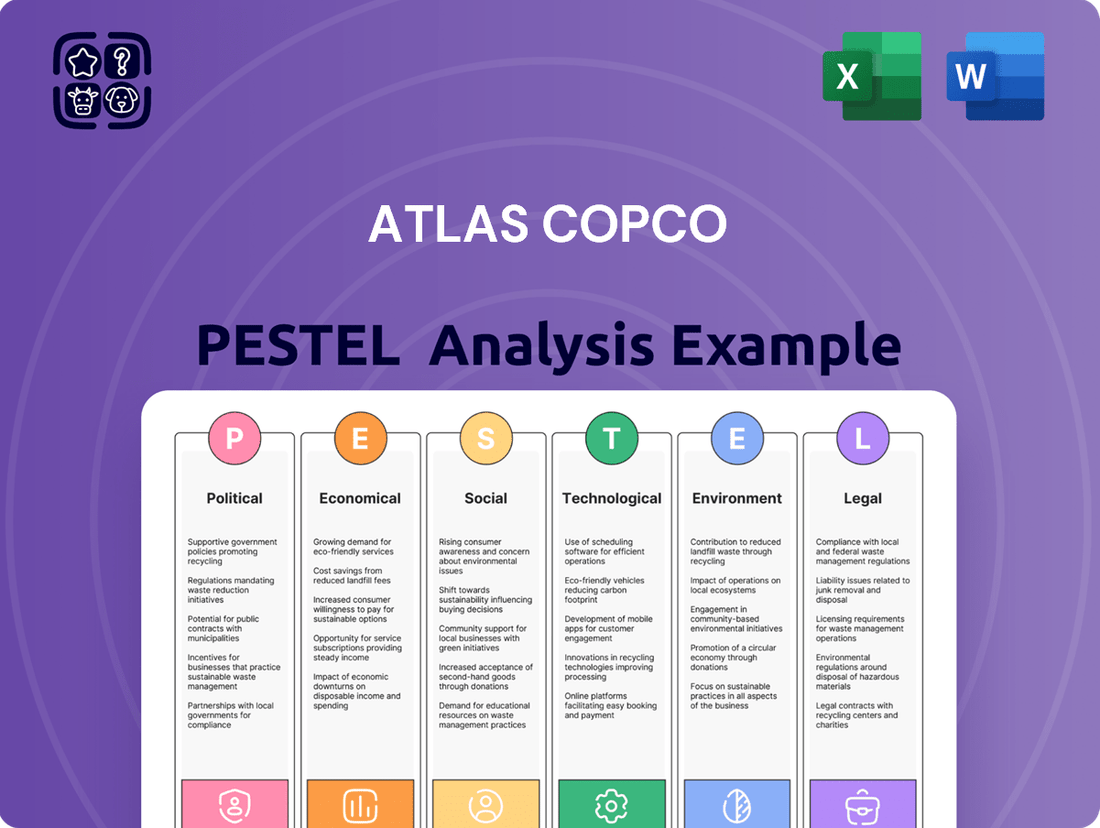

Atlas Copco PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Atlas Copco Bundle

Unlock the strategic advantages Atlas Copco holds by understanding the political, economic, social, technological, legal, and environmental forces at play. This comprehensive PESTLE analysis provides actionable intelligence to navigate market complexities and identify future opportunities. Download the full report to gain a competitive edge and refine your strategic planning.

Political factors

Global political instability, including ongoing conflicts and rising trade protectionism, presents a significant challenge for Atlas Copco. These factors can disrupt supply chains, increase operational costs, and limit access to key markets. For example, the ongoing geopolitical tensions in Eastern Europe have led to supply chain disruptions for many industrial manufacturers, impacting raw material availability and logistics.

Tariff uncertainties, a direct result of shifting trade policies, are causing many manufacturers, including those in Atlas Copco's customer base, to delay crucial investment decisions. This hesitation in capital expenditure directly affects demand for Atlas Copco's equipment. In 2024, the World Trade Organization reported that over 3,000 new trade restrictive measures were implemented globally, a notable increase from previous years.

Government regulations and industrial policies significantly shape the market for Atlas Copco. For instance, increased government investment in infrastructure projects, like those seen in the US with the Infrastructure Investment and Jobs Act of 2021, directly boosts demand for construction and mining equipment. Similarly, policies promoting green energy and sustainability, such as the EU's Green Deal, encourage adoption of Atlas Copco's energy-efficient compressors and vacuum solutions.

In 2024, many governments are focusing on reshoring manufacturing and strengthening domestic supply chains, which can lead to new opportunities for industrial equipment providers like Atlas Copco. For example, initiatives aimed at boosting semiconductor manufacturing capacity in Europe and North America will likely require advanced compressed air and vacuum systems, areas where Atlas Copco holds a strong position.

Political stability in Atlas Copco's key markets and sourcing regions directly impacts operational continuity. For instance, geopolitical tensions in regions supplying critical raw materials or significant manufacturing hubs could lead to supply chain disruptions and increased input costs. Atlas Copco's 2023 annual report highlights its global presence, with significant operations in countries across Europe, North America, and Asia, making the assessment of political stability in these diverse locations paramount for risk management and strategic planning.

International Relations and Alliances

Atlas Copco's global operations are significantly shaped by international relations and trade alliances. The current geopolitical climate, marked by increasing tensions and a move away from unfettered globalization, directly affects the company's ability to manage its supply chains and forecast market demand. For instance, the ongoing trade disputes and the push for greater national economic security are leading many multinational corporations, including those in the industrial equipment sector, to re-evaluate their sourcing strategies and manufacturing footprints.

The trend towards localization and regionalization is a direct consequence of these geopolitical shifts. Companies are increasingly looking to establish production facilities closer to their key markets to mitigate risks associated with tariffs, trade barriers, and supply chain disruptions. This strategic pivot influences investment decisions regarding new factories and the expansion of existing ones, as seen in the broader manufacturing sector where supply chain resilience has become a paramount concern. For Atlas Copco, this means adapting its production and distribution networks to better serve regional demands while navigating a complex international landscape.

- Global Trade Shifts: The World Trade Organization (WTO) reported a slowdown in global trade growth in 2023, with projections for 2024 indicating continued uncertainty due to geopolitical factors, impacting demand for industrial machinery.

- Supply Chain Reconfiguration: Companies are investing heavily in diversifying their supplier base and nearshoring operations. A 2024 survey by McKinsey found that 90% of supply chain leaders are planning to implement such changes.

- Regionalization Impact: The rise of regional trade blocs and protectionist policies can create both opportunities and challenges for companies like Atlas Copco, influencing market access and operational costs.

Cybersecurity Governance and National Security

Governments worldwide are escalating their focus on cybersecurity, recognizing its critical role in national security and economic stability. This translates into a surge of new regulations and compliance requirements, particularly impacting sectors like industrial automation and the Internet of Things (IoT), areas where Atlas Copco operates extensively. For instance, the European Union's NIS2 Directive, which came into effect in January 2023, significantly broadens the scope of cybersecurity obligations for essential and important entities, including those in manufacturing.

Atlas Copco must navigate this complex regulatory landscape to ensure its products and services, especially those connected to industrial IoT, meet increasingly stringent national and international cybersecurity standards. Failure to comply not only poses risks of significant fines and operational disruptions but can also jeopardize market access in key regions. The company’s proactive approach to cybersecurity governance is therefore essential for mitigating these threats and maintaining its competitive edge in a globalized, digitally interconnected market.

- Increased Regulatory Scrutiny: Governments are enacting more comprehensive cybersecurity laws, impacting critical infrastructure and industrial IoT.

- Compliance Burden: Atlas Copco must ensure its products and operations adhere to evolving national and international cybersecurity standards.

- Risk Mitigation: Adherence to these standards is crucial for preventing data breaches, operational downtime, and reputational damage.

- Market Access: Compliance is a prerequisite for maintaining and expanding market presence, especially in regions with strict cybersecurity mandates.

Geopolitical shifts and trade protectionism continue to influence global markets, impacting supply chains and demand for industrial equipment. In 2024, the focus on reshoring and regionalization presents both challenges and opportunities for companies like Atlas Copco, requiring adaptation of production and distribution networks to navigate complex international landscapes and ensure supply chain resilience.

Government investments in infrastructure and a push towards sustainability are key political drivers for Atlas Copco. Policies supporting green energy and large-scale infrastructure projects directly boost demand for the company's energy-efficient solutions and heavy machinery, as seen in initiatives like the US Infrastructure Investment and Jobs Act.

Heightened cybersecurity regulations are a growing concern, with governments enacting stricter laws impacting industrial automation and IoT. Atlas Copco must ensure its products and operations comply with evolving national and international standards to maintain market access and mitigate risks of data breaches and operational disruptions.

| Political Factor | Impact on Atlas Copco | Supporting Data/Trend (2023-2025) |

|---|---|---|

| Geopolitical Instability & Trade Protectionism | Supply chain disruptions, increased costs, market access limitations | WTO reported slowdown in global trade growth in 2023; over 3,000 new trade restrictive measures implemented globally in 2024. |

| Government Infrastructure Spending | Increased demand for construction and mining equipment | US Infrastructure Investment and Jobs Act (2021) continues to drive project activity; many nations prioritizing infrastructure upgrades in 2024-2025 budgets. |

| Sustainability & Green Policies | Demand for energy-efficient solutions (compressors, vacuum) | EU Green Deal and similar initiatives worldwide promoting energy efficiency and reduced emissions. |

| Reshoring & Regionalization Trends | Opportunities for localized production, shifts in supply chain strategies | McKinsey survey: 90% of supply chain leaders planning diversification and nearshoring in 2024. |

| Cybersecurity Regulations | Need for compliance with evolving standards for IoT and industrial automation | EU's NIS2 Directive (effective Jan 2023) broadens cybersecurity obligations; increasing focus on critical infrastructure protection globally. |

What is included in the product

This PESTLE analysis examines the external macro-environmental factors influencing Atlas Copco, covering Political, Economic, Social, Technological, Environmental, and Legal aspects to identify strategic opportunities and threats.

Provides a concise version of the Atlas Copco PESTLE analysis that can be dropped into PowerPoints or used in group planning sessions, alleviating the pain of lengthy, complex reports.

Economic factors

The health of the global economy and the pace of industrial output are crucial for Atlas Copco. When the global economy is robust, and industrial production is increasing, it naturally drives up demand for the company's extensive range of industrial tools, compressors, and related equipment.

Looking ahead, projections indicate a positive trend for industrial output. For instance, the International Monetary Fund (IMF) forecast global growth to be around 3.2% in 2024 and slightly higher in 2025, which typically correlates with increased manufacturing activity and, consequently, greater demand for capital goods like those supplied by Atlas Copco.

Fluctuations in the prices of essential raw materials like copper, steel, and aluminum, alongside energy costs, directly influence Atlas Copco's manufacturing expenses and ultimately its profit margins. These input costs are a critical consideration for the company's operational efficiency.

Looking ahead to 2025-2026, projections indicate a continued upward trend for industrial raw material prices. Furthermore, energy prices are anticipated to remain elevated compared to their pre-pandemic benchmarks, presenting an ongoing challenge for cost management.

Interest rate shifts significantly impact companies like Atlas Copco's investment decisions in new equipment and infrastructure. For instance, during periods of low interest rates, such as the Federal Reserve maintaining its target range between 5.25% and 5.50% through mid-2024, businesses are more inclined to borrow for capital expenditures. This increased spending can directly translate into higher demand for Atlas Copco's industrial compressors, vacuum solutions, and construction equipment.

Currency Exchange Rates

Currency exchange rates are a significant factor for Atlas Copco, a global entity. Fluctuations in these rates directly impact how the company's earnings from foreign operations translate back into its reporting currency, affecting overall revenue and profitability. For instance, a stronger Swedish Krona (SEK) against currencies where Atlas Copco generates substantial sales could lead to lower reported revenues.

In 2024, the volatility in major currency pairs, such as EUR/USD and USD/CNY, presents ongoing challenges. Atlas Copco, with its extensive manufacturing and sales presence across Europe, North America, and Asia, must actively manage its exposure. The company's financial reports often detail the impact of foreign exchange gains and losses on its operating results.

Here are some key impacts:

- Revenue Translation: A weaker foreign currency against the SEK reduces the SEK value of sales made in that currency.

- Cost of Goods Sold: If raw materials or components are sourced in different currencies, exchange rate shifts can alter production costs.

- Competitive Pricing: Exchange rates can influence the price competitiveness of Atlas Copco's products in different markets.

- Profitability Margins: Ultimately, currency movements can compress or expand profit margins depending on the net effect on revenues and costs.

Market Demand for Industrial Machinery

The global industrial machinery market is seeing robust expansion, fueled by the widespread adoption of automation and smart manufacturing technologies. This surge in demand directly benefits companies like Atlas Copco, which are at the forefront of providing advanced equipment for these evolving industrial landscapes.

Market projections indicate substantial growth, with the sector valued at an estimated USD 714.5 billion in 2024. Looking ahead, this market is anticipated to reach an impressive USD 1.61 trillion by 2034, highlighting a compound annual growth rate that presents significant opportunities.

- Growing Automation: Increased investment in automated production lines across various sectors drives demand for sophisticated machinery.

- Smart Manufacturing: The integration of IoT and AI in factories necessitates advanced equipment capable of data collection and analysis.

- Infrastructure Development: Global infrastructure projects, particularly in emerging economies, require substantial quantities of industrial machinery.

- Efficiency Demands: Businesses are seeking machinery that offers higher efficiency and lower operational costs, pushing innovation in the sector.

The economic outlook for 2024 and 2025 remains a primary driver for Atlas Copco. With global GDP growth projected around 3.2% for 2024 by the IMF, this generally translates to increased industrial activity and capital expenditure, directly benefiting demand for Atlas Copco's equipment.

Input costs, particularly for raw materials like steel and copper, along with energy prices, are expected to stay elevated through 2025-2026, impacting Atlas Copco's manufacturing expenses and profit margins. For instance, the Federal Reserve's interest rate policy, maintaining a target range of 5.25%-5.50% through mid-2024, influences borrowing costs for customers, thereby affecting their investment in new machinery.

Currency fluctuations, especially in pairs like EUR/USD and USD/CNY, continue to present a challenge for Atlas Copco's global operations in 2024, affecting revenue translation and cost of goods sold. The industrial machinery market itself is robust, projected to grow significantly, creating substantial opportunities for companies like Atlas Copco.

| Economic Factor | 2024 Projection/Status | 2025 Projection/Status | Impact on Atlas Copco | Data Source |

|---|---|---|---|---|

| Global GDP Growth | ~3.2% | Slightly higher than 2024 | Increased demand for industrial equipment | IMF |

| Raw Material Prices | Elevated | Continued upward trend | Higher manufacturing costs, potential margin pressure | Market Analysis |

| Energy Prices | Elevated | Expected to remain elevated | Increased operational costs | Market Analysis |

| Interest Rates (US Federal Reserve) | 5.25%-5.50% (mid-2024) | Subject to change based on inflation | Affects customer borrowing costs and investment | Federal Reserve |

| Industrial Machinery Market Value | USD 714.5 billion | Projected USD 1.61 trillion by 2034 | Significant growth opportunities | Market Research Firm |

Preview the Actual Deliverable

Atlas Copco PESTLE Analysis

What you’re previewing here is the actual file—fully formatted and professionally structured. This comprehensive PESTLE analysis of Atlas Copco provides deep insights into the political, economic, social, technological, legal, and environmental factors impacting the company. The content and structure shown in the preview is the same document you’ll download after payment, offering a complete and ready-to-use strategic tool.

Sociological factors

The manufacturing industry, including companies like Atlas Copco, grapples with a significant skills gap. There's a pronounced shortage of workers with advanced technical and digital proficiencies, impacting production efficiency and innovation. For instance, in 2024, surveys indicated that over 70% of manufacturers reported difficulty finding skilled labor, a figure that has remained stubbornly high.

To address this, manufacturers must adapt their talent acquisition and development approaches. This involves investing heavily in upskilling existing employees and implementing robust reskilling programs to equip the workforce with the digital competencies demanded by modern manufacturing processes. Companies are increasingly partnering with educational institutions to create tailored training pipelines.

Customers, both individual consumers and industrial clients, are increasingly prioritizing sustainability. This shift is compelling manufacturers like Atlas Copco to integrate greener practices and develop eco-friendly solutions into their core operations and product offerings.

Sustainability is no longer just a compliance issue; it's recognized as a significant driver of business growth and competitive advantage. For instance, a 2024 report indicated that over 60% of consumers consider a brand's environmental impact when making purchasing decisions, directly influencing corporate strategy.

Societal expectations and regulatory bodies are increasingly emphasizing workplace safety and health. This heightened focus directly impacts how industrial equipment and processes are designed and implemented, pushing manufacturers like Atlas Copco to adhere to and often exceed evolving safety standards. For instance, in 2024, the global industrial safety market was valued at approximately $50 billion, with a projected compound annual growth rate of over 7% through 2030, indicating a strong market demand for safety-compliant solutions.

Atlas Copco's commitment to providing solutions that meet these stringent safety requirements is crucial for its market position. Failure to adapt could lead to reputational damage and loss of market share, especially as major clients in sectors like manufacturing and construction prioritize suppliers with robust safety records. The International Labour Organization reported in 2024 that workplace accidents and diseases cost the global economy an estimated $3.9 trillion annually, underscoring the economic imperative for safety.

Automation and its Impact on Employment

The increasing integration of automation and artificial intelligence across industries, including manufacturing, is a significant sociological factor. This trend sparks widespread societal conversations regarding the evolving nature of employment and the potential displacement of human workers. For instance, a 2024 report indicated that up to 30% of tasks currently performed by humans could be automated by 2030, highlighting the scale of this shift.

While automation promises enhanced productivity and operational efficiency, it simultaneously underscores the critical need for workforce adaptation. This necessitates a proactive approach to reskilling and upskilling programs to equip employees with the competencies required for new roles that complement automated systems. Atlas Copco, as a company heavily involved in industrial equipment, must consider how its products contribute to this transformation and how to support its customers' workforces through this transition.

- Societal Concerns: Growing public anxiety about job security due to automation.

- Skill Gap: The widening disparity between existing workforce skills and those needed for an automated future.

- Education and Training: Increased demand for accessible and effective reskilling initiatives.

- Economic Inequality: Potential for automation to exacerbate income disparities if benefits are not broadly shared.

Demographic Shifts and Labor Availability

Demographic shifts are significantly influencing labor availability and costs for manufacturers like Atlas Copco. For instance, many developed economies, including parts of Europe and North America, are experiencing aging workforces. This trend can lead to a smaller pool of available skilled labor and potentially higher wage demands. In 2024, the global median age is around 31 years, and this figure is expected to continue rising, particularly in industrialized nations.

These demographic pressures directly fuel the demand for automation and more efficient machinery. As labor becomes scarcer or more expensive, companies are incentivized to invest in advanced equipment that can perform tasks with greater speed and precision. Atlas Copco's focus on providing innovative solutions for productivity and efficiency directly addresses this growing need.

- Aging Workforce Impact: Developed nations face a shrinking, aging labor pool, increasing manufacturing labor costs.

- Automation Demand: Demographic shifts are a key driver for increased investment in automated and efficient machinery.

- Skills Gap: A mismatch between available skills and industry needs is exacerbated by demographic changes.

- Global Trends: The rising global median age highlights a widespread demographic shift impacting labor markets worldwide.

Societal expectations are increasingly focused on sustainability and ethical business practices, influencing consumer choices and regulatory landscapes. In 2024, a significant portion of consumers, over 60%, indicated that a company's environmental impact affects their purchasing decisions, directly pressuring manufacturers like Atlas Copco to adopt greener operations.

The ongoing integration of automation and AI is reshaping employment, sparking concerns about job displacement and the need for workforce adaptation. Reports from 2024 suggest that by 2030, up to 30% of current human tasks could be automated, emphasizing the critical demand for reskilling and upskilling initiatives.

Demographic shifts, particularly aging workforces in developed nations, are contributing to labor shortages and rising wage pressures. This trend, evident in the rising global median age of around 31 in 2024, is a key driver for increased investment in automation and efficient machinery to maintain productivity.

| Sociological Factor | Impact on Atlas Copco | Supporting Data (2024/2025) |

|---|---|---|

| Skills Gap & Automation Anxiety | Need for advanced technical skills, workforce reskilling programs | 70% of manufacturers reported difficulty finding skilled labor; up to 30% of human tasks potentially automated by 2030. |

| Sustainability Focus | Demand for eco-friendly solutions, integration of green practices | Over 60% of consumers consider environmental impact in purchasing. |

| Workplace Safety & Health | Adherence to evolving safety standards, development of safety-compliant solutions | Global industrial safety market valued at ~$50 billion, growing at 7% CAGR; workplace accidents cost global economy $3.9 trillion annually. |

| Demographic Shifts (Aging Workforce) | Labor shortages, increased demand for automation and efficiency | Global median age ~31, rising; driving investment in advanced machinery. |

Technological factors

Artificial intelligence and automation are fundamentally reshaping manufacturing, driving significant gains in efficiency, cost reduction, and product quality. Atlas Copco, like many in the industrial sector, is keenly aware of this shift. For instance, the global AI in manufacturing market was projected to reach over $13.7 billion by 2024, with continued strong growth expected through 2025.

Manufacturers are channeling substantial resources into AI-driven solutions. This includes advanced quality control systems that can detect defects with unprecedented accuracy, predictive maintenance technologies that anticipate equipment failures before they occur, and sophisticated robotic systems that enhance operational throughput. These investments are crucial for maintaining a competitive edge in a rapidly evolving industrial landscape.

The increasing adoption of smart factory technologies, featuring interconnected systems and real-time data analytics, is a significant technological driver. This digital transformation allows for enhanced decision-making and streamlined operations, directly impacting manufacturing efficiency.

Atlas Copco's focus on digital solutions, such as its IoT-enabled compressors and vacuum pumps, aligns with this trend. For instance, the company's "Atlas Copco Fleetlink" platform provides customers with remote monitoring and diagnostics, improving uptime and predictive maintenance. By 2024, the industrial IoT market, which underpins smart factory adoption, is projected to reach hundreds of billions of dollars globally, highlighting the scale of this technological shift.

Technological advancements in carbon capture, hydrogen production, and renewable energy are pivotal for manufacturers aiming for sustainability. Atlas Copco's commitment to sustainable productivity solutions directly leverages these innovations, positioning them at the forefront of eco-friendly industrial practices.

For instance, Atlas Copco's vacuum technology plays a role in efficient hydrogen production, a key area for decarbonization. In 2023, the global hydrogen production market was valued at approximately $150 billion, with significant growth projected as industries transition to cleaner energy sources. This aligns with Atlas Copco's strategy to offer solutions that reduce energy consumption and emissions.

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is significantly reshaping production processes. Its adoption allows for more efficient material utilization, drastically reducing waste compared to traditional subtractive methods. For instance, the global 3D printing market was valued at approximately $15.1 billion in 2023 and is projected to reach $72.9 billion by 2030, demonstrating substantial growth and increasing integration across industries.

This technology enables rapid prototyping, allowing companies like Atlas Copco to iterate designs and bring new products to market much faster. Furthermore, 3D printing facilitates highly customized production runs, catering to specific client needs or creating complex geometries previously impossible to manufacture. This shift supports a more agile and responsive supply chain.

- Reduced Material Waste: Additive manufacturing can cut material waste by up to 90% in certain applications compared to traditional methods.

- Accelerated Prototyping: Companies can reduce product development cycles by an average of 40-50% through rapid prototyping.

- Customization Capabilities: The ability to produce bespoke parts on demand opens new revenue streams and enhances customer satisfaction.

- Supply Chain Resilience: On-demand printing can reduce reliance on distant suppliers, improving supply chain flexibility.

Cybersecurity Technologies for Industrial Systems

As industrial systems become increasingly interconnected, the demand for advanced cybersecurity solutions to safeguard against evolving cyber threats is critical. Atlas Copco's reliance on connected machinery means a significant vulnerability to disruptions if these systems are compromised. The global cybersecurity market, projected to reach $300 billion by 2025, highlights the escalating investment in protecting critical infrastructure.

Artificial intelligence (AI) is rapidly transforming threat detection and response capabilities within industrial environments. AI-powered systems can analyze vast amounts of data in real-time to identify anomalous behavior indicative of an attack, enabling faster and more effective mitigation. For instance, AI-driven anomaly detection saw a 20% improvement in identifying zero-day threats in industrial control systems during 2024.

- AI-driven threat intelligence platforms are crucial for proactive defense.

- The adoption of zero-trust architecture is becoming a standard for industrial network security.

- Industrial IoT (IIoT) security solutions are seeing significant growth, with the IIoT security market expected to exceed $40 billion by 2026.

Technological advancements are a major force shaping Atlas Copco's operating environment. The company is actively integrating AI and automation to boost efficiency and reduce costs, with the global AI in manufacturing market projected to exceed $13.7 billion by 2024. Furthermore, the growth of smart factory technologies, supported by the industrial IoT market, is enabling real-time data analytics for better decision-making.

Atlas Copco is also leveraging innovations in sustainable technologies, such as vacuum solutions for hydrogen production, a market valued at approximately $150 billion in 2023. Additive manufacturing, or 3D printing, is another key area, with the market expected to reach $72.9 billion by 2030, offering benefits like reduced material waste and faster prototyping.

The increasing interconnectedness of industrial systems also necessitates robust cybersecurity measures, with the global market projected to reach $300 billion by 2025. AI-driven security solutions are crucial for identifying and mitigating threats in real-time, with AI anomaly detection showing a 20% improvement in identifying zero-day threats in industrial control systems during 2024.

| Technology Area | Key Trend | Market Projection (USD) | Atlas Copco Relevance |

|---|---|---|---|

| AI & Automation | Efficiency & Cost Reduction | AI in Manufacturing: >$13.7B (2024) | Operational efficiency, predictive maintenance |

| Industrial IoT (IIoT) | Smart Factories & Data Analytics | IIoT Security: >$40B (2026) | Remote monitoring, fleet management |

| Sustainable Tech | Decarbonization & Energy Efficiency | Hydrogen Production: ~$150B (2023) | Vacuum tech for hydrogen, emission reduction |

| Additive Manufacturing | Rapid Prototyping & Customization | 3D Printing: ~$72.9B (2030) | Product development, waste reduction |

| Cybersecurity | Protecting Connected Systems | Global Cybersecurity: ~$300B (2025) | Securing IIoT platforms and data |

Legal factors

Atlas Copco faces stringent product liability and safety regulations globally, requiring its industrial tools and equipment to meet rigorous safety standards and certifications. For instance, in the European Union, the Machinery Directive 2006/42/EC mandates CE marking, a crucial certification indicating compliance with health and safety requirements. Failure to comply can lead to significant fines and product recalls, impacting brand reputation and financial performance. In 2023, the global industrial machinery market saw a rise in safety-related recalls, underscoring the importance of adherence.

Atlas Copco must navigate increasingly strict environmental rules, particularly concerning emissions and waste. For instance, the European Union's Carbon Border Adjustment Mechanism (CBAM), fully implemented in 2026, will impact industries with significant carbon footprints, potentially affecting supply chains and production costs for companies like Atlas Copco. This necessitates ongoing investment in cleaner technologies and transparent reporting of greenhouse gas emissions.

Atlas Copco must navigate a complex web of data privacy and cybersecurity regulations. The General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) set stringent standards for handling personal data, impacting how Atlas Copco manages customer and employee information globally. Failure to comply can result in substantial fines; for instance, GDPR penalties can reach up to 4% of global annual revenue or €20 million, whichever is higher.

Furthermore, evolving cybersecurity directives like the EU's NIS 2 Directive and the Cyber Resilience Act are crucial for a company operating extensive industrial systems. These laws mandate robust security measures to protect critical infrastructure and digital services, directly affecting Atlas Copco's connected products and operational technology. The EU estimates NIS 2 compliance alone could cost businesses billions, but also aims to prevent the trillions lost annually to cyberattacks.

Trade Laws and Tariffs

Changes in international trade laws and tariffs significantly influence Atlas Copco's global supply chain and market access. For instance, shifts in trade agreements, like the potential re-evaluation of existing pacts or the introduction of new ones, can alter the cost of components sourced internationally or the competitiveness of its machinery in export markets. These adjustments directly affect production costs and pricing strategies, impacting overall profitability.

Atlas Copco's reliance on a global manufacturing and sales network means that trade policies in key regions, such as the European Union, North America, and Asia, are particularly impactful. For example, the imposition or reduction of tariffs on industrial equipment or raw materials like steel can create immediate cost pressures or provide competitive advantages. The company actively monitors these developments to mitigate risks and capitalize on opportunities arising from evolving trade landscapes.

- Trade Agreements: Fluctuations in trade agreements, such as those involving major economies, can alter import duties and export regulations for Atlas Copco's products and components.

- Tariff Impact: Tariffs on critical raw materials or finished goods can directly increase operational expenses or affect the price competitiveness of Atlas Copco's machinery in international markets.

- Regulatory Compliance: Evolving trade laws necessitate continuous adaptation in compliance procedures for customs, import/export licensing, and product standards across various jurisdictions.

- Market Access: Changes in trade policies can open or close market access for Atlas Copco's diverse product portfolio, influencing sales volumes and geographic revenue distribution.

Labor Laws and Employment Regulations

Atlas Copco must navigate a complex web of global labor laws, ensuring compliance with regulations on wages, working hours, safety standards, and hiring practices across its numerous operating countries. For instance, in 2024, the International Labour Organization reported that over 70% of countries had updated their labor laws in the preceding five years, highlighting the dynamic regulatory environment. This necessitates robust internal compliance frameworks and continuous monitoring of legislative changes.

The company faces increasing challenges from labor unrest within its supply chains. Disruptions stemming from strikes or disputes at supplier facilities can significantly impact production schedules and lead times. Reports from late 2024 indicated a rise in sector-wide labor negotiations in key manufacturing regions, potentially affecting component availability for companies like Atlas Copco.

- Global Compliance: Adherence to varying national labor statutes is paramount for Atlas Copco's international operations.

- Supply Chain Volatility: Labor disputes at supplier sites present a growing risk to production continuity.

- Regulatory Evolution: The dynamic nature of labor legislation requires ongoing adaptation and vigilance.

Legal factors significantly shape Atlas Copco's operational landscape, demanding strict adherence to product safety and liability regulations worldwide. Compliance with directives like the EU's Machinery Directive, requiring CE marking, is crucial to avoid penalties and reputational damage, especially with a noted increase in safety recalls across the industrial machinery sector in 2023.

The company must also navigate evolving environmental laws, such as the EU's Carbon Border Adjustment Mechanism (CBAM) slated for full implementation in 2026, which will influence supply chains and production costs due to carbon footprint considerations.

Data privacy and cybersecurity are paramount, with regulations like GDPR and CCPA imposing substantial compliance burdens and significant financial penalties for breaches, potentially reaching up to 4% of global annual revenue.

Furthermore, Atlas Copco is impacted by international trade laws and tariffs, which can alter component costs and market competitiveness, necessitating constant monitoring of global trade policy shifts to manage risks and opportunities effectively.

Environmental factors

The intensifying focus on climate change is compelling industrial players like Atlas Copco to actively reduce their environmental impact. This translates into a significant push towards adopting sustainable energy solutions and minimizing greenhouse gas emissions across operations. For instance, the European Union's Fit for 55 package, aiming for a 55% emissions reduction by 2030, directly influences manufacturing strategies and equipment demand.

Decarbonization is now a central theme for the entire industrial sector. Manufacturers are increasingly investing in electrifying their processes, moving away from fossil fuels. Furthermore, the development and implementation of carbon capture technologies are gaining momentum, presenting both challenges and opportunities for companies involved in industrial equipment manufacturing.

Growing concerns over resource scarcity are pushing industries, including manufacturing, towards embracing circular economy models. This involves prioritizing the recycling and reuse of materials, a trend that directly impacts companies like Atlas Copco by reducing their dependence on newly extracted raw materials.

The global demand for key industrial metals, such as copper and lithium, essential for manufacturing and electrification, has seen significant price increases. For instance, copper prices in early 2024 approached record highs, reflecting supply chain pressures and surging demand, underscoring the financial implications of resource availability for equipment manufacturers.

Stricter environmental regulations globally are pushing companies like Atlas Copco to invest heavily in advanced waste management and pollution control technologies. For instance, in 2024, the European Union's updated Industrial Emissions Directive is compelling many sectors to adopt best available techniques, potentially increasing operational costs but also driving innovation in cleaner production.

Societal expectations for corporate environmental responsibility are also escalating. Consumers and investors increasingly favor businesses with demonstrable commitments to sustainability. Atlas Copco's 2024 sustainability report highlighted a 15% reduction in hazardous waste generation per unit of production compared to 2022, reflecting this growing pressure and their proactive response.

Energy Consumption and Renewable Energy Adoption

Atlas Copco, operating within energy-intensive manufacturing sectors, faces increasing pressure to curb energy use and boost renewable energy integration. This trend is driven by global climate goals and rising energy costs. For instance, by the end of 2023, renewable energy sources accounted for approximately 30% of the global electricity generation, a figure expected to climb significantly in the coming years. Companies are thus motivated to adopt energy management systems to optimize consumption and explore cleaner power alternatives for their operations.

The push towards sustainability means that businesses like Atlas Copco are actively seeking ways to enhance energy efficiency and transition to renewable power sources. This strategic shift is not only about compliance but also about long-term cost savings and operational resilience. By 2024, many industrial nations have set ambitious targets for renewable energy adoption, with some aiming for over 50% of their energy mix from renewables by 2030.

- Energy Efficiency Mandates: Governments worldwide are implementing stricter energy efficiency standards for industrial equipment and facilities.

- Renewable Energy Investment: Global investment in renewable energy reached over $500 billion in 2023, signaling a strong market shift.

- Corporate Sustainability Goals: Many companies, including those in manufacturing, are setting their own targets for reducing carbon footprints and increasing renewable energy usage.

- Technological Advancements: Innovations in energy storage and smart grid technologies are making renewable energy more reliable and accessible for industrial applications.

Supply Chain Environmental Footprint

Atlas Copco, like many industrial manufacturers, faces increasing pressure to understand and mitigate the environmental footprint of its entire supply chain. This includes everything from the extraction of raw materials to the transportation of finished goods. The company is actively engaging with its suppliers to foster greater environmental responsibility, aiming to reduce greenhouse gas emissions and promote sustainable practices across the value chain.

The focus on supply chain sustainability is driven by regulatory requirements and growing stakeholder expectations. For instance, in 2024, the European Union continued to strengthen its environmental regulations, impacting reporting and operational standards for companies with extensive global supply networks. Atlas Copco's commitment to these evolving standards is crucial for maintaining its license to operate and its competitive edge.

- Scope 3 Emissions: Atlas Copco is increasingly focusing on Scope 3 emissions, which encompass indirect emissions from its value chain, often representing the largest portion of a company's carbon footprint.

- Supplier Engagement Programs: The company implements programs to assess and improve the environmental performance of its key suppliers, encouraging them to adopt cleaner production methods and reduce waste.

- Circular Economy Principles: Efforts are underway to integrate circular economy principles, such as material efficiency and product lifecycle management, to minimize environmental impact from sourcing to end-of-life.

- Transportation Efficiency: Strategies are being developed to optimize logistics and transportation routes to lower fuel consumption and associated emissions in product delivery.

Environmental factors significantly influence Atlas Copco's operations, pushing for greater sustainability and reduced ecological impact. The global drive towards decarbonization, exemplified by initiatives like the EU's Fit for 55 aiming for a 55% emissions reduction by 2030, directly shapes demand for cleaner industrial technologies. This also necessitates increased investment in electrifying processes and exploring carbon capture solutions.

Resource scarcity is another key driver, encouraging a shift towards circular economy models that prioritize material recycling and reuse. This trend impacts raw material sourcing and costs; for example, copper prices in early 2024 neared record highs due to supply chain pressures and demand, highlighting the financial implications of material availability.

Stricter environmental regulations worldwide compel companies like Atlas Copco to invest in advanced waste management and pollution control. The EU's updated Industrial Emissions Directive in 2024 is a prime example, requiring adherence to best available techniques and potentially increasing operational costs while fostering cleaner production innovations.

Societal expectations for corporate environmental responsibility are also rising, with consumers and investors favoring sustainable businesses. Atlas Copco's 2024 sustainability report noted a 15% reduction in hazardous waste per production unit compared to 2022, demonstrating a proactive response to these escalating pressures.

| Environmental Factor | Impact on Atlas Copco | Relevant Data/Initiative |

|---|---|---|

| Climate Change & Decarbonization | Drives demand for energy-efficient and low-emission solutions; necessitates investment in electrification and carbon capture. | EU Fit for 55 package (55% emissions reduction by 2030). |

| Resource Scarcity | Promotes circular economy models; affects raw material costs and supply chain stability. | Copper prices approached record highs in early 2024. |

| Environmental Regulations | Requires investment in pollution control and waste management technologies; influences operational standards. | EU Industrial Emissions Directive updates (2024). |

| Corporate Social Responsibility | Increases pressure for demonstrable sustainability commitments; influences investor and consumer choices. | Atlas Copco's 2024 report: 15% reduction in hazardous waste per production unit (vs. 2022). |

PESTLE Analysis Data Sources

Our Atlas Copco PESTLE analysis is built upon a robust foundation of data, drawing from official government publications, reputable financial institutions, and leading industry research firms. This ensures that every aspect of the macro-environment is analyzed with accuracy and relevance.