Symbotic PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Symbotic Bundle

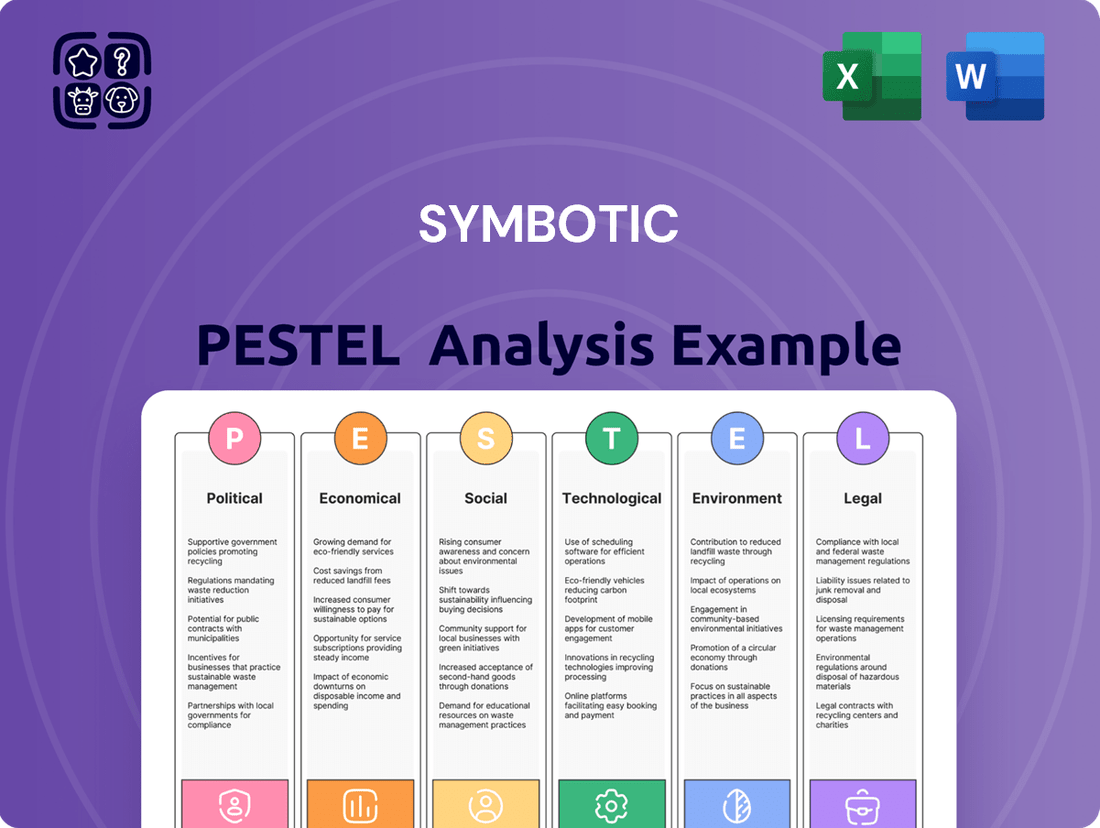

Gain a strategic advantage with our comprehensive PESTLE Analysis of Symbotic. Understand the intricate interplay of Political, Economic, Social, Technological, Legal, and Environmental factors that are shaping its operational landscape. This detailed report is your key to unlocking actionable insights and anticipating future market shifts. Don't be left behind; download the full analysis now to empower your decision-making and secure your competitive edge.

Political factors

Governments worldwide are recognizing automation's role in bolstering supply chain resilience and domestic manufacturing. This focus translates into potential incentives, such as grants and tax credits, designed to encourage businesses to adopt advanced automation technologies. For Symbotic, this governmental push can significantly de-risk the initial investment for its clients.

For instance, the U.S. CHIPS and Science Act of 2022, while focused on semiconductors, signals a broader trend of government investment in advanced manufacturing and technological modernization. Similar initiatives are emerging in Europe and Asia, aiming to reshore critical industries. These policies directly lower the barrier to entry for companies considering Symbotic's automated warehouse solutions.

Shifting global trade policies, including tariffs and a growing emphasis on reshoring or nearshoring, directly impact investment decisions in automation. For instance, the imposition of tariffs on goods from certain regions can make domestic production, and thus domestic automation, more economically attractive.

Symbotic's automated warehouse solutions are particularly well-positioned as companies increasingly seek to localize their supply chains. This trend is driven by a desire to mitigate geopolitical risks, such as trade disputes or international shipping disruptions, as seen with the ongoing challenges in global freight capacity reported in late 2024.

By enhancing domestic warehouse efficiency, Symbotic's technology supports businesses aiming to reduce their reliance on long-distance, international shipping routes. This localization strategy strengthens the domestic market demand for advanced automation solutions like those Symbotic offers.

The political landscape increasingly scrutinizes automation's effect on employment, with potential for labor unions to lobby against technologies that displace human workers. This could create hurdles for Symbotic's market penetration, especially in regions with strong union presence. For instance, in 2024, the United Auto Workers (UAW) continued to voice concerns about automation in manufacturing, a sentiment that could extend to the logistics sector.

Conversely, governments often view automation as a critical tool to combat persistent labor shortages in warehousing and supply chain operations, a trend exacerbated by demographic shifts and evolving workforce preferences. This perspective could translate into policy support for automation solutions that enhance, rather than entirely replace, human capabilities. The U.S. Bureau of Labor Statistics projected a 4% job growth for warehouse workers from 2022 to 2032, indicating ongoing demand that automation could help meet.

Anticipating these dynamics, policymakers may introduce regulations aimed at facilitating a smoother transition for the workforce, potentially including retraining programs or incentives for companies adopting human-augmenting automation. Such frameworks could offer Symbotic opportunities if its solutions are perceived as collaborative with the existing labor force.

Regulatory Environment for Logistics Infrastructure

Governments worldwide are increasingly prioritizing the enhancement of national logistics infrastructure, recognizing its critical role in economic competitiveness. This focus directly benefits warehouse automation specialists like Symbotic. For instance, the United States' Infrastructure Investment and Jobs Act of 2021 allocated $1.2 trillion, with a significant portion directed towards improving ports, roads, and rail networks, which are essential for efficient supply chain operations.

Policies that simplify the complex web of permits and approvals for infrastructure projects, including those for advanced distribution centers, can substantially accelerate the deployment of automated systems. Smart city initiatives, which often integrate advanced technology for traffic management and urban planning, can also create synergistic opportunities for automated logistics networks. The adoption of digital twin technology in infrastructure planning, as seen in various European Union projects, further supports the integration of automated supply chains.

- Government Investment: The U.S. Infrastructure Investment and Jobs Act earmarks billions for port modernization and supply chain resilience, directly supporting the ecosystem Symbotic operates within.

- Streamlined Permitting: Initiatives to reduce regulatory hurdles for infrastructure development can shorten the time to market for new automated facilities.

- Smart City Integration: Public-private partnerships in smart city development can facilitate the seamless integration of automated logistics with urban transportation and utility networks.

- Public-Private Partnerships (PPPs): Collaborative efforts between government entities and private companies are becoming more prevalent in large-scale infrastructure projects, offering avenues for deploying advanced automation solutions.

Geopolitical Stability and Supply Chain Resilience

Geopolitical instability, a persistent challenge in global trade, directly impacts supply chain reliability. The ongoing global conflicts and trade disputes, particularly evident in the 2024-2025 period, have underscored the fragility of extended international supply networks. Companies are increasingly prioritizing resilience over pure cost efficiency, seeking ways to onshore or nearshore critical operations.

Symbotic's advanced automation solutions are perfectly positioned to address this shift. By enabling the creation of highly efficient, high-density warehouses, Symbotic empowers businesses to bring more logistics control in-house. This reduces reliance on external, potentially volatile, shipping routes and foreign labor markets. For example, the increased investment in domestic warehousing infrastructure by major retailers in 2024, seeking to mitigate disruptions from the Red Sea shipping crisis, highlights this trend.

- Increased Investment in Domestic Warehousing: Retailers and manufacturers significantly boosted spending on domestic automated warehouse solutions in 2024 to counter global shipping delays.

- Reduced Supply Chain Vulnerability: Symbotic's technology allows companies to store more inventory closer to end consumers, buffering against disruptions from geopolitical events affecting international transit.

- Alignment with National Security: By strengthening domestic logistics capabilities, Symbotic's solutions contribute to national interests in maintaining essential goods supply during crises.

Governments are actively promoting automation to enhance domestic manufacturing and supply chain resilience, offering incentives like tax credits and grants. This governmental support, exemplified by legislation like the U.S. CHIPS and Science Act, lowers the investment barrier for adopting advanced automation technologies such as Symbotic's warehouse solutions.

Shifting trade policies, including tariffs and the push for reshoring, make domestic production and automation more economically appealing. Symbotic's technology directly supports businesses looking to localize their supply chains, mitigating risks from geopolitical events and global shipping disruptions reported throughout 2024.

The political discourse around automation's impact on jobs presents a dual-edged sword; while labor unions may express concerns, governments also view automation as a solution to persistent labor shortages in logistics, as projected by the U.S. Bureau of Labor Statistics for warehouse workers through 2032.

Governments are prioritizing logistics infrastructure, with initiatives like the U.S. Infrastructure Investment and Jobs Act, which includes significant funding for ports and supply chains. These investments, coupled with efforts to streamline permitting, create a more favorable environment for deploying advanced automated systems.

| Factor | Description | Impact on Symbotic | 2024/2025 Data Point |

| Government Investment & Incentives | Financial support and tax breaks for automation adoption. | Reduces client investment risk, drives demand. | U.S. Infrastructure Investment and Jobs Act (2021) allocated $1.2T for infrastructure, including supply chains. |

| Trade Policy & Reshoring | Tariffs and emphasis on domestic production. | Increases attractiveness of domestic automation. | Global trade disruptions in 2024 highlighted the need for resilient, localized supply chains. |

| Labor Market Policies | Government stance on automation and employment. | Potential for support or resistance based on job impact. | U.S. Bureau of Labor Statistics projected 4% job growth for warehouse workers (2022-2032), indicating ongoing demand automation can address. |

| Infrastructure Development | Government spending on logistics and transportation networks. | Enhances the ecosystem for automated logistics. | Retailers increased domestic warehousing investment in 2024 to mitigate shipping delays. |

What is included in the product

This PESTLE analysis offers a comprehensive examination of the external macro-environmental factors impacting Symbiotic, covering Political, Economic, Social, Technological, Environmental, and Legal dimensions. It provides actionable insights for strategic decision-making by identifying potential threats and opportunities within Symbiotic's operating landscape.

The Symbotic PESTLE Analysis offers a structured framework to proactively identify and address external threats and opportunities, thereby reducing the anxiety and uncertainty associated with unforeseen market shifts.

Economic factors

The relentless expansion of e-commerce, a trend accelerated by shifting consumer behaviors, is a direct catalyst for the escalating demand for advanced warehouse automation. As online retail continues its upward trajectory, Symbotic's sophisticated automation solutions become increasingly critical for clients aiming to meet heightened customer expectations for swift order fulfillment and accurate inventory management.

In 2024, global e-commerce sales were projected to reach over $6.5 trillion, a figure expected to climb even higher in 2025. This immense volume necessitates highly efficient operational capabilities, directly translating into a greater need for the automated systems Symbotic provides to streamline warehouse operations.

The increasing complexity of supply chains and the constant pressure for faster delivery times mean that businesses are actively seeking ways to optimize their warehousing. Symbotic's ability to offer integrated automation solutions positions it to capitalize on this growing demand from retailers and distributors alike.

Persistent labor shortages in warehousing and logistics are making automation a more attractive investment. In 2024, the U.S. Bureau of Labor Statistics reported a significant gap in available workers for these sectors, pushing wages higher. This economic pressure makes Symbotic's automated solutions, which reduce the need for manual labor, increasingly appealing for businesses looking to control operational costs and maintain efficiency.

Inflationary pressures directly impact Symbotic's operational costs, potentially increasing expenses for raw materials used in hardware components and the energy required to power its advanced automation systems. For instance, the Consumer Price Index (CPI) in the US, a key inflation indicator, saw a significant rise throughout 2023 and into early 2024, impacting manufacturing inputs. This also extends to the cost of skilled labor needed for software development and ongoing system maintenance, as demand for specialized technical expertise remains high.

Despite these internal cost challenges, Symbotic's automation solutions offer a compelling counter-inflationary benefit to its clients. By enhancing operational efficiency, minimizing material waste, and optimizing labor deployment, Symbotic's systems can significantly lower a client's overall cost of doing business over time. This hedging effect against rising labor and material costs becomes increasingly valuable in an inflationary economic climate, making automation a strategic investment for many businesses.

Capital Expenditure and Investment Trends

Companies' willingness to invest in substantial automation projects, like those Symbotic offers, is closely tied to overall economic confidence and the prevailing interest rate environment. When businesses feel optimistic about the future and capital is readily available, they are more inclined to undertake significant capital expenditures. For instance, in early 2024, many sectors saw a rebound in investment intentions, driven by a more stable economic outlook compared to the previous year.

While elevated interest rates can present a hurdle for some capital projects, the compelling return on investment (ROI) often associated with advanced automation, especially in terms of efficiency improvements and labor cost reductions, can make these investments highly attractive. Symbotic's solutions, which aim to significantly boost warehouse productivity, often demonstrate payback periods that justify the upfront cost, even in a higher interest rate climate. The company's ability to secure major deals, such as its agreements with Walmart and Target, underscores this continued investment appetite.

Symbotic's strong financial performance in 2024 and early 2025, marked by increasing revenue and strategic partnerships, directly reflects sustained investment trends in warehouse automation. These deals not only validate Symbotic's technology but also signal a broader industry commitment to modernizing supply chains through automation. The demand for efficient, labor-saving solutions remains a key driver for capital allocation in the logistics and retail sectors.

- Economic Confidence: Surveys in late 2023 and early 2024 indicated a cautious but growing optimism among business leaders regarding capital investment.

- Interest Rate Impact: While higher rates increase borrowing costs, the projected ROI from automation projects often outweighs this, with many companies prioritizing long-term efficiency gains.

- Symbotic's Deals: Major agreements with large retailers in 2023 and 2024 highlight the ongoing significant capital deployment into automated warehousing solutions.

- ROI Justification: The clear benefits of reduced labor costs and increased throughput make automation a priority capital expenditure, even with tighter financing conditions.

Supply Chain Disruptions and Resilience Investment

Recent global supply chain disruptions, exacerbated by events like the COVID-19 pandemic and geopolitical tensions, have underscored the critical need for enhanced resilience and efficiency. Companies are now prioritizing investments in technologies designed to mitigate these vulnerabilities. For instance, in 2023, businesses globally increased spending on supply chain visibility and risk management tools by an estimated 15-20% compared to pre-pandemic levels.

Symbotic's automated warehouse systems directly address these concerns by significantly bolstering supply chain resilience. Their solutions improve inventory accuracy, a key factor in preventing stockouts during times of high demand or unexpected shortages. Furthermore, the acceleration of throughput and optimization of space utilization enabled by Symbotic's technology helps companies maintain operational continuity even when facing external shocks.

The impact of these improvements is substantial. Companies implementing advanced automation often see a reduction in order fulfillment times by 30-50% and a decrease in inventory carrying costs by up to 10%. This enhanced operational agility is crucial for navigating future disruptions effectively.

- Increased Investment in Resilience: Global spending on supply chain risk management technology saw a significant uptick in 2023, reflecting a strategic shift towards building more robust operations.

- Symbotic's Role: Symbotic's automation enhances supply chain resilience through improved inventory accuracy, faster throughput, and better space utilization.

- Operational Benefits: Businesses adopting such technologies can expect reduced fulfillment times and lower inventory costs, directly mitigating the impact of disruptions.

- Market Demand: The growing emphasis on supply chain reliability is driving strong demand for advanced automation solutions like those offered by Symbotic.

The sustained growth of e-commerce, projected to exceed $6.5 trillion in global sales for 2024 and continue its upward trend, directly fuels the demand for Symbotic's advanced warehouse automation. This economic driver necessitates enhanced operational efficiency to meet consumer expectations for rapid fulfillment. Furthermore, persistent labor shortages, with significant unfilled positions in logistics as reported by the U.S. Bureau of Labor Statistics in 2024, make automation an increasingly cost-effective solution for businesses seeking to control operational expenses and maintain productivity.

| Economic Factor | 2024/2025 Data Point | Impact on Symbotic |

|---|---|---|

| E-commerce Growth | Projected global sales > $6.5 trillion (2024) | Increased demand for automation to meet fulfillment needs |

| Labor Shortages | Significant unfilled logistics positions (2024) | Makes automation a more attractive investment for cost control |

| Inflationary Pressures | Rising CPI impacting raw materials and energy | Increases Symbotic's operational costs, but clients benefit from hedging |

| Investment Confidence | Cautious optimism in capital investment (late 2023/early 2024) | Supports demand for Symbotic's large-scale automation projects |

Preview Before You Purchase

Symbotic PESTLE Analysis

The Symbiotic PESTLE Analysis preview you see is the exact, fully formatted document you’ll receive after purchase. This comprehensive report breaks down the Political, Economic, Social, Technological, Legal, and Environmental factors impacting Symbiotic. You'll gain immediate access to this professionally structured analysis, ready for your strategic planning. No surprises, just the complete PESTLE framework for Symbiotic.

Sociological factors

The increasing integration of advanced automation, such as Symbotic's robotic systems, is fundamentally altering the employment landscape in warehouses. While this technological shift raises concerns about job displacement for traditional manual labor, it simultaneously generates demand for new roles focused on system maintenance, programming, and oversight. For instance, the U.S. Bureau of Labor Statistics projected that employment in warehousing and storage is expected to grow 7% from 2022 to 2032, faster than the average for all occupations, highlighting the changing nature of jobs within the sector.

Symbotic and its clientele must proactively address the sociological implications of this workforce transformation. This involves investing in comprehensive retraining and upskilling initiatives to equip existing employees with the competencies needed for the automated environment. Companies like Symbotic are increasingly offering specialized training programs, and by 2024, many logistics firms are reporting significant investments in employee development to bridge the skills gap, ensuring a smoother transition and fostering a collaborative human-robot workforce.

Public sentiment towards automation and AI, especially regarding job displacement and data security, significantly shapes the landscape for companies like Symbotic. Surveys in late 2024 and early 2025 indicate a growing awareness, with a Pew Research Center study showing 58% of Americans are concerned about AI's impact on jobs, while 42% see potential benefits like increased productivity.

A narrative emphasizing how automation, like Symbotic's warehouse robotics, can boost efficiency and safety, while simultaneously creating new, skilled roles in system maintenance and oversight, is vital for broader acceptance. For instance, reports from the World Economic Forum in 2024 highlighted that while automation might displace some tasks, it's projected to create 97 million new jobs globally by 2025, often in areas requiring human-AI collaboration.

Symbotic's success hinges on fostering public trust; demonstrating how their AI-driven systems enhance operational safety and create more intellectually stimulating jobs, rather than simply replacing human workers, will be key. This positive framing is essential for navigating potential regulatory hurdles and encouraging widespread adoption of their technology in various industries.

Consumers today expect near-instantaneous delivery and precise order accuracy, a shift largely fueled by the e-commerce boom. This demand is so pervasive that by 2024, a significant majority of online shoppers prioritize fast shipping, with many willing to pay a premium for same-day or next-day delivery options. Retailers are under immense pressure to meet these evolving expectations.

Symbotic's automation technology directly addresses this sociological pressure by enabling warehouses to process orders with unprecedented speed and accuracy. For instance, Symbotic's systems have demonstrated the ability to handle millions of SKUs and significantly reduce order fulfillment times, thereby enhancing customer satisfaction. This capability is crucial for businesses aiming to retain customers and build loyalty in a competitive market where delivery speed is often a deciding factor.

Safety and Ergonomics in Automated Workplaces

The increasing integration of robotics in warehouses, like those managed by Symbotic, directly impacts worker safety and ergonomics. Concerns often arise regarding the physical interaction between humans and automated systems. Symbotic's approach, bolstered by its investment in and integration of technologies like those from Veo Robotics, aims to mitigate these risks. Veo Robotics’ FreeMove system, for instance, provides advanced safety features for robots, allowing for more fluid and secure human-robot collaboration. This technology helps prevent collisions and ensures that robots operate within safe parameters around human workers, thereby creating a more secure operational environment.

By automating physically demanding tasks, Symbotic's systems can significantly reduce the strain on human workers. This shift can lead to fewer workplace injuries and improved long-term employee well-being. For example, repetitive lifting, bending, and reaching, common in traditional warehousing, are largely handled by Symbotic's automated storage and retrieval systems (AS/RS) and robotic arms. This not only enhances efficiency but also prioritizes the physical health of the workforce. Such advancements are crucial as companies strive to create sustainable and safe work environments, especially as the adoption of automation accelerates, potentially leading to a reduction in lost-time injury frequency rates in the logistics sector.

Symbotic's focus on human-robot collaboration is a key sociological factor in its workplace design. This isn't just about replacing human labor but about creating a partnership where robots handle the strenuous or dangerous aspects, and humans focus on oversight, complex problem-solving, or tasks requiring fine motor skills and judgment. This dynamic is essential for worker acceptance and morale. Studies in human-robot interaction consistently show that clear safety protocols and well-defined collaborative roles lead to higher job satisfaction and reduced anxiety among employees working alongside automation. The company’s commitment to developing these collaborative systems is vital for the future of warehouse operations.

The impact on the workforce extends beyond immediate safety. It involves retraining and upskilling employees to work effectively within these new automated environments. Symbotic's technological advancements necessitate a workforce capable of managing and interacting with sophisticated robotic systems. This sociological shift requires investment in training programs to ensure employees are equipped for these evolving roles, fostering a more skilled and adaptable labor pool. The success of these automated workplaces hinges on successfully integrating human capital with technological capabilities, a trend expected to shape the logistics industry significantly through 2025 and beyond.

Ethical Considerations of AI and Robotics

As Symbotic's AI-powered robotics advance, ethical considerations are increasingly critical. The autonomy of these systems in decision-making, especially in complex logistics environments, raises questions about accountability. For instance, if an AI system directs a robotic arm to make a decision that results in damage or injury, determining responsibility becomes a significant challenge.

Potential biases embedded within AI algorithms also pose a societal risk. If training data reflects historical human biases, the AI could inadvertently perpetuate unfair practices, such as uneven distribution of tasks or resources. This is a growing concern as AI is integrated into more aspects of the economy, with studies in 2024 highlighting that AI bias mitigation remains a key research area.

Transparency in how AI makes decisions is another crucial element for building societal trust. Understanding the logic behind an AI's actions is essential for debugging, improvement, and ensuring fairness. Without clear explanations, public acceptance of advanced robotics in critical infrastructure could be hindered.

- Accountability: Establishing clear lines of responsibility for AI-driven decisions in automated warehouses.

- Bias Mitigation: Proactively identifying and correcting biases in AI algorithms to ensure equitable operation.

- Algorithmic Transparency: Developing methods to understand and explain the reasoning behind AI actions.

- Societal Trust: Fostering public confidence through ethical AI development and deployment practices.

Sociological factors significantly influence the adoption and perception of automation like Symbotic's. Public concern over job displacement, evident in 2024 surveys showing a majority worried about AI's impact, necessitates a narrative emphasizing new job creation in system oversight and maintenance. Consumer demand for rapid delivery, with many willing to pay extra for speed by 2024, pushes companies to adopt efficient automation. Furthermore, workplace safety and employee well-being are paramount, with advancements in human-robot collaboration and automation of strenuous tasks contributing to fewer injuries. Ethical considerations regarding AI accountability and bias, highlighted by ongoing research in 2024, are crucial for building societal trust and ensuring equitable implementation.

Technological factors

Symbotic's core business thrives on sophisticated AI and machine learning, powering everything from inventory tracking to the precise movements of their warehouse robots. These technologies are the engine for optimizing operations.

The ongoing evolution of AI means Symbotic's systems can become even smarter. This translates to better predictive capabilities, more accurate decision-making, and systems that learn and adapt, ultimately boosting efficiency and precision in warehouses.

For instance, AI's ability to analyze vast datasets in real-time allows Symbotic to anticipate potential bottlenecks and reroute robotic fleets proactively. This level of intelligent automation is key to their value proposition.

By mid-2024, investments in AI and machine learning across the logistics sector were projected to reach significant figures, with companies like Symbotic poised to capture a substantial portion of this growth by demonstrating tangible ROI through enhanced operational throughput.

Robotics hardware is constantly getting better, with companies developing robots that are more nimble, have sharper sensors, and are cheaper to make. This progress directly helps Symbotic create even more advanced warehouse automation solutions. For instance, the increasing sophistication of robotic arms and grippers, coupled with advancements in AI-powered vision systems, allows for more precise and rapid handling of diverse goods, a core competency for Symbotic.

The trend towards miniaturization in robotics is particularly impactful. Smaller, more energy-efficient robots can navigate tighter spaces within warehouses, leading to higher-density storage solutions. This means Symbotic can design systems that maximize available warehouse footprint, a critical factor given the rising costs of industrial real estate. By 2024, the global industrial robotics market was projected to reach over $60 billion, with significant growth driven by these hardware advancements.

Symbotic's technology boasts strong integration capabilities, a key technological factor for its success. Its proprietary platform is designed to seamlessly connect with clients' existing warehouse management systems (WMS) and enterprise resource planning (ERP) software. This compatibility is crucial for widespread adoption, as it minimizes disruption and upfront costs for businesses looking to upgrade their automation. For instance, in 2023, Symbotic announced an expanded partnership with Walmart, a major client, highlighting the successful integration of its automated systems into Walmart's extensive supply chain infrastructure.

Cybersecurity and Data Protection

As Symbotic's automated warehouse solutions become more integrated and reliant on digital infrastructure, cybersecurity and data protection are critical. The increasing volume of sensitive client and operational data stored and processed necessitates advanced safeguards against evolving cyber threats. Failure to maintain robust security could lead to significant financial losses, reputational damage, and disruption of services.

Symbotic's commitment to cybersecurity is essential for maintaining client trust and operational continuity. Continuous investment in state-of-the-art security protocols, regular vulnerability assessments, and employee training are crucial. For instance, the global cost of cybercrime was projected to reach $10.5 trillion annually by 2025, highlighting the immense financial stakes involved in data protection.

- Increased Sophistication of Cyberattacks: With more interconnected systems, Symbotic faces a growing risk from advanced persistent threats and ransomware attacks targeting operational technology.

- Data Privacy Regulations: Compliance with regulations like GDPR and CCPA mandates stringent data protection measures, with significant fines for non-compliance, impacting companies globally.

- Protection of Intellectual Property: Safeguarding Symbotic's proprietary automation technology and algorithms from theft or espionage is paramount to maintaining its competitive edge.

- Ensuring System Uptime and Reliability: Cyber incidents can cripple warehouse operations, leading to costly downtime and impacting supply chain efficiency for Symbotic's clients.

Competitive Technology Landscape

The warehouse automation sector is experiencing rapid advancements, with companies like Berkshire Grey and Honeywell actively developing their own solutions. Symbotic’s competitive edge relies on its continued investment in research and development, aiming to launch next-generation AI-powered robotics and software. This innovation is crucial for maintaining market share against a backdrop of increasing automation adoption across industries, projected to reach $100 billion globally by 2030, according to some market forecasts.

Strategic moves, such as Walmart’s acquisition of its internal robotics division in 2023, highlight the trend of major players building in-house capabilities. Symbotic must leverage its intellectual property and a robust patent portfolio, which stood at over 1,000 patents globally as of early 2024, to defend its market position. This focus on proprietary technology is key to differentiating its offerings in a market where interoperability and scalability are becoming paramount.

- Continuous Innovation: Competitors are consistently introducing new robotic systems and AI algorithms.

- Strategic Acquisitions: Companies are consolidating by acquiring promising automation technology firms.

- Intellectual Property: A strong patent portfolio is essential for protecting Symbotic's technological advancements.

- R&D Investment: Ongoing commitment to research is vital for developing industry-leading solutions.

Symbotic's technological advantage is rooted in its advanced AI and machine learning capabilities, which enhance operational efficiency. The continuous improvement in robotics hardware, including greater dexterity and reduced costs, directly fuels Symbotic's ability to offer more sophisticated automation. Furthermore, the company's focus on seamless integration with existing client systems is a critical technological factor for market adoption.

Cybersecurity is a paramount concern, given the increasing volume of sensitive data handled by Symbotic's systems. Protecting intellectual property and ensuring system uptime are vital, especially as global cybercrime costs were projected to reach $10.5 trillion annually by 2025. Symbotic's commitment to robust security protocols is therefore essential for client trust and operational continuity.

The company's competitive edge is maintained through ongoing investment in research and development for next-generation AI and robotics, a necessary strategy in a market projected to reach $100 billion globally by 2030. A strong patent portfolio, exceeding 1,000 patents globally by early 2024, is crucial for defending its market position against competitors and strategic acquisitions within the sector.

Legal factors

Symbotic's operations, which involve managing extensive operational data for clients, are heavily influenced by data privacy and security regulations. Laws like the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States impose strict requirements on how this data is collected, stored, and used. Failure to comply can result in substantial fines; for instance, GDPR penalties can reach up to 4% of global annual revenue or €20 million, whichever is higher.

Ensuring the security of this data is not just a best practice but a significant legal obligation for Symbotic. This legal imperative directly shapes their system architecture, demanding robust security measures for data handling and storage. Furthermore, these regulations necessitate careful drafting of client contracts to clearly define responsibilities regarding data protection and breach notification, impacting the legal framework of their service agreements.

Symbotic's competitive edge hinges on protecting its cutting-edge AI, software, and hardware. Patents and robust intellectual property rights are crucial for this, allowing the company to shield its innovations from competitors and pursue legal recourse if its technology is misused.

The legal landscape surrounding AI and robotics is evolving rapidly, with ongoing discussions about patentability of AI-generated inventions and the scope of protection for software. As of early 2025, Symbotic's ability to secure and defend patents for its unique automation solutions, like those deployed in Walmart's advanced distribution centers, directly impacts its market exclusivity and future revenue streams.

The legal framework surrounding AI and robotics is rapidly developing, creating uncertainty for companies like Symbotic. As autonomous systems become more prevalent, questions of who is responsible when something goes wrong, such as a malfunction leading to an accident, are becoming critical. This directly impacts Symbotic's operational and product liability.

Globally, new regulations are being introduced to define accountability for AI-driven actions. For instance, the European Union's AI Act, expected to be fully implemented in 2024, categorizes AI systems by risk level, with stricter rules for high-risk applications. This could influence Symbotic's insurance needs and product design to comply with varying international standards.

These evolving laws could necessitate significant investments in compliance and risk management for Symbotic. Understanding and adapting to these legal shifts is crucial to ensure continued market access and to mitigate potential financial and reputational damage stemming from liability issues in their autonomous warehouse solutions.

Worker Safety and Automation Standards

Symbotic must strictly adhere to occupational safety regulations and industry-specific standards for robotics, especially concerning human-robot interaction in industrial settings. These legal frameworks are crucial for ensuring worker well-being and dictate the design and operational procedures for Symbotic’s automated systems. For instance, the Occupational Safety and Health Administration (OSHA) in the US sets stringent guidelines for workplace safety, including those pertaining to automated machinery. As of 2024, the increasing integration of AI and robotics in warehouses, a core market for Symbotic, necessitates continuous review and adaptation to evolving safety protocols to prevent accidents and ensure compliance.

Compliance not only mitigates legal risks and potential fines but also directly impacts operational efficiency and public trust. Failure to meet these standards can lead to significant penalties; for example, OSHA can impose fines of up to $15,625 per violation for serious offenses as of 2024, and even higher for willful or repeat violations. Symbotic’s commitment to robust safety engineering and transparent operational protocols is therefore essential for maintaining its market position and customer confidence in the evolving landscape of warehouse automation.

- Regulatory Compliance: Adherence to OSHA, ANSI, and ISO standards for industrial robotics ensures safe human-robot collaboration.

- Worker Training Mandates: Legal requirements often stipulate comprehensive training for personnel operating or working alongside automated systems.

- System Design Standards: Regulations influence the physical design of robots and automated systems, mandating features like safety guards, emergency stops, and proximity sensors.

Contractual Agreements and Service Level Agreements

The legal framework surrounding Symbotic's client contracts and Service Level Agreements (SLAs) is paramount to its operational stability and client trust. These agreements clearly delineate project scope, deployment timelines, ongoing maintenance responsibilities, and performance benchmarks, directly influencing revenue recognition and client satisfaction. For instance, Symbotic's ability to meet its contractual obligations, such as guaranteed uptime or system efficiency, directly impacts its financial performance and potential for penalties or bonuses. The robustness of these legal documents underpins the long-term viability of their partnerships.

Key considerations within Symbotic's legal agreements include:

- Service Level Agreements (SLAs): Clearly defined performance metrics and uptime guarantees are essential for client retention and revenue assurance.

- Deployment Schedules: Adherence to agreed-upon implementation timelines is critical to avoid contractual breaches and maintain client project momentum.

- Maintenance and Support: Contractual obligations for system upkeep and technical support are vital for ensuring operational continuity and client operational efficiency.

- Performance Guarantees: Legal stipulations around system performance and output directly link to Symbotic's ability to secure future business and maintain its reputation.

Symbotic's operations are significantly shaped by data privacy laws such as GDPR and CCPA, with potential fines up to 4% of global annual revenue for non-compliance. These regulations mandate robust data security measures, impacting system architecture and contractual agreements concerning data handling and breach notification.

Intellectual property law is critical for Symbotic to protect its proprietary AI, software, and hardware innovations. As of early 2025, the patentability of AI-generated inventions remains a developing legal area, directly influencing Symbotic's market exclusivity and revenue potential for solutions like those at Walmart.

The evolving legal landscape for AI and robotics introduces liability questions, particularly regarding malfunctions in autonomous systems. The EU's AI Act, largely in effect by 2024, categorizes AI by risk, potentially affecting Symbotic's compliance investments and product design across different jurisdictions.

Adherence to occupational safety regulations, like those from OSHA, is vital for Symbotic's automated warehouse solutions, dictating system design and operational procedures. Non-compliance, as seen with OSHA fines up to $15,625 per serious violation in 2024, underscores the importance of safety protocols for maintaining market trust and operational integrity.

Environmental factors

Symbotic's commitment to sustainability aligns with growing market demands for eco-friendly supply chains. Clients and consumers are increasingly scrutinizing the environmental impact of logistics, pushing for greener warehousing solutions. This trend directly benefits Symbotic, as its automated systems are designed to enhance operational efficiency and reduce the carbon footprint of warehouse operations.

By optimizing warehouse space and improving inventory accuracy, Symbotic’s technology minimizes the need for excessive energy consumption and reduces material waste. For instance, a more efficient warehouse layout can lead to a significant reduction in heating, cooling, and lighting costs. Furthermore, better inventory management can decrease product damage and obsolescence, directly contributing to waste reduction goals.

The global push for sustainability is evident in increasing ESG (Environmental, Social, and Governance) investments. In 2024, sustainable investments are projected to reach new highs, with a significant portion allocated to companies demonstrating strong environmental stewardship. Symbotic's ability to offer tangible improvements in energy efficiency and waste reduction positions it favorably within this expanding market, appealing to both environmentally conscious clients and investors.

The energy efficiency of automated warehouse systems is a significant environmental factor. Symbotic's advanced robotics and AI-powered optimization are designed to minimize power consumption, directly contributing to a reduced carbon footprint for their clients. This focus on efficiency is crucial as global energy demands continue to rise, with data centers alone projected to consume 13% of global electricity by 2026, highlighting the need for energy-conscious automation in all industrial sectors.

Symbotic's automation solutions significantly enhance inventory accuracy, a critical factor in waste reduction. By minimizing picking and packing errors, their systems prevent products from becoming obsolete due to mismanagement or damage. This efficiency directly translates to less material waste, supporting a more circular economy and reducing the environmental burden of discarded goods.

The drive towards sustainability is increasingly impacting supply chain operations. For instance, the global waste management market was valued at approximately $2.2 trillion in 2023 and is projected to grow, highlighting the economic and environmental imperative to reduce waste. Symbotic's technology directly addresses this by optimizing inventory levels, thereby decreasing the likelihood of overstocking and subsequent product obsolescence.

By improving the flow of goods and reducing handling, Symbotic's systems contribute to a more resource-efficient supply chain. This is particularly relevant as consumers and regulators alike demand greater environmental accountability from businesses. A 2024 survey indicated that over 70% of consumers consider sustainability when making purchasing decisions, pushing companies to adopt practices that minimize their environmental footprint, including waste reduction.

Carbon Footprint of Logistics Operations

Symbotic's automation solutions can significantly contribute to reducing the carbon footprint of logistics operations. By optimizing warehouse layouts and inventory management, their systems minimize the need for extensive transportation, a major source of emissions. For instance, efficient storage and retrieval processes can reduce the miles trucks travel to fulfill orders.

The company's technology directly impacts environmental sustainability within the supply chain. Optimized routing and reduced travel distances translate into lower fuel consumption and, consequently, fewer greenhouse gas emissions. This focus on efficiency helps Symbotic's clients achieve their environmental, social, and governance (ESG) goals.

Consider these benefits:

- Reduced transportation emissions: By consolidating shipments and optimizing delivery routes, Symbotic's automation can cut down on the number of miles vehicles travel.

- Lower energy consumption in warehouses: Efficient operations mean less time for machinery to be idle, leading to reduced overall energy usage.

- Minimized waste: Improved inventory accuracy and faster throughput help reduce product damage and obsolescence, thereby cutting down on waste disposal.

Globally, the logistics sector is under increasing pressure to decarbonize. The International Energy Agency reported that transportation accounted for approximately 24% of direct CO2 emissions from energy use in 2022, with road transport being the largest contributor. Symbotic's approach addresses this critical environmental challenge by making logistics inherently more efficient.

Compliance with Environmental Regulations

Symbotic’s manufacturing, product materials, and operations must align with environmental regulations. This includes rules on electronic waste, hazardous substances, and energy efficiency. For instance, the global e-waste generated reached an estimated 53.6 million metric tons in 2022, a figure expected to grow. Companies like Symbotic face increasing scrutiny and potential penalties for non-compliance.

Staying compliant is not just about avoiding fines; it's fundamental to responsible business conduct and maintaining a positive brand image. As environmental awareness grows, so do regulatory frameworks.

- E-waste Management: Symbotic must manage the lifecycle of its electronic components to meet evolving disposal and recycling standards.

- Hazardous Materials: Compliance with regulations on the use and disposal of hazardous materials in manufacturing is essential.

- Energy Consumption: Meeting energy efficiency standards for its facilities and products is increasingly important.

- Supply Chain Transparency: Ensuring suppliers also adhere to environmental standards adds another layer of compliance.

Environmental factors significantly influence Symbotic's operations and market positioning. The global drive for sustainability is creating demand for greener supply chains, directly benefiting Symbotic's efficiency-focused automation. For example, improved warehouse operations can cut energy consumption, a critical concern as global energy needs rise. Symbotic's technology also minimizes waste through enhanced inventory accuracy, addressing a growing market value in waste management solutions.

PESTLE Analysis Data Sources

Our PESTLE analysis is meticulously crafted using a blend of publicly available government data, reputable market research reports, and reputable academic studies. This comprehensive approach ensures that each factor, from technological advancements to socio-cultural shifts, is grounded in verifiable and timely information.