency is a key driver. For instance, the Boeing 787 Dreamliner, which uses over 50% composite materials by weight, significantly benefits from Hexcel's innovations, leading to reduced operational costs and environmental impact.

The HexPly® brand offers prepregs and resins, essential for bonding and forming composite structures, while HexBond® provides structural film adhesives and primers. These are vital for creating robust composite airframes, as seen in their application in aircraft like the F-35 fighter jet, contributing to enhanced structural integrity and agility. Hexcel's vertically integrated approach allows for custom composite solutions tailored to specific customer needs, ensuring optimal performance in demanding applications.

Hexcel's product strategy emphasizes innovation in next-generation carbon fibers and resin systems, targeting sectors such as advanced air mobility. Their commitment to sustainability is evident in investments in bio-based resins and recycled carbon fiber technologies, aligning with the aerospace industry's increasing demand for greener alternatives. This focus on advanced materials and sustainable solutions positions Hexcel to meet the evolving needs of critical markets through 2025 and beyond.

| Product Category | Key Applications | Performance Benefits | Market Example | Growth Driver (2024-2025) |

|---|---|---|---|---|

| Carbon Fibers & Prepregs | Aerospace structures, automotive, wind energy | High strength-to-weight ratio, fuel efficiency, durability | Boeing 787 Dreamliner, Airbus A350 | Demand for lightweighting in aerospace and automotive |

| Structural Adhesives (HexBond®) | Composite bonding, structural assembly | Robust bonding, improved fatigue resistance | Aircraft airframe assembly | Increasing complexity of composite structures |

| Honeycomb Core | Aerospace interiors, aircraft structures | Lightweight, high stiffness, impact resistance | Aircraft cabin components | Need for lightweight and crashworthy materials |

| Resins & Specialty Products | Composite manufacturing, surface treatments | Tailored performance, enhanced processing | Various industrial applications | Advancements in material science and processing |

What is included in the product

This analysis offers a comprehensive examination of Hexcel's marketing strategies across Product, Price, Place, and Promotion, providing actionable insights for strategic decision-making.

It delves into Hexcel's core marketing elements, offering a detailed understanding of their competitive positioning and strategic approaches.

Simplifies complex marketing strategies into actionable insights, alleviating the pain of information overload for busy executives.

Provides a clear, concise overview of Hexcel's 4Ps, reducing the burden of deciphering intricate marketing plans.

Place

Hexcel's direct sales strategy is fundamental to its market position, focusing on major Original Equipment Manufacturers (OEMs) and key customers. This approach is essential for delivering highly specialized advanced composite materials that often require bespoke solutions and extensive technical partnership.

The company's direct engagement with giants like Airbus and Boeing, along with their respective subcontractors, underscores the critical nature of these relationships. In 2024, Airbus and its supply chain represented a significant portion of Hexcel's business, accounting for approximately 40% of its sales. Boeing and its subcontractors contributed another 15%.

Hexcel's global manufacturing footprint is a key element of its marketing strategy, enabling it to effectively serve a diverse international clientele. With around 5,900 employees spread across 20 manufacturing facilities worldwide, the company demonstrates a significant global reach. This expansive network is crucial for maintaining tight control over its supply chains and ensuring prompt delivery of advanced composite materials, a vital aspect for its aerospace and defense customers who rely on consistent production schedules.

Hexcel actively cultivates strategic partnerships to enhance its market position. A prime example is its long-term agreement with Kongsberg Defence & Aerospace, ensuring a steady supply of advanced composite materials like HexWeb® honeycombs and HexPly® prepregs. This collaboration not only solidifies Hexcel's distribution but also secures its involvement in critical defense programs.

Further strengthening its innovation pipeline, Hexcel collaborates with research institutions such as FIDAMC. These partnerships are crucial for accelerating the development and adoption of cutting-edge composite materials. By bridging the gap between research and commercial application, Hexcel ensures its materials are at the forefront of technological advancement across aerospace, defense, and industrial sectors.

Presence in Key Aerospace Hubs

Hexcel strategically leverages its presence at pivotal aerospace and defense events, including the highly anticipated Aero India 2025. This engagement is crucial for showcasing its advanced material solutions and reinforcing its integral role within global aerospace supply chains.

By actively participating in these key regional hubs, Hexcel fosters direct interaction with its customer base. This allows for immediate feedback and the cultivation of new business prospects, particularly in rapidly expanding markets such as India, which is projected to see significant growth in its aerospace sector in the coming years.

- Aero India 2025 Participation: Hexcel actively exhibits at major industry shows to demonstrate its latest composite technologies.

- Customer Engagement: Direct interaction at these events facilitates understanding of evolving customer needs and market trends.

- Market Penetration: Presence in key hubs like India supports expansion into high-growth aerospace and defense markets.

- Value Chain Integration: Exhibitions reinforce Hexcel's position as a critical supplier within the aerospace ecosystem.

Vertical Integration for Supply Chain Control

Hexcel's commitment to vertical integration, from carbon fiber production to advanced composite materials like prepregs and honeycomb, grants them substantial control over their supply chain. This strategy is crucial for maintaining the consistent quality and availability of critical components, especially in the demanding aerospace and defense sectors. For instance, Hexcel's proprietary resin systems are developed in-house, allowing for precise tailoring to specific performance requirements, which is a significant competitive advantage. This control directly translates to enhanced reliability and efficiency for their customers, supporting high-volume manufacturing needs.

This integrated approach allows Hexcel to manage costs and lead times more effectively, a key factor in securing long-term contracts. In 2023, Hexcel reported a 10% increase in its commercial aerospace segment, partly attributed to the reliable supply of its advanced materials. By controlling each stage of production, Hexcel can also foster innovation, developing next-generation composite solutions that push the boundaries of material science. This end-to-end capability ensures that customers receive not just raw materials, but fully optimized composite systems.

- In-house manufacturing of carbon fiber, prepreg, and honeycomb.

- Ensures consistent quality and supply chain reliability.

- Enables development of tailored composite solutions.

- Supports high-rate production and customer efficiency.

Hexcel's place strategy is deeply rooted in its direct engagement with key industry players, particularly Original Equipment Manufacturers (OEMs) in the aerospace and defense sectors. This direct approach ensures that Hexcel's highly specialized advanced composite materials, often requiring custom solutions, are delivered with the necessary technical support and partnership. The company's significant presence within the supply chains of major manufacturers like Airbus, which accounted for approximately 40% of Hexcel's sales in 2024, and Boeing (15%), highlights the critical nature of these established relationships.

Hexcel's global network of 20 manufacturing facilities, supported by around 5,900 employees, is central to its place strategy. This expansive footprint allows for efficient service to a worldwide customer base and maintains rigorous control over its supply chains, ensuring timely delivery of advanced composites vital for aerospace and defense production schedules. Strategic alliances, such as the one with Kongsberg Defence & Aerospace for HexWeb® honeycombs and HexPly® prepregs, further solidify Hexcel's market access and integration into key defense programs.

The company's participation in significant industry events, like Aero India 2025, is a deliberate strategy to showcase its technological advancements and reinforce its position within global aerospace supply chains. These engagements facilitate direct customer interaction, providing valuable feedback and opening avenues for new business, especially in high-growth markets like India's expanding aerospace sector.

| Customer Segment | 2024 Sales Contribution (Approx.) | Strategic Significance |

|---|---|---|

| Airbus & Subcontractors | 40% | Core relationship, drives demand for advanced composites. |

| Boeing & Subcontractors | 15% | Key partner, crucial for military and commercial aircraft programs. |

| Other Aerospace & Defense | 30% | Diversified customer base, growth opportunities. |

| Industrial Markets | 15% | Emerging sector, potential for new applications of composite technology. |

Full Version Awaits

Hexcel 4P's Marketing Mix Analysis

The preview shown here is the actual document you’ll receive instantly after purchase—no surprises. This comprehensive Hexcel 4P's Marketing Mix Analysis details product, price, place, and promotion strategies. You can confidently purchase, knowing you're getting the complete, ready-to-use analysis.

Promotion

Hexcel's promotion strategy centers on specialized B2B marketing, targeting engineers and procurement professionals in aerospace, defense, and industrial sectors. This approach highlights technical specifications and performance advantages, crucial for complex, long-term sales cycles.

Their technical sales force possesses deep product expertise, enabling them to effectively communicate value propositions and address the intricate needs of their clientele. This direct engagement is key to building trust and securing partnerships in high-value markets.

Hexcel's strategic engagement at key industry events like JEC World 2024 and the upcoming Aero India 2025 demonstrates a commitment to market visibility. These gatherings are crucial for showcasing their latest advancements in advanced composite materials, directly addressing market demands for lightweighting and sustainability solutions.

By participating in events such as the Carbon Fiber 2024 Conference, Hexcel positions itself as a thought leader, facilitating discussions on critical industry trends. This proactive approach allows them to gather market intelligence and reinforce their brand as an innovator in the advanced materials sector.

Hexcel actively showcases its thought leadership and innovation through participation in industry conferences and technical forums. For instance, in 2024, the company presented on advancements in automated fiber placement for aerospace applications, a key area where Hexcel's material science expertise drives efficiency and performance.

By sharing insights on topics like the environmental benefits of advanced composites and the challenges of scaling up composite production, Hexcel positions itself as a forward-thinking leader. This strategy reinforces their role as a crucial partner in developing the next generation of aircraft and other high-performance structures, a testament to their commitment to pushing material boundaries.

Investor Relations and Financial Communications

Hexcel actively manages its investor relations and financial communications to foster transparency and build trust with stakeholders. This includes regular updates through earnings calls, detailed annual reports, and strategic investor presentations. For instance, in their Q1 2024 earnings call, Hexcel highlighted a 12% year-over-year increase in revenue, driven by strong demand in commercial aerospace, demonstrating their commitment to open financial dialogue.

These efforts are crucial for attracting and retaining capital by clearly articulating Hexcel's financial health, strategic direction, and future growth potential. The company's proactive communication strategy aims to provide financial decision-makers with the insights needed to make informed investment choices, contributing to a stable shareholder base.

- Quarterly Earnings Calls: Hexcel provides real-time financial performance updates and answers investor questions.

- Annual Reports: Comprehensive documentation of financial results and strategic initiatives.

- Investor Presentations: Detailed outlooks on growth prospects and market positioning.

- Transparency: Cultivating investor confidence through open and consistent communication.

Sustainability Initiatives and Corporate Responsibility

Hexcel actively promotes its sustainability initiatives, showcasing a dedication to reducing its environmental footprint. This includes tangible goals for decreasing greenhouse gas emissions, minimizing waste sent to landfills, and lowering freshwater consumption across its operations. For instance, in 2023, Hexcel reported a 15% reduction in Scope 1 and 2 greenhouse gas emissions compared to their 2019 baseline, demonstrating progress towards their 2030 targets.

These efforts are often a collaborative endeavor, with Hexcel engaging customers in developing innovative recycling programs for composite materials. By highlighting these partnerships and achievements, Hexcel reinforces its image as a responsible corporate citizen. This resonates strongly with an increasing customer base that prioritizes environmentally sound products and supply chains, a trend particularly evident in the aerospace and defense sectors where Hexcel is a key supplier.

The company's commitment extends to transparent reporting, often detailing progress against key performance indicators. For example, Hexcel aims to divert 90% of its manufacturing waste from landfills by 2025, a goal they were on track to meet with 85% diversion achieved by the end of 2023. These actions not only contribute to a healthier planet but also enhance Hexcel's brand value and competitive positioning.

Key aspects of Hexcel's sustainability promotion include:

- Greenhouse Gas Emission Reduction: Targeting significant cuts in Scope 1 and 2 emissions, with a 2030 goal to reduce intensity by 30% from a 2019 baseline.

- Waste Minimization: Focusing on reducing manufacturing waste to landfills, aiming for 90% diversion by 2025.

- Water Stewardship: Implementing strategies to decrease freshwater usage in its facilities, particularly in water-stressed regions.

- Circular Economy Initiatives: Collaborating with customers on recycling programs for advanced composite materials, fostering a more sustainable lifecycle.

Hexcel's promotional efforts are deeply rooted in its specialized B2B approach, emphasizing technical expertise and performance benefits to engineers and procurement specialists in aerospace, defense, and industrial markets. Their direct sales force, equipped with extensive product knowledge, is central to conveying value propositions and addressing complex client needs, fostering essential trust for long-term partnerships.

Participation in key industry events like JEC World 2024 and the upcoming Aero India 2025 is vital for Hexcel's market visibility, showcasing advancements in composite materials that meet demands for lightweighting and sustainability. Further engagement at conferences such as the Carbon Fiber 2024 Conference positions Hexcel as a thought leader, facilitating discussions on industry trends and reinforcing its innovative brand image.

Hexcel's investor relations and financial communications are designed for transparency, utilizing earnings calls and annual reports to build stakeholder trust. For instance, their Q1 2024 earnings call reported a 12% year-over-year revenue increase, driven by commercial aerospace demand, underscoring their commitment to open financial dialogue.

The company actively promotes its sustainability initiatives, setting tangible goals for reducing greenhouse gas emissions, waste, and water consumption. Hexcel reported a 15% reduction in Scope 1 and 2 greenhouse gas emissions by 2023 compared to a 2019 baseline, demonstrating progress toward its 2030 targets.

Price

Hexcel's pricing for high-performance materials is deeply rooted in value-based principles, reflecting the substantial benefits these advanced composites deliver. Customers in demanding sectors like aerospace pay a premium because Hexcel's materials offer unparalleled strength-to-weight ratios, leading to significant improvements in fuel efficiency and overall performance. For instance, the adoption of advanced composites in commercial aircraft can reduce structural weight by 20-30%, translating into millions of dollars in fuel savings over the aircraft's lifecycle.

This value proposition justifies Hexcel's pricing structure, which is not simply cost-plus. Instead, it aligns with the tangible cost savings and performance enhancements customers achieve. In 2024, the aerospace industry's continued focus on sustainability and operational efficiency further amplifies the perceived value of lightweighting solutions, allowing Hexcel to command prices that reflect these critical customer needs and the advanced R&D investment required to produce these materials.

Hexcel's pricing strategy is heavily influenced by long-term contracts with major aerospace customers like Airbus and Boeing. These agreements, often spanning multiple years, provide a stable revenue stream and predictable pricing for both Hexcel and its clients.

These strategic partnerships lock in business for significant aircraft programs, with pricing structures directly tied to volume commitments and the anticipated lifecycle of each program. For instance, in 2024, Hexcel continued to benefit from its established relationships, securing multi-year supply agreements that underpin its revenue visibility.

Hexcel maintains a leading stance in aerospace composites, but its pricing strategy is deeply influenced by competitors such as Toray and Solvay. This competitive pressure necessitates a careful balance between premium pricing for its advanced materials and market accessibility.

The company's extensive product range and in-house manufacturing capabilities, known as vertical integration, provide a significant competitive advantage. This allows Hexcel to control quality and costs, supporting its market position, even as it navigates the threat of original equipment manufacturers (OEMs) developing their own composite capabilities.

While Hexcel benefits from its technological leadership, there's a growing concern about potential commoditization in certain industrial applications. This risk could impact pricing power, especially in sectors where material differentiation is less pronounced, contrasting with the high-value aerospace market.

Impact of External Factors and Supply Chain

Hexcel's pricing strategy is significantly shaped by external forces like fluctuating raw material costs and supply chain vulnerabilities. For instance, the aerospace industry, a key market for Hexcel, experienced significant supply chain disruptions in 2023 and early 2024, impacting material availability and lead times. These pressures directly affect Hexcel's cost of goods sold, necessitating careful price adjustments to preserve profitability.

The company's proactive stance on operational excellence is crucial for navigating these challenges. By focusing on efficiency improvements and cost management, Hexcel aims to absorb some of the external cost pressures. This commitment was evident in their efforts throughout 2023 to optimize production processes, which helped to offset some of the inflationary impacts on their material inputs.

Tariffs and trade policies also represent a notable external factor influencing Hexcel's pricing. Changes in import/export duties can alter the landed cost of raw materials or finished goods, requiring strategic pricing adjustments. Hexcel's ability to maintain competitive pricing in a global market hinges on its agility in responding to these evolving trade landscapes.

Key considerations for Hexcel's pricing in light of external factors include:

- Raw Material Cost Volatility: Hexcel's composite materials rely on specialized inputs, the prices of which can be highly variable. For example, carbon fiber precursor costs saw upward pressure in late 2023 due to energy prices and specific supply constraints.

- Supply Chain Resilience: Disruptions, such as those seen in global shipping and logistics in 2023, can increase freight costs and delay deliveries, impacting Hexcel's ability to meet demand and potentially forcing price increases.

- Tariff and Trade Policy Impact: The imposition or removal of tariffs on key raw materials or finished products can directly alter Hexcel's cost structure and competitive positioning, necessitating pricing recalibrations.

- Operational Efficiency as a Mitigator: Hexcel's ongoing investments in manufacturing technology and process optimization are designed to counter these external cost pressures and maintain healthy profit margins.

Strategic Capital Allocation and Shareholder Returns

Hexcel's financial strategy centers on robust free cash flow generation, enabling significant returns to shareholders via dividends and share buybacks. This disciplined approach to capital allocation, coupled with a steadfast focus on cost management and operational improvements, underpins the company's financial stability and long-term growth prospects. Such financial health allows Hexcel to strategically invest in innovation, which indirectly supports its pricing power by ensuring a competitive product portfolio.

In 2024, Hexcel demonstrated this commitment to shareholder returns. For instance, the company repurchased approximately $200 million of its stock, alongside paying out dividends, reflecting a balanced approach to capital deployment. This strategy is crucial for maintaining investor confidence and supporting the company's ability to fund research and development, a key driver for future product differentiation and pricing strategy.

- Shareholder Returns: Hexcel aims to return a substantial portion of its free cash flow to shareholders.

- Capital Allocation: The company prioritizes disciplined capital allocation, balancing reinvestment in the business with shareholder payouts.

- Financial Health: Strong free cash flow and cost control ensure financial viability, supporting strategic pricing decisions.

- Innovation Investment: Financial strength enables continued investment in R&D, crucial for maintaining a competitive edge.

Hexcel's pricing strategy is fundamentally value-based, reflecting the significant performance enhancements and cost savings its advanced composite materials offer customers, particularly in the aerospace sector. This approach allows them to command premium prices, as seen in their continued success in 2024 securing multi-year supply agreements with major OEMs.

The company balances this premium pricing with competitive pressures from rivals like Toray and Solvay, leveraging its vertical integration and technological leadership to maintain market position. While aerospace pricing is strong, there's a noted risk of commoditization in some industrial applications, which could impact future pricing power.

External factors such as raw material cost volatility, supply chain disruptions impacting freight costs, and trade policies necessitate agile pricing adjustments. Hexcel's focus on operational efficiency in 2023 helped mitigate some of these inflationary pressures on their inputs.

Financial discipline, including significant shareholder returns in 2024 with approximately $200 million in stock repurchases, supports Hexcel's ability to invest in R&D, a critical component of maintaining its pricing advantage through product differentiation.

| Factor | Impact on Hexcel Pricing | 2023/2024 Data/Trend |

|---|---|---|

| Value Proposition | Justifies premium pricing; linked to fuel efficiency and weight reduction. | Aerospace lightweighting remains a key driver for value perception. |

| Competition | Requires balancing premium with market accessibility. | Ongoing competition from Toray and Solvay influences pricing benchmarks. |

| Raw Material Costs | Directly impacts cost of goods sold, necessitating price adjustments. | Carbon fiber precursor costs saw upward pressure late 2023 due to energy and supply constraints. |

| Shareholder Returns | Financial health enables R&D investment, supporting pricing power. | Approx. $200 million in stock repurchases in 2024, alongside dividends. |

4P's Marketing Mix Analysis Data Sources

Our Hexcel 4P's Marketing Mix Analysis is grounded in a comprehensive review of publicly available data, including financial reports, investor relations materials, and official company announcements. We also incorporate insights from industry publications and market research to ensure a robust understanding of Hexcel's strategic decisions.