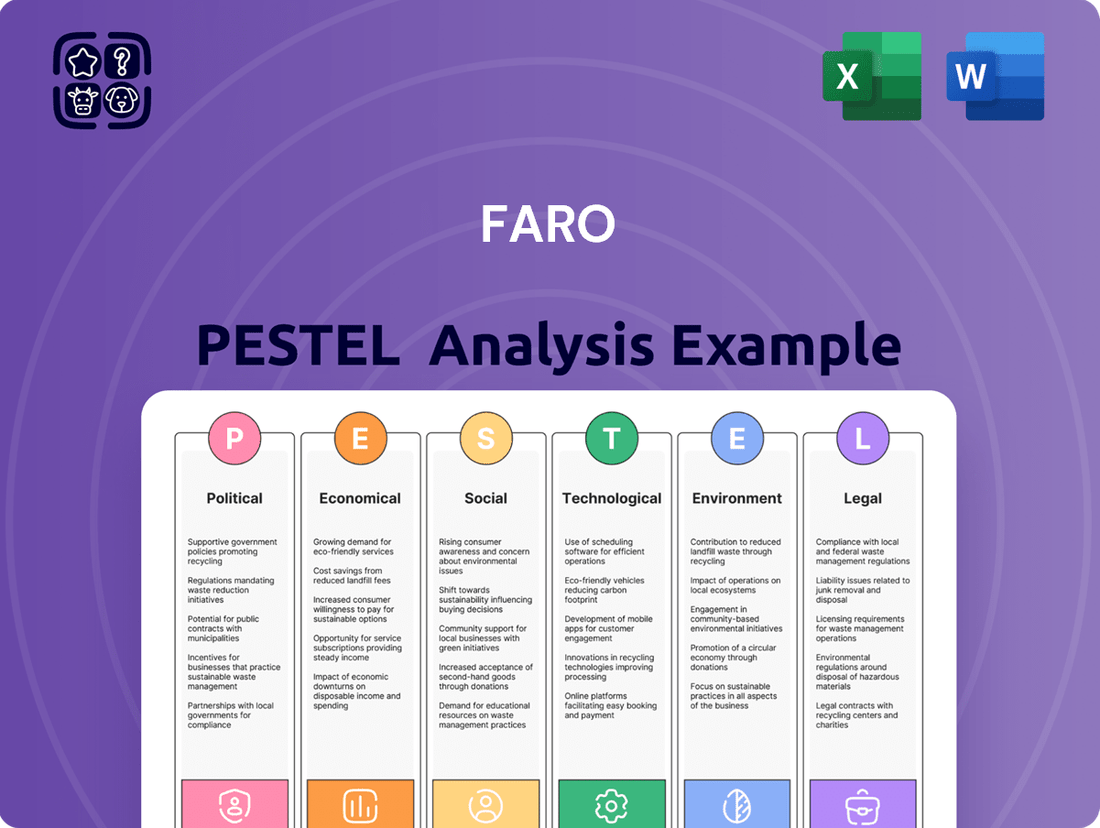

FARO PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

FARO Bundle

Unlock critical insights into the external forces shaping FARO's trajectory with our comprehensive PESTLE analysis. Understand how political shifts, economic fluctuations, technological advancements, social trends, environmental considerations, and legal frameworks are impacting the company's operations and future growth. Equip yourself with actionable intelligence to refine your strategies and gain a competitive edge. Download the full version now for an in-depth understanding.

Political factors

Government spending on infrastructure, especially in areas like construction and public safety, directly impacts the need for FARO's advanced 3D measurement and imaging technologies. For instance, the United States' Infrastructure Investment and Jobs Act, enacted in 2021 with a substantial budget, is expected to drive significant investment in roads, bridges, and public transit through 2025 and beyond. This surge in large-scale projects necessitates accurate spatial data for design, monitoring, and quality control, creating a fertile ground for FARO's solutions.

Changes in international trade policies and the imposition of tariffs directly affect FARO's global supply chain. For instance, disruptions in trade agreements or the introduction of new tariffs can increase the cost of essential raw materials and components, impacting FARO's overall production expenses.

An escalating tariff war between major economies, such as the US and China, poses a significant risk. In 2024, continued trade tensions could lead to higher prices for electronic components and industrial machinery, directly affecting FARO's manufacturing costs and potentially diminishing its competitive edge in key global markets.

Government initiatives promoting advanced manufacturing and clean technology adoption are becoming increasingly important. For instance, the US CHIPS and Science Act, with its significant funding for semiconductor manufacturing, signals a broader trend towards industrial policy. This focus on domestic production and technological advancement creates fertile ground for companies like FARO, whose solutions are crucial for precision manufacturing and quality control in these burgeoning sectors.

These policies can directly translate into increased demand for FARO's 3D measurement and imaging technologies. As governments incentivize the reshoring of manufacturing and the development of high-tech industries, businesses will need cutting-edge tools to ensure accuracy, efficiency, and innovation. The emphasis on clean energy manufacturing, for example, will likely drive adoption of FARO's solutions for optimizing production processes and ensuring the quality of new energy components.

Geopolitical Stability and International Relations

Global geopolitical tensions, particularly those impacting key manufacturing hubs and trade routes, pose a significant risk to FARO's supply chain and market access. Shifting international relations can lead to increased trade barriers or disruptions, directly affecting the cost and availability of components and finished goods. For instance, ongoing trade disputes and regional conflicts in 2024-2025 have already demonstrated their capacity to reroute global trade flows, impacting companies reliant on international manufacturing and distribution networks.

Uncertainty stemming from these geopolitical shifts can also dampen customer investment in the manufacturing sector, a core market for FARO's metrology and imaging solutions. Businesses may delay capital expenditures on advanced manufacturing technologies amid concerns about future market stability or the security of their own international operations. This cautious approach by customers directly influences FARO's sales pipeline and revenue projections, especially given the cyclical nature of capital equipment spending.

- Supply Chain Vulnerability: Geopolitical instability in regions like Southeast Asia, a critical manufacturing base, could disrupt the supply of components essential for FARO's products, potentially increasing lead times and costs.

- Market Demand Volatility: Trade wars or sanctions imposed by major economies in 2024-2025 have already shown the potential to reduce demand for capital goods in affected regions, impacting FARO's customer base.

- Investment Hesitation: Companies facing economic uncertainty due to geopolitical events may postpone investments in advanced manufacturing equipment, a key driver for FARO's growth. For example, a projected slowdown in global manufacturing investment in late 2024 could translate to reduced demand for FARO's solutions.

Regulatory Environment for Industrial Operations

The regulatory environment for industrial operations is continuously evolving, with increasing demands for robust security controls, transparent incident reporting, and comprehensive risk management frameworks. These shifts directly impact how manufacturers plan their operations and allocate capital for technological advancements. For instance, by the end of 2024, many industrial sectors are expected to see stricter cybersecurity mandates, potentially increasing compliance costs.

FARO's advanced data capture and analysis solutions are becoming increasingly vital for businesses striving to meet these complex regulatory requirements. Their ability to provide detailed, verifiable data for compliance purposes positions them as a key partner for manufacturers navigating this landscape.

- Increased focus on data integrity: Regulations often require auditable trails for operational data, a core strength of FARO's offerings.

- Mandatory incident reporting: New rules may necessitate detailed reporting of operational disruptions, where FARO's precise measurement and documentation capabilities are invaluable.

- Cybersecurity compliance: As industrial systems become more connected, adherence to evolving cybersecurity standards will be paramount, influencing technology investments.

Government spending on infrastructure, particularly in the US with the Infrastructure Investment and Jobs Act, is a significant driver for FARO's technologies through 2025. Trade policies and tariffs directly influence FARO's supply chain costs, with potential escalating tariffs in 2024 impacting component prices. Government initiatives promoting advanced manufacturing and clean tech, like the US CHIPS Act, create demand for FARO's precision solutions.

Geopolitical tensions in 2024-2025 can disrupt supply chains and dampen customer investment in manufacturing, impacting FARO's sales. Evolving regulations, especially cybersecurity mandates by the end of 2024, increase compliance costs for manufacturers, highlighting the value of FARO's data integrity solutions.

| Political Factor | Impact on FARO | 2024/2025 Data/Trend |

|---|---|---|

| Infrastructure Spending | Increased demand for 3D measurement and imaging | US Infrastructure Investment and Jobs Act driving projects through 2025. |

| Trade Policies & Tariffs | Supply chain cost increases, potential competitive disadvantage | Potential for higher component costs due to trade disputes in 2024. |

| Advanced Manufacturing Initiatives | Growth opportunities in high-tech sectors | US CHIPS Act funding semiconductor manufacturing, boosting precision needs. |

| Geopolitical Instability | Supply chain disruption, market demand volatility | Trade disputes and regional conflicts rerouting global trade flows. |

| Regulatory Evolution | Increased need for compliance solutions, higher operational costs | Stricter cybersecurity mandates expected by end of 2024. |

What is included in the product

The FARO PESTLE Analysis provides a comprehensive examination of the external macro-environmental factors influencing the company across Political, Economic, Social, Technological, Environmental, and Legal dimensions.

Provides a clear, actionable framework that helps businesses proactively identify and address external threats and opportunities, thereby reducing uncertainty and mitigating potential risks.

Economic factors

Global economic growth is projected to moderate in 2024 and 2025, with the IMF forecasting 3.2% and 3.1% respectively. Manufacturing output, a key driver for FARO's advanced metrology solutions, is closely tied to this economic health. For instance, the Purchasing Managers' Index (PMI) for global manufacturing hovered around 50 in early 2024, indicating a stabilization after a period of contraction, which is crucial for capital investment decisions by FARO's customer base.

Regions like Asia-Pacific, which saw manufacturing PMI figures often above 50 in late 2023 and early 2024, represent significant demand centers for FARO's precision measurement technologies. North America's manufacturing sector also shows resilience, with industrial production growth expected to be modest but positive. A strong manufacturing output directly translates to increased customer spending on quality control and process optimization tools that FARO provides.

Inflationary pressures continue to be a significant concern, with the U.S. Consumer Price Index (CPI) showing a 3.3% increase year-over-year as of May 2024, indicating persistent elevated costs for businesses and consumers alike. This trend directly impacts FARO's operational expenses, as the cost of raw materials and essential components has risen considerably. For instance, key metals and electronic parts, crucial for manufacturing FARO's advanced metrology and 3D scanning solutions, have seen price hikes ranging from 5% to 15% over the past year.

These increased input costs are not isolated to FARO; its customers, primarily in manufacturing and construction sectors, are also grappling with higher expenses. This economic reality might temper their willingness to invest in new capital equipment and software solutions, potentially slowing down adoption rates for FARO's offerings. Many of FARO's clients are reporting that higher material costs are forcing them to re-evaluate their capital expenditure budgets for 2024 and 2025, with a focus on essential operational upgrades rather than discretionary technology investments.

Global investment in digital transformation and Industry 4.0 continues to surge, presenting substantial growth avenues for companies like FARO. These advancements are reshaping manufacturing, making precise 3D measurement and imaging essential for real-time data analysis and quality assurance.

The adoption of technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) within smart manufacturing is a key driver. For instance, by the end of 2024, it's projected that over 75% of large enterprises will have implemented IoT solutions, directly increasing the need for the data capture and analysis capabilities FARO offers.

This trend is further amplified by the focus on enhancing operational efficiency and product quality through advanced analytics. As of early 2025, many industrial sectors are reporting significant improvements in defect detection and process optimization, attributed to the integration of smart technologies, underscoring the market demand for FARO's solutions.

Currency Exchange Rate Fluctuations

Currency exchange rate fluctuations present a significant economic factor for FARO, a global company. Changes in the value of currencies can directly impact the reported revenue and profitability derived from international sales. For instance, if the US Dollar strengthens against other major currencies, FARO's reported earnings from sales in Europe or Asia could appear lower when converted back to USD.

Furthermore, these fluctuations affect the cost of components FARO imports. If the US Dollar weakens, the cost of acquiring parts manufactured in countries with stronger currencies will increase, potentially squeezing profit margins. This dynamic requires careful financial management and hedging strategies to mitigate risks. As of late 2024, major currency pairs like EUR/USD have shown volatility, with the Euro experiencing periods of strength and weakness against the Dollar, directly influencing the financial outcomes of companies with substantial cross-border operations like FARO.

- Impact on Revenue: A stronger USD can reduce the reported value of international sales.

- Impact on Costs: A weaker USD increases the cost of imported components.

- 2024 Volatility: Major currency pairs like EUR/USD have demonstrated significant fluctuations throughout the year.

- Mitigation Strategies: Companies like FARO often employ hedging techniques to manage currency risk.

Market Size and Growth of 3D Metrology Industry

The global 3D metrology market is experiencing robust expansion, with projections suggesting continued strong growth. For instance, the market was valued at approximately $9.5 billion in 2023 and is anticipated to reach around $17.8 billion by 2030, demonstrating a compound annual growth rate (CAGR) of roughly 9.4% during this period. This upward trend is a significant economic tailwind for companies like FARO.

This growth is fueled by the increasing adoption of 3D measurement technologies across various sectors. Industries such as automotive, aerospace, and manufacturing are heavily investing in precision measurement solutions to enhance quality control, streamline production, and improve product design. These are core markets for FARO's offerings.

- Market Expansion: The 3D metrology market is projected to grow from $9.5 billion in 2023 to $17.8 billion by 2030.

- CAGR: This represents a compound annual growth rate of approximately 9.4% over the forecast period.

- Key Drivers: Increased demand for precision measurement in automotive, aerospace, and manufacturing sectors.

- Industry Investment: Significant investment in 3D measurement technologies for quality control and production efficiency.

Global economic growth is expected to moderate in 2024 and 2025, with the IMF forecasting 3.2% and 3.1% respectively. This stabilization in manufacturing output, a key sector for FARO's metrology solutions, indicates a potential for renewed capital investment by its customer base. Regions like Asia-Pacific, with consistently positive manufacturing PMIs, remain strong demand centers.

Inflationary pressures persist, with the U.S. CPI at 3.3% year-over-year in May 2024, impacting operational costs for both FARO and its clients. This could lead to cautious spending on new technologies, with customers prioritizing essential upgrades. For example, costs for key metals and electronic components have risen by 5% to 15% in the past year.

The global 3D metrology market is on a strong growth trajectory, projected to expand from approximately $9.5 billion in 2023 to $17.8 billion by 2030, a CAGR of 9.4%. This expansion is driven by increased adoption in sectors like automotive and aerospace, which are investing heavily in precision measurement for quality control and efficiency, directly benefiting FARO.

| Economic Factor | 2024/2025 Outlook | Impact on FARO | Key Data Points |

|---|---|---|---|

| Global Economic Growth | Moderating (IMF: 3.2% in 2024, 3.1% in 2025) | Stabilizing demand for metrology solutions | Global manufacturing PMI around 50 (early 2024) |

| Inflation | Persistent, elevated | Increased operational costs, potential customer budget constraints | U.S. CPI +3.3% YoY (May 2024); Component costs up 5-15% |

| Market Growth (3D Metrology) | Strong, projected CAGR of 9.4% | Significant growth opportunities | Market size: $9.5B (2023) to $17.8B (2030) |

| Currency Fluctuations | Volatile | Impacts reported revenue and import costs | EUR/USD volatility observed (late 2024) |

Full Version Awaits

FARO PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive FARO PESTLE analysis dives deep into the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the company, providing actionable insights.

Sociological factors

The industrial automation sector faces a significant and widening skills gap, particularly in areas like Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and Supervisory Control and Data Acquisition (SCADA) systems. This shortage directly affects FARO's customer base, as companies struggle to find personnel capable of operating and maintaining advanced automated systems.

This deficit in skilled labor could boost demand for FARO's user-friendly 3D measurement solutions that minimize the need for extensive specialized operator training. Alternatively, it underscores the critical need for robust training initiatives to ensure customers can effectively leverage complex automation technologies, including FARO's advanced metrology tools.

The manufacturing sector, a key market for FARO, is seeing significant digital transformation, with a projected 10% annual growth in its adoption of Industry 4.0 technologies through 2025. This increased embrace of automation and digital workflows directly correlates with a higher demand for precise 3D scanning and measurement tools to optimize production processes and quality control.

In construction, digital adoption is accelerating, with smart building technologies expected to reach $11.5 billion globally by 2026, up from $5.8 billion in 2021. This trend fuels the need for FARO's reality capture solutions to improve project planning, site monitoring, and as-built documentation, enhancing efficiency and reducing errors.

Public safety agencies are also increasingly leveraging digital tools, with investments in advanced imaging and data analysis solutions growing. For instance, the use of 3D laser scanning in crime scene reconstruction and accident reconstruction is becoming standard practice, indicating a strong market opportunity for FARO's specialized offerings in this domain.

Societal expectations are increasingly prioritizing worker well-being and the accuracy of information. Industries such as construction and manufacturing are seeing a heightened demand for technologies that bolster on-site safety and ensure data integrity. For instance, in 2023, workplace injuries in the construction sector cost over $14 billion in direct medical expenses, highlighting the critical need for safety enhancements.

FARO's advanced data capture and analysis tools directly address these concerns. Their solutions can map hazardous areas, monitor structural integrity, and provide real-time feedback, thereby contributing to safer work environments. This focus on precision not only reduces the risk of accidents but also builds trust in the data used for crucial decision-making and regulatory compliance.

Demographic Shifts and Aging Workforce

The aging workforce presents a significant challenge, particularly in industrial sectors where experienced professionals are retiring, leaving behind a critical knowledge vacuum. This demographic shift directly contributes to an widening skills gap, impacting operational efficiency and innovation.

This trend is projected to intensify. For instance, in the United States, the number of workers aged 55 and over in the labor force is expected to continue growing, with projections indicating they will represent a substantial portion of the workforce in the coming years. This means a significant loss of institutional knowledge and hands-on expertise across various industries.

- Knowledge Vacuum: Retirement of seasoned workers leads to loss of decades of practical experience and industry-specific know-how.

- Skills Gap Exacerbation: Fewer younger workers entering skilled trades or industrial roles means the gap between available jobs and qualified candidates widens.

- Automation Imperative: The loss of human expertise accelerates the demand for automated solutions and intelligent systems to bridge the operational and knowledge gaps.

- Economic Impact: Reduced productivity and increased training costs can negatively affect company profitability and competitiveness.

Demand for Remote Work and Digital Collaboration

The shift towards remote work and the increasing complexity of projects, particularly in sectors like construction and engineering, are driving a greater need for digital collaboration tools. This trend directly fuels the demand for cloud-based solutions that enable seamless data sharing and analysis, even when teams are geographically dispersed. FARO's offerings, which are designed to facilitate this kind of remote interaction with 3D reality data, are well-positioned to capitalize on this growing market.

Consider the impact on productivity: A 2024 report indicated that companies offering flexible remote work options saw an average productivity increase of 13%. This suggests that solutions enhancing remote collaboration, like those from FARO, can directly contribute to improved operational efficiency for their clients.

- Increased Demand for Cloud-Based Solutions: The need for accessible, real-time data sharing for complex projects is escalating.

- Remote Project Management Growth: By 2025, it's projected that over 40% of the global workforce will be operating in a hybrid or fully remote capacity, highlighting the importance of digital collaboration platforms.

- FARO's Strategic Advantage: Platforms enabling remote data analysis and collaboration, such as FARO's cloud-based solutions, are poised for significant growth as businesses adapt to new work paradigms.

Societal expectations are increasingly prioritizing worker well-being and data accuracy, especially in construction and manufacturing. Industries are demanding technologies that enhance on-site safety and ensure data integrity, a critical need given that workplace injuries in construction cost over $14 billion in direct medical expenses in 2023.

FARO's advanced data capture and analysis tools directly address these concerns by mapping hazardous areas and monitoring structural integrity, contributing to safer work environments. This focus on precision not only reduces accident risks but also builds trust in data used for crucial decision-making and regulatory compliance.

The aging workforce is a significant challenge, leading to a loss of practical experience and a widening skills gap in industrial sectors. Projections show a continued growth in workers aged 55 and over in the US labor force, exacerbating this knowledge vacuum and increasing the demand for automation.

The shift towards remote work and project complexity is driving demand for digital collaboration tools, with over 40% of the global workforce projected to be remote or hybrid by 2025. This trend highlights the importance of cloud-based solutions like FARO's for seamless data sharing and analysis, with companies offering remote work seeing a 13% productivity increase in 2024.

Technological factors

FARO's core business is directly fueled by ongoing breakthroughs in 3D measurement and imaging. Innovations in areas like laser scanning, optical digitizing, and computed tomography are constantly pushing the boundaries of what's possible, enabling FARO to develop increasingly sophisticated products. This technological evolution is paramount for the company to stay ahead in a competitive market.

The demand for higher precision, increased speed, and enhanced ease of use in 3D measurement devices is a constant driver for FARO's research and development. For instance, advancements in portable coordinate measuring machines (CMMs) and 3D scanners are crucial for industries requiring meticulous quality control and reverse engineering. FARO's commitment to these improvements ensures their solutions remain indispensable for sectors like automotive manufacturing and aerospace engineering.

The growing integration of AI, Machine Learning, and IoT into industrial metrology and reality capture is a major technological shift. These technologies are powering automated quality control, predictive maintenance, and real-time data analysis, directly impacting FARO's product innovation. For instance, the global AI market in manufacturing was projected to reach $12.7 billion in 2024, highlighting the significant investment and adoption in this area.

These advancements allow for more sophisticated data processing and actionable insights, enhancing decision-making capabilities for FARO's customers. The IoT, in particular, enables seamless data flow from sensors and devices, creating a connected ecosystem for improved operational efficiency. By 2025, it's estimated that over 75 billion IoT devices will be connected worldwide, underscoring the pervasive nature of this technology.

The increasing demand for portable and handheld 3D measurement devices reflects a significant market trend towards on-site, flexible data capture. This shift empowers users to conduct measurements directly in the field, reducing the need for transporting bulky components to controlled environments.

FARO's strategic advantage lies in its comprehensive portfolio of these devices, catering to a wide array of customer needs across various industries. For instance, the company's Quantum Max ScanArms, introduced in 2024, exemplify this commitment, offering enhanced portability and advanced scanning capabilities for intricate on-site inspections and reverse engineering projects.

Cloud Computing and Data Management Solutions

The increasing reliance on cloud-based solutions for storing, sharing, and analyzing vast amounts of 3D measurement data is fundamentally reshaping project management across industries. FARO's strategic imperative involves effectively integrating its offerings with cloud platforms to enhance customer accessibility, operational flexibility, and collaborative capabilities. For instance, by mid-2024, the global cloud computing market was projected to reach over $1.3 trillion, highlighting the significant shift towards cloud adoption.

FARO's success hinges on its ability to harness cloud technologies to streamline data workflows and provide seamless access to its powerful analytics tools. This cloud integration is crucial for enabling real-time collaboration among geographically dispersed teams, a trend amplified by the continued growth of remote work environments. By Q1 2025, it's estimated that over 90% of enterprises will be utilizing hybrid or multi-cloud strategies, underscoring the ubiquity of cloud infrastructure.

- Enhanced Data Accessibility: Cloud platforms allow users to access large 3D datasets from any location, fostering greater project mobility.

- Improved Collaboration: Shared cloud environments facilitate real-time teamwork and data sharing among project stakeholders.

- Scalable Data Management: Cloud solutions offer flexible storage and processing power, adapting to the growing volume of 3D scan data.

- Advanced Analytics Integration: Cloud-based platforms enable the seamless integration of FARO's analytical software for deeper insights.

Evolution of Digital Twin and 4D Digital Reality Solutions

The growing adoption of digital twin technology and the emergence of 4D digital reality solutions offer significant avenues for FARO. These advancements allow for the integration of 3D data with temporal elements, leading to more sophisticated asset and process monitoring, simulation, and analysis.

The digital twin market is projected to reach USD 39.5 billion by 2027, growing at a CAGR of 35.9% from 2022, indicating strong demand for these solutions. FARO's expertise in 3D scanning and data capture positions it well to capitalize on this trend, enabling clients to create highly accurate and dynamic digital replicas of their physical assets.

- Enhanced Asset Management: Digital twins allow for real-time performance monitoring and predictive maintenance, reducing downtime and operational costs.

- Improved Simulation and Planning: 4D digital reality enables detailed simulations of construction projects or manufacturing processes over time, optimizing workflows and identifying potential issues early.

- Data-Driven Decision Making: The integration of time-series data with 3D models provides deeper insights, supporting more informed strategic and operational decisions.

- Market Growth: The global digital twin market is experiencing robust expansion, presenting a fertile ground for FARO's technological offerings.

Technological advancements are the bedrock of FARO's innovation, particularly in 3D measurement and imaging. The company's growth is intrinsically linked to progress in laser scanning, optical digitizing, and computed tomography, which continually enhance product sophistication and market competitiveness.

The demand for greater precision, speed, and user-friendliness in 3D measurement devices fuels FARO's R&D efforts. Innovations in portable CMMs and 3D scanners are critical for industries like automotive and aerospace, ensuring FARO's solutions remain essential for quality control and reverse engineering.

The integration of AI, Machine Learning, and IoT into industrial metrology is a significant technological shift, driving automated quality control and real-time data analysis. The global AI market in manufacturing was projected to reach $12.7 billion in 2024, underscoring the importance of these technologies for FARO.

The increasing adoption of cloud-based solutions for managing 3D data is reshaping project workflows, making cloud integration a strategic imperative for FARO. By mid-2024, the global cloud computing market was projected to exceed $1.3 trillion, highlighting the widespread shift towards cloud infrastructure.

| Technological Factor | Impact on FARO | Supporting Data/Trend (2024-2025) |

| 3D Measurement & Imaging Advancements | Drives product innovation and competitiveness. | Continuous breakthroughs in laser scanning and optical digitizing. |

| AI, ML, and IoT Integration | Enables automated quality control and real-time data analysis. | Global AI in manufacturing market projected at $12.7 billion in 2024. |

| Cloud Computing Adoption | Enhances data accessibility, collaboration, and scalability. | Global cloud computing market projected over $1.3 trillion by mid-2024. |

| Digital Twin & 4D Reality | Opens new avenues for asset monitoring and simulation. | Digital twin market projected to reach USD 39.5 billion by 2027 (from 2022). |

Legal factors

FARO operates within an increasingly complex legal landscape shaped by evolving data privacy and cybersecurity regulations. The company must navigate stringent compliance requirements, especially concerning the sensitive 3D scanning data collected by its industrial IoT devices. Failure to adhere to these laws, such as GDPR or CCPA, could result in significant fines and reputational damage. For instance, in 2023, the global cost of data breaches reached an average of $4.45 million, highlighting the financial risks associated with non-compliance.

Industry-specific quality and compliance standards are a critical legal factor for FARO. For instance, the automotive sector, a key market for FARO, faces stringent regulations like ISO/TS 16949, which mandates rigorous quality management systems. Similarly, the aerospace industry adheres to standards such as AS9100, demanding extreme precision and traceability in manufacturing processes. Failure to meet these evolving legal requirements can result in significant penalties and exclusion from lucrative contracts.

FARO, a key player in measurement and imaging technology, operates under stringent product liability laws and safety regulations. This means the company must rigorously ensure the safety and dependability of its hardware and software offerings to avoid costly legal challenges and protect its reputation. For instance, adherence to standards like ISO 9001, which FARO has achieved, demonstrates a commitment to quality management systems that inherently support product safety.

Intellectual Property Rights and Patents

FARO Technologies relies heavily on protecting its intellectual property, particularly its patents covering innovative 3D measurement and imaging technologies. These patents are fundamental to maintaining its competitive edge in the market. For instance, in 2024, the company continued to actively manage its patent portfolio, which is essential for its ongoing research and development investments.

The legal landscape governing patents and trade secrets directly dictates FARO's capacity to secure its proprietary solutions. Robust patent protection allows FARO to prevent competitors from replicating its unique technological advancements, thereby safeguarding its market share and profitability. As of mid-2025, the company's ongoing legal strategy emphasizes the enforcement and expansion of its patent rights.

- Patent Portfolio Strength: FARO's intellectual property, especially its patents, is a core asset protecting its advanced 3D scanning and metrology solutions.

- Legal Framework Impact: The effectiveness of patent and trade secret laws directly influences FARO's ability to maintain exclusivity for its technologies.

- Competitive Advantage: Strong IP protection is critical for FARO to deter imitation and sustain its leadership in the 3D technology sector.

- R&D Investment Protection: Legal safeguards ensure that FARO's significant investments in developing new measurement and imaging innovations are adequately protected.

International Trade Laws and Customs Regulations

FARO's global reach necessitates strict adherence to international trade laws and customs regulations, impacting everything from component sourcing to product distribution. Navigating these complex legal frameworks is critical for seamless operations and avoiding costly penalties. For instance, in 2024, the World Trade Organization (WTO) reported that global trade facilitation measures saved businesses an estimated $150 billion annually, highlighting the financial impact of efficient customs procedures.

Changes in export controls, particularly concerning advanced technologies, could directly affect FARO's ability to supply its sophisticated measurement and imaging solutions to certain international markets. Similarly, evolving import tariffs and duties on raw materials or finished goods can alter production costs and pricing strategies. As of early 2025, many countries are reviewing their trade agreements, with a notable trend towards increased scrutiny of technology transfers, potentially impacting companies like FARO that operate in high-tech sectors.

- Compliance with international trade laws, export controls, and customs regulations is paramount for FARO's global operational efficiency.

- Shifts in these legal landscapes can directly influence FARO's access to critical components and its market penetration capabilities.

- The global trade environment in 2024-2025 shows a heightened focus on technology transfer regulations, posing potential challenges for advanced technology exporters.

FARO's intellectual property, particularly its patents on advanced 3D scanning and metrology, is crucial for its market leadership. The strength of patent and trade secret laws directly impacts its ability to protect its innovations and deter competitors. As of mid-2025, FARO continues to actively manage and enforce its patent portfolio, safeguarding its significant investments in research and development.

Environmental factors

The increasing global focus on sustainability and green manufacturing is prompting industries to adopt eco-friendlier production methods. This shift presents a significant opportunity for FARO, as its technologies can support efficient resource utilization, waste minimization, and improved environmental oversight within manufacturing and construction sectors.

For instance, the global market for green building materials was valued at approximately $250 billion in 2023 and is projected to reach over $450 billion by 2030, indicating a strong demand for solutions that enhance sustainable practices in construction, a key market for FARO.

Stricter environmental regulations on industrial emissions and waste management are increasingly impacting FARO's manufacturing clients. For example, the European Union's Industrial Emissions Directive (IED) sets stringent limits for pollutants, requiring advanced monitoring solutions. This trend is global, with many nations enhancing their air quality and hazardous substance control measures.

FARO's advanced metrology and 3D scanning technologies are crucial tools for companies needing to monitor and comply with these evolving environmental standards. By enabling precise measurement of emissions sources and waste streams, FARO's solutions help manufacturers ensure regulatory adherence and minimize environmental impact.

The global push towards a circular economy is reshaping industries, with a growing emphasis on product durability, reusability, and recyclability. This shift directly impacts how products are conceived and manufactured, pushing for more sustainable lifecycle management. For instance, the European Union's Circular Economy Action Programme aims to significantly boost recycling rates and reduce waste, setting a clear direction for businesses.

FARO's advanced 3D measurement and scanning technologies are instrumental in this transition. By enabling precise digital modeling of products, these solutions facilitate the design of components for easier disassembly, repair, and ultimately, more efficient recycling. This capability directly supports manufacturers in meeting evolving regulatory demands and consumer expectations for environmentally responsible products, a trend demonstrably growing in markets like Germany, which reported over 67% of its municipal waste being recycled or recovered in 2022.

Energy Efficiency and Carbon Footprint Reduction

Industries globally are facing increasing pressure to enhance energy efficiency and slash carbon emissions. This trend is driving significant investment in process optimization technologies. For instance, the European Union's Carbon Border Adjustment Mechanism (CBAM), fully operational in 2026, will impose costs on carbon-intensive imports, further incentivizing efficiency improvements across supply chains.

FARO's metrology and 3D scanning solutions play a crucial role in this transition. By providing highly accurate measurements and enabling rigorous quality control, FARO technologies help optimize manufacturing processes. This optimization directly leads to reduced material waste and more efficient energy consumption during production, indirectly contributing to a smaller carbon footprint for its clients.

- Reduced Waste: Improved precision minimizes scrap, lowering the energy and resources needed for rework or replacement.

- Process Optimization: Accurate data allows for fine-tuning of machinery and workflows, leading to less energy usage per unit produced.

- Sustainable Manufacturing: By supporting lean and efficient production, FARO's tools align with corporate sustainability goals and regulatory demands for reduced environmental impact.

Climate Change Adaptation and Resilient Infrastructure

The escalating urgency of climate change adaptation is driving a significant need for robust, resilient infrastructure. This shift directly translates into a growing demand for sophisticated data capture and analysis tools. FARO's technologies are exceptionally well-positioned to address this market, offering capabilities crucial for evaluating the integrity of existing structures and mapping environmental impacts. For instance, the global market for climate change adaptation solutions is projected to reach hundreds of billions of dollars by 2030, with infrastructure resilience being a core component.

FARO's solutions play a vital role in planning for and executing resilient new construction projects. By providing precise 3D scanning and data management, the company enables engineers and architects to accurately assess site conditions, monitor construction progress, and ensure that new builds can withstand environmental stressors. This is particularly relevant as global investments in climate-resilient infrastructure are expected to see substantial growth. For example, the World Economic Forum highlighted that an estimated $1.3 trillion in annual infrastructure investment is needed globally to meet climate goals through 2030.

- Demand for advanced data capture: The need to assess and monitor existing infrastructure for climate resilience creates a market for high-precision 3D scanning and reality capture technologies.

- Monitoring environmental impacts: FARO's tools can be used to track changes in the environment around infrastructure projects, aiding in impact assessments and adaptation planning.

- Planning resilient construction: Accurate data from FARO solutions supports the design and construction of new infrastructure that is better equipped to handle climate-related challenges.

- Market growth: The increasing focus on climate adaptation is expected to fuel significant growth in the market for solutions that support infrastructure resilience.

The global push for sustainability is a significant tailwind for FARO, as industries increasingly adopt eco-friendly practices. FARO's technologies support efficient resource use and waste reduction, key aspects of green manufacturing. For instance, the global green building materials market, valued at approximately $250 billion in 2023, is set to exceed $450 billion by 2030, highlighting demand in construction, a core FARO market.

Stricter environmental regulations worldwide, such as the EU's Industrial Emissions Directive, necessitate advanced monitoring. FARO's metrology and 3D scanning solutions enable precise measurement for compliance, helping clients minimize their environmental footprint. For example, Germany's recycling rate, over 67% in 2022, reflects this regulatory drive for better waste management.

The circular economy trend emphasizes product durability and recyclability, driving demand for solutions that facilitate disassembly and reuse. FARO's digital modeling capabilities support this by enabling easier product lifecycle management. The EU's Circular Economy Action Programme sets ambitious recycling targets, pushing manufacturers towards more sustainable product design.

Industries are also focused on energy efficiency and carbon emission reduction, driven by initiatives like the EU's Carbon Border Adjustment Mechanism (CBAM), fully operational in 2026. FARO's precision tools optimize manufacturing processes, leading to reduced material waste and lower energy consumption per unit produced, indirectly aiding clients in their carbon reduction goals.

PESTLE Analysis Data Sources

Our PESTLE analysis is meticulously constructed using a blend of official government statistics, reputable academic research, and leading industry publications. This approach ensures that each factor, from political stability to technological advancements, is grounded in verifiable and current information.