Fong's PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Fong's Bundle

Uncover the hidden forces shaping Fong's future with our comprehensive PESTLE analysis. From evolving political landscapes to technological disruptions, understand how these external factors create both challenges and opportunities. Gain critical insights to inform your investment or strategic decisions. Download the full version now for a deeper dive into Fong's market environment.

Political factors

Governments globally are actively promoting sustainable manufacturing, particularly in sectors like textiles. For instance, the European Union's Strategy for Sustainable and Circular Textiles, launched in 2022, sets ambitious targets for reducing waste and increasing the use of recycled materials. This policy landscape directly encourages businesses to adopt greener production methods.

These governmental pushes translate into tangible incentives and regulations. Many countries are offering tax breaks or subsidies for investments in energy-efficient equipment and the adoption of circular economy principles. In 2024, for example, several nations introduced new grants for companies investing in advanced recycling technologies for textiles, aiming to divert millions of tons of waste from landfills.

Fong's strategic decision to invest in resource-efficient machinery is therefore highly aligned with these evolving political directives. By prioritizing machinery that minimizes energy consumption and waste generation, Fong is positioning itself to benefit from favorable policies and potentially avoid future regulatory penalties associated with less sustainable practices.

Changes in international trade agreements and the imposition of tariffs directly influence the cost of raw materials and the competitive edge of textile machinery manufacturers. For instance, the US's imposition of tariffs on textiles from China, and subsequent retaliatory measures, underscore the inherent instability in global trade dynamics. Fong's, operating as a worldwide supplier, must adeptly manage these intricate trade environments to preserve its standing in the market.

Geopolitical tensions in major textile production hubs like Southeast Asia and South Asia can significantly disrupt global supply chains. For instance, ongoing trade disputes or regional conflicts can lead to increased shipping costs and delays, impacting the timely delivery of raw materials and finished goods. This instability directly affects businesses like Fong's, potentially causing fluctuations in demand and complicating long-term investment in new manufacturing equipment, as seen in the 2024 supply chain disruptions affecting numerous apparel companies.

Labor Laws and Ethical Sourcing Regulations

Governments and international bodies are increasingly scrutinizing and strengthening labor laws, pushing for ethical sourcing across industries, including textiles. This trend directly impacts Fong's, requiring diligent oversight of its supply chain to ensure compliance with new mandates. For instance, the Uyghur Forced Labor Prevention Act, enacted in the US, places a significant burden on companies to prove their goods are free from forced labor, with potential penalties for non-compliance. Similarly, the EU Corporate Sustainability Due Diligence Directive (CSDDD), expected to be fully implemented by 2025, will mandate that companies identify, prevent, and mitigate human rights and environmental harms in their operations and value chains. This means Fong's must proactively adapt its sourcing and operational policies to meet these heightened ethical and legal standards.

The push for ethical sourcing necessitates robust due diligence processes. Fong's needs to verify that its suppliers adhere to fair labor practices, which can involve audits, certifications, and transparent reporting. Failure to comply with these evolving regulations can lead to significant reputational damage and financial penalties. For example, a 2024 report indicated that supply chain disruptions due to non-compliance with labor laws cost companies an average of 7% of their annual revenue. Therefore, Fong's must integrate these legal and ethical considerations into its core business strategy to mitigate risks and maintain its social license to operate.

- Increased regulatory scrutiny on labor practices globally.

- Legislation like the Uyghur Forced Labor Prevention Act demands supply chain transparency.

- The EU Corporate Sustainability Due Diligence Directive (CSDDD) will impose mandatory human rights and environmental due diligence.

- Non-compliance with ethical sourcing regulations can result in substantial financial and reputational costs.

Corporate Sustainability Reporting Directives

New political directives are significantly reshaping corporate responsibilities, particularly concerning environmental, social, and governance (ESG) disclosures. The European Union's Corporate Sustainability Reporting Directive (CSRD), for instance, mandates standardized ESG reporting for a broad range of companies, including those operating within the textile industry. This legislation aims to foster greater transparency and accountability in how businesses manage their environmental and social impacts.

For companies like Fong's, adapting to these evolving regulatory landscapes is crucial. Meeting these stringent reporting requirements will necessitate robust data collection and reporting mechanisms. By 2024, the CSRD had already begun impacting thousands of companies across the EU, setting a precedent for global sustainability reporting standards.

- CSRD Expansion: The directive is progressively expanding its scope, with larger EU companies and listed non-EU companies expected to comply by 2025 and 2028 respectively.

- Increased Transparency: Regulations like CSRD push for a 360-degree view of a company's impact, covering environmental, social, and governance aspects.

- Data Assurance: The directives often include requirements for independent assurance of reported sustainability data, adding another layer of compliance.

- Competitive Advantage: Proactive adaptation to these standards can provide a competitive edge, attracting investors and customers who prioritize sustainability.

Governments are increasingly prioritizing sustainable practices and circular economy models within the textile sector. Policies like the EU's Strategy for Sustainable and Circular Textiles (2022) and the introduction of grants for advanced recycling technologies in 2024 highlight a clear trend towards incentivizing greener production.

These political shifts translate into tangible benefits for companies like Fong that invest in resource-efficient machinery, aligning with global sustainability goals and potentially reducing future regulatory risks.

The political landscape also impacts global trade through tariffs and trade agreements, affecting raw material costs and competitive dynamics for manufacturers like Fong. Geopolitical tensions in key textile regions can further disrupt supply chains, leading to increased costs and delivery delays, as evidenced by 2024 supply chain disruptions.

What is included in the product

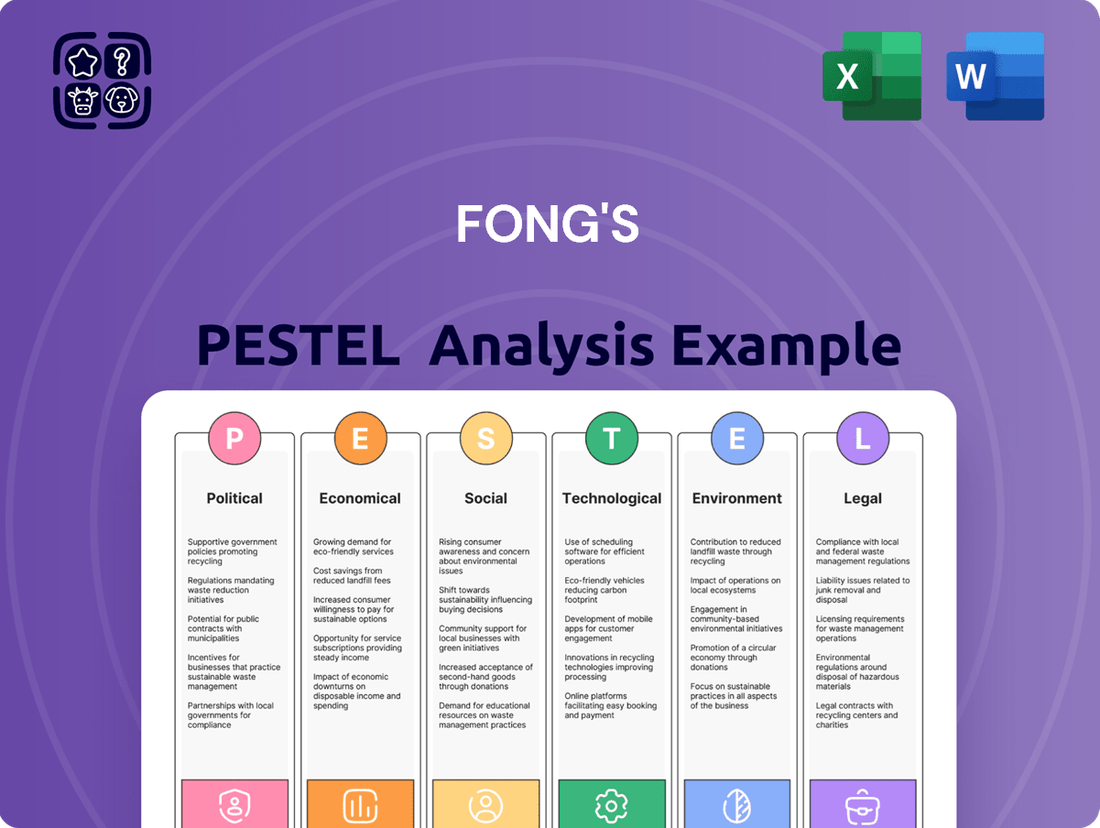

Fong's PESTLE Analysis provides a comprehensive examination of the external macro-environmental factors impacting the business across Political, Economic, Social, Technological, Environmental, and Legal dimensions. This detailed evaluation aims to equip stakeholders with actionable insights to navigate the dynamic business landscape and inform strategic decision-making.

Fong's PESTLE Analysis offers a visually segmented breakdown by PESTEL categories, enabling quick interpretation of external factors and their impact.

Economic factors

The overall health of the global economy significantly impacts investment in new textile machinery. For instance, a projected global GDP growth of 2.7% in 2024, according to the IMF, suggests a moderate economic environment. However, an economic slowdown can dampen demand for apparel and textiles, leading textile manufacturers to postpone capital expenditures on new equipment.

Looking ahead to 2025, the IMF forecasts a slight acceleration in global GDP growth to 2.9%. This potential economic pickup could encourage textile businesses to increase their investment in upgrading machinery, driven by anticipated higher consumer spending on fashion and home textiles.

Fluctuations in the cost of essential raw materials, like steel and specialized alloys, directly impact Fong's machinery manufacturing expenses. For instance, global steel prices saw a notable increase in early 2024, with benchmarks like the TSI US HRC futures contract trading around $750 per ton, up from $600 in late 2023. This surge directly translates to higher production costs for Fong.

Energy prices are another critical factor. In 2024, European energy markets, particularly for natural gas, have remained more volatile and generally higher than in North America or many Asian manufacturing hubs. Average industrial electricity prices in Germany in the latter half of 2024 hovered around €0.25 per kWh, significantly impacting operational overheads compared to, for example, the US Midwest at around $0.07 per kWh.

These input cost differentials can notably affect Fong's competitive positioning. Manufacturers in regions with higher energy expenses may struggle to match the pricing of competitors in lower-cost areas, potentially impacting market share. Effectively managing and hedging against these volatile raw material and energy costs is paramount for Fong's sustained profitability and competitive edge in the global market.

Currency exchange rate volatility presents a significant challenge for Fong's as a global manufacturer. Fluctuations in foreign exchange rates directly impact the pricing of its machinery sold internationally and the value of profits sent back home. For instance, if Fong's home currency strengthens significantly against the currencies of its major export markets, its machinery will become more expensive for overseas buyers, potentially dampening demand.

Conversely, a weaker domestic currency can make Fong's exports more attractive and cost-competitive abroad. This dynamic was evident in late 2024, where many emerging market currencies experienced significant depreciation against the US dollar, offering a potential pricing advantage for manufacturers in those regions. Fong's must employ robust financial strategies, such as hedging with forward contracts or currency options, to buffer its financial performance against these unpredictable currency movements.

Consumer Spending and Textile Demand

Consumer spending habits significantly shape the textile industry. In 2023, global retail sales of apparel and footwear reached approximately $1.7 trillion, demonstrating the substantial market size influenced by consumer purchasing power and preferences. Spending on non-essential items, including fashion and luxury textiles, directly translates to demand for textile machinery. For Fong's, understanding these trends is crucial for aligning machinery production with market needs.

Shifting consumer preferences are a key driver for innovation in textile manufacturing. A growing emphasis on sustainability, ethical sourcing, and eco-friendly materials means that demand for machinery capable of processing recycled fibers or using less water and energy is on the rise. Reports from 2024 indicate that the sustainable fashion market is projected to grow substantially, creating opportunities for manufacturers offering advanced, environmentally conscious equipment.

Fong's must adapt its product development to cater to these evolving consumer demands. This includes investing in machinery that can handle new, sustainable materials and support more efficient, less impactful production processes. For instance, the market for advanced textile recycling machinery is expected to see significant growth through 2025, driven by both consumer pressure and regulatory changes.

- Consumer Spending Impact: Global apparel and footwear retail sales in 2023 were around $1.7 trillion, highlighting the direct link between consumer expenditure and textile sector activity.

- Sustainability Drive: Consumer demand for sustainable textiles is increasing, influencing the need for machinery that supports eco-friendly production methods and recycled materials.

- Machinery Innovation: Fong's needs to focus on developing machinery that can process sustainable fabrics and improve production efficiency to meet market shifts.

- Market Growth: The sustainable fashion market is experiencing robust growth, projected to continue through 2025, indicating a strong demand for related textile machinery.

Market Size and Growth of Textile Machinery

The global textile machinery market is experiencing robust expansion, anticipated to reach USD 30.3 billion in 2024. This growth is fueled by a clear trend towards automated and advanced machinery, a segment where Fong's excels. The market is projected to continue this upward trajectory, with an estimated Compound Annual Growth Rate (CAGR) of 5.2% between 2025 and 2034, indicating substantial long-term opportunities.

This expanding market size, particularly the increasing demand for sophisticated solutions, directly benefits Fong's. The Asia-Pacific region is a key driver of this growth, reflecting a strong appetite for technological upgrades in textile manufacturing. Fong's strategic focus on innovation and efficiency positions it well to capitalize on these market dynamics.

- Market Valuation: The global textile machinery market was valued at USD 30.3 billion in 2024.

- Projected Growth: Expected to grow at a CAGR of 5.2% from 2025 to 2034.

- Key Demand Driver: Increasing demand for automated and advanced machinery, especially in Asia-Pacific.

- Opportunity for Fong's: Significant potential for Fong's due to its focus on innovative and efficient solutions.

Global economic growth directly influences demand for textile machinery. With the IMF projecting a 2.7% global GDP growth for 2024 and a slight uptick to 2.9% in 2025, this suggests a generally stable, though not booming, economic climate. A slowdown could lead textile manufacturers to delay capital expenditures on new equipment, impacting Fong's sales.

Fluctuations in raw material and energy costs significantly affect Fong's production expenses. For example, steel prices saw an increase in early 2024, with US HRC futures around $750 per ton. Additionally, industrial electricity prices in Germany averaged €0.25 per kWh in late 2024, a stark contrast to the US Midwest's $0.07 per kWh, directly impacting manufacturing overheads and competitive pricing.

Currency exchange rate volatility poses a challenge for Fong's global operations. A stronger home currency can make exports more expensive, potentially reducing demand, while a weaker currency can offer a competitive pricing advantage. For instance, the depreciation of many emerging market currencies against the US dollar in late 2024 presented such opportunities.

Consumer spending on apparel and textiles, which reached approximately $1.7 trillion globally in 2023, drives demand for textile machinery. Evolving preferences towards sustainability are also critical, increasing demand for machinery that can process recycled materials and support eco-friendly production, a trend expected to grow through 2025.

| Economic Factor | 2024 Data/Projection | 2025 Projection | Impact on Fong's |

|---|---|---|---|

| Global GDP Growth | 2.7% (IMF) | 2.9% (IMF) | Influences capital expenditure by textile manufacturers. |

| Steel Prices (US HRC Futures) | ~ $750/ton (Early 2024) | Volatile | Directly impacts manufacturing costs. |

| Industrial Electricity (Germany) | ~ €0.25/kWh (Late 2024) | Volatile | Affects operational overheads and competitiveness. |

| Global Apparel & Footwear Retail Sales | ~$1.7 Trillion (2023) | Growing | Indicates overall demand for textiles, indirectly for machinery. |

| Sustainable Fashion Market | Growing | Projected significant growth | Drives demand for specialized, eco-friendly machinery. |

Preview the Actual Deliverable

Fong's PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use.

This comprehensive PESTLE analysis of Fong's provides a detailed breakdown of the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the business.

Understand the strategic landscape and identify key opportunities and threats that could shape Fong's future success.

This is a real screenshot of the product you’re buying—delivered exactly as shown, no surprises.

Sociological factors

Consumers are increasingly prioritizing sustainability and ethical sourcing in their fashion choices, driving a significant shift in the textile industry. This growing consciousness means brands are under pressure to embrace circular business models and environmentally sound manufacturing processes. For instance, a 2024 survey indicated that over 60% of Gen Z consumers consider a brand's sustainability efforts when making purchasing decisions.

This societal trend directly impacts textile manufacturers, compelling them to invest in advanced machinery that minimizes waste, optimizes resource utilization, and facilitates the use of recycled or eco-friendly materials. The market for sustainable apparel is projected to reach $150 billion by 2025, demonstrating the scale of this opportunity.

Fong's innovative machinery, engineered with sustainability at its core, is strategically positioned to capitalize on this evolving consumer demand. Our equipment supports reduced water consumption by up to 30% and energy usage by 20% compared to conventional machinery, aligning perfectly with the industry's sustainability imperative.

The textile industry, including companies like Fong's, is grappling with a significant shift in workforce needs. Automation and digitalization are rapidly changing the landscape, demanding new skill sets. For instance, in 2024, the global textile machinery market is projected to reach over $20 billion, with a growing emphasis on smart and automated systems, requiring workers proficient in operating and maintaining these advanced technologies.

To address this, Fong's and its clients are increasingly prioritizing workforce well-being and skill development. This means investing in training programs to upskill existing employees and attract new talent capable of handling sophisticated machinery and digital interfaces. Reports from 2024 indicate a surge in demand for technicians with expertise in mechatronics and data analytics within the manufacturing sector, directly impacting textile operations.

Global awareness of health and safety in manufacturing is escalating, leading to more stringent regulations for textile producers. This trend directly influences operational costs and compliance burdens for companies like Fong's clients. For instance, in 2024, the International Labour Organization reported a 15% increase in workplace accident investigations in the garment sector across several Asian countries, highlighting the growing scrutiny.

Fong's can proactively address these concerns by innovating machinery that prioritizes worker well-being. Developing equipment with advanced safety features, such as enclosed moving parts and improved ventilation systems, can significantly reduce employee exposure to hazardous chemicals and repetitive strain injuries. This focus not only meets regulatory demands but also resonates with increasingly conscious consumers who value ethically produced goods.

Shifting Consumer Preferences towards Quality and Longevity

Consumers are increasingly prioritizing quality and durability, moving away from disposable fast fashion. This trend favors textile manufacturers capable of producing long-lasting, customizable items. For instance, the global sustainable fashion market was valued at approximately $6.5 billion in 2023 and is projected to reach over $10 billion by 2030, indicating a significant shift in consumer spending habits towards more enduring products.

This growing demand for 'slow fashion' encourages investment in advanced machinery that can create specialized, high-quality fabrics. Fong's commitment to environmentally conscious and durable textile solutions directly addresses this evolving consumer preference. Reports from 2024 suggest that over 60% of consumers are willing to pay a premium for clothing made from sustainable and durable materials.

- Growing demand for durable textiles: Consumers actively seek clothing that lasts longer.

- Investment in advanced machinery: Manufacturers are adapting to produce specialized, high-quality fabrics.

- Rise of 'slow fashion': A direct contrast to the disposable nature of fast fashion is gaining traction.

- Willingness to pay more for sustainability: A significant portion of consumers prioritize eco-friendly and long-lasting options.

Brand Reputation and Corporate Social Responsibility (CSR)

Brand reputation and corporate social responsibility (CSR) are increasingly vital in the textile sector, with consumers and clients demanding greater accountability. Companies like Fong face mounting pressure to demonstrate positive social and environmental impacts throughout their value chains. A strong commitment to sustainability, therefore, directly enhances a company's brand image, making it more attractive to partners prioritizing ethical operations.

Fong's proactive approach to improving sustainability in textile manufacturing is a strategic advantage. This focus can significantly bolster its brand image, appealing to a growing segment of clients who actively seek out and value responsible business practices. Transparency and ethical conduct are no longer optional but essential for building trust and maintaining market relevance.

The emphasis on transparency and ethical practices in the textile industry is a significant sociological factor. For instance, a 2024 report indicated that over 60% of consumers consider a brand's sustainability efforts when making purchasing decisions. This trend directly impacts how companies like Fong are perceived and selected by business partners.

- Consumer Demand for Sustainability: Growing consumer awareness drives demand for ethically produced textiles, influencing brand choice.

- Investor Scrutiny: Investors increasingly evaluate CSR performance as a key indicator of long-term viability and risk management.

- Supply Chain Transparency: Clients and regulators expect detailed information on labor practices, environmental impact, and material sourcing.

- Reputational Risk: Negative publicity stemming from poor CSR can severely damage brand reputation and market share.

Societal values are shifting, with consumers increasingly prioritizing sustainability and ethical production in their purchasing decisions. This is driving demand for durable, responsibly sourced textiles and influencing brand loyalty. A 2024 survey revealed that over 60% of consumers consider a brand's ethical practices when buying clothes.

This heightened awareness necessitates that textile manufacturers invest in advanced machinery that supports eco-friendly processes and worker well-being. Fong's equipment, designed with reduced water and energy consumption, aligns with these evolving consumer expectations and industry trends, positioning the company favorably in a market that values responsible manufacturing.

The focus on brand reputation and corporate social responsibility (CSR) is paramount, as consumers and business partners demand greater accountability. Fong's commitment to sustainability enhances its brand image and attractiveness to clients who prioritize ethical operations, making transparency and ethical conduct essential for market relevance.

| Sociological Factor | Impact on Textile Industry | Fong's Strategic Alignment |

|---|---|---|

| Consumer Demand for Sustainability | Growing preference for eco-friendly and ethically produced garments. | Fong's machinery supports reduced water/energy use, aligning with consumer values. |

| Emphasis on Quality and Durability | Shift from fast fashion to 'slow fashion' favoring long-lasting products. | Fong's equipment enables production of specialized, high-quality fabrics. |

| Brand Reputation & CSR | Increased scrutiny on company ethics and social impact by consumers and investors. | Fong's sustainability focus enhances brand image and attracts ethically-minded clients. |

| Workforce Skill Evolution | Demand for workers proficient in automation, digitalization, and advanced machinery operation. | Fong's machinery requires skilled operators, necessitating investment in training and development. |

Technological factors

The textile industry's embrace of Industry 4.0 is a major technological driver. Fong's, by developing smart dyeing and finishing machinery, is at the forefront of this digital shift. This integration of AI, IoT, and robotics is boosting efficiency across the sector.

Technological advancements are revolutionizing the textile industry, pushing for greener dyeing and finishing. Innovations like waterless dyeing, supercritical CO2 technology, and digital printing are gaining traction, significantly cutting down water, energy, and chemical usage. This directly supports Fong's commitment to offering sustainable, eco-conscious products.

The global market for textile chemicals is projected to reach approximately $26 billion by 2026, with a growing segment dedicated to sustainable alternatives. Technologies that minimize environmental impact are becoming increasingly competitive, offering Fong a clear advantage in meeting evolving consumer and regulatory demands.

The textile industry is increasingly benefiting from the integration of the Internet of Things (IoT) and Artificial Intelligence (AI). This technological shift enables real-time monitoring of manufacturing processes, allowing for proactive identification of potential equipment failures through predictive maintenance. For instance, companies are seeing reductions in unplanned downtime by up to 25% by implementing AI-driven predictive maintenance strategies, according to recent industry reports from 2024.

Fong's can capitalize on these advancements by adopting IoT-enabled machinery and AI analytics platforms. This will not only optimize the performance of its own textile production lines but also empower the company to offer more advanced, data-driven solutions to its clientele. Such adoption is crucial for staying competitive, as a significant portion of leading textile manufacturers are expected to invest heavily in these technologies throughout 2025 to improve efficiency and product quality.

R&D Investment in Energy and Water-Saving Technologies

Fong's commitment to research and development in energy and water-saving technologies is a significant technological factor influencing its market position. Continuous innovation in textile machinery to reduce resource consumption is vital for staying competitive. Fong's strategic focus on developing machines that minimize waste and optimize water and energy usage directly addresses growing market demands for sustainability.

This R&D investment translates into tangible benefits. For instance, advancements in dyeing technologies can drastically cut down water usage. Reports from the International Textile Manufacturers Federation (ITMF) in 2024 indicated a sector-wide drive towards reducing water consumption by up to 30% in certain processes by 2025. Fong's development of machines that achieve these efficiencies, such as low liquor ratio dyeing machines, positions it favorably.

- Focus on Efficiency: Fong is investing in R&D to create textile machinery that significantly lowers energy and water consumption, aligning with global sustainability goals.

- Market Demand Alignment: This technological focus addresses a key market driver where customers increasingly demand environmentally friendly solutions.

- Competitive Advantage: Innovations leading to reduced operational costs for clients through resource savings provide Fong with a distinct competitive edge.

- Waste Reduction: The development of machinery designed to minimize fabric and chemical waste further enhances Fong's appeal in a resource-conscious market.

Emergence of Digital Twins and Simulation Technologies

Digital twins, essentially virtual copies of physical assets or processes, are revolutionizing manufacturing. Textile companies are leveraging this technology to simulate and fine-tune operations, thereby minimizing costly errors and reducing material waste before any physical changes are made. This predictive capability significantly boosts operational efficiency and supports sustainability goals.

The adoption of digital twins in the textile industry is projected to grow substantially. For instance, the global digital twin market was valued at approximately $3.5 billion in 2023 and is anticipated to reach over $30 billion by 2028, indicating a strong trend towards simulation technologies. This growth is driven by the demand for enhanced product development, predictive maintenance, and optimized supply chains.

- Enhanced Operational Efficiency: Textile firms can test process improvements virtually, leading to faster implementation and reduced downtime.

- Waste Reduction: Simulations allow for the identification and correction of potential issues that could lead to material waste, improving eco-friendliness.

- Cost Savings: By predicting and preventing errors, companies can significantly lower operational and material costs.

- Accelerated Innovation: Digital twins facilitate rapid prototyping and testing of new designs or manufacturing techniques.

Technological advancements are reshaping the textile industry, with Fong's smart machinery at the forefront. AI, IoT, and robotics are boosting efficiency, and innovations like waterless dyeing and digital printing are reducing environmental impact, aligning with Fong's sustainable goals. The global textile chemicals market, projected to reach $26 billion by 2026, shows a growing demand for eco-friendly alternatives, a space where Fong's innovations offer a competitive edge.

The integration of AI and IoT is enabling predictive maintenance in textile manufacturing, with companies seeing up to a 25% reduction in unplanned downtime as of 2024. Fong can leverage these technologies to optimize its own production and offer advanced, data-driven solutions. Leading textile manufacturers are expected to significantly invest in these areas throughout 2025 to enhance efficiency and product quality.

Fong's commitment to R&D in energy and water-saving technologies is a key differentiator. The ITMF reported in 2024 that the sector aims to cut water consumption by up to 30% in certain processes by 2025. Fong’s development of low liquor ratio dyeing machines directly addresses this industry-wide push for resource efficiency and waste minimization.

Digital twins are also transforming textile manufacturing by allowing virtual simulation and optimization, reducing errors and material waste. The digital twin market is set to grow from $3.5 billion in 2023 to over $30 billion by 2028, highlighting the increasing adoption of simulation technologies for improved product development and operational efficiency.

| Technology | Impact on Textile Industry | Fong's Opportunity | Market Trend (2024-2025) |

|---|---|---|---|

| Industry 4.0 (AI, IoT, Robotics) | Increased efficiency, real-time monitoring, predictive maintenance | Optimize production, offer advanced client solutions | Significant investment by leading manufacturers |

| Sustainable Dyeing & Finishing | Reduced water, energy, chemical usage | Meet growing demand for eco-friendly products | Growing segment within $26B textile chemicals market |

| Digital Twins | Virtual simulation, error reduction, waste minimization | Enhance product development, improve operational planning | Projected market growth to over $30B by 2028 |

Legal factors

Global environmental regulations are tightening, especially for industries like textile dyeing and finishing. These rules focus on reducing water discharge, managing chemical use, and handling waste more responsibly. For instance, the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation impacts chemical imports and usage, pushing for safer alternatives and stricter controls.

Many countries are now implementing or strengthening laws that set lower limits for pollutants in wastewater and mandate the phase-out of hazardous chemicals. By 2024, many regions are expected to have even more rigorous standards for chemical substance management in textiles, aligning with circular economy principles that prioritize resource efficiency and waste reduction.

Fong's machinery plays a crucial role in helping its clients meet these evolving environmental demands. Innovations in water treatment and chemical application technology within Fong's equipment are designed to ensure compliance with discharge permits and reduce the overall environmental footprint of textile manufacturing operations.

Textile machinery, including Fong's products, must meet stringent international safety and quality standards to guarantee both reliable operation and the well-being of factory workers. For instance, conformity with CE marking in Europe and UL certification in North America are often prerequisites for market access. These evolving regulations necessitate ongoing investment in machinery design and manufacturing process enhancements. Fong's commitment to adhering to these global testing benchmarks, such as those set by the International Organization for Standardization (ISO), is crucial for maintaining product integrity and customer trust.

Protecting Fong's intellectual property, particularly for its innovative machinery designs and proprietary technologies, is paramount to sustaining its competitive edge in the advanced textile solutions market. Strong legal protections, especially in patents and trademarks, are vital to deterring infringement and safeguarding Fong's market leadership.

As of early 2024, Fong's boasts a significant patent portfolio, with over 150 active patents globally, a testament to its continuous investment in research and development. This robust intellectual property strategy is designed to shield its technological advancements and secure its position against competitors seeking to replicate its unique offerings.

International Trade Laws and Compliance

Fong must meticulously adhere to international trade regulations, such as anti-dumping rules, economic sanctions, and import/export controls, to ensure its global business activities remain lawful and efficient. Navigating these legal frameworks is paramount for avoiding penalties and maintaining market access. For instance, in 2024, the World Trade Organization (WTO) reported a significant increase in trade disputes, highlighting the evolving landscape of international commerce.

Geopolitical shifts frequently introduce new trade barriers and restrictions, compelling Fong to proactively adapt its legal strategies. This dynamic environment necessitates constant monitoring of global political developments and their potential impact on trade policies. As of early 2025, several major economies have implemented updated tariffs and non-tariff barriers, directly affecting supply chains.

- Global Trade Compliance: Fong's commitment to international trade laws, including anti-dumping measures, sanctions, and import/export regulations, underpins its ability to operate across borders.

- Geopolitical Impact: Evolving geopolitical tensions can result in new trade restrictions, demanding agile legal navigation and risk management for Fong.

- Evolving Regulations: The global regulatory environment for trade is in constant flux, requiring Fong to stay abreast of changes to maintain compliance and avoid disruptions.

- Market Access and Risk: Adherence to these legal factors directly influences Fong's market access and mitigates the financial and operational risks associated with non-compliance.

Extended Producer Responsibility (EPR) Schemes

New legislation is increasingly placing Extended Producer Responsibility (EPR) on manufacturers, particularly in the textile sector. For example, the European Union's Strategy for Sustainable and Circular Textiles, expected to be fully implemented by 2025, mandates EPR schemes that require producers to cover the costs of managing textile waste. This legal framework directly incentivizes companies to invest in product design that prioritizes durability, repairability, and recyclability, thereby shifting demand towards advanced machinery capable of processing recycled textile materials.

The financial implications are significant, as producers will bear the direct costs of collection, sorting, and recycling. This could lead to increased operational expenses for businesses not yet equipped for circular economy practices.

- EPR mandates drive investment in sustainable product design.

- Demand for textile recycling machinery is expected to rise.

- EU textile strategy aims for full EPR implementation by 2025.

- Producers will finance textile waste management, influencing cost structures.

Legal frameworks surrounding environmental protection are increasingly stringent, impacting industries like textile manufacturing. Regulations focus on reducing water pollution, managing chemical usage, and improving waste handling, with many regions enforcing stricter standards for chemical substances by 2024 and aligning with circular economy principles by 2025.

Fong's machinery is designed to help clients meet these evolving environmental regulations, incorporating advanced water treatment and chemical application technologies to ensure compliance and minimize environmental impact.

Intellectual property protection, especially for innovative machinery designs, is crucial for Fong's market position. As of early 2024, Fong holds over 150 active patents globally, safeguarding its technological advancements.

International trade regulations, including anti-dumping rules and import/export controls, require careful navigation, especially with the WTO reporting an increase in trade disputes in 2024 and several economies implementing new tariffs as of early 2025.

Environmental factors

The textile sector faces substantial pressure to curb its high water and energy usage, especially in dyeing and finishing stages. For instance, the World Bank reported in 2023 that textile dyeing alone accounts for about 20% of global wastewater. Fong's commitment to creating sophisticated machinery that boosts efficiency and lowers resource input directly tackles this significant environmental challenge.

The textile industry is facing increasing pressure globally to reduce waste and embrace circular economy models. This shift involves more than just recycling; it encompasses initiatives for collecting used textiles, encouraging their reuse, and developing robust recycling processes to turn old materials into new ones. For instance, the Ellen MacArthur Foundation reported in 2023 that only 1% of clothing is recycled into new clothing, highlighting the vast potential for improvement and innovation in this area.

Fong's business model, which focuses on solutions that facilitate closed-loop systems and the processing of recycled materials, directly aligns with these growing environmental demands. By enabling the efficient reuse and reprocessing of textiles, Fong can capitalize on the market's need for sustainable solutions. The European Union's commitment to a circular economy, with targets for textile waste management, further underscores the strategic advantage of Fong's approach. In 2022, the EU's textile waste generation was estimated at 12.6 million tonnes, with less than 1% being recycled into new garments.

Growing consumer and regulatory pressure is fueling a significant increase in the demand for non-toxic dyes and chemicals within the textile industry. This shift is directly impacting manufacturers like Fong, who must ensure their machinery can effectively handle these eco-friendly alternatives. For instance, the global green textile market, encompassing eco-friendly dyes, is projected to reach a substantial valuation, with some estimates suggesting it could exceed $20 billion by 2025, highlighting the scale of this transition.

Climate Change and Carbon Footprint Reduction

The textile industry is a major source of global carbon emissions, with estimates suggesting it accounts for up to 10% of the world's total. This reality places significant pressure on companies to actively reduce their carbon footprints. Fong's innovative approach, focusing on low-carbon and energy-efficient dyeing and finishing technologies, directly addresses this critical environmental challenge.

By offering these advanced solutions, Fong empowers its clients to not only meet increasingly stringent climate targets but also to actively participate in broader decarbonization movements. For instance, the textile sector's energy consumption is substantial, with dyeing and finishing processes often being the most energy-intensive stages. Fong's technologies aim to significantly lower this energy demand.

The global push for sustainability is intensifying, with regulations and consumer demand increasingly favoring environmentally responsible practices. Fong's commitment to developing greener technologies positions it favorably in this evolving landscape. Consider that by 2025, many jurisdictions are expected to have enhanced regulations on industrial emissions, making such technological advancements crucial for compliance and competitive advantage.

- Textile Industry Emissions: Contributes approximately 10% of global CO2 emissions.

- Energy Intensity: Dyeing and finishing are highly energy-consumptive processes within textiles.

- Client Benefits: Fong's technologies help clients achieve climate targets and reduce operational costs.

- Market Demand: Growing consumer and regulatory pressure for sustainable textile production.

Resource Scarcity and Sustainable Sourcing

Concerns over dwindling resources like water and essential raw materials are increasingly pushing industries towards sustainable sourcing and production. This shift favors the adoption of organic, recycled, and bio-based materials throughout the supply chain.

Fong's machinery is integral to this transition, facilitating the efficient processing of these more environmentally friendly inputs. For instance, the demand for recycled plastics, a key area for sustainable sourcing, saw global capacity reach approximately 12.7 million metric tons in 2023, with projections indicating continued growth driven by regulatory pressures and consumer demand.

- Water Scarcity: Global water stress affects over 40% of the world's population, highlighting the critical need for water-efficient manufacturing processes, which Fong's equipment can support through advanced recycling and minimal-use technologies.

- Raw Material Trends: The market for bio-based plastics, an alternative to petroleum-based ones, is expected to grow significantly, with some estimates placing its value at over $100 billion by 2030, underscoring the importance of machinery capable of handling these novel materials.

- Circular Economy Focus: Initiatives promoting a circular economy are gaining momentum, with companies investing heavily in recycling infrastructure. The global recycling market was valued at over $400 billion in 2023, demonstrating a strong economic incentive for sustainable material processing.

- Sustainable Sourcing Investments: Major corporations are setting ambitious targets for sustainable sourcing. For example, many consumer goods companies aim to have 100% of their packaging be recyclable, reusable, or compostable by 2025 or 2030, directly impacting the types of materials Fong's machinery will need to process.

Environmental regulations are tightening globally, pushing the textile industry towards more sustainable practices. Fong's machinery, designed for efficiency and reduced resource consumption, directly addresses these evolving compliance requirements and market expectations.

The industry's significant carbon footprint, estimated at up to 10% of global CO2 emissions, necessitates a move towards low-carbon technologies. Fong's focus on energy-efficient dyeing and finishing processes offers a tangible solution for clients aiming to reduce their environmental impact and operational costs.

Water scarcity and the need for responsible raw material sourcing are critical concerns. Fong's equipment is pivotal in enabling the efficient processing of organic, recycled, and bio-based materials, aligning with the growing demand for circular economy models and sustainable supply chains.

| Environmental Factor | Industry Impact | Fong's Relevance | Supporting Data (2023-2025) |

|---|---|---|---|

| Water Usage | Textile dyeing accounts for 20% of global wastewater. | Fong's machinery enhances water efficiency. | Growing water stress affecting over 40% of the global population. |

| Waste & Recycling | Less than 1% of clothing is recycled into new clothing. | Facilitates closed-loop systems and recycled material processing. | EU textile waste generation estimated at 12.6 million tonnes (2022). |

| Carbon Emissions | Textile sector contributes up to 10% of global CO2 emissions. | Offers low-carbon and energy-efficient technologies. | Pressure to reduce industrial emissions intensifying by 2025. |

| Material Sourcing | Demand for sustainable, organic, and recycled materials is rising. | Processes environmentally friendly inputs efficiently. | Bio-based plastics market projected to exceed $100 billion by 2030. |

PESTLE Analysis Data Sources

Our PESTLE analysis draws on a diverse range of data sources, including government reports, academic research, industry publications, and reputable news outlets. This comprehensive approach ensures that our insights are grounded in factual information and reflect the current macro-environmental landscape.