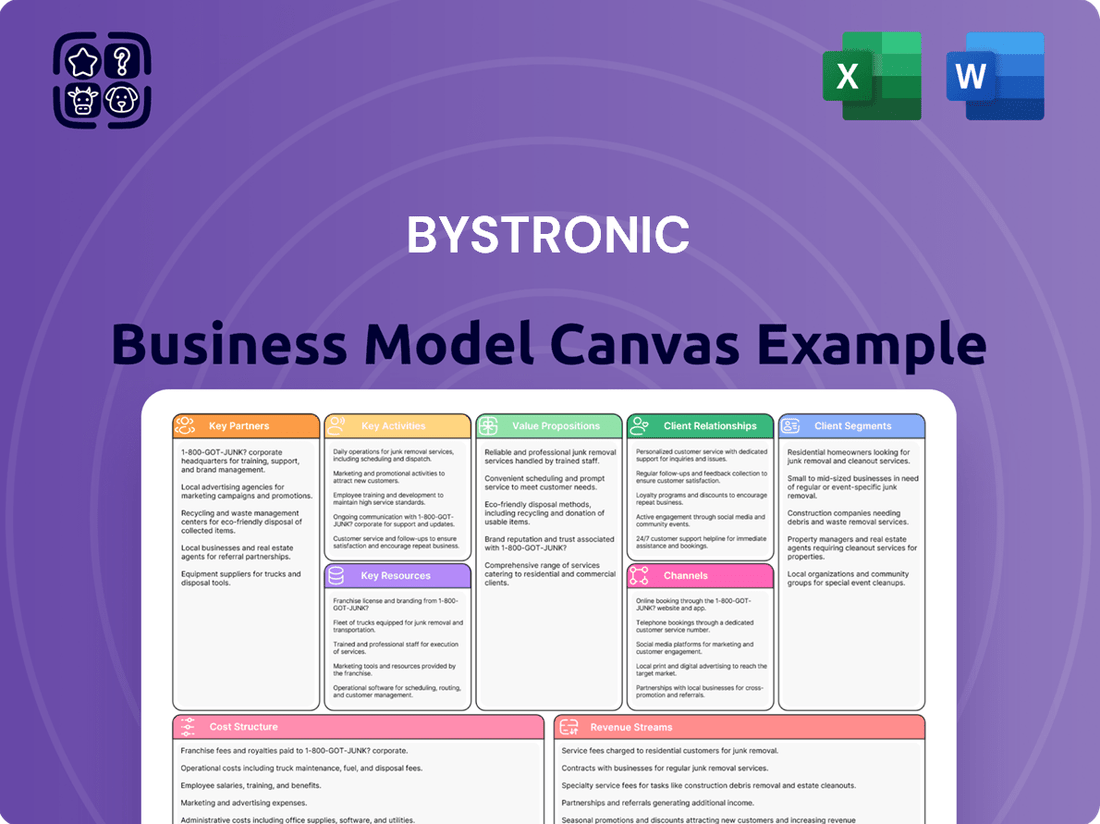

Bystronic Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Bystronic Bundle

Uncover the core strategies behind Bystronic's success with our comprehensive Business Model Canvas. This detailed analysis breaks down their customer relationships, revenue streams, and key resources, offering a clear roadmap to their market dominance. Get the full picture and apply these proven strategies to your own business.

Partnerships

Bystronic actively collaborates with technology and software partners to embed advanced digital solutions into its machinery, driving automation and smart factory integration. This strategic approach focuses on enhancing operational efficiency and connectivity for its clients.

A prime example of this commitment is the full integration of Kurago, now operating as Bystronic Software, and the establishment of an innovation lab in the Basque Country. This move significantly bolsters Bystronic's digital transformation efforts, ensuring its offerings remain at the forefront of industry innovation.

Bystronic's collaborations with material science innovators, such as SSAB, are fundamental to its business model. These partnerships are key to exploring and refining laser cutting and bending techniques for emerging, eco-friendly materials. This includes advancements with recycled steel and fossil-free steel alternatives, directly influencing the future of sheet metal processing.

Bystronic's strategic alliances with automation and robotics specialists are crucial for delivering end-to-end solutions that streamline customer operations. These partnerships enable the integration of advanced loading and unloading systems, as well as fully automated bending cells, enhancing efficiency and productivity. For instance, Bystronic's commitment to automation is evident in its continuous development of robotic bending solutions, aiming to address labor shortages and boost throughput in the sheet metal industry.

Research and Development Institutions

Bystronic actively collaborates with universities and research institutes to drive innovation, particularly in areas like sustainable manufacturing and energy efficiency. This partnership helps them explore cutting-edge laser technologies and new material processing techniques.

These collaborations are crucial for Bystronic's R&D efforts, allowing them to stay ahead in developing advanced solutions. For instance, their commitment to exploring new materials and processes is directly fueled by these external research engagements.

- Focus on Sustainability: Partnerships with institutions researching eco-friendly manufacturing processes.

- Technological Advancement: Joint projects exploring next-generation laser cutting and bending technologies.

- Innovation Pipeline: Access to early-stage research and potential startup technologies to integrate into their product roadmap.

Service and Support Network Partners

Bystronic cultivates a robust service and support network by partnering with local entities worldwide. These collaborations are crucial for delivering prompt maintenance, repairs, and spare parts, ensuring customers receive expert assistance close to their operations.

This strategy allows Bystronic to maintain its global presence and uphold high standards of customer satisfaction, even in geographically diverse markets. By leveraging these partnerships, they effectively extend their reach and reinforce their commitment to machine uptime and longevity.

- Global Reach: Partnerships enable Bystronic to offer localized service and support, crucial for a company with a significant international customer base.

- Customer Satisfaction: Access to local service and spare parts directly impacts customer satisfaction by minimizing downtime and ensuring efficient operations.

- Machine Longevity: Regular, accessible maintenance and readily available parts through partners help extend the operational life of Bystronic's machinery.

- Market Penetration: Strong local service networks can be a key differentiator, aiding in market penetration and customer loyalty in new and established regions.

Bystronic's key partnerships are vital for driving innovation and expanding its market reach. Collaborations with technology firms, material science experts like SSAB, and automation specialists are central to developing advanced, sustainable solutions in sheet metal processing.

These alliances ensure Bystronic remains at the cutting edge, integrating digital capabilities and exploring new materials, such as fossil-free steel. Their network of local service partners globally is also critical for delivering responsive customer support and maximizing machine uptime.

| Partner Type | Key Contribution | Example/Impact |

|---|---|---|

| Technology & Software | Digitalization, automation, smart factory integration | Integration of Kurago (Bystronic Software), innovation lab in Basque Country |

| Material Science | Processing new and sustainable materials | Collaboration with SSAB on laser cutting and bending for recycled and fossil-free steel |

| Automation & Robotics | End-to-end process automation | Development of robotic bending solutions, automated cells |

| Academic & Research | Cutting-edge research, new technologies | Exploring sustainable manufacturing and advanced laser technologies |

| Local Service Providers | Global service and support network | Prompt maintenance, repairs, and spare parts delivery worldwide |

What is included in the product

A detailed breakdown of Bystronic's strategy, outlining its customer segments, value propositions, and key activities in the sheet metal processing industry.

This canvas provides a strategic overview of Bystronic's approach to innovation, customer relationships, and revenue streams within the global machine manufacturing sector.

Bystronic's Business Model Canvas acts as a pain point reliever by providing a clear, structured overview that simplifies the complexity of their operations.

It offers a one-page snapshot of core components, making it easier to identify and address challenges within their business strategy.

Activities

Bystronic's commitment to innovation is evident in its continuous investment in research and development. This focus drives the creation of cutting-edge laser cutting systems, press brakes, and automation solutions designed to meet evolving industry demands.

Key R&D achievements include the development of the 'Intelligent Cutting Process (ICP)' autonomy kit, which enhances operational efficiency and precision. Furthermore, Bystronic has introduced new tube laser cutters like the ByTube Star 330, showcasing their dedication to expanding their product portfolio with advanced capabilities.

Bystronic's core activity centers on the precision manufacturing and assembly of advanced machinery, notably their laser cutting systems and press brakes. These machines are engineered for the demanding sheet metal processing industry, where quality and performance are paramount.

In 2023, Bystronic reported a significant increase in its order intake, reaching CHF 3,131.4 million, demonstrating robust demand for its high-quality machinery. This growth underscores the company's capability in producing sophisticated equipment that meets stringent industry standards.

Bystronic's key activity in software development focuses on creating integrated solutions like the BySoft Suite. This suite is designed to streamline the entire customer workflow, from initial quotes to final delivery, significantly enhancing operational efficiency and driving digital transformation in manufacturing environments.

The development and integration of these advanced software platforms are crucial for Bystronic's value proposition. For instance, in 2023, Bystronic reported a substantial increase in its service and software revenue, indicating strong customer adoption and reliance on its digital offerings to optimize their production processes.

Global Sales, Marketing, and Distribution

Bystronic's global sales and marketing strategy is designed to connect with a broad spectrum of customers worldwide. They actively participate in key industry exhibitions, such as EuroBLECH and FABTECH, which are crucial platforms for demonstrating their cutting-edge machinery and innovative solutions to a global audience.

These events are vital for generating leads and strengthening customer relationships. In 2024, Bystronic continued its tradition of showcasing advancements in laser cutting, bending, and automation technologies, aiming to capture market share in both established and emerging economies.

The company's distribution network is a critical component, ensuring efficient delivery and support. This global reach allows them to cater to diverse market needs, from large industrial manufacturers to smaller, specialized workshops.

- Global Reach: Bystronic maintains a presence in over 30 countries, facilitating direct sales and service interactions.

- Industry Events: Participation in major trade shows like EuroBLECH 2024 and FABTECH 2024 provides significant visibility and lead generation opportunities.

- Digital Marketing: Investment in digital platforms and content marketing enhances brand awareness and customer engagement globally.

- Customer Support: A robust network of service technicians and sales representatives ensures localized support and expertise for clients worldwide.

Customer Service, Support, and Training

Bystronic’s commitment to customer service, support, and training is a cornerstone of its business model, ensuring customers maximize their investment in cutting-edge machinery. This involves providing comprehensive after-sales services, including essential maintenance, readily available spare parts, and responsive technical support. For instance, in 2023, Bystronic reported that its service business segment contributed significantly to overall revenue, highlighting the value customers place on these offerings.

Furthermore, Bystronic offers extensive training programs designed to empower operators and maintenance personnel. This focus on skill development ensures optimal machine performance and longevity, directly translating into higher productivity and reduced downtime for clients. The company’s investment in digital service tools, such as remote diagnostics and predictive maintenance, further underscores its dedication to proactive customer support.

- After-Sales Services: Maintenance, spare parts, and technical support are critical for operational continuity.

- Training Programs: Empowering users ensures efficient machine operation and extended product lifespan.

- Digital Service Tools: Remote diagnostics and predictive maintenance enhance customer support efficiency.

- Customer Relationship Building: These activities foster loyalty and long-term partnerships.

Bystronic’s key activities revolve around the design, manufacturing, and distribution of advanced machinery for sheet metal processing, alongside the development of integrated software solutions. This dual focus on hardware innovation and digital integration is central to their value proposition, ensuring customers benefit from efficient, precise, and connected manufacturing processes.

The company actively engages in research and development to introduce cutting-edge technologies, exemplified by their intelligent autonomy kits and new tube laser cutters. Complementing this, their software suite, BySoft, streamlines customer workflows from quoting to delivery, enhancing operational efficiency and driving digital transformation. Bystronic’s global sales and marketing efforts, including participation in major industry events like EuroBLECH and FABTECH, are crucial for market penetration and customer engagement.

Furthermore, robust customer service, including comprehensive after-sales support, training, and digital service tools, ensures customers maximize their investment and maintain optimal machine performance. This integrated approach solidifies Bystronic’s position as a leading provider in the sheet metal processing industry.

| Key Activity | Description | 2023/2024 Relevance |

|---|---|---|

| Machinery Manufacturing | Precision engineering and assembly of laser cutting, bending, and automation systems. | Order intake reached CHF 3,131.4 million in 2023, reflecting strong demand for high-quality machinery. |

| Software Development | Creation of integrated software solutions like the BySoft Suite to optimize customer workflows. | Service and software revenue saw a substantial increase in 2023, indicating strong adoption of digital offerings. |

| Research & Development | Continuous investment in innovation for cutting-edge laser cutting, press brakes, and automation. | Introduction of advancements like the Intelligent Cutting Process (ICP) autonomy kit and new tube laser cutters. |

| Sales & Marketing | Global outreach through industry events, digital marketing, and a strong distribution network. | Active participation in EuroBLECH 2024 and FABTECH 2024 to showcase new technologies and generate leads. |

| Customer Service & Support | Providing after-sales services, training, and digital tools for optimal machine utilization. | Service business segment contributed significantly to overall revenue in 2023, highlighting customer reliance on support. |

What You See Is What You Get

Business Model Canvas

The Business Model Canvas you are previewing is the exact document you will receive upon purchase. This is not a simplified sample or a marketing mockup, but a direct representation of the comprehensive file you will gain access to. Once your order is complete, you will download this same, fully detailed Business Model Canvas, ready for your strategic planning and analysis.

Resources

Bystronic's advanced manufacturing facilities are the backbone of their high-quality laser cutting systems and press brakes. These state-of-the-art production sites, strategically located in countries like Switzerland and China, leverage cutting-edge machinery and technology to ensure precision and efficiency. In 2023, Bystronic reported a significant investment in its production capabilities, aiming to further enhance automation and digitalization across its global manufacturing footprint.

Bystronic's intellectual property, particularly its patents and the BySoft Suite software, forms a core component of its business model. These proprietary technologies are central to their ability to deliver integrated and optimized solutions for the sheet metal processing industry, distinguishing them from competitors.

The BySoft Suite, for instance, acts as a digital backbone, connecting Bystronic's machines and enabling seamless workflow management from design to production. This software ecosystem is a significant differentiator, offering customers enhanced efficiency and control over their manufacturing processes.

While specific patent numbers are not publicly detailed in their business model canvas, Bystronic’s continuous investment in research and development underscores the importance of protecting its technological innovations. This commitment ensures they maintain a leading position in a rapidly evolving market.

Bystronic's innovation engine relies heavily on its highly skilled workforce. This includes specialized engineers, adept software developers, and dedicated R&D experts who are crucial for developing cutting-edge solutions in the sheet metal processing industry.

These experts are the backbone of Bystronic's ability to deliver complex technological products and services. Their expertise directly translates into the advanced machinery and software that Bystronic offers its global clientele.

In 2024, Bystronic continued to invest in its human capital, recognizing that a skilled workforce is paramount for maintaining its competitive edge. The company's commitment to research and development, driven by these experts, ensures a steady stream of innovative products that meet evolving market demands.

Global Sales and Service Network

Bystronic's global sales and service network, spanning over 30 countries, is a critical asset. This extensive reach ensures direct customer engagement and facilitates the delivery of localized expertise and prompt support. For instance, in 2024, Bystronic continued to strengthen its presence in key markets, with a particular focus on expanding service capabilities in emerging economies.

This network allows Bystronic to offer comprehensive after-sales service, including maintenance, repairs, and spare parts, directly to its customers worldwide. The ability to provide timely and effective service is paramount in maintaining customer satisfaction and loyalty in the capital-intensive machinery sector.

- Global Presence: Operations in over 30 countries.

- Local Expertise: Subsidiaries and agents provide market-specific knowledge.

- Customer Support: Timely service and maintenance are key differentiators.

- Sales Reach: Direct access to a broad customer base for new equipment sales.

Strong Brand Reputation and Customer Base

Bystronic's strong brand reputation is built on decades of delivering high-quality, efficient, and sustainable solutions for sheet metal processing. This reputation is a significant intangible asset, fostering trust and loyalty among its customers.

The company boasts a deeply entrenched and loyal customer base, a testament to its reliable products and dedicated service. This existing clientele provides a stable revenue stream and a powerful platform for future growth and innovation.

In 2023, Bystronic reported a significant increase in its order intake, reaching CHF 3,185.5 million, highlighting the ongoing demand for its solutions and the strength of its customer relationships. This robust performance underscores the value placed on Bystronic's brand and its established market position.

- Brand Equity: Bystronic is recognized globally for its innovation and reliability in laser cutting and bending technologies.

- Customer Loyalty: A substantial portion of Bystronic's revenue comes from repeat customers, indicating high satisfaction levels.

- Market Trust: The company's commitment to sustainability and efficiency resonates with a growing segment of environmentally conscious buyers.

- Sales Growth: In 2023, Bystronic achieved a net sales of CHF 2,962.3 million, reflecting continued market penetration and customer acquisition.

Bystronic's key resources include its advanced manufacturing facilities, a testament to its commitment to precision and efficiency, as seen in its 2023 investments in automation and digitalization. The company’s intellectual property, especially the BySoft Suite, acts as a digital backbone, integrating machines for optimized workflows. Furthermore, a highly skilled workforce of engineers and software developers drives innovation, ensuring Bystronic remains at the forefront of sheet metal processing technology, with continued investment in human capital evident in 2024.

| Key Resource | Description | 2023/2024 Data Point |

|---|---|---|

| Manufacturing Facilities | State-of-the-art production sites leveraging cutting-edge machinery. | Investment in automation and digitalization across global footprint (2023). |

| Intellectual Property (BySoft Suite) | Proprietary software enabling integrated and optimized manufacturing workflows. | Acts as a digital backbone connecting machines for seamless workflow management. |

| Skilled Workforce | Specialized engineers, software developers, and R&D experts driving innovation. | Continued investment in human capital to maintain competitive edge (2024). |

| Global Sales & Service Network | Extensive reach in over 30 countries ensuring direct customer engagement and support. | Strengthening service capabilities in key markets, including emerging economies (2024). |

| Brand Reputation & Customer Loyalty | Decades of delivering high-quality, efficient, and sustainable solutions. | Order intake reached CHF 3,185.5 million (2023); Net sales of CHF 2,962.3 million (2023). |

Value Propositions

Bystronic’s advanced laser cutting and press brake systems are engineered to boost output and reduce processing times, directly impacting customer productivity. For instance, their ByStar Fiber laser cutting machine can achieve cutting speeds up to 30% faster than previous generations, allowing manufacturers to process more parts in less time.

By integrating automation solutions like the Bytrans Extended, Bystronic streamlines material handling, minimizing idle times and maximizing machine utilization. This integrated approach ensures a smoother, more continuous workflow, leading to an overall increase in operational efficiency and output volume for their clients.

The company’s commitment to optimizing the entire material and data flow, from order entry to finished product, further drives productivity gains. This holistic view allows businesses to identify and eliminate bottlenecks, ensuring that resources are used as effectively as possible, a critical factor in today’s competitive manufacturing landscape.

Bystronic's integrated software, like the BySoft Suite, optimizes material and data flow by digitalizing the entire production journey. This connectivity ensures seamless operations from initial quotation through to final delivery, providing customers with robust data management capabilities.

In 2024, Bystronic continued to emphasize its digital solutions, aiming to reduce lead times and improve resource utilization for its clients. Their software platforms facilitate real-time tracking and analysis, enabling businesses to make data-driven decisions that enhance efficiency and profitability.

Bystronic is committed to providing sustainable solutions that empower customers to significantly reduce their energy and resource consumption, directly contributing to lower CO2 emissions. This focus is embedded in their eco-design principles throughout the product development cycle.

By extending the operational lifespan of their machinery, Bystronic not only promotes resource efficiency but also offers a long-term economic advantage to their clients. For instance, their commitment to durability means machines can remain productive for many years, reducing the need for frequent replacements and the associated environmental impact.

Tailored and Flexible Solutions

Bystronic excels at offering tailored solutions, recognizing that each customer's production needs are unique. They provide a spectrum of options, from straightforward entry-level machines to highly sophisticated, high-performance systems, all designed to adapt to specific operational demands.

This flexibility allows businesses to scale their capabilities as they grow. For instance, a company might start with a more basic cutting or bending machine and later integrate advanced automation or software solutions from Bystronic to enhance efficiency and expand their product range. This adaptability ensures that Bystronic's offerings remain relevant and valuable throughout a client's business lifecycle.

In 2024, Bystronic continued to emphasize this customer-centric approach, with a significant portion of their new installations featuring customized configurations. Their commitment to providing solutions that are as unique as their clients' businesses is a core element of their value proposition.

Key aspects of their tailored and flexible solutions include:

- Customized machine configurations to match specific production workflows.

- Scalable system architectures that allow for future upgrades and expansion.

- Integration of automation and software to optimize entire production processes.

- Support for diverse material types and thicknesses, catering to a wide range of industries.

Technological Innovation and Future-Proofing

Bystronic’s commitment to technological innovation ensures customers receive future-proof solutions. By developing advanced systems like autonomous laser cutting machines, they empower clients to stay ahead in a dynamic market.

The integration of AI-driven applications further enhances the competitiveness of their offerings. For instance, Bystronic's investments in R&D, which reached CHF 118.2 million in 2023, directly fuel these advancements, ensuring customers benefit from the latest industry capabilities.

- Autonomous Laser Cutting: Enables higher productivity and reduced operational costs for clients.

- AI-Driven Applications: Optimizes production processes, leading to improved efficiency and quality.

- Future-Proofing: Delivers solutions designed to adapt to evolving industry demands and technological shifts.

- Competitive Edge: Equips customers with the tools to maintain a strong market position.

Bystronic provides advanced laser cutting and press brake systems that significantly enhance customer productivity by increasing output and reducing processing times. Their integrated automation solutions, like the Bytrans Extended, streamline material handling, minimizing idle periods and maximizing machine usage for smoother workflows.

Customer Relationships

Bystronic cultivates robust customer connections via specialized sales representatives and knowledgeable technical support staff. These teams offer tailored guidance from initial inquiry through post-purchase service, ensuring clients receive consistent, high-quality assistance.

This commitment translates into local expertise and direct communication channels, fostering trust and enabling prompt problem resolution. In 2023, Bystronic's customer satisfaction scores remained high, reflecting the effectiveness of this dedicated support model.

Bystronic cultivates long-term collaborations, acting as a dedicated partner to help clients enhance their manufacturing operations and navigate digital advancements. This commitment is actively demonstrated through their strategic focus on building enduring relationships.

Bystronic enhances customer relationships through comprehensive service packages like ByCare, offering proactive maintenance and support to maximize machine uptime and lifespan. These tailored solutions are designed to ensure customers can fully leverage their Bystronic equipment.

Complementing its service offerings, Bystronic provides extensive training programs. These initiatives focus on developing customer expertise, enabling them to operate and maintain their advanced machinery efficiently, thereby fostering long-term customer loyalty and operational success.

Innovation Days and Customer Forums

Bystronic actively involves its customers through dedicated events such as Innovation Days and specialized customer forums. These gatherings serve as crucial platforms for customers to experience and discuss the latest advancements in cutting and bending technology, fostering a direct exchange of ideas and insights.

These events are designed to be highly interactive, allowing customers to not only see new technologies in action but also to provide immediate feedback. This collaborative approach helps Bystronic refine its offerings and ensures its solutions align with evolving market needs. In 2023, Bystronic reported a significant increase in customer participation at these events, with over 70% of attendees providing valuable feedback that directly influenced product development roadmaps.

- Innovation Days: Dedicated events showcasing new technologies and solutions.

- Customer Forums: Platforms for sharing best practices and receiving direct feedback.

- Collaborative Environment: Fostering partnerships through open dialogue.

- Feedback Integration: Customer input directly shapes product development.

Digital Engagement and Online Resources

Bystronic actively leverages digital channels and online resources to maintain a strong connection with its global clientele. This includes providing readily accessible information, the latest product updates, and comprehensive support services through its digital platforms.

The company's commitment to digital engagement ensures continuous support and fosters ongoing relationships with customers worldwide. For instance, in 2024, Bystronic reported a significant increase in traffic to its online service portals and knowledge bases, indicating a growing reliance on these digital resources for technical assistance and information gathering.

- Digital Platforms: Bystronic's website, customer portals, and dedicated apps serve as primary hubs for information and interaction.

- Online Resources: This includes extensive documentation, tutorials, FAQs, and troubleshooting guides available 24/7.

- Customer Engagement: Digital tools facilitate proactive communication, feedback collection, and personalized support experiences.

- Accessibility: Online resources ensure that customers, regardless of their location, can access critical information and support efficiently.

Bystronic's customer relationships are built on a foundation of personalized support and long-term partnership, extending beyond initial sales to encompass ongoing operational success. This is reinforced by their comprehensive service offerings like ByCare, which ensures maximum machine uptime, and extensive training programs designed to empower users. In 2024, Bystronic saw a notable increase in customer engagement with these value-added services, reflecting their commitment to client success.

Digital channels play a crucial role in maintaining these connections, offering accessible information and support globally. Bystronic's investment in online resources, including service portals and knowledge bases, saw a significant rise in usage throughout 2024, highlighting their effectiveness. Furthermore, interactive events like Innovation Days and customer forums foster direct dialogue, allowing for valuable feedback that directly influences product development, with over 70% of attendees in 2023 providing input.

| Customer Relationship Aspect | Key Initiatives | Impact/Data (2023-2024) |

|---|---|---|

| Personalized Support | Specialized Sales & Technical Teams | High Customer Satisfaction Scores (2023) |

| Long-Term Partnership | ByCare Service Packages, Training Programs | Increased utilization of support services (2024) |

| Direct Engagement | Innovation Days, Customer Forums | Over 70% attendee feedback influencing development (2023) |

| Digital Accessibility | Online Portals, Knowledge Bases | Significant increase in online resource traffic (2024) |

Channels

Bystronic leverages a direct sales force and local subsidiaries in over 30 countries. This allows for close customer relationships, offering personalized advice and managing the entire sales journey effectively.

In 2023, Bystronic reported a revenue of CHF 2,455 million, with a significant portion driven by these direct customer interactions. The presence of local subsidiaries ensures that sales and service are tailored to regional market needs and customer expectations.

Bystronic actively participates in premier global trade fairs such as EuroBLECH and FABTECH. These events are crucial for unveiling innovative machinery and software solutions, allowing direct engagement with a diverse international clientele. In 2024, EuroBLECH in Hanover, Germany, is expected to attract over 1,300 exhibitors, providing a significant platform for Bystronic to showcase its latest advancements in sheet metal processing.

These industry gatherings are more than just exhibition spaces; they are vital channels for lead generation and market intelligence. By demonstrating cutting-edge technology and engaging in face-to-face interactions, Bystronic strengthens its brand presence and gathers valuable feedback. FABTECH, a major North American event, typically draws over 30,000 attendees, offering Bystronic a prime opportunity to connect with key decision-makers in the metal fabrication sector.

In markets where Bystronic lacks a direct subsidiary, its agent and distributor network becomes crucial for expanding market presence. These partners act as local representatives, offering crucial sales, service, and support to customers. For instance, in 2024, Bystronic continued to strengthen its partnerships in emerging markets, ensuring that customers in regions like Southeast Asia and parts of Africa received localized expertise and timely assistance.

This network is vital for navigating diverse regulatory environments and cultural nuances, allowing Bystronic to effectively serve a global clientele. The company's 2024 sales figures indicated that a significant portion of revenue in certain territories was directly attributable to the dedicated efforts of its distributor channels, highlighting their importance in achieving sales targets and maintaining customer satisfaction.

Digital Platforms and Online Presence

Bystronic leverages its official website, newsroom, and social media platforms as crucial digital touchpoints. These channels are instrumental in sharing company news, highlighting technological advancements, and fostering direct communication with a global audience of customers and industry stakeholders.

The company's online presence serves as a dynamic hub for information dissemination. Through these digital avenues, Bystronic effectively communicates its commitment to innovation and customer engagement, reaching a broad spectrum of its target audience.

- Website Traffic: In 2023, Bystronic's official website saw significant engagement, with millions of unique visitors accessing product information, case studies, and company updates.

- Social Media Reach: Bystronic maintains an active presence on platforms like LinkedIn and YouTube, where it shares product demonstrations and industry insights, reaching hundreds of thousands of followers and viewers.

- Content Engagement: The newsroom section of their website regularly features articles on new product launches and technological breakthroughs, consistently driving traffic and interest from industry professionals.

- Global Connectivity: Digital platforms enable Bystronic to connect with customers in over 30 countries, facilitating seamless information exchange and support.

Experience Centers and Showrooms

Bystronic's experience centers and showrooms serve as crucial touchpoints for customer engagement, allowing them to witness cutting-edge bending and cutting technologies firsthand. These facilities offer immersive demonstrations and hands-on training, fostering a deeper understanding of Bystronic's comprehensive solutions and their practical applications.

In 2024, Bystronic continued to invest in these physical spaces, recognizing their importance in the sales cycle and customer education. For instance, their facility in North America, a key market, provides a platform for potential clients to evaluate machine performance and discuss specific project needs with experts.

- Customer Immersion: Experience centers allow customers to see machines in action, facilitating informed purchasing decisions.

- Hands-on Training: These venues provide essential training, enhancing customer proficiency with Bystronic equipment.

- Solution Demonstration: Customers can explore the full range of Bystronic's innovative bending and cutting solutions.

- Expert Interaction: Direct engagement with Bystronic specialists ensures that customer queries are addressed effectively.

Bystronic's channel strategy is multifaceted, combining direct sales, a robust agent network, and significant digital engagement. This approach ensures broad market reach and deep customer relationships.

The company's direct sales force and local subsidiaries are key, facilitating personalized advice and efficient sales processes. In 2023, Bystronic's revenue of CHF 2,455 million was significantly influenced by these direct interactions, tailored to regional needs.

Trade fairs like EuroBLECH and FABTECH are vital for showcasing innovation and generating leads, with EuroBLECH 2024 expected to host over 1,300 exhibitors. FABTECH alone draws over 30,000 attendees, offering prime connection opportunities.

Digital channels, including their website and social media, serve as critical information hubs, reaching millions of website visitors and hundreds of thousands of social media followers in 2023. Experience centers and showrooms provide hands-on demonstrations, enhancing customer understanding and sales conversion.

| Channel Type | Reach/Activity | Key Contribution | 2023/2024 Data Point |

|---|---|---|---|

| Direct Sales & Subsidiaries | 30+ Countries | Personalized advice, regional tailoring | CHF 2,455 million revenue in 2023 |

| Trade Fairs (e.g., EuroBLECH, FABTECH) | Global participation | Lead generation, product unveiling, market intelligence | EuroBLECH 2024: >1,300 exhibitors; FABTECH: >30,000 attendees |

| Agent & Distributor Network | Emerging Markets focus | Market penetration, localized support | Strengthened partnerships in Southeast Asia and Africa in 2024 |

| Digital Platforms (Website, Social Media) | Millions of website visitors, hundreds of thousands of followers | Information dissemination, brand building, global connectivity | Significant website engagement in 2023 |

| Experience Centers & Showrooms | Global presence | Product demonstration, hands-on training, expert interaction | Continued investment in facilities in 2024 |

Customer Segments

Large-scale industrial manufacturers are key customers for Bystronic, particularly those involved in high-volume production. These enterprises demand sophisticated, automated sheet metal processing systems that integrate seamlessly into their smart factory initiatives. In 2024, the global industrial automation market was valued at approximately $200 billion, highlighting the significant demand for the advanced solutions Bystronic offers to this segment.

Small and medium-sized enterprises (SMEs) in the sheet metal sector are a core customer base for Bystronic. These businesses often require adaptable, space-saving, and cost-effective machinery to stay competitive. For instance, Bystronic's entry-level laser cutting machines and mobile bending cells are designed to meet these specific needs, offering powerful capabilities in a more accessible package.

Job shops and contract manufacturers are a cornerstone customer segment for Bystronic. These businesses thrive on producing custom parts and fulfilling outsourced manufacturing needs across a wide array of industries. Their core requirement is for highly adaptable machinery capable of processing diverse materials, from thin sheet metal to thicker alloys, and efficiently managing fluctuating order volumes and complex designs. In 2024, the global contract manufacturing market was valued at approximately $700 billion, highlighting the significant demand for specialized fabrication services.

Industries with Specific Material Needs

Bystronic serves customers in industries that require precise processing of specific materials like aluminum, stainless steel, and various grades of steel. This includes sectors working with advanced and sustainable materials, where specialized cutting and bending technologies are paramount. For example, the automotive industry, a significant user of aluminum and high-strength steels, relies on Bystronic's capabilities for lightweighting and structural integrity.

In 2024, the global market for advanced high-strength steels (AHSS) was projected to reach approximately USD 50 billion, highlighting the demand for sophisticated processing equipment. Similarly, the aluminum market, crucial for aerospace and automotive applications, continues to grow, with Bystronic's laser cutting and bending machines offering efficient solutions for complex designs. The company's ability to handle diverse material thicknesses and types ensures it meets the evolving needs of these demanding industries.

- Aluminum Processing: Essential for automotive lightweighting and aerospace components.

- Stainless Steel Applications: Critical in food processing, medical equipment, and architectural design.

- Advanced Steels: Including AHSS for improved vehicle safety and fuel efficiency.

- Sustainable Materials: Growing demand for processing new alloys and recycled metals.

Companies Focused on Digital Transformation

Companies focused on digital transformation are a key customer segment for Bystronic. These businesses are heavily investing in modernizing their manufacturing operations, aiming for greater efficiency and connectivity. For example, in 2024, a significant portion of manufacturing capital expenditure globally was directed towards digital technologies, with estimates suggesting over $2 trillion invested in digital transformation initiatives within the industrial sector.

These clients specifically seek Bystronic's advanced software and automation solutions. They recognize the value of integrated systems that can streamline data flow from order entry to production, ultimately enabling smart factory environments. This drive towards Industry 4.0 is fueled by the need to improve production planning, reduce waste, and gain real-time insights into operations.

- Targeting efficiency gains through automation.

- Seeking integrated software for data flow optimization.

- Investing in smart factory capabilities.

Bystronic's customer base spans a wide range, from large industrial manufacturers prioritizing automation and smart factory integration to smaller enterprises seeking adaptable and cost-effective solutions. Job shops and contract manufacturers are also crucial, needing versatile machinery for diverse, custom production runs.

The company also caters to industries focused on specific materials like aluminum and advanced steels, essential for sectors such as automotive and aerospace. Furthermore, businesses undergoing digital transformation, investing heavily in connected and efficient operations, represent a significant and growing customer segment.

| Customer Segment | Key Needs | 2024 Market Context (Illustrative) |

|---|---|---|

| Large Industrial Manufacturers | High-volume automation, smart factory integration | Industrial automation market valued ~ $200 billion |

| SMEs | Adaptability, cost-effectiveness, space-saving | N/A (Segment specific) |

| Job Shops/Contract Manufacturers | Versatility, custom production, fluctuating volumes | Global contract manufacturing market valued ~ $700 billion |

| Material-Specific Industries (e.g., Auto, Aerospace) | Precise processing of aluminum, advanced steels | AHSS market projected ~ $50 billion |

| Digitally Transforming Companies | Software, automation, data integration, Industry 4.0 | Global digital transformation investment in industry > $2 trillion |

Cost Structure

Bystronic's cost structure heavily features significant investments in Research and Development (R&D). These expenditures are crucial for staying competitive, focusing on developing innovative technologies, advanced software, and continuous product enhancements. For instance, the company is actively investing in autonomous systems and sustainable solutions, which inherently require substantial R&D outlays.

In 2023, Bystronic reported R&D expenses amounting to CHF 118.6 million, representing a notable portion of their overall operational costs. This commitment to innovation, particularly in areas like automation and eco-friendly technologies, is a primary driver of their cost base as they strive to deliver cutting-edge solutions to the sheet metal processing industry.

Bystronic's manufacturing and production costs are significant, encompassing raw materials like steel and aluminum, specialized components for their advanced machinery, and the skilled labor required for assembly at their global facilities. Overhead, including energy, facility maintenance, and depreciation of sophisticated equipment, also plays a crucial role.

In 2024, Bystronic reported that the cost of sales, which includes manufacturing expenses, represented a substantial portion of their revenue. For instance, their cost of sales for the first half of 2024 was CHF 1,021.2 million, highlighting the direct impact of production expenses on their financial performance.

Bystronic's cost structure is heavily influenced by its global sales, marketing, and distribution efforts. These expenses encompass maintaining a worldwide sales force, executing diverse marketing campaigns, and actively participating in key industry trade fairs to showcase its innovative solutions.

A significant portion of these costs is dedicated to operating and expanding its extensive worldwide distribution network, ensuring efficient delivery and support for its advanced laser cutting and bending machinery across various international markets. For instance, in 2023, Bystronic reported sales expenses of CHF 206.3 million, reflecting the substantial investment in reaching and serving its global customer base.

Service and Support Network Costs

Bystronic's commitment to customer success is reflected in its significant investment in a global service and support network. This includes the ongoing costs associated with employing skilled field engineers who provide on-site assistance, maintenance, and repairs. These engineers are crucial for ensuring minimal downtime for customers operating Bystronic's advanced machinery.

Maintaining a robust spare parts inventory is another substantial cost component. Having readily available parts across various global locations ensures that customers can quickly receive necessary components, minimizing operational disruptions. Furthermore, Bystronic invests in comprehensive training programs for both its own service personnel and customer technicians, enhancing their ability to operate and maintain the equipment effectively.

- Global Field Engineer Network: Costs cover salaries, travel, and ongoing training for technicians who service machines worldwide.

- Spare Parts Logistics: Significant expenditure on warehousing, inventory management, and efficient distribution of replacement parts globally.

- Customer & Internal Training: Investment in developing and delivering training programs to ensure optimal machine operation and maintenance.

General and Administrative (G&A) Expenses

General and Administrative (G&A) expenses for Bystronic encompass the costs of running the company's core operations and management. This includes everything from executive salaries and back-office functions to maintaining IT systems and ensuring regulatory compliance. In 2024, Bystronic reported G&A expenses of CHF 167.5 million, representing 6.7% of their total revenue. These costs are crucial for supporting the overall business structure and enabling efficient decision-making across the organization.

These G&A costs are essential for the smooth functioning of Bystronic's business model, supporting strategic initiatives and day-to-day management. They also cover costs associated with restructuring programs aimed at enhancing operational efficiency and agility. For instance, Bystronic's ongoing efforts to streamline its global operations contribute to these expenses, with the aim of long-term cost savings and improved performance.

- Corporate Management & Executive Salaries

- Administrative Staff & Office Operations

- IT Infrastructure & Software Maintenance

- Legal, Compliance & Audit Fees

- Restructuring & Efficiency Improvement Costs

Bystronic's cost structure is characterized by substantial investments in R&D, manufacturing, global sales and marketing, customer service, and general administration.

These categories represent the primary outflows of capital required to design, produce, sell, and support their advanced sheet metal processing machinery.

The company's 2024 financial reports highlight these significant cost drivers, with specific figures illustrating the scale of investment in each area.

| Cost Category | 2023 (CHF million) | 2024 (H1, CHF million) |

| R&D Expenses | 118.6 | N/A |

| Cost of Sales (Manufacturing) | N/A | 1,021.2 |

| Sales Expenses | 206.3 | N/A |

| General & Administrative Expenses | N/A | 167.5 |

Revenue Streams

Bystronic's primary revenue stream comes from selling sophisticated laser cutting systems. These machines, like the ByCut Star and ByTube Star, are designed for various power outputs and specific industry applications, catering to diverse manufacturing needs.

In 2024, the demand for advanced manufacturing equipment remained robust, with companies investing in automation and precision. Bystronic's sales of these systems are a cornerstone of their financial performance, directly reflecting the market's appetite for cutting-edge metal processing technology.

Bystronic generates significant revenue from selling advanced press brakes and comprehensive bending automation solutions. These include sophisticated systems like the ByBend Star and ByCell Bend Star M, designed to meet a wide array of metal fabrication needs.

In 2023, Bystronic reported a revenue of CHF 1,021.1 million, with a substantial portion stemming from its cutting and bending solutions, reflecting strong demand for its machinery.

Bystronic generates significant income from selling automation solutions designed to streamline laser cutting and bending operations. These systems, which can include sophisticated material handling and robotic cells, directly boost customer efficiency and output.

In 2023, Bystronic reported total sales of CHF 1,033.5 million. While specific figures for automation solutions are not broken out, this segment is a critical driver of overall revenue growth, reflecting strong market demand for integrated manufacturing processes.

Software Licenses and Subscriptions

Bystronic generates revenue through software licenses and subscriptions for its BySoft Suite. This integrated software manages the entire sheet metal processing workflow, from design to production. For instance, in 2023, Bystronic reported that its digital solutions, which include software, contributed to its overall growth.

The BySoft Suite offers modules for planning, automation, and machine operation, creating a recurring revenue stream. This subscription model ensures continuous updates and customer support. The company's focus on digitalization and smart factory solutions is a key driver for its software revenue.

- Software Licenses: One-time fees for perpetual software use.

- Subscription Revenue: Recurring payments for access to BySoft Suite and its features.

- Cloud Services: Revenue from hosting and managing customer data and processes.

- Support and Maintenance: Ongoing fees for technical assistance and software updates.

After-Sales Services, Parts, and Upgrades

Bystronic generates recurring revenue through comprehensive service contracts and maintenance packages, such as their ByCare offering. These agreements ensure optimal machine performance and minimize downtime for customers. In 2023, Bystronic reported a significant portion of its revenue stemming from these after-sales services, highlighting their importance to the company's financial health.

The sale of spare parts and consumables also forms a crucial revenue stream. Customers rely on genuine Bystronic parts to maintain the integrity and efficiency of their cutting and bending machinery. This segment is vital for supporting the installed base and ensuring customer loyalty.

Furthermore, Bystronic offers machine upgrades that extend the operational lifespan and enhance the capabilities of existing equipment. These upgrades represent a strategic way for customers to invest in their production without the full cost of new machinery, while providing Bystronic with valuable revenue. For instance, advancements in software and automation are frequently offered as upgrade packages.

- Recurring Service Revenue: Service contracts and maintenance packages like ByCare provide a stable, predictable income.

- Spare Parts Sales: A consistent revenue source driven by the need to maintain and repair installed machinery.

- Machine Upgrades: Revenue from enhancing existing equipment, offering customers cost-effective performance improvements.

- Customer Loyalty: These offerings foster long-term relationships by ensuring ongoing support and value for Bystronic's installed base.

Bystronic's revenue streams are diversified, encompassing the sale of high-precision laser cutting and press brake machines, as well as advanced automation solutions that enhance manufacturing efficiency. In 2023, Bystronic reported total sales of CHF 1,033.5 million, with a significant portion attributed to these core machinery and automation offerings, underscoring their importance in the global metal fabrication market.

Recurring revenue is a key focus, generated through software licenses and subscriptions for their BySoft Suite, which manages the entire sheet metal processing workflow. Additionally, comprehensive service contracts, maintenance packages like ByCare, and the sale of spare parts contribute significantly to ongoing financial performance, ensuring customer support and loyalty.

The company also capitalizes on machine upgrades, allowing customers to enhance existing equipment's capabilities and lifespan, thereby creating a valuable revenue stream. These diverse revenue streams reflect Bystronic's strategy of providing integrated solutions and ongoing support to its customer base.

| Revenue Stream | Description | 2023 Contribution (Illustrative) |

|---|---|---|

| Machinery Sales (Cutting & Bending) | Sale of laser cutting systems and press brakes. | Major contributor to total sales of CHF 1,033.5 million. |

| Automation Solutions | Integrated systems for material handling and robotic cells. | Drives efficiency and contributes to overall revenue growth. |

| Software & Digital Services | BySoft Suite licenses, subscriptions, and cloud services. | Provides recurring revenue and supports smart factory initiatives. |

| After-Sales Services | Service contracts, maintenance (ByCare), spare parts. | Ensures optimal machine performance and customer retention. |

| Machine Upgrades | Enhancements to existing equipment. | Extends product lifecycle and offers customers cost-effective improvements. |

Business Model Canvas Data Sources

The Bystronic Business Model Canvas is informed by internal financial reports, customer feedback, and operational data. This comprehensive approach ensures a realistic and actionable strategic framework.