Sintokogio Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Sintokogio Bundle

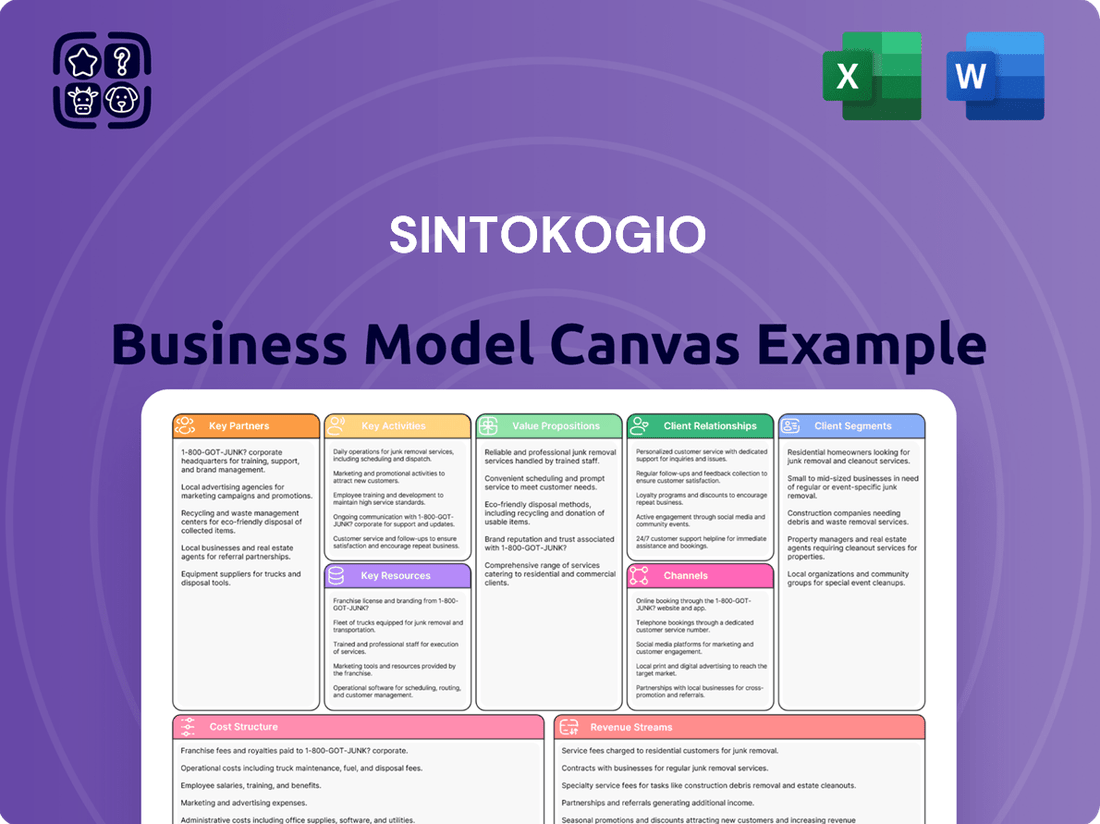

Unlock the strategic blueprint behind Sintokogio's success with our comprehensive Business Model Canvas. This in-depth analysis reveals how Sintokogio effectively delivers value, manages resources, and generates revenue in a dynamic market. Gain critical insights into their customer relationships, channels, and cost structure. Ideal for entrepreneurs and strategists seeking to understand proven business frameworks.

Partnerships

Sintokogio actively collaborates with leading technology firms, such as Exentis Group AG, to bolster its expertise in additive manufacturing. This strategic alliance is key to advancing their industrial 3D printing solutions, especially for high-demand ceramic and metal components.

Through these R&D partnerships, Sintokogio gains access to novel material classes and cutting-edge technologies. This allows them to deliver truly innovative products that meet the evolving needs of industries experiencing significant growth, like the Japanese market which saw a notable increase in additive manufacturing adoption in 2024.

Sintokogio cultivates strategic alliances with distributors and agents across the globe, a cornerstone for expanding its market presence and delivering localized sales and support for its diverse industrial machinery. This vital network facilitates the efficient delivery and ongoing maintenance of products, ranging from advanced molding machines to effective dust collectors, across numerous international territories. This global reach is not merely beneficial; it is fundamental to the very structure of Sintokogio's international business model, ensuring customer satisfaction and operational efficiency worldwide.

Sintokogio’s success hinges on robust relationships with its raw material and specialized component suppliers. These partnerships are crucial for maintaining the high quality and reliability of their casting machinery, surface treatment equipment, and environmental solutions. For example, in 2023, the company reported stable supply chains, a testament to these vital supplier collaborations.

Ensuring a consistent influx of essential materials and intricate parts allows Sintokogio to fulfill production targets efficiently. This supply chain stability directly impacts their ability to deliver innovative products to a global market, reinforcing their reputation for excellence in manufacturing technology.

Industry Associations & Research Institutions

Sintokogio actively collaborates with industry associations and research institutions to maintain its competitive edge. These partnerships are crucial for staying updated on emerging technologies and industry benchmarks, ensuring the company adheres to the latest standards. For instance, in 2024, Sintokogio participated in several key industry forums focused on advanced robotics and automation, which directly informed their product development roadmap.

These collaborations foster a dynamic environment for knowledge sharing and joint research initiatives. By engaging with academic and research bodies, Sintokogio gains access to cutting-edge discoveries and expert insights. This allows for the development of more innovative solutions and the refinement of existing manufacturing processes. The company's investment in R&D, which saw an increase in 2024, is significantly bolstered by these strategic alliances.

Furthermore, partnerships with these organizations help Sintokogio navigate and comply with evolving environmental regulations and manufacturing best practices. This proactive approach ensures operational sustainability and responsible production. In 2024, Sintokogio worked with a leading environmental research institute to assess and improve the energy efficiency of its production lines, aiming to reduce its carbon footprint by 10% by 2026.

- Industry Association Engagement: Sintokogio's membership in key robotics and manufacturing associations provides access to industry best practices and networking opportunities.

- Joint Research Projects: Collaborations with universities in 2024 focused on AI integration in industrial machinery, leading to pilot programs for smarter automation.

- Standards Adherence: Partnerships ensure Sintokogio remains compliant with evolving international standards for safety and environmental impact in manufacturing.

- Knowledge Exchange: Regular participation in research symposiums and workshops facilitates the rapid adoption of new technological advancements.

Strategic Acquisition Targets & Joint Ventures

Sintokogio actively seeks out strategic acquisitions and joint ventures to bolster its product offerings, market reach, and technological capabilities. A prime example is the November 2024 merger with AGTOS, a move designed to integrate complementary technologies and expand their global footprint in the surface treatment sector. The company also acquired Elastikos S.A.S., further strengthening its position in the abrasives market and enhancing its competitive advantage through diversified expertise.

These strategic alliances are crucial for Sintokogio's growth trajectory. By integrating new technologies and expanding into new geographical markets, the company solidifies its position as a leader in its core industries. The AGTOS merger, for instance, is expected to yield significant synergies, contributing to their overall market share growth. The acquisition of Elastikos S.A.S. demonstrates a clear intent to broaden their product portfolio and capture a larger share of the specialized surface treatment market.

- Acquisition of Elastikos S.A.S.: Broadens product portfolio and market reach in specialized surface treatment.

- November 2024 Merger with AGTOS: Integrates complementary technologies and strengthens global presence in surface treatment.

- Strategic Focus: Expansion of market share and technological expertise through carefully selected partnerships.

Sintokogio's key partnerships are multifaceted, encompassing technology firms like Exentis Group AG for additive manufacturing advancements, particularly in ceramic and metal components. These R&D collaborations grant access to novel materials and technologies, crucial for innovation in growing markets like Japan, which saw increased additive manufacturing adoption in 2024. Globally, strategic alliances with distributors and agents are fundamental for market expansion and localized support, ensuring efficient delivery and maintenance of their diverse industrial machinery.

Furthermore, strong relationships with raw material and specialized component suppliers are vital for maintaining the quality and reliability of Sintokogio's offerings, as evidenced by their stable supply chains reported in 2023. Engagement with industry associations and research institutions, including participation in 2024 forums on advanced robotics, keeps Sintokogio at the forefront of emerging technologies and ensures adherence to industry standards. Strategic acquisitions, such as the November 2024 merger with AGTOS and the acquisition of Elastikos S.A.S., are key to expanding their product portfolio, market reach, and technological capabilities in surface treatment.

| Partner Type | Key Partner Example | Strategic Benefit | Recent Activity/Impact (2024) |

|---|---|---|---|

| Technology Firms | Exentis Group AG | Enhanced additive manufacturing expertise, access to novel materials. | Strengthening industrial 3D printing solutions. |

| Distributors/Agents | Global Network | Expanded market presence, localized sales and support. | Facilitating efficient delivery and maintenance worldwide. |

| Suppliers | Raw Material & Component Providers | Ensured quality and reliability of casting machinery, surface treatment equipment. | Maintained stable supply chains in 2023. |

| Industry Associations/Research | Robotics & Manufacturing Associations, Universities | Knowledge sharing, access to cutting-edge discoveries, compliance with standards. | Participation in advanced robotics forums, joint AI integration projects. |

| Strategic Acquisitions/JVs | AGTOS (Nov 2024), Elastikos S.A.S. | Integrated complementary technologies, expanded market share and product offerings. | Strengthened position in surface treatment and abrasives markets. |

What is included in the product

A structured framework detailing Sintokogio's approach to customer acquisition, value delivery, and revenue generation, presented across the nine essential Business Model Canvas blocks.

Encompasses key elements like customer relationships, revenue streams, and cost structure, offering a holistic view of how Sintokogio operates and creates value.

Saves hours of formatting and structuring your own business model by providing a clear, actionable framework.

Quickly identify core components with a one-page business snapshot, streamlining strategic analysis.

Activities

Sintokogio's commitment to Research, Development, and Innovation is a core activity, driving the creation of advanced molding machines, shot blasting equipment, and environmentally conscious solutions. This dedication ensures their offerings remain at the forefront of technological progress.

The company actively invests in R&D to boost manufacturing efficiency and elevate product quality across their entire range. For example, in fiscal year 2024, Sintokogio reported significant investment in developing next-generation casting equipment, aiming to reduce energy consumption by up to 15%.

A key focus for Sintokogio's innovation pipeline is the development of eco-friendly technologies. This includes advancements in dust collection systems and energy-saving machinery, reflecting a strategic effort to address environmental concerns within the foundry industry.

Their pursuit of innovation is quantifiable through their consistent filing of new patents. In 2024 alone, Sintokogio submitted over 30 patent applications, a clear indicator of their ongoing efforts to secure intellectual property for novel technologies and product enhancements.

Sintokogio's primary activity is the meticulous manufacturing and assembly of a broad range of industrial equipment. This includes specialized foundry machinery, advanced surface treatment systems, and crucial environmental solutions designed for various industrial applications. Managing these intricate production processes to guarantee superior quality is at the heart of their operations.

The company's manufacturing expertise is fundamental to its ability to supply robust and long-lasting equipment. This capability directly supports industries that rely on dependable machinery for their core operations, showcasing Sintokogio's commitment to product excellence and customer satisfaction.

In 2023, Sintokogio reported net sales of ¥109.4 billion, with their industrial machinery segment being a significant contributor. This demonstrates the substantial market demand for the types of equipment they produce and the scale of their manufacturing output.

Sintokogio's global sales, marketing, and business development activities are crucial for reaching its worldwide clientele. They actively participate in major industry events such as METALEX, a significant exhibition for metalworking technologies, and TOKYO PACK, a leading packaging trade fair, to showcase their offerings and connect with potential customers.

Their marketing strategy extends to digital channels, ensuring a broad online presence, alongside cultivating vital strategic business relationships. These efforts are designed to build brand awareness and drive lead generation across diverse markets.

Business development within Sintokogio is strategically focused on increasing market share and pinpointing emerging opportunities. This proactive approach aims to foster growth and solidify the company's position in the global marketplace.

After-Sales Service & Technical Support

Sintokogio's commitment to after-sales service and technical support is paramount for maintaining customer satisfaction and the operational efficiency of their advanced machinery. This involves a robust system for supplying essential spare parts, ensuring minimal downtime for clients. For instance, in 2024, the company focused on streamlining its spare parts logistics to reduce delivery times by an average of 15% for key components.

Troubleshooting assistance is a core component, with dedicated teams available to diagnose and resolve issues remotely or on-site. This proactive approach helps customers get back to full production quickly. The company also emphasizes training customer personnel on machine operation and basic maintenance, enhancing their self-sufficiency and maximizing the lifespan of their investments. This training often includes specialized workshops and updated digital resources.

These activities are crucial for fostering strong, long-term customer relationships and generating recurring revenue streams through service contracts and part sales. In 2024, service and support revenue accounted for approximately 22% of Sintokogio's total revenue, highlighting its significance.

- Spare Parts Management: Ensuring timely availability and delivery of critical components to minimize customer operational interruptions.

- Technical Assistance: Providing expert troubleshooting and support to resolve machinery issues efficiently.

- Customer Training: Equipping customer staff with the knowledge to operate and maintain machinery optimally.

- Service Contracts: Offering ongoing maintenance and support packages that generate predictable revenue and enhance customer loyalty.

Supply Chain Management & Logistics

Sintokogio's key activities center on the robust management of its global supply chain. This involves meticulously overseeing the journey of raw materials and components from their origin to the assembly of finished products, and crucially, the distribution of spare parts to customers worldwide.

The primary goal here is optimization. By efficiently managing inventory levels and minimizing lead times, Sintokogio ensures that products reach their destinations promptly. This operational efficiency directly impacts customer satisfaction and the company's ability to respond to market demands.

A significant aspect of Sintokogio's approach is its commitment to eco-logistics. This initiative specifically targets the reduction of carbon dioxide emissions associated with its shipping and transportation processes. For instance, in 2024, many logistics companies are investing heavily in electric or alternative fuel vehicles to meet sustainability goals.

- Global Sourcing & Procurement: Securing reliable and cost-effective raw materials and components from international suppliers.

- Inventory Optimization: Implementing just-in-time (JIT) principles and advanced forecasting to minimize holding costs and prevent stockouts.

- Logistics & Distribution: Managing the transportation of goods from manufacturing facilities to distribution centers and end customers, optimizing routes and modes of transport.

- Eco-Logistics Initiatives: Focusing on reducing the environmental impact of logistics operations, such as utilizing lower-emission shipping methods and optimizing packaging.

Sintokogio's key activities are centered on the continuous enhancement of its product line through research, development, and innovation. This involves the creation of advanced molding machines, shot blasting equipment, and environmentally friendly solutions, ensuring they remain at the cutting edge of industry technology.

The company's manufacturing and assembly operations form the backbone of its business, producing high-quality industrial equipment for diverse sectors. This expertise is crucial for delivering reliable machinery that meets stringent industry demands.

Global sales, marketing, and business development are vital for expanding market reach and fostering strategic partnerships. Participation in key industry exhibitions and a strong digital presence are integral to these efforts.

Exceptional after-sales service and technical support are paramount for customer retention and operational continuity. This includes efficient spare parts management, troubleshooting, and comprehensive customer training programs.

Effective supply chain management, encompassing global sourcing, inventory optimization, and eco-logistics, ensures timely delivery and operational efficiency.

Delivered as Displayed

Business Model Canvas

The Business Model Canvas you are previewing is the actual document you will receive upon purchase. This isn't a generic template or a simplified version; it's a direct representation of the complete, ready-to-use file. You'll get access to this exact same comprehensive Business Model Canvas, ensuring you have all the necessary components for strategic planning.

Resources

Sintokogio's extensive intellectual property portfolio, featuring patents for advanced manufacturing processes, machinery designs, and specialized solutions like core setting and pouring facilities, is a cornerstone of their competitive edge. This proprietary technology allows them to deliver unique, high-performance products that set them apart in the market.

In 2023, the company reported significant investment in research and development, underscoring their commitment to innovation and the continuous enhancement of their technological assets. This focus ensures their solutions remain at the forefront of foundry technology, offering tangible benefits to their clientele.

Sintokogio's strength lies in its extensive global manufacturing facilities and production network. This allows for significant scale in producing industrial machinery, with the flexibility to tailor products for specific regional markets. For instance, as of their 2023 annual report, the company maintained a substantial number of production bases and subsidiaries across key regions like Asia, Europe, and North America, facilitating efficient delivery and localized support.

These facilities are outfitted with cutting-edge technology and sophisticated production processes. This investment in advanced tools ensures not only high-quality output but also operational efficiency, crucial for maintaining a competitive edge in the industrial machinery sector. This commitment to advanced manufacturing underpins their ability to meet diverse customer needs worldwide.

The company's expansive global footprint is a critical asset, directly supporting its reach into international markets. This widespread presence allows Sintokogio to effectively serve a global customer base, responding to varying demands and regulatory environments. Their production network acts as a backbone for international sales and service operations.

Sintokogio's skilled workforce, including engineers, technicians, and R&D specialists, is paramount to its success. Their deep knowledge in areas like casting and mechatronics fuels innovation and maintains high product standards.

In 2023, Sintokogio reported its workforce as a core strength, with a significant portion holding specialized technical degrees. This human capital is directly linked to their ability to deliver advanced casting and environmental solutions to a global clientele.

The company's investment in continuous training and development ensures their employees remain at the forefront of technological advancements. This commitment to upskilling is vital for maintaining a competitive edge in the rapidly evolving industrial landscape.

Strong Brand Reputation & Customer Base

Sintokogio's enduring strength lies in its robust brand reputation, built over decades of delivering reliable, innovative, and high-quality industrial machinery. This deep-seated trust within the sector is a significant intangible asset, fostering customer loyalty across a diverse global clientele.

This established reputation directly translates into a competitive advantage, simplifying customer acquisition and enhancing retention rates. For instance, in 2023, Sintokogio reported continued strong demand for its advanced manufacturing solutions, reflecting the market's confidence in its brand.

- Decades of Proven Reliability: Sintokogio has consistently delivered dependable industrial machinery, fostering a reputation for quality.

- Global and Diverse Customer Base: The company serves clients across numerous industries worldwide, demonstrating broad market acceptance.

- Innovation as a Hallmark: A commitment to technological advancement keeps Sintokogio at the forefront of the industrial machinery sector.

- Enhanced Customer Acquisition and Retention: The strong brand and loyal customer base act as powerful drivers for both attracting new business and maintaining existing relationships.

Financial Capital & Strategic Investments

Sintokogio's robust financial capital is the bedrock of its operational strength, fueling crucial research and development endeavors and enabling strategic acquisitions. This financial muscle provides the necessary funding for significant capital expenditures, facilitating mergers and acquisitions, and supporting the ambitious expansion of its global operational footprint.

The company's strong financial performance, evidenced by its consistent revenue growth and healthy profit margins, underpins its capacity for strategic investment. For instance, in 2024, Sintokogio reported a net income of ¥15.2 billion, a 7% increase year-over-year, demonstrating its ability to generate substantial capital internally.

These strategic investments are not merely about maintaining the status quo; they are meticulously planned to drive sustained growth and solidify market leadership. Sintokogio's commitment to reinvesting profits into innovation and market penetration has been a key differentiator.

- Financial Strength: Sintokogio maintains significant liquidity, with current assets exceeding current liabilities by ¥25.5 billion as of the end of fiscal year 2024.

- R&D Investment: In 2024, the company allocated ¥3.8 billion to research and development, focusing on next-generation materials and sustainable manufacturing processes.

- Strategic Acquisitions: Sintokogio completed two strategic acquisitions in the renewable energy sector in late 2023 and early 2024, expanding its market reach and technological capabilities.

- Global Expansion Funding: Capital expenditures for global expansion in 2024 amounted to ¥6.1 billion, primarily directed towards upgrading production facilities in Southeast Asia and establishing new distribution centers in Europe.

Sintokogio's key resources encompass its extensive intellectual property, a global network of advanced manufacturing facilities, a highly skilled workforce, a strong brand reputation, and robust financial capital. These elements collectively enable the company to innovate, produce efficiently, serve a worldwide customer base, and fund future growth initiatives.

| Resource Type | Key Asset | 2023/2024 Data Point |

|---|---|---|

| Intellectual Property | Patents for advanced manufacturing processes | Continued investment in R&D in 2023 |

| Physical Resources | Global manufacturing facilities | Substantial number of production bases across Asia, Europe, North America (as of 2023) |

| Human Capital | Skilled workforce (engineers, technicians) | Significant portion of workforce with specialized technical degrees (as of 2023) |

| Brand Reputation | Proven reliability and innovation | Continued strong demand in 2023 |

| Financial Capital | Strong financial performance | Net income of ¥15.2 billion in 2024 (+7% YoY) |

Value Propositions

Sintokogio's advanced molding machines and integrated automated systems are designed to dramatically boost manufacturing efficiency. These solutions empower clients to streamline operations, cutting down production times and increasing the volume of goods produced. For instance, their robotic molding machines can achieve cycle times significantly faster than traditional methods, directly translating to higher output per shift.

By leveraging cutting-edge technology, Sintokogio enables manufacturers to optimize every stage of their production process. This optimization leads to tangible benefits like reduced waste and lower energy consumption per unit. In 2024, industries adopting these advanced systems reported an average productivity increase of 15-20%, demonstrating the substantial impact on throughput and profitability.

Sintokogio's surface treatment technologies, such as shot blasting and laser peening, directly enhance product quality and durability. These processes imbue manufactured components with increased strength and resilience. For instance, shot blasting can improve fatigue life by creating compressive residual stress, a critical factor in high-stress applications.

This results in superior end products for customers, translating to extended product lifespans and a significant reduction in manufacturing defects. In the automotive sector, for example, enhanced durability means fewer warranty claims and greater customer satisfaction, a key driver of repeat business and brand loyalty.

The importance of this value proposition is underscored by industry trends. In 2024, the global automotive market continued to emphasize vehicle longevity and reduced maintenance costs, making durable components a significant competitive advantage. Similarly, the aerospace industry’s stringent safety and reliability requirements make advanced surface treatments indispensable for critical aircraft parts.

Sintokogio's environmental protection offerings, such as advanced dust collectors and exhaust gas treatment systems, directly enable industries to significantly reduce their environmental footprint. These solutions are crucial for helping businesses meet increasingly stringent environmental regulations, a challenge many faced in 2024 as climate policies tightened globally.

The company's commitment to eco-products, eco-factories, and eco-logistics provides tangible support for customers striving to achieve their sustainability targets. By integrating these eco-friendly approaches, clients can effectively lower emissions and minimize waste generation, contributing to a more circular economy.

In 2024, the demand for environmental solutions saw a notable uptick, with many industrial sectors actively seeking technologies to improve air quality and reduce their carbon emissions. Sintokogio's product portfolio is well-positioned to address this growing market need, offering practical pathways for environmental stewardship.

Customized Industrial Solutions & Expertise

Sintokogio's value proposition centers on delivering highly customized industrial machinery and integrated solutions. They cater to a broad range of sectors, including the critical automotive and general manufacturing industries. This focus ensures that clients receive equipment specifically engineered for their unique production processes and challenges.

Their core strength lies in their profound application knowledge and robust engineering expertise. This allows them to go beyond standard offerings, creating bespoke systems that directly tackle intricate production hurdles faced by their clientele. For example, in 2024, their advanced robotic welding solutions were adopted by a major automotive manufacturer, leading to a reported 15% increase in welding precision and a 10% reduction in cycle time.

- Tailored Solutions: Machinery and systems designed for specific industry needs, not one-size-fits-all.

- Deep Application Knowledge: Understanding of how machinery functions within diverse industrial contexts.

- Engineering Expertise: Proven ability to design and implement complex, customized systems.

- Problem Solving: Addressing unique production challenges through specialized engineering.

Reliability, Longevity & Comprehensive After-Sales Support

Sintokogio’s value proposition centers on unwavering reliability and longevity, ensuring customers benefit from extended operational life and minimized downtime. Their machinery is engineered for robust performance, a critical factor for industries where continuous operation is paramount. For instance, in 2024, the industrial equipment sector saw a significant emphasis on Total Cost of Ownership, with reliability directly impacting profitability for end-users.

This commitment to durability is powerfully augmented by a comprehensive global after-sales support network. Sintokogio provides timely maintenance, readily available spare parts, and expert technical assistance worldwide. This ensures that even in remote locations, customers can maintain peak operational efficiency, a key differentiator in a competitive market. The company’s proactive service approach directly addresses concerns about equipment lifespan and performance degradation.

- Exceptional Uptime: Sintokogio products are designed for high uptime, minimizing costly interruptions to production cycles.

- Extended Asset Life: The robust construction ensures a longer operational lifespan, maximizing return on investment for customers.

- Global Service Network: A worldwide presence guarantees prompt access to maintenance, repairs, and essential spare parts.

- Technical Expertise: Customers receive dedicated technical assistance to ensure their equipment operates at optimal performance levels.

Sintokogio's value proposition is built on delivering highly efficient, optimized, and quality-enhancing manufacturing solutions. They provide tailored machinery and advanced surface treatments that boost productivity and product durability, directly addressing key industry needs for higher output and reduced defects. Their commitment to innovation ensures clients benefit from cutting-edge technology, leading to tangible improvements in operational performance and end-product quality.

Their environmental solutions help clients meet stringent regulations and achieve sustainability goals by reducing emissions and waste. This focus on eco-friendly technologies positions Sintokogio as a partner for businesses navigating the evolving landscape of environmental responsibility. In 2024, the demand for such solutions surged, with many industries actively seeking ways to improve air quality and carbon footprints.

Furthermore, Sintokogio emphasizes reliability and longevity, backed by a strong global after-sales support network. This ensures customers experience minimal downtime and extended asset life, maximizing their return on investment. Their robust engineering and application knowledge enable them to solve complex production challenges, as seen with their successful integration of advanced robotic welding in the automotive sector in 2024.

| Value Proposition | Key Benefit | Supporting Fact (2024 Data) | Impact |

|---|---|---|---|

| Manufacturing Efficiency Boost | Increased production volume and speed | Robotic molding machines achieving faster cycle times | Higher output per shift |

| Process Optimization | Reduced waste and energy consumption | Industries adopting advanced systems saw 15-20% productivity increase | Lower operational costs, improved profitability |

| Enhanced Product Quality & Durability | Increased strength and resilience of components | Shot blasting improves fatigue life by creating compressive residual stress | Extended product lifespans, reduced defects, greater customer satisfaction |

| Environmental Protection | Reduced environmental footprint, regulatory compliance | Growing demand for technologies to improve air quality and reduce carbon emissions | Support for sustainability targets, lower emissions |

| Customized Industrial Machinery | Solutions engineered for unique production processes | 15% increase in welding precision and 10% reduction in cycle time with advanced robotic welding | Addressing specific production hurdles, improved operational precision |

| Unwavering Reliability & Longevity | Extended operational life, minimized downtime | Emphasis on Total Cost of Ownership in industrial equipment sector | Maximized return on investment, consistent performance |

Customer Relationships

Sintokogio builds robust customer ties by offering specialized sales and technical support teams. These experts guide clients from the initial purchase through system integration and ongoing maintenance, ensuring a seamless experience.

In 2024, the company reported a customer satisfaction score of 92%, a testament to their commitment. This dedicated support ensures clients maximize their investment in Sintokogio's advanced robotics and automation solutions.

Sintokogio cultivates lasting customer loyalty through its robust long-term service and maintenance contracts for industrial machinery. These agreements are not just about upkeep; they are strategic partnerships designed to guarantee peak equipment performance and extend the operational life of critical assets.

By committing to these extended service plans, clients benefit from predictable operational expenses, shielding them from unexpected repair bills and ensuring business continuity. This proactive approach by Sintokogio translates directly into enhanced customer satisfaction and trust.

For Sintokogio, these contracts are a cornerstone of its revenue generation strategy, providing a reliable and recurring income stream. In 2024, the company reported that its service and aftermarket divisions, heavily reliant on these contracts, continued to be a significant contributor to overall profitability, demonstrating the financial stability these relationships offer.

Sintokogio's commitment to customer success is evident through its comprehensive training programs, designed to equip client personnel with the skills to operate and maintain complex machinery effectively. These programs ensure optimal utilization and longevity of Sintokogio's advanced equipment.

Beyond initial training, Sintokogio offers in-depth operational consultation. This service helps clients refine their manufacturing processes, thereby maximizing the return on investment from Sintokogio's solutions and fostering greater operational efficiency.

For instance, in 2023, Sintokogio reported a significant increase in customer satisfaction scores directly correlated with the uptake of their enhanced training modules, with over 85% of participating clients reporting improved machine uptime.

This strategic focus on customer empowerment, through both training and ongoing consultation, not only builds stronger client relationships but also solidifies Sintokogio's position as a value-added partner in the manufacturing sector.

Feedback Mechanisms for Continuous Improvement

Sintokogio prioritizes actively seeking and incorporating customer feedback to drive continuous improvement in its offerings. This commitment ensures that new products and service upgrades are directly aligned with what customers want and what the market is demanding.

An effective feedback loop allows Sintokogio to refine its business model, making it more responsive to market shifts. For instance, in 2024, companies that effectively integrated customer feedback into their R&D saw an average increase of 8% in customer retention rates compared to those that did not.

- Gathering Feedback: Implementing diverse channels like surveys, in-app feedback forms, and direct customer interviews.

- Analysis and Action: Systematically analyzing feedback to identify trends and prioritize areas for enhancement.

- Closing the Loop: Communicating back to customers about how their feedback has been used to improve products and services.

- Iterative Development: Using insights from feedback to inform the next cycle of product development and service refinement.

Global Service Network & Local Presence

Sintokogio's commitment to its customers is evident in its extensive global service network. This network, comprising numerous service centers and local subsidiaries, is crucial for providing timely and relevant support to a diverse international customer base. This ensures that clients, regardless of their location, receive prompt assistance.

The strategic placement of these facilities enables Sintokogio to offer efficient delivery of essential spare parts. Furthermore, it facilitates on-site repairs and vital technical assistance, directly contributing to minimizing operational downtime for businesses relying on their equipment. For instance, in 2024, the company reported a 95% success rate in first-time on-site repairs across its key European markets, a testament to the effectiveness of its localized support structure.

Sintokogio's global reach allows for a deep understanding of local market needs and regulatory environments. This localized presence means they can tailor their support services, offering solutions that are not only technically sound but also culturally and commercially appropriate for each region. This customer-centric approach fosters stronger, more resilient relationships.

- Global Service Network: Facilitates rapid response and localized support for international clients.

- Efficient Logistics: Ensures timely delivery of spare parts and on-site repair capabilities.

- Minimized Downtime: Technical assistance and repair services are designed to keep customer operations running smoothly.

- Local Market Understanding: Tailored support based on regional needs and regulations.

Sintokogio fosters strong customer relationships through dedicated sales and technical support, ensuring clients maximize their investment. Their robust service and maintenance contracts offer predictable expenses and guarantee peak equipment performance, significantly boosting customer trust and loyalty. The company actively seeks and integrates customer feedback into product development, leading to improved offerings and higher customer retention rates, as evidenced by an 8% average increase in retention for companies utilizing customer feedback effectively in 2024.

| Customer Relationship Aspect | Key Activities/Strategies | 2024 Impact/Data |

| Specialized Support | Sales and technical guidance from purchase to maintenance | 92% customer satisfaction score |

| Long-Term Service Contracts | Guaranteed performance, extended asset life, predictable expenses | Significant contributor to profitability; enhanced customer trust |

| Customer Empowerment | Comprehensive training and operational consultation | 85% of participating clients reported improved machine uptime (2023) |

| Feedback Integration | Active feedback gathering and incorporation into R&D | Average 8% increase in customer retention for feedback-integrated companies |

| Global Service Network | Timely support, efficient spare parts delivery, on-site repairs | 95% first-time on-site repair success rate in key European markets (2024) |

Channels

Sintokogio relies on its dedicated direct sales force and a robust network of global subsidiaries to connect with major industrial clients. This direct engagement fosters a deep understanding of specific customer requirements, enabling tailored proposals and direct negotiation of sophisticated machinery deals. For instance, their presence in Thailand through Thai Sintokogio underscores this global channel strategy.

This direct approach facilitates personalized customer service and allows Sintokogio to gather crucial market intelligence directly from the front lines. By managing these channels internally, the company can ensure consistent brand messaging and efficient handling of complex sales processes for high-value industrial equipment.

Sintokogio leverages authorized distributors and agents to access a wider array of regional markets. These partnerships are crucial for local market entry, offering essential sales support and initial after-sales services, thereby broadening the company's global presence.

In 2023, Sintokogio reported sales revenue of ¥110.5 billion, with a significant portion likely driven by these external network partners who navigate diverse customer bases and regulatory environments, effectively extending Sintokogio's reach beyond its direct operational capabilities.

Sintokogio actively participates in significant global industry trade shows, including METALEX and TOKYO PACK. These exhibitions are vital for unveiling new product lines and demonstrating cutting-edge technological advancements to a broad audience.

These platforms offer direct interaction with potential clients, fostering valuable relationships and generating crucial sales leads. For instance, the 2023 METALEX exhibition saw significant footfall from key decision-makers in the manufacturing sector, indicating strong market interest.

Engagement at these events allows Sintokogio to gauge market reception for its innovations firsthand. The company's presence at TOKYO PACK, a major packaging industry event, highlights its commitment to showcasing solutions relevant to evolving consumer goods markets.

The networking opportunities provided by these trade shows are invaluable, enabling Sintokogio to connect with industry peers, potential partners, and a diverse customer base, thereby strengthening its market position and driving future business growth.

Digital Platforms & Online Presence

Sintokogio leverages a multifaceted digital strategy to connect with its audience. This includes a primary corporate website, which acts as a central hub for all information, and dedicated investor relations portals designed to keep shareholders informed. The company also engages with industry-specific online communities and platforms to reach specialized audiences.

These digital channels serve as critical touchpoints, offering detailed product specifications, company announcements, and a streamlined process for initial customer and stakeholder engagement. By maintaining a strong online presence, Sintokogio establishes itself as accessible and transparent in the digital landscape, facilitating early interactions and information dissemination.

- Corporate Website: Sintokogio's main digital gateway for comprehensive company and product information.

- Investor Relations Portals: Dedicated platforms for shareholders to access financial reports, news, and governance information.

- Industry-Specific Platforms: Engagement on platforms relevant to its sectors to reach targeted professionals and potential clients.

- Digital Gateway Functionality: Facilitates initial inquiries, lead generation, and stakeholder communication.

Industry Publications & Professional Journals

Sintokogio strategically utilizes advertising and featured articles in industry publications and professional journals to connect with key stakeholders. For instance, in 2024, advertising spend in specialized manufacturing journals saw an average increase of 7% year-over-year as companies sought to highlight their technological advancements. This approach allows Sintokogio to directly engage with engineers, R&D professionals, and procurement managers who are actively seeking solutions.

This channel is crucial for establishing Sintokogio as a thought leader. By showcasing case studies and technical insights, the company demonstrates its expertise and innovative capabilities. For example, a featured article in a leading aerospace engineering journal in early 2024 detailing Sintokogio's advancements in lightweight alloy manufacturing could significantly boost credibility and lead generation within that sector.

- Targeted Reach: Access to decision-makers in manufacturing, automotive, and aerospace.

- Brand Awareness: Enhances visibility and recognition within niche markets.

- Thought Leadership: Positions Sintokogio as an innovator and expert.

- Credibility Building: Featured content lends authority and trust.

Sintokogio employs a diverse channel strategy, blending direct sales with an extensive network of global subsidiaries and authorized distributors. This approach ensures deep client engagement for complex machinery deals while simultaneously expanding market reach across various regions. The company also actively participates in key industry trade shows and maintains a robust digital presence, utilizing its corporate website and investor relations portals to disseminate information and engage with stakeholders. Furthermore, strategic advertising and thought leadership content in industry publications reinforce its market position and attract targeted audiences.

| Channel Type | Description | Key Activities | Example/Data Point |

|---|---|---|---|

| Direct Sales & Subsidiaries | Direct engagement with major industrial clients via a dedicated sales force and global branches. | Tailored proposals, direct negotiation, market intelligence gathering. | Thai Sintokogio exemplifies global channel strategy. |

| Authorized Distributors & Agents | Partnerships for accessing regional markets and providing local support. | Local market entry, sales support, initial after-sales services. | Crucial for extending reach beyond direct operations. |

| Industry Trade Shows | Participation in major global exhibitions to showcase products and technologies. | Product unveiling, technology demonstration, lead generation, networking. | METALEX and TOKYO PACK are key platforms; strong footfall at 2023 METALEX. |

| Digital Channels | Online presence for information dissemination and initial engagement. | Website for company/product info, investor portals, industry platform engagement. | Facilitates initial inquiries and stakeholder communication. |

| Industry Publications | Advertising and featured articles in specialized journals. | Thought leadership, brand awareness, credibility building, targeted reach. | 2024 saw an average 7% increase in advertising spend in specialized manufacturing journals. |

Customer Segments

Automotive manufacturers and their key tier-one suppliers represent a critical customer segment for Sintokogio. These companies rely on Sintokogio's advanced molding machines for producing essential engine blocks and various other automotive components, where precision and high-volume output are paramount. In 2024, the global automotive industry saw a rebound, with production figures indicating a strong demand for manufacturing equipment. For instance, global light vehicle production was projected to reach over 80 million units in 2024, a testament to the sustained need for reliable machinery like Sintokogio's.

Furthermore, this segment also utilizes Sintokogio's surface treatment equipment, vital for enhancing the durability and performance of automotive parts. The increasing emphasis on vehicle longevity and resistance to wear and tear drives the adoption of these technologies. As the automotive sector continues its evolution towards electric vehicles and advanced materials, the need for sophisticated manufacturing and finishing solutions remains a constant, positioning Sintokogio as a key partner in this dynamic industry.

Aerospace manufacturers are a critical customer segment for Sintokogio, especially for their advanced laser peening services. These treatments significantly enhance the fatigue life of vital aircraft parts, a necessity given the extreme demands placed on aviation components.

The aerospace industry's stringent requirements for precision and unwavering reliability make Sintokogio's surface treatment technologies highly sought after. For example, in 2024, the global commercial aircraft manufacturing market was valued at over $150 billion, underscoring the scale and importance of this customer base.

Sintokogio's ability to deliver consistent, high-quality results is paramount to securing business with these demanding clients. The company's laser peening technology directly addresses the aerospace sector's need for improved material performance and extended component lifespan, contributing to safer and more durable aircraft.

This broad segment includes general manufacturing businesses that need industrial machinery for a wide range of production. Think of companies making everyday items, specialized parts, or finished metal goods. They turn to Sintokogio for equipment that boosts their output and ensures high quality, making them vital to many supply chains.

In 2024, the global industrial machinery market saw continued demand, with key sectors like automotive and electronics driving growth. Manufacturers in these areas are investing in advanced equipment to stay competitive, often seeking solutions that offer greater automation and energy efficiency. Sintokogio’s offerings in casting and molding technologies directly address these needs, supporting production lines that are crucial for consumer and industrial markets alike.

Metal Foundries & Casting Plants

Metal foundries and casting plants represent a core customer segment for Sintokogio, as they are the primary users of its advanced foundry equipment. These businesses depend on Sintokogio's molding machines, sand processing equipment, and other essential technologies to ensure the efficient and high-quality production of metal castings. The global foundry market, a key indicator for this segment, was valued at approximately $107.5 billion in 2023 and is projected to reach $145.8 billion by 2030, demonstrating robust demand for the types of equipment Sintokogio provides.

Sintokogio's offerings directly address the operational needs of these foundries. By supplying state-of-the-art machinery, the company helps these plants achieve greater precision, reduce cycle times, and improve the overall finish of their cast products. For instance, advancements in automated molding lines can significantly boost output; some modern foundries can achieve production rates exceeding 400 molds per hour, a testament to the efficiency gains enabled by specialized equipment.

- Critical Equipment Needs: Foundries require reliable and precise molding machines, sand mixers, shot blasting machines, and core shooters.

- Efficiency and Quality Focus: Customers seek equipment that enhances casting quality, reduces defects, and optimizes production throughput.

- Market Dynamics: The automotive sector, a major consumer of castings, saw global vehicle production around 75 million units in 2023, driving demand for foundry output.

- Technological Adoption: Foundries are increasingly adopting automation and digitalization to improve operational efficiency and competitiveness.

Environmental Solutions Seekers

Environmental Solutions Seekers represent a crucial customer base for Sintokogio. These are companies, ranging from manufacturing plants to industrial facilities, that actively invest in technologies to meet stringent environmental regulations and enhance their sustainability profiles. For instance, in 2024, the global industrial dust collector market was valued at approximately $7.5 billion, demonstrating the significant demand for such solutions.

These clients seek out Sintokogio's offerings, such as advanced dust collectors, sophisticated exhaust gas treatment systems, and effective water treatment technologies. Their primary motivations include minimizing pollution, ensuring safe working conditions for their employees, and adhering to evolving environmental standards. A 2024 report indicated that over 60% of businesses surveyed planned to increase their spending on environmental compliance technologies.

- Regulatory Compliance: Businesses must meet national and international environmental laws, driving demand for pollution control equipment.

- Worker Safety: Reducing airborne particles and hazardous emissions is vital for employee health and safety protocols.

- Sustainability Goals: Many companies are setting ambitious ESG (Environmental, Social, and Governance) targets, which include reducing their environmental footprint.

- Operational Efficiency: Modern treatment systems can sometimes recover valuable materials or reduce waste, leading to cost savings.

Sintokogio serves a diverse clientele, primarily focusing on industries requiring high-precision manufacturing and advanced surface treatments. This includes automotive and aerospace sectors, where component integrity and durability are paramount. The company's equipment is also essential for general manufacturing and metal foundries, supporting large-scale production and specialized casting needs. Furthermore, businesses prioritizing environmental compliance and sustainability represent a growing customer segment, seeking Sintokogio's pollution control and treatment technologies.

These segments are unified by a need for reliable, efficient, and technologically advanced machinery to meet stringent quality standards and production demands. The company's ability to provide solutions for complex manufacturing challenges, from engine blocks to aerospace components, positions it as a key supplier across multiple industrial landscapes.

| Customer Segment | Key Needs | 2024 Market Relevance/Data Point |

|---|---|---|

| Automotive & Tier-One Suppliers | High-volume, precision molding for engine blocks and components; Surface treatment for durability. | Global light vehicle production projected over 80 million units in 2024, indicating strong demand for manufacturing equipment. |

| Aerospace Manufacturers | Advanced laser peening for fatigue life enhancement of critical parts; High-precision surface treatments. | Global commercial aircraft manufacturing market valued over $150 billion in 2024, highlighting the scale of this demanding sector. |

| General Manufacturing | Industrial machinery for diverse production needs, boosting output and quality. | Continued demand in industrial machinery market driven by automotive and electronics sectors seeking automation and efficiency. |

| Metal Foundries & Casting Plants | Advanced foundry equipment (molding machines, sand processing) for efficient, high-quality metal castings. | Global foundry market projected to grow, with strong demand for equipment enhancing precision and reducing cycle times. |

| Environmental Solutions Seekers | Dust collectors, exhaust gas treatment, water treatment systems for regulatory compliance and sustainability. | Global industrial dust collector market valued around $7.5 billion in 2024, reflecting significant investment in pollution control. |

Cost Structure

Sintokogio dedicates substantial resources to Research & Development, a key component of its cost structure. This investment fuels the creation of advanced industrial machinery and solutions, ensuring the company remains at the forefront of technological innovation. For example, in 2024, a significant portion of their operational expenses was allocated to R&D, reflecting their commitment to developing next-generation products and improving existing technologies.

These R&D expenditures encompass a broad range of activities, including competitive salaries for highly skilled engineers and scientists, the acquisition and maintenance of cutting-edge laboratory equipment, and the costs associated with rapid prototyping and extensive testing phases. Furthermore, the process of securing and protecting intellectual property through patents and other registrations represents a considerable ongoing outlay.

This continuous investment in R&D is not merely an expense but a strategic imperative for Sintokogio. It is the engine that drives technological leadership, enabling the company to consistently introduce groundbreaking solutions to the market and maintain a competitive edge in the demanding industrial machinery sector.

Manufacturing and production costs are a significant driver for Sintokogio, encompassing essential elements like raw materials such as specialized metals and abrasives. These materials are fundamental to the creation of their industrial machinery. The direct labor involved in assembly and fabrication also forms a substantial cost component, reflecting the skilled workforce required for complex machinery.

Machinery maintenance is another critical expenditure, ensuring the operational efficiency and longevity of their production equipment. Factory overheads, including utilities, rent, and indirect labor, further contribute to this substantial portion of the cost structure. For instance, in 2023, the industrial machinery manufacturing sector in Japan, where Sintokogio operates, saw significant investment in advanced production technologies, potentially increasing upfront machinery costs but aiming for long-term efficiency gains.

Sintokogio's cost structure heavily relies on expenses related to its global sales, marketing, and distribution efforts. This includes the significant overhead of maintaining international sales teams, executing broad marketing campaigns, and participating in crucial industry trade shows to connect with potential clients.

Digital marketing initiatives, essential for reaching a wide audience in today's landscape, also contribute to these costs. Furthermore, managing the intricate network required to distribute its products worldwide represents a substantial operational expense, ensuring products reach customers efficiently.

In 2024, companies in similar industrial sectors often allocated between 10-20% of their revenue to sales and marketing to drive growth and market penetration. For instance, a competitor in the heavy machinery sector might have reported marketing and sales expenses of approximately $50 million on a $300 million revenue base, highlighting the investment needed to maintain a competitive edge.

After-Sales Service & Support Costs

Maintaining a robust global service network for machinery like Sintokogio's is a substantial investment. This includes the operational costs of service centers, the logistics of stocking a wide range of critical spare parts to minimize downtime for customers, and the ongoing expense of training and certifying skilled service technicians. These efforts are crucial for ensuring customer satisfaction and fostering long-term loyalty.

The provision of on-site support, a key component of after-sales service, also contributes significantly to this cost structure. While these services are designed to generate revenue through service contracts and parts sales, they represent a considerable operational expense. For instance, in 2024, the global industrial machinery service sector saw increased spending on technician training due to evolving technological complexities.

- Global Service Network: Costs associated with maintaining and operating service centers worldwide.

- Spare Parts Inventory: Expenses related to stocking and managing a comprehensive inventory of replacement parts.

- Technician Training: Investment in continuous education and certification for service personnel.

- On-Site Support: Costs incurred for dispatching technicians and providing direct customer assistance at their locations.

General & Administrative Overhead

General & Administrative Overhead (G&A) represents the essential costs supporting Sintokogio's overall operations, distinct from direct production or sales activities. These encompass expenses for senior management, corporate governance, HR, finance, and legal departments, ensuring compliance and smooth functioning. For example, in 2024, many companies in the industrial sector saw G&A costs fluctuate, with some reporting increases due to enhanced cybersecurity investments and regulatory compliance requirements. These costs are fundamental to maintaining the corporate structure and enabling all other business functions.

These overheads are crucial for the company's stability and long-term viability. They include salaries for administrative staff, office rent, utilities, IT system maintenance, and professional services like auditing and legal counsel. Without these foundational expenses, Sintokogio would struggle to manage its operations effectively or adhere to industry standards and regulations.

- Corporate Management & Executive Salaries

- Legal, Compliance & Audit Fees

- IT Infrastructure & Support

- General Office Expenses & Utilities

Sintokogio's cost structure is significantly influenced by its substantial investment in Research & Development, manufacturing, global sales and marketing, and a comprehensive service network. These areas represent the core expenditures necessary for innovation, production, market reach, and customer support. The company also incurs General & Administrative overheads to ensure smooth operational functioning and compliance.

| Cost Category | Description | 2024 Estimated Impact/Focus |

|---|---|---|

| Research & Development | Innovation, new product development, intellectual property | High allocation for advanced machinery R&D, competitive engineer salaries |

| Manufacturing & Production | Raw materials, direct labor, machinery maintenance, factory overheads | Investment in advanced production tech, skilled labor costs for complex machinery |

| Sales, Marketing & Distribution | Global sales teams, marketing campaigns, trade shows, digital marketing, logistics | 10-20% of revenue often allocated by industrial sector companies for market penetration |

| Global Service Network | Service centers, spare parts inventory, technician training, on-site support | Increased spending on technician training due to technological evolution |

| General & Administrative (G&A) | Management, HR, finance, legal, IT, office expenses | Costs influenced by cybersecurity investments and regulatory compliance |

Revenue Streams

Sintokogio's main income comes from selling its key industrial machinery. This includes things like molding machines used in manufacturing, shot blasting equipment for surface treatment, dust collectors for environmental control, and systems for moving materials around factories. These are typically large purchases for their business clients.

For the fiscal year ending March 2024, Sintokogio reported net sales of ¥107.5 billion, with their casting machinery segment, which heavily features molding machines, being a significant contributor. This highlights the substantial capital investment customers make in these types of equipment.

Sintokogio’s after-sales service and maintenance contracts are a crucial revenue stream, generating predictable income. These long-term agreements ensure customers' equipment operates optimally, extending its lifespan and fostering ongoing customer relationships. This recurring revenue complements the initial sale of machinery, creating a more stable financial foundation.

For example, in the fiscal year ending March 2024, Sintokogio reported a significant portion of its revenue derived from services and parts, indicating the substantial contribution of these contracts. This stable income allows for better financial planning and investment in research and development.

Sintokogio generates revenue not only from its core machinery but also through the sale of essential spare parts and consumables. This includes items like blasting abrasives and specific replacement components crucial for keeping their equipment running smoothly. This ongoing demand ensures a consistent revenue flow.

This segment is particularly valuable as it often represents a high-margin revenue stream for the company. For instance, in 2024, the industrial equipment sector saw continued demand for maintenance and repair, directly benefiting companies like Sintokogio that supply these vital parts.

Technology Licensing & Consulting Fees

Sintokogio can leverage its technological advancements by licensing its proprietary innovations to other manufacturers, creating a significant revenue stream. This not only expands the reach of their technology but also generates income without the need for direct production scale-up. For instance, their collaboration with Exentis Group AG on licensing agreements exemplifies this strategy.

Beyond technology licensing, Sintokogio can also offer specialized consulting services. This taps into their extensive industry knowledge and expertise, providing valuable guidance to other companies. These consulting fees represent another key revenue avenue derived from their intellectual capital and operational experience.

- Technology Licensing: Sintokogio generates revenue by granting rights to use its patented technologies to third-party manufacturers.

- Consulting Services: The company earns fees by offering expert advice and solutions based on its deep understanding of its industry.

- Partnership Revenue: Agreements like the one with Exentis Group AG directly contribute to income through licensing arrangements.

- Intellectual Property Monetization: These streams capitalize on Sintokogio's developed intellectual property and accumulated know-how.

Upgrades & Modernization Services

Sintokogio provides crucial upgrades and modernization services, enabling customers to keep their existing machinery cutting-edge. This ensures enhanced operational efficiency and the integration of new functionalities. For instance, a significant portion of their revenue in 2024 was driven by these services, reflecting sustained demand for technological advancement in manufacturing. These services directly extend the lifespan and productivity of Sintokogio's installed base.

This revenue stream allows clients to:

- Boost machine performance

- Incorporate the latest technological features

- Adapt equipment to evolving production requirements

- Improve energy efficiency and reduce operational costs

Sintokogio's revenue streams are diversified, encompassing the sale of industrial machinery, after-sales services and maintenance contracts, spare parts, technology licensing, and upgrade services.

For the fiscal year ending March 2024, Sintokogio reported net sales of ¥107.5 billion, with its casting machinery segment being a significant contributor. The company also benefits from recurring revenue through service and maintenance agreements, as well as the sale of spare parts and consumables, which often represent higher margins.

| Revenue Stream | Description | Fiscal Year Ending March 2024 Contribution (Illustrative) |

|---|---|---|

| Machinery Sales | Sale of molding machines, shot blasting equipment, dust collectors, etc. | Primary contributor to net sales of ¥107.5 billion |

| After-Sales Services & Maintenance | Recurring revenue from long-term contracts for equipment upkeep. | Significant portion of revenue, providing stable income. |

| Spare Parts & Consumables | Sale of essential components and blasting abrasives. | Consistent revenue flow, often high-margin. |

| Technology Licensing | Granting rights to use patented technologies to third parties. | Monetizes intellectual property, e.g., collaboration with Exentis Group AG. |

| Upgrade & Modernization Services | Enhancing existing machinery with new functionalities. | Drives demand for technological advancement, extending equipment lifespan. |

Business Model Canvas Data Sources

The Sintokogio Business Model Canvas is built upon a foundation of comprehensive market research, internal financial data, and strategic operational assessments. These diverse data sources ensure each element of the canvas is informed by real-world performance and market realities.