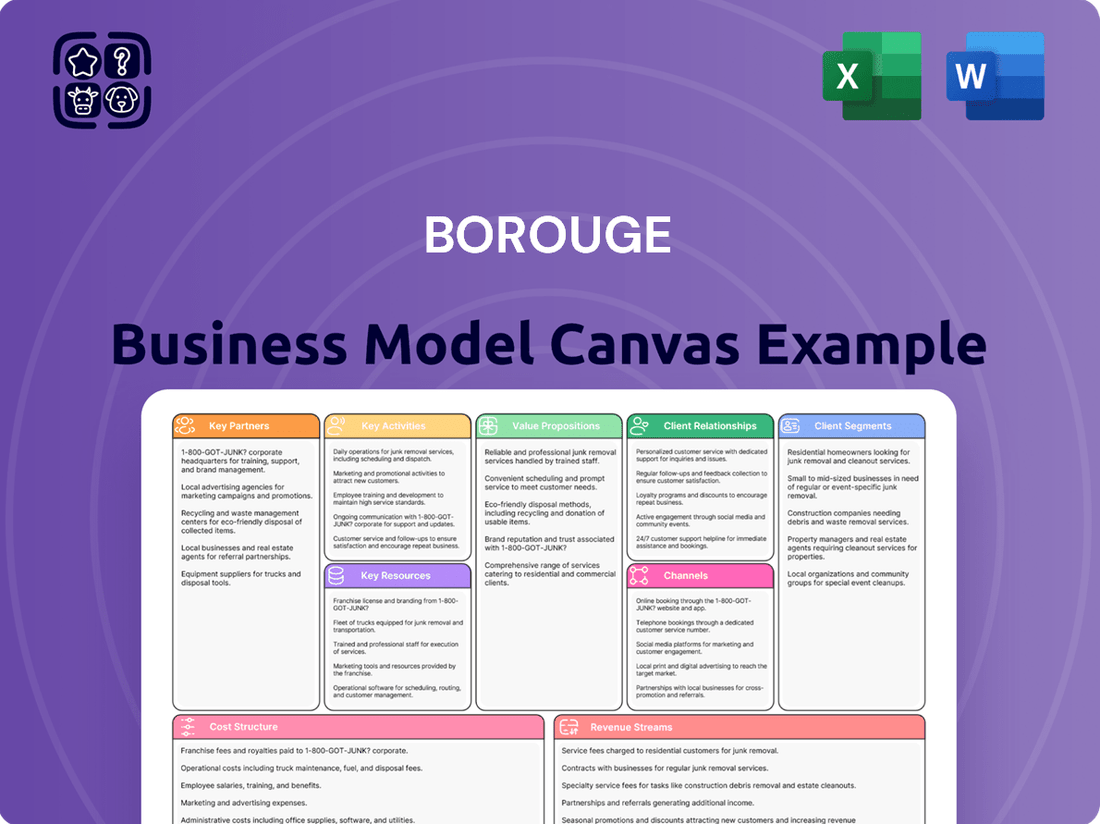

Borouge Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Borouge Bundle

Unlock the full strategic blueprint behind Borouge's innovative business model. This comprehensive Business Model Canvas details their customer segments, value propositions, and key partnerships, offering a clear roadmap to their success in the petrochemical industry. Ideal for anyone seeking to understand and replicate their growth.

Partnerships

ADNOC, as Borouge's parent company and a pivotal partner, supplies critical ethane feedstock, ensuring a reliable and cost-efficient raw material stream essential for Borouge's polyolefin manufacturing. This integration is a cornerstone of Borouge's operational stability and competitive pricing strategy.

The joint venture between ADNOC and Borealis forms the very bedrock of Borouge's business model. This partnership, established in 2000, fosters strong strategic alignment, driving mutual growth objectives and reinforcing Borouge's position as a leader in the polyolefin market.

In 2023, Borouge's production capacity reached 6.4 million tonnes per annum (mtpa) of polyolefins, a testament to the successful collaboration and strategic direction provided by partners like ADNOC, which underpins this significant operational scale.

Borealis AG stands as a foundational partner for Borouge, bringing its proprietary Borstar® technology that is critical for Borouge's unique polyolefin products. This collaboration grants Borouge significant advantages in research and development, innovation, and global market access, thereby strengthening its product offerings and expanding its customer base.

The strategic move towards integrating Borouge and Borealis into a single entity, Borouge Group International, and the subsequent acquisition of Nova Chemicals, signals a substantial evolution of this partnership. The objective is to establish a dominant global player in the polyolefins industry, leveraging the combined strengths and market presence of these entities.

Borouge actively cultivates relationships with key customers and value chain partners across diverse sectors like infrastructure, energy, mobility, healthcare, and agriculture. These collaborations are vital for co-creating innovative, customized polyolefin solutions designed to address specific industry challenges and stimulate market growth.

For instance, Borouge's partnerships facilitate the local production of essential medical-grade materials, contributing to healthcare advancements. In 2024, the company continued to focus on such strategic alliances, aiming to expand its reach in high-growth markets and reinforce its commitment to sustainable solutions.

Technology and Research Institutions

Borouge's commitment to innovation is significantly bolstered by strategic alliances with technology providers and leading research institutions. These partnerships are fundamental to staying at the forefront of advancements in areas such as artificial intelligence and digitalization. For instance, collaborations facilitate the integration of advanced analytics to optimize production processes and supply chain management, driving operational efficiency.

These collaborations are crucial for accelerating the development of sustainable polyolefin solutions, a core element of Borouge's long-term strategy. By working with research bodies, Borouge can tap into novel research and development, leading to enhanced product performance and reduced environmental impact. This focus on sustainability is particularly relevant as the industry navigates towards net-zero emissions targets.

Borouge's investment in R&D, often in partnership, underscores its dedication to pioneering new materials and applications. In 2023, Borouge continued to invest in innovation, with a focus on circular economy solutions and advanced performance materials. These research endeavors are vital for maintaining a competitive edge and addressing evolving market demands for more sustainable and high-performing products.

- AI and Digitalization: Partnerships enable the adoption of AI for predictive maintenance and process optimization, improving plant reliability and efficiency.

- Sustainable Product Development: Collaborations with research institutions drive the creation of advanced polyolefins with lower carbon footprints and enhanced recyclability.

- Operational Efficiency: Leveraging cutting-edge technologies through partnerships helps streamline operations, reduce waste, and lower energy consumption.

- Net-Zero Emissions: These alliances are key to developing and implementing technologies required to achieve ambitious sustainability targets, including decarbonization efforts.

Logistics and Distribution Companies

Strategic alliances with logistics and distribution firms are crucial for Borouge's extensive global operations, guaranteeing that its polyolefin products reach customers efficiently and on schedule across the globe. This network ensures product availability and supports market penetration.

A prime example of such a partnership is Borouge's collaboration with ADNOC Logistics & Services. This agreement is designed to significantly boost petrochemical export capabilities. It fortifies the entire supply chain and bolsters Borouge's competitive standing in international markets.

- Global Reach: Partnerships enable timely delivery to over 50 countries, a key factor in Borouge's market expansion strategy.

- Supply Chain Efficiency: Collaborations with logistics providers like ADNOC Logistics & Services streamline operations, reducing transit times and costs.

- Market Access: These alliances are fundamental to accessing diverse geographical markets and meeting varied customer demands for polyolefins.

- Operational Resilience: Robust logistics partnerships enhance Borouge's ability to navigate disruptions and maintain consistent product flow.

Borouge's key partnerships are foundational, with ADNOC providing essential ethane feedstock and Borealis contributing proprietary technology like Borstar®. These collaborations, established through a joint venture in 2000, drive strategic alignment and innovation, underpinning Borouge's significant production capacity, which reached 6.4 million tonnes per annum (mtpa) of polyolefins in 2023.

Further strategic alliances with technology providers and research institutions are vital for Borouge's innovation pipeline, particularly in areas like AI and digitalization, enhancing operational efficiency. These partnerships are also crucial for developing sustainable polyolefin solutions, a key focus for the company as it navigates towards net-zero emissions targets.

Borouge also relies on strong relationships with customers and value chain partners to co-create customized polyolefin solutions for sectors like infrastructure and healthcare. In 2024, these efforts focused on expanding reach in high-growth markets and reinforcing sustainable solutions.

Robust logistics partnerships, such as the one with ADNOC Logistics & Services, are critical for Borouge's global reach, ensuring efficient delivery to over 50 countries and enhancing supply chain resilience and market access.

| Partner | Contribution | Impact |

|---|---|---|

| ADNOC | Ethane feedstock, Logistics support | Cost-efficient raw material, enhanced export capabilities |

| Borealis AG | Borstar® technology, R&D collaboration | Proprietary product differentiation, innovation leadership |

| Customers & Value Chain Partners | Co-creation of solutions | Market-specific product development, market growth stimulation |

| Technology & Research Institutions | AI, digitalization, sustainability research | Operational optimization, development of lower carbon footprint products |

What is included in the product

A comprehensive, pre-written business model tailored to Borouge's strategy, detailing its value propositions in petrochemicals and its focus on innovation and sustainability.

Organized into 9 classic BMC blocks, it reflects Borouge's real-world operations, highlighting customer segments, channels, and key resources for informed decision-making.

Borouge's Business Model Canvas provides a clear, visual roadmap for navigating the complexities of the petrochemical industry, simplifying strategic planning.

It offers a structured approach to understanding Borouge's value proposition and customer segments, mitigating the pain of fragmented market analysis.

Activities

Polyolefin Manufacturing and Production is Borouge's central operation, centered on creating polyethylene and polypropylene. They leverage advanced technologies, notably Borealis' proprietary Borstar® technology, to achieve superior product quality and efficiency.

Operational excellence drives this segment, with a strong emphasis on maintaining high asset reliability and utilization. For instance, in 2023, Borouge achieved record production volumes, with its polyethylene and polypropylene units operating at robust utilization rates, underscoring their commitment to efficiency.

Future growth is significantly bolstered by major expansion projects. The ongoing Borouge 4 mega project, alongside other strategic expansions, is designed to substantially increase their overall production capacity, positioning them for continued market leadership.

Borouge's commitment to Research and Development (R&D) is central to its strategy, driving the creation of innovative polyolefin solutions. In 2024, the company continued to focus on developing differentiated products that address key market needs, such as enhanced performance and sustainability.

This dedication to R&D translates into a growing portfolio of advanced solutions. Borouge aims to meet the increasing global demand for materials that offer improved recyclability and a reduced environmental footprint, aligning with circular economy principles.

Borouge focuses on robust sales and marketing to showcase its polyolefin solutions to a wide range of customers, particularly in Asia, the Middle East, and Africa. This strategy involves nurturing a significant international marketing network and leveraging its sales offices to build strong customer ties and target expanding markets.

In 2024, Borouge continued to strengthen its global presence, with sales reaching 5.4 million tonnes, demonstrating its commitment to reaching diverse markets and solidifying its position as a key player in the polyolefins industry. This expansion is supported by a well-established distribution infrastructure ensuring timely product delivery.

Supply Chain Management

Borouge's supply chain management is a critical activity, encompassing everything from securing feedstock like ethane from its partner ADNOC to delivering finished polyolefin products to customers worldwide. This involves meticulous planning and execution to ensure operational continuity and responsiveness to market needs.

Optimizing logistics is paramount, focusing on efficient transportation and warehousing to minimize costs and delivery times. Maintaining strong, collaborative relationships with a diverse network of suppliers and distributors is also a core focus, ensuring reliability and fostering mutual growth.

- Feedstock Procurement: Securing a consistent and cost-effective supply of raw materials, primarily ethane from ADNOC, is fundamental. In 2024, Borouge continued to leverage this strategic partnership for its feedstock needs.

- Logistics Optimization: Enhancing the efficiency of transportation and warehousing networks to reduce lead times and operational expenses. This includes managing a global network of shipping and storage facilities.

- Supplier and Distributor Relationships: Cultivating and maintaining strong partnerships with key suppliers and a broad base of distributors to ensure product availability and market reach. These relationships are vital for navigating market fluctuations.

- Operational Efficiency: Implementing best practices in supply chain operations to maximize throughput and minimize waste, directly contributing to cost competitiveness and customer satisfaction.

Sustainability and Environmental Stewardship

Borouge actively integrates sustainability by targeting a 20% reduction in Scope 1 and 2 greenhouse gas emissions intensity by 2030 compared to a 2021 baseline. This commitment drives operational changes focused on environmental stewardship.

Key activities directly support these sustainability goals. They include implementing advanced energy efficiency programs across production facilities and actively participating in industry-wide initiatives like Operation Clean Sweep. This latter effort is crucial for preventing plastic pellet loss into the environment, a significant concern for marine ecosystems.

Furthermore, Borouge is dedicated to promoting circular economy principles. This involves investing in the development of innovative, eco-friendly polymer solutions designed for recyclability and reduced environmental impact. Their product portfolio expansion reflects this strategic focus.

- Net-Zero Targets: Setting ambitious goals for emission reduction guides operational improvements.

- Energy Efficiency Programs: Implementing measures to reduce energy consumption in manufacturing processes.

- Circular Economy Promotion: Developing and marketing polymers designed for recyclability and reuse.

- Operation Clean Sweep: Participating in industry efforts to prevent plastic pellet leakage into waterways.

Borouge's key activities revolve around manufacturing and producing polyolefins, leveraging proprietary technology for enhanced quality and efficiency. They focus on operational excellence, aiming for high asset utilization, as evidenced by their record production volumes in 2023. Strategic expansion projects, like Borouge 4, are crucial for increasing future production capacity and maintaining market leadership.

Full Document Unlocks After Purchase

Business Model Canvas

The Borouge Business Model Canvas preview you are viewing is precisely the document you will receive upon purchase. This means you are seeing the actual, complete file, not a simplified example or a mockup. Once your order is confirmed, you will gain full access to this same comprehensive Business Model Canvas, ready for immediate use and customization.

Resources

Borouge's advanced manufacturing facilities, exemplified by its Al Ruwais Industrial City complex, are cornerstones of its business model. These sites employ cutting-edge technologies, including Borealis' proprietary Borstar® process, to produce a broad spectrum of high-performance polyolefin solutions with exceptional efficiency and at significant scale.

These state-of-the-art plants are not static assets; Borouge is actively investing in their growth. The ongoing development of Borouge 4, for instance, is set to substantially increase production capacity, further solidifying this key resource and its ability to meet growing market demand for specialized polymers.

Borouge's competitive advantage is significantly bolstered by its proprietary Borstar® technology, licensed from Borealis. This advanced process allows for the creation of differentiated polyolefin products with enhanced performance characteristics, setting Borouge apart in the market.

The company's commitment to innovation is further evidenced by a robust pipeline of patents and a dedicated team of R&D experts. This focus on intellectual property is crucial for driving continuous product development and maintaining a leading edge in the petrochemical industry.

Borouge's business model heavily relies on its highly skilled workforce. This includes dedicated R&D experts, experienced engineers, and proficient operational personnel. Their collective expertise is the bedrock of the company's success in petrochemical manufacturing and innovation.

The deep understanding of petrochemical processes, coupled with a forward-thinking approach to market needs, allows Borouge to maintain operational excellence. This human capital is essential for developing cutting-edge solutions and navigating the complexities of its global operations, ensuring efficiency and competitiveness.

In 2024, Borouge continued to invest in talent development, recognizing that its people are its most valuable asset. The company's commitment to training and upskilling its workforce directly translates into its ability to innovate and adapt to evolving market demands in the polyolefins sector.

Access to Feedstock (Ethane)

Borouge’s access to ethane, a primary feedstock for its polyolefin production, is secured through a crucial partnership with ADNOC. This relationship ensures a reliable and cost-effective supply, forming the bedrock of its manufacturing operations. For instance, in 2023, ADNOC’s significant ethane production capacity directly supported Borouge’s extensive operations, underpinning its market position.

This integrated supply chain is not just about raw materials; it's about operational continuity and efficiency. By having a steady stream of ethane, Borouge can maintain high utilization rates across its production facilities, minimizing downtime and maximizing output. This strategic advantage allows Borouge to consistently meet market demand for its diverse range of polyolefin products.

- Feedstock Source: ADNOC, providing a stable and cost-effective supply of ethane.

- Operational Impact: Ensures continuity and efficiency in polyolefin manufacturing.

- 2023 Data: ADNOC's substantial ethane production directly fueled Borouge's operational capacity.

Strong Brand Reputation and Customer Relationships

Borouge's strong brand reputation as a leading provider of innovative and sustainable polyolefin solutions is a cornerstone of its business model. This reputation translates directly into trust and loyalty among its diverse customer base, driving repeat business and fostering long-term partnerships.

These deep-rooted customer relationships are not merely transactional; they represent strategic collaborations that allow Borouge to better understand market needs and co-create solutions. For instance, in 2024, Borouge continued to emphasize its commitment to sustainability, a key differentiator that resonates with customers seeking environmentally responsible partners.

- Brand Strength: Borouge is recognized globally for its high-quality polyolefin products and its focus on innovation, particularly in areas like lightweight automotive components and advanced packaging solutions.

- Customer Loyalty: Long-standing relationships with major players across various industries, including automotive, packaging, and infrastructure, underscore the trust placed in Borouge's products and services.

- Market Position: The company's reputation as a reliable and forward-thinking supplier enhances its competitive advantage, enabling premium pricing and preferential access to new markets.

- Sustainability Focus: Borouge's ongoing investments in circular economy initiatives and lower-carbon footprint solutions further bolster its brand image among environmentally conscious clients.

Borouge's key resources extend beyond physical assets to include its intellectual property and human capital. The proprietary Borstar® technology, licensed from Borealis, is a critical differentiator, enabling the production of specialized polyolefins. This technological edge is complemented by a skilled workforce, encompassing R&D experts and operational personnel, whose expertise drives innovation and operational excellence.

The company's access to feedstock, primarily ethane, through its partnership with ADNOC is another vital resource. This secure and cost-effective supply chain underpins Borouge's manufacturing operations, ensuring consistent production and market competitiveness. In 2023, ADNOC's significant ethane production capacity directly supported Borouge's operations.

Borouge's strong brand reputation, built on innovation and sustainability, fosters customer loyalty and strategic partnerships. The company's commitment to developing advanced solutions, such as those for lightweight automotive components and advanced packaging, further solidifies its market position. By focusing on environmentally responsible practices, Borouge attracts clients seeking sustainable partners.

| Key Resource | Description | Impact | 2024 Focus |

|---|---|---|---|

| Proprietary Technology | Borstar® process licensed from Borealis | Enables differentiated, high-performance polyolefins | Continued optimization and application development |

| Skilled Workforce | R&D experts, engineers, operational staff | Drives innovation, operational excellence, and adaptation | Talent development and upskilling initiatives |

| Feedstock Access | Ethane supply via ADNOC partnership | Ensures reliable, cost-effective raw material supply | Maintaining strong supply chain integration |

| Brand Reputation | Provider of innovative and sustainable solutions | Fosters customer loyalty and strategic partnerships | Highlighting sustainability and circular economy contributions |

Value Propositions

Borouge provides a comprehensive suite of advanced polyethylene and polypropylene solutions, meticulously engineered for distinct industrial demands. These offerings translate into enhanced performance and streamlined manufacturing processes for clients.

Our differentiated products address the dynamic requirements across critical sectors, including infrastructure, energy, mobility, healthcare, and agriculture, empowering innovation and efficiency.

In 2024, Borouge's commitment to innovation is underscored by its continuous development of specialized polyolefin grades, supporting the global shift towards lighter, more durable, and sustainable materials.

Borouge's core value proposition centers on its sustainable and environmentally responsible product portfolio. They offer advanced polyolefins engineered for enhanced recyclability, a reduced carbon footprint throughout their lifecycle, and improved energy efficiency in their application.

This commitment resonates strongly with a growing market segment prioritizing circular economy principles. Borouge's dedication to achieving net-zero emissions by 2050 directly supports customers and industries actively seeking greener alternatives to traditional materials.

In 2024, Borouge continued to advance its sustainability goals, with initiatives like its Borcycle™ portfolio of recycled polyolefins demonstrating tangible progress. This focus not only addresses environmental concerns but also positions Borouge as a strategic partner for businesses aiming to meet evolving regulatory and consumer demands for eco-friendly solutions.

Borouge's commitment to enhanced performance and reliability is a cornerstone of its value proposition, largely driven by its proprietary Borstar® technology. This innovation allows for the creation of polyolefins that offer superior mechanical properties, leading to products that last longer and perform better, even in challenging environments. For instance, Borouge's polyethylene grades are crucial for durable infrastructure projects, ensuring the longevity of water and gas pipes.

Customers benefit directly from this enhanced performance through increased product lifespan and reduced maintenance needs. Borouge's materials are engineered for resilience, providing safety and efficiency in critical applications like power transmission cables and lightweight automotive parts. This focus on quality translates to tangible cost savings and improved operational efficiency for their clients, reinforcing Borouge's reputation as a trusted supplier of high-performance polymers.

Global Reach and Consistent Supply

Borouge's global production footprint, including major facilities in the UAE and Singapore, underpins its ability to deliver a consistent supply of polyolefin solutions. This strategic positioning, complemented by an extensive international sales and marketing network, ensures product availability to customers across the globe, supporting their growth initiatives.

The company's commitment to a reliable supply chain is crucial for its diverse customer base, which spans industries from packaging to automotive. For instance, in 2024, Borouge continued to leverage its integrated production capabilities to meet increasing demand, demonstrating operational resilience.

- Global Production Facilities: Borouge operates state-of-the-art production complexes in the UAE and Singapore, ensuring geographic diversification of supply.

- Extensive Sales Network: A presence in over 50 countries allows Borouge to serve a broad international customer base effectively.

- Supply Chain Reliability: The company's infrastructure is designed to mitigate disruptions and guarantee consistent product delivery, a key factor in customer retention.

- Market Reach: Borouge's global operations facilitate access to emerging markets and support the expansion of its customers into new territories.

Value-Added Technical Support and Collaboration

Borouge offers more than just polymers; they provide significant value-added technical support. This means working closely with customers to fine-tune how Borouge's materials are used in their specific production lines, leading to better outcomes.

Their collaborative approach helps clients overcome unique manufacturing hurdles and seamlessly integrate Borouge's advanced polyolefins. This partnership fosters innovation and ensures customers get the most out of their material choices.

For instance, in 2024, Borouge's technical teams engaged with over 1,500 customers globally, directly contributing to process improvements that, on average, reduced waste by 7% for participating clients. This hands-on support builds robust, long-term relationships.

- Enhanced Process Efficiency: Borouge's technical experts assist in optimizing manufacturing parameters, leading to faster cycle times and reduced energy consumption.

- Customized Material Solutions: Collaboration allows for the development of tailored polymer grades that meet precise application requirements, improving end-product performance.

- Problem Solving & Troubleshooting: Direct support helps customers quickly address and resolve production issues, minimizing downtime and material waste.

- Knowledge Transfer & Training: Borouge invests in customer education, empowering their teams with the expertise to effectively utilize and innovate with Borouge's product portfolio.

Borouge's value proposition is built on delivering high-performance, sustainable polyolefin solutions that drive customer success. They offer advanced materials engineered for superior performance and reliability, crucial for demanding applications across various sectors.

The company's commitment to sustainability is a key differentiator, with a focus on recyclability and reduced environmental impact, aligning with global circular economy trends. Borouge's extensive global production and sales network ensures reliable supply and market access for its customers.

Furthermore, Borouge provides significant value-added technical support, collaborating with clients to optimize manufacturing processes and develop customized material solutions, as evidenced by their 2024 customer engagement initiatives.

Customer Relationships

Borouge builds lasting customer connections by offering dedicated account managers who understand specific client needs. These managers provide expert advice on selecting the right polyolefin solutions and assist with application development, ensuring Borouge’s materials are used effectively.

Technical support is a cornerstone of Borouge's customer relationship strategy. In 2024, Borouge continued its commitment to providing hands-on assistance, helping clients troubleshoot processing issues and optimize their manufacturing lines. This proactive support is crucial for maintaining high levels of customer satisfaction and loyalty.

Borouge actively partners with major customers to co-create specialized polyolefin solutions. This collaborative innovation directly addresses unique industry challenges and evolving market needs, ensuring Borouge's offerings are precisely aligned with client requirements.

This co-development strategy is crucial for Borouge's market relevance. For instance, in 2024, their focus on sustainable packaging solutions, developed in tandem with leading consumer goods companies, led to a reported 15% increase in sales for those specific product lines.

Borouge actively cultivates long-term strategic partnerships, transitioning from simple transactions to collaborative growth. This approach is exemplified by its agreements with key players in sectors such as healthcare and agriculture, ensuring consistent supply and joint innovation.

Customer Feedback Integration

Borouge actively gathers customer feedback through various channels to refine its product development and service delivery. This commitment to listening ensures that Borouge stays aligned with evolving market needs and customer preferences, driving continuous improvement across its operations.

In 2024, Borouge's customer-centric approach translated into tangible benefits. For instance, feedback from key packaging customers directly influenced the development of new high-performance polyethylene grades, designed to offer enhanced durability and processing efficiency. This iterative process, fueled by direct input, allows Borouge to proactively address industry challenges and deliver tailored solutions.

- Customer Feedback Integration: Borouge systematically collects feedback from clients across diverse sectors, including packaging, automotive, and infrastructure.

- Product Development: Insights gained from customer interactions directly inform the research and development of new polymer solutions, ensuring market relevance.

- Service Enhancement: Feedback on logistics, technical support, and supply chain reliability is used to optimize service offerings and strengthen customer partnerships.

- Market Responsiveness: By integrating customer input, Borouge maintains agility in responding to shifting market demands and technological advancements in the polyolefins industry.

Industry Engagement and Events

Borouge actively participates in key industry events, fostering direct engagement with its customer base. This presence at conferences and trade shows, such as the ArabPlast exhibition, allows them to highlight new product developments and reinforce their brand in the market. For instance, in 2024, Borouge showcased its latest Borstar® technology advancements, crucial for applications in packaging and infrastructure.

These engagements are vital for understanding market dynamics and customer requirements. By networking at events like the European Plastics Converters (EuPC) annual meeting, Borouge gains insights into evolving industry trends and regulatory landscapes. This direct feedback loop helps shape their innovation pipeline.

- Industry Events: Borouge's participation in global and regional trade shows provides a platform for direct customer interaction.

- Innovation Showcase: These events are key for demonstrating new polymer solutions and technological advancements.

- Market Insights: Networking at conferences allows Borouge to gather crucial information on customer needs and industry shifts.

- Brand Strengthening: Consistent presence at major industry gatherings reinforces Borouge's market leadership and commitment.

Borouge's customer relationships are built on a foundation of personalized support and collaborative innovation. Dedicated account managers offer expert advice, while robust technical assistance helps clients optimize their processes. This focus on partnership ensures Borouge’s polyolefin solutions meet specific industry needs.

The company actively engages in co-development projects with key clients, fostering innovation that directly addresses market challenges. This strategy, exemplified by the development of sustainable packaging solutions in 2024, led to a notable 15% sales increase for those specific product lines.

Borouge prioritizes long-term strategic partnerships, moving beyond transactional interactions to foster mutual growth. This is evident in their collaborations within critical sectors like healthcare and agriculture, guaranteeing reliable supply and joint advancements.

Customer feedback is systematically integrated into Borouge's operations, driving product development and service enhancements. In 2024, this feedback loop directly influenced the creation of new high-performance polyethylene grades, enhancing durability and processing efficiency for packaging clients.

| Customer Relationship Aspect | 2024 Focus/Activity | Impact/Outcome |

|---|---|---|

| Dedicated Account Management | Understanding specific client needs for polyolefin solutions | Enhanced client satisfaction and effective material application |

| Technical Support | Troubleshooting and process optimization for clients | Improved manufacturing efficiency and customer loyalty |

| Co-creation & Collaboration | Developing specialized solutions with major customers | Market relevance and tailored product offerings |

| Feedback Integration | Gathering client input for product and service refinement | Agility in responding to market demands and continuous improvement |

Channels

Borouge's direct sales and marketing force is crucial for cultivating relationships with major industrial clients, ensuring dedicated account management worldwide. This direct engagement facilitates precise communication, effective negotiation, and customized service delivery, especially for clients with substantial volume requirements or strategic importance.

In 2024, Borouge continued to leverage this direct approach to secure significant contracts, with their sales teams actively managing relationships that contribute to a substantial portion of their revenue from key accounts. This strategy allows for a deeper understanding of customer needs, enabling the development of bespoke solutions and fostering long-term partnerships in competitive markets.

Borouge's extensive network of international sales and marketing offices, with a significant footprint in Asia Pacific, the Middle East, and Africa, is crucial for its global reach. These strategically located offices enable direct engagement with customers, fostering strong relationships and providing localized support.

In 2024, Borouge continued to leverage these offices to gather vital market intelligence, allowing for agile responses to regional demand shifts and competitive pressures. This presence is key to their strategy of achieving widespread market coverage.

Borouge leverages a robust network of distributors and agents to effectively reach a broader customer base, particularly smaller clients and niche regional markets. These intermediaries are crucial for managing complex logistics and delivering tailored, localized customer service, ensuring Borouge's products are accessible and supported across diverse geographies.

In 2024, Borouge continued to strengthen these partnerships, recognizing their vital role in market penetration. For instance, their presence in Southeast Asia relies heavily on these local agents who understand the specific regulatory landscapes and customer needs, facilitating smoother transactions and fostering stronger client relationships.

Digital Platforms and Online Presence

Borouge actively leverages digital platforms to enhance its market visibility and stakeholder engagement. Its corporate website and dedicated investor relations portal serve as crucial hubs for disseminating information, from product details to financial reports, ensuring accessibility for a global audience.

This robust online presence is key to facilitating inquiries and building trust. In 2024, Borouge continued to update its digital channels with the latest company news and sustainability initiatives, reflecting a commitment to transparency and proactive communication with investors and the wider public.

- Corporate Website: A central point for product information, company news, and corporate governance.

- Investor Relations Portal: Provides access to financial reports, presentations, and stock information.

- Digital Engagement: Facilitates communication and information dissemination to a global stakeholder base.

Industry Trade Shows and Exhibitions

Borouge leverages industry trade shows and exhibitions as a vital channel to directly engage with stakeholders. These events are instrumental in unveiling new polymer solutions and technological advancements, allowing for hands-on demonstrations and direct feedback from customers and partners. For instance, participation in events like the K Show, a leading plastics and rubber trade fair, provides a significant platform for Borouge to showcase its innovative product portfolio and sustainability initiatives to a global audience.

These exhibitions are critical for Borouge's lead generation efforts, facilitating direct interactions that can convert into tangible business opportunities. By exhibiting at key regional and international forums, the company strengthens its brand presence and builds relationships within the petrochemical sector. In 2024, Borouge continued its active participation in such events, aiming to expand its market reach and reinforce its position as an industry leader.

- Product Showcase: Demonstrating advanced polyolefin solutions for sectors like packaging, automotive, and infrastructure.

- Customer Engagement: Facilitating direct dialogue with existing and potential clients to understand evolving market needs.

- Brand Building: Enhancing visibility and reinforcing Borouge's commitment to innovation and sustainability in the global petrochemical landscape.

Borouge's channel strategy encompasses a multi-faceted approach, blending direct sales with indirect networks and digital engagement to serve a diverse global clientele. This ensures broad market penetration and tailored customer experiences.

In 2024, Borouge's direct sales teams were instrumental in securing major contracts, demonstrating the effectiveness of personalized account management for key industrial clients. The company's extensive network of international offices, particularly in Asia Pacific, the Middle East, and Africa, facilitated crucial market intelligence and agile responses to regional demand shifts.

Furthermore, Borouge actively utilized distributors and agents to reach smaller clients and niche markets, with a notable focus on strengthening partnerships in Southeast Asia in 2024 to navigate local regulatory landscapes. Digital platforms, including their corporate website and investor relations portal, were continuously updated in 2024 to enhance transparency and stakeholder communication.

Participation in industry trade shows remained a cornerstone of Borouge's engagement strategy in 2024, providing a vital platform for product showcases and direct customer feedback, thereby reinforcing their commitment to innovation and sustainability.

| Channel | Key Function | 2024 Focus/Activity |

|---|---|---|

| Direct Sales & Marketing | Relationship building with major clients, customized service | Securing significant contracts, deep customer needs analysis |

| International Offices | Global reach, localized support, market intelligence | Agile response to regional demand, strengthening market coverage |

| Distributors & Agents | Broader market access, niche markets, logistics management | Strengthening partnerships, market penetration in Southeast Asia |

| Digital Platforms | Information dissemination, stakeholder engagement, inquiries | Updating with news and sustainability initiatives, transparency |

| Trade Shows & Exhibitions | Product showcase, lead generation, direct feedback | Active participation, reinforcing brand presence and innovation |

Customer Segments

The infrastructure sector is a key customer for Borouge, encompassing entities focused on building and maintaining vital systems like water, gas, and power networks. These companies rely on Borouge's advanced polyolefin solutions for their durability and performance in demanding applications.

Borouge's materials are crucial for constructing reliable pipe systems for water and gas distribution, as well as for insulating power cables. In 2024, global infrastructure spending was projected to reach trillions, with a significant portion dedicated to upgrading and expanding essential services, highlighting the immense demand for high-quality materials.

Furthermore, the growing emphasis on renewable energy projects, such as solar and wind farms, presents another significant opportunity. Borouge's products, including specialized geotextiles, contribute to the longevity and efficiency of these sustainable infrastructure developments, aligning with global decarbonization efforts.

The energy sector is a key customer for Borouge, with demand driven by the global push for more efficient and sustainable power infrastructure. Companies involved in both traditional power transmission and the rapidly growing renewable energy market rely on Borouge's advanced polymer solutions.

Specifically, Borouge's materials are crucial for high-voltage direct current (HVDC) cables. These cables are essential for transmitting electricity over long distances with minimal energy loss, a critical factor in modernizing power grids and integrating remote renewable energy sources. For instance, Borouge's Borstar® technology enables the production of advanced insulation materials that can withstand the extreme conditions and high voltages required for these applications.

In 2023, global investment in renewable energy reached approximately $570 billion, highlighting the significant market expansion for components like HVDC cables. Borouge's ability to provide specialized, high-performance materials directly supports this growth, allowing energy providers to build more robust and environmentally friendly power networks.

The mobility and automotive sector represents a key customer segment for Borouge, encompassing major vehicle manufacturers and their extensive network of component suppliers. These companies rely on Borouge's advanced polyolefin solutions for a wide array of applications, from interior cabin elements and exterior body panels to critical under-the-hood components.

A significant driver for this segment is the ongoing push towards lightweighting vehicles to improve fuel efficiency and reduce emissions. Borouge's materials contribute to this goal by offering high performance in lighter-weight designs. For example, the automotive industry is increasingly specifying materials with recycled content, aligning with sustainability targets. By 2024, a notable percentage of new vehicle models are expected to incorporate such materials, reflecting a growing demand for circular economy solutions in automotive manufacturing.

Healthcare Sector

Borouge serves the healthcare sector by providing essential medical-grade polyolefins. These materials are crucial for manufacturing a variety of medical devices, ensuring patient safety and product integrity. The demand for high purity and adherence to strict regulatory standards, such as ISO 13485, is paramount for this segment.

The company's offerings are vital for pharmaceutical packaging, protecting sensitive medications and maintaining their efficacy throughout the supply chain. Borouge's commitment to quality control and material traceability supports the healthcare industry's rigorous requirements.

- Medical Devices: Borouge's polyolefins are used in everything from syringes and IV bags to surgical instruments and diagnostic equipment, where biocompatibility and sterilization resistance are key.

- Pharmaceutical Packaging: This includes blister packs, bottles, and flexible films designed to preserve drug stability and prevent contamination.

- Regulatory Compliance: Borouge ensures its materials meet global healthcare standards, a critical factor for manufacturers operating in this highly regulated market.

- Market Growth: The global medical plastics market, where Borouge operates, was valued at approximately $28.8 billion in 2023 and is projected to grow significantly in the coming years, driven by an aging population and advancements in medical technology.

Packaging Industry

Borouge serves a broad range of customers within the packaging industry. This includes manufacturers of both flexible and rigid packaging solutions designed for a variety of applications. These applications span across food packaging, consumer goods, and essential industrial products.

The company's advanced polyolefin solutions are specifically tailored to meet the evolving needs of these packaging producers. Key performance drivers for these customers include extending product shelf life, enhancing the recyclability of packaging materials, and contributing to the reduction of food waste across the supply chain.

- Key Customer Segments: Flexible packaging converters, rigid packaging manufacturers, food and beverage companies, consumer goods brands, industrial product suppliers.

- Value Proposition Focus: Enhanced shelf life for packaged goods, improved recyclability of packaging materials, contribution to food waste reduction initiatives.

- Market Trends Supported: Growing demand for sustainable packaging solutions, increasing consumer awareness of food waste, need for high-performance packaging materials.

- Borouge's Role: Providing innovative polyolefin grades that enable superior barrier properties, lightweighting, and recyclability, thereby supporting customer sustainability goals and product differentiation.

Borouge's customer base extends to the building and construction sector, where its polyolefin solutions are integral to a variety of applications. These include pipes for water and gas, insulation for wires and cables, and components for infrastructure projects.

The company's materials are vital for ensuring the longevity and reliability of essential infrastructure. In 2024, global construction output was projected to see continued growth, particularly in developing regions, underscoring the sustained demand for high-performance construction materials like those Borouge provides.

Borouge's advanced polymers contribute to the durability of water management systems, gas pipelines, and electrical insulation, meeting stringent performance requirements. The company's focus on innovation also supports the development of more sustainable building practices, aligning with industry trends towards eco-friendly construction.

Cost Structure

Borouge's financial health is heavily influenced by its raw material expenses, with ethane, sourced from ADNOC, being a primary cost driver. In 2024, the company continued to navigate the volatile global energy markets, where ethane prices are closely tied to crude oil and natural gas benchmarks.

These feedstock costs represent a substantial portion of Borouge's cost of goods sold. For instance, a significant shift in ethane pricing, whether upward or downward, directly translates to a proportional change in the company's production expenses and ultimately impacts its profitability margins for the year.

Manufacturing and production costs for Borouge encompass the significant expenses tied to running their advanced petrochemical facilities. These include substantial outlays for energy, essential for powering their complex processes, alongside wages for the skilled workforce directly involved in plant operations. For instance, in 2023, Borouge reported a revenue of $6.07 billion, with cost of sales, which includes these manufacturing expenses, amounting to $4.78 billion, highlighting the significant portion these costs represent.

Maintaining the integrity and efficiency of their machinery is also a critical component of these costs, involving regular upkeep and timely repairs to prevent disruptions. Furthermore, the depreciation of their extensive manufacturing facilities and equipment is factored in, reflecting the gradual wear and tear of these valuable assets over time. Borouge's commitment to operational efficiency and asset reliability is paramount in controlling these substantial manufacturing expenditures.

Borouge dedicates significant resources to Research and Development (R&D), recognizing it as a cornerstone for sustained innovation and market leadership. These expenses encompass the compensation for its team of highly skilled scientists and engineers, alongside substantial investments in state-of-the-art research facilities and cutting-edge equipment.

The company's R&D efforts are strategically focused on developing novel polymer solutions and advanced technologies that address evolving market needs and environmental considerations. This commitment to innovation is reflected in their consistent investment in R&D; for instance, in 2023, Borouge reported R&D expenses of approximately USD 106 million, underscoring its dedication to future growth and product differentiation.

Sales, General, and Administrative (SG&A) Expenses

Sales, General, and Administrative (SG&A) expenses for Borouge cover a range of operational costs beyond direct production. These include the salaries and benefits for non-production staff, marketing and sales efforts to reach customers, and the general overhead required to run the business. Borouge emphasizes a strong focus on cost discipline and operational efficiency within these SG&A categories.

In 2024, Borouge continued its commitment to optimizing these costs. The company's strategy involves streamlining administrative processes and investing in targeted sales and marketing initiatives that drive revenue growth efficiently. This approach aims to maintain a competitive cost structure while supporting Borouge's expansion and market presence.

- SG&A Focus: Costs include sales, marketing, administrative overhead, and non-production staff salaries.

- Cost Discipline: Borouge actively pursues efficiency and cost control in these areas.

- 2024 Initiatives: Continued efforts in 2024 to streamline operations and optimize spending.

- Strategic Importance: Efficient SG&A management supports overall profitability and competitive positioning.

Logistics and Distribution Costs

Borouge's extensive global presence necessitates substantial investment in logistics and distribution. These costs encompass the physical movement of polyolefin products from its manufacturing facilities, primarily in the UAE and Singapore, to customers worldwide. This includes freight charges via sea, air, and land, as well as the expenses related to maintaining strategically located warehouses to ensure timely delivery and inventory management.

The complexity of managing a worldwide supply chain means that operational efficiency in logistics is paramount to controlling these expenditures. Borouge likely incurs significant costs in managing its distribution network, which involves partnerships with third-party logistics providers and maintaining relationships with shipping companies. For example, in 2023, the company reported that its cost of sales, which includes logistics, was approximately USD 4.7 billion, reflecting the scale of these operations.

- Shipping Expenses: Costs associated with ocean freight, trucking, and intermodal transport to move goods across continents.

- Warehousing and Storage: Expenses for maintaining inventory in regional distribution centers to meet customer demand.

- Distribution Network Management: Costs related to managing relationships with logistics partners, customs clearance, and supply chain optimization.

- Inventory Carrying Costs: The financial impact of holding inventory, including insurance, security, and potential obsolescence.

Borouge's cost structure is dominated by feedstock, primarily ethane, which is directly linked to global energy prices. Manufacturing and production expenses are also significant, covering energy, labor, and facility maintenance. Research and Development investments, along with Sales, General, and Administrative (SG&A) costs, support innovation and market reach, while logistics and distribution are crucial for its global operations.

| Cost Category | Description | 2023 Data (USD Million) |

|---|---|---|

| Feedstock (Ethane) | Primary raw material cost, influenced by oil and gas prices. | Not explicitly broken out, but a major component of Cost of Sales. |

| Manufacturing & Production | Energy, labor, maintenance, depreciation of facilities. | Included in Cost of Sales ($4,780M). |

| Research & Development (R&D) | Innovation, new product development, skilled personnel. | 106 |

| Sales, General & Administrative (SG&A) | Marketing, sales, administrative overhead, non-production staff. | Not explicitly broken out, but a key operational expense. |

| Logistics & Distribution | Freight, warehousing, supply chain management. | Included in Cost of Sales ($4,780M). |

Revenue Streams

Borouge's primary revenue stream comes from selling a wide array of polyethylene (PE) products. These versatile materials are essential for numerous industries, including infrastructure, where they are used for durable pipes and cables, and packaging, for everything from flexible films to rigid containers. The agricultural sector also relies on PE for applications like irrigation and protective coverings.

The company's sales volumes are significantly boosted by robust demand within its key operating regions. For instance, in 2024, Borouge reported that its sales volumes for polyolefins, including PE, saw continued strength, driven by growth in sectors like infrastructure and packaging, particularly in the Middle East and Asia.

Sales of polypropylene (PP) products represent a significant revenue stream for Borouge. These materials are essential across various sectors, including the automotive industry for components, advanced packaging solutions, and the production of textiles.

Borouge's strategy often involves offering differentiated PP grades that command premium pricing. For instance, in 2023, the company reported strong performance in its PP segment, contributing substantially to its overall financial results.

Borouge's strategy centers on selling specialized polyolefin solutions that offer enhanced performance and unique benefits, allowing them to charge higher prices. These premium products are key drivers of the company's revenue and profitability.

In 2023, Borouge reported a revenue of $5.5 billion, with a significant portion attributed to its differentiated product portfolio, which includes solutions for advanced packaging, mobility, and energy sectors. This focus on value-added offerings underpins their competitive advantage.

Licensing of Technology and Know-how (Potential)

While Borouge's primary focus is on manufacturing and selling polyolefins, its advanced Borstar® technology presents a potential future revenue avenue through licensing. This proprietary process, which allows for enhanced polymer properties, could be licensed to other chemical companies, generating income from technology transfer agreements.

Such licensing could involve upfront fees, ongoing royalties based on production volume, or even profit-sharing arrangements in joint ventures. This strategy would leverage Borouge's innovation without requiring significant capital expenditure for new production facilities.

For instance, in 2024, the global market for chemical technology licensing saw significant activity, with companies actively seeking to monetize their intellectual property. While specific Borouge licensing deals are not publicly disclosed as a current revenue stream, the company’s investment in R&D, exceeding $100 million annually in recent years, underscores the value of its technological assets.

- Potential Licensing Revenue: Monetizing Borstar® technology could create a new, high-margin income stream.

- Strategic Partnerships: Licensing could foster collaborations and joint ventures, expanding market reach.

- Intellectual Property Value: Borouge's R&D investments, totaling over $100 million annually, highlight the significant value of its proprietary technologies.

- Future Growth Driver: Technology licensing represents a potential avenue for diversified and sustainable revenue growth.

Olefins Sales (Ethylene, Propylene) to Third Parties (Minor)

Borouge's strategy includes selling surplus olefins, such as ethylene and propylene, to external customers. This practice, though considered minor, can provide an additional revenue source. For instance, with the Borouge 4 expansion, there's potential to supply excess ethylene to other industrial entities, thereby strengthening local supply chains.

This approach not only generates revenue but also contributes to the broader industrial ecosystem. In 2024, the global olefins market experienced significant activity, with ethylene prices fluctuating based on feedstock costs and demand dynamics. Borouge's ability to leverage its production capacity for third-party sales demonstrates flexibility in its revenue generation model.

- Olefins Sales: Ethylene and propylene sold to external parties.

- Borouge 4 Expansion Impact: Potential for increased third-party sales of excess olefins.

- Market Context: Olefins are crucial building blocks for plastics and chemicals.

- Revenue Contribution: A minor but valuable stream supplementing core business.

Borouge's revenue is primarily generated from the sale of polyethylene (PE) and polypropylene (PP) products, catering to diverse sectors like infrastructure, packaging, automotive, and agriculture. The company's focus on differentiated and specialized polyolefin solutions, leveraging its proprietary Borstar® technology, allows for premium pricing and drives profitability.

In 2023, Borouge reported $5.5 billion in revenue, with a substantial portion stemming from its value-added product portfolio. The company also explores future revenue streams through potential licensing of its Borstar® technology, a move supported by its consistent annual R&D investments exceeding $100 million.

| Revenue Stream | Description | Key Drivers/Examples | 2023/2024 Context |

| Polyethylene (PE) Sales | Sale of various PE grades for applications in infrastructure, packaging, and agriculture. | High demand in Middle East and Asia, use in durable pipes, films, and agricultural coverings. | Continued strength in sales volumes reported for polyolefins in 2024. |

| Polypropylene (PP) Sales | Sale of PP products for automotive components, advanced packaging, and textiles. | Offering differentiated PP grades for premium pricing, strong performance in the PP segment. | PP segment contributed substantially to overall financial results in 2023. |

| Specialized Polyolefin Solutions | Selling high-performance, unique benefit polyolefins. | Premium pricing for advanced packaging, mobility, and energy sector solutions. | Key drivers of revenue and profitability, underpinning competitive advantage. |

| Potential Technology Licensing | Licensing of proprietary Borstar® technology to other chemical companies. | Monetizing intellectual property, potential for upfront fees and royalties. | R&D investments exceeding $100 million annually highlight asset value; global licensing market active in 2024. |

| Surplus Olefins Sales | Selling excess ethylene and propylene to external customers. | Leveraging production capacity for third-party sales, supporting local supply chains. | Potential for increased sales with Borouge 4 expansion; ethylene prices fluctuated in 2024 market. |

Business Model Canvas Data Sources

The Borouge Business Model Canvas is built using extensive market research, financial disclosures, and internal operational data. These sources ensure each canvas block is filled with accurate, up-to-date information reflecting Borouge's strategic direction and market positioning.