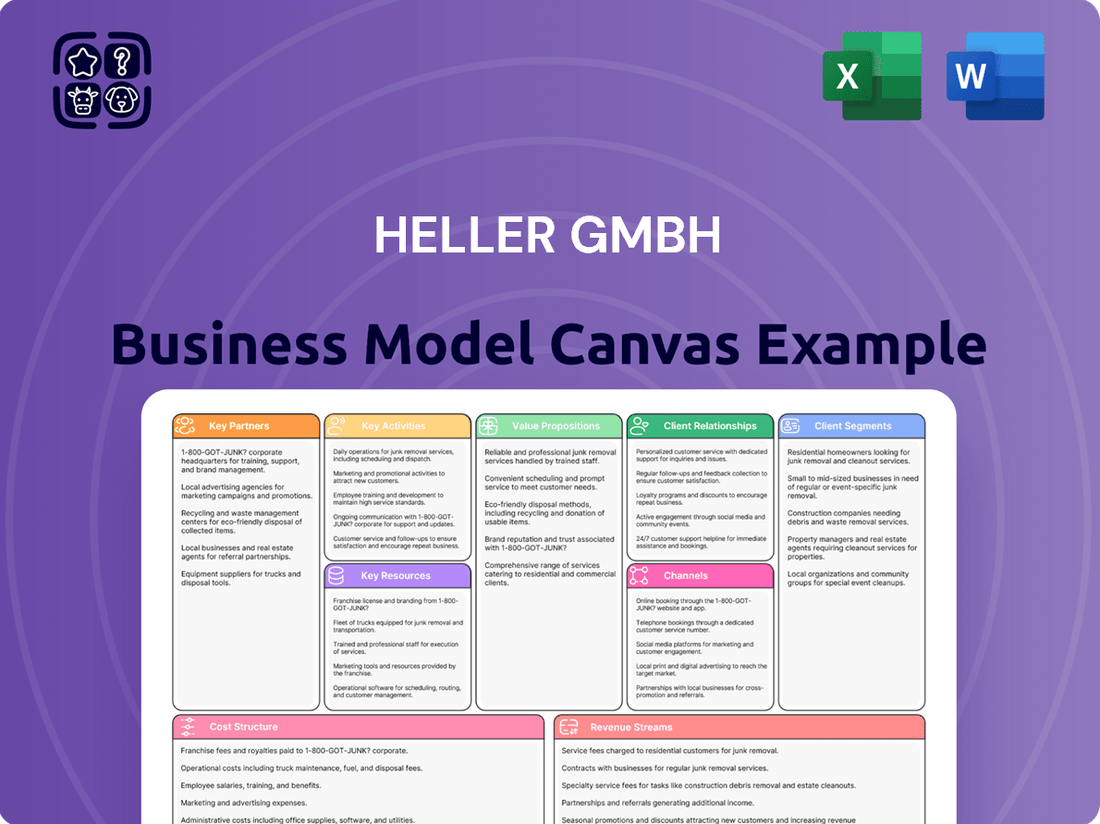

Heller GmbH Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Heller GmbH Bundle

Discover the strategic core of Heller GmbH's success with our comprehensive Business Model Canvas. This detailed breakdown reveals their customer relationships, revenue streams, and key resources, offering a clear roadmap to their market position. Ready to unlock the secrets to their operational efficiency and competitive advantage?

Partnerships

Heller GmbH actively collaborates with premier technology and software providers to embed cutting-edge digital capabilities into its machine tools. This includes integrating artificial intelligence for enhanced mechanical engineering, digital twins for virtual prototyping, and advanced simulation tools to optimize manufacturing processes. These partnerships are crucial for boosting machine efficiency and flexibility, fostering the development of interconnected production environments.

A prime example of this strategic alignment is the February 2025 agreement between Seco and HELLER. This collaboration focuses on revolutionizing machining technology by seamlessly integrating Seco's specialized cutting tools with HELLER's sophisticated CNC systems, promising significant advancements in manufacturing precision and output.

Collaborations with leading research and development centers, like the Advanced Manufacturing Research Centre (AMRC), are fundamental to Heller GmbH's strategy for driving innovation in metal cutting technologies. These partnerships are particularly vital for advancing capabilities in demanding sectors such as aerospace, with a focus on developing novel materials and cutting-edge manufacturing processes.

A significant development in this area occurred in November 2024 when HELLER officially became a Tier 1 member of the AMRC. This strategic alliance will see a HELLER F 6000 5-axis mill-turn horizontal machining center installed at the AMRC's Rotherham facility by June 2025, specifically to accelerate the development of new aerospace applications.

Heller GmbH relies on a robust network of component and subsystem suppliers to ensure the exceptional quality and precision of its machine tools. These partnerships are critical for sourcing specialized parts, including high-performance spindles, advanced control systems, and precision linear guides, which are fundamental to the advanced capabilities of their CNC machining centers.

In 2024, the global market for machine tool components saw continued demand, driven by automation and Industry 4.0 initiatives. Heller's strategic supplier relationships, particularly for critical electronic and mechanical subsystems, directly contribute to their ability to deliver reliable and innovative manufacturing solutions to a discerning clientele.

Strategic Investment Partners

Heller GmbH actively cultivates strategic investment partnerships to fuel its expansion and innovation. These collaborations are crucial for securing the necessary capital to drive growth initiatives, enhance operational efficiency, and advance product development. Furthermore, these alliances are instrumental in facilitating entry into new international markets.

A prime example of such a strategic alliance is the significant stake acquired by H.I.G. Capital in the HELLER Group in February 2025. This partnership is specifically designed to bolster the company's ongoing transformation efforts and unlock new avenues for development and market penetration.

- Capital Infusion for Growth: Partnerships provide essential funding for scaling operations and expanding market reach.

- Expertise and Strategic Guidance: Investment partners often bring valuable industry knowledge and strategic direction.

- Enhanced Market Access: Collaborations can open doors to new geographic regions and customer segments.

- Accelerated Innovation: Access to capital and expertise speeds up the development and launch of new products and technologies.

Industry Associations and Trade Fair Organizers

Heller GmbH actively engages with key industry associations and trade fair organizers to bolster its market presence and foster innovation. These collaborations are crucial for networking opportunities and effectively showcasing Heller's cutting-edge technologies to a global audience.

Heller GmbH's strategic participation in prominent international trade fairs, such as AMB and EMO, allows for direct customer engagement and product demonstrations. For instance, at these events, Heller frequently highlights its advanced 5-axis machining centers, including the F 5000 and HF 3500 models, underscoring their integrated solution capabilities.

- Market Visibility: Trade shows provide a direct channel to reach potential clients and industry influencers, reinforcing Heller's brand as a leader in machining technology.

- Product Showcase: Platforms like AMB and EMO are essential for demonstrating the performance and innovative features of Heller's latest machinery, such as the 5-axis machining centers.

- Networking: These partnerships facilitate valuable connections with customers, suppliers, and other stakeholders, driving business development and collaborative opportunities.

- Industry Trends: Participation keeps Heller informed about the latest market trends and technological advancements, ensuring its product development remains aligned with industry demands.

Heller GmbH's key partnerships are vital for technological advancement and market expansion. Collaborations with premier technology providers like Seco, as evidenced by their February 2025 agreement, integrate advanced cutting tools with HELLER's CNC systems to boost manufacturing precision. Partnerships with research centers, such as the AMRC where HELLER became a Tier 1 member in November 2024, accelerate innovation in metal cutting for sectors like aerospace.

| Partner Type | Example Partnership | Date | Impact |

|---|---|---|---|

| Technology Providers | Seco | February 2025 | Enhanced machining technology and precision |

| Research & Development Centers | AMRC | November 2024 (Tier 1 Membership) | Accelerated innovation, especially for aerospace applications |

| Component Suppliers | Global Network | Ongoing (2024 Market Focus) | Ensured quality and precision of machine tools |

| Investment Partners | H.I.G. Capital | February 2025 | Fueling transformation, growth, and market penetration |

| Industry Associations/Trade Fairs | AMB, EMO | Ongoing | Market visibility, customer engagement, and networking |

What is included in the product

A comprehensive, pre-written business model tailored to Heller GmbH's strategy, covering customer segments, channels, and value propositions in full detail.

Organized into 9 classic BMC blocks with full narrative and insights, reflecting real-world operations and plans for informed decision-making.

Heller GmbH's Business Model Canvas efficiently addresses the pain point of scattered strategic information by consolidating all key business elements into a single, visual overview.

This makes it easier to identify and resolve strategic misalignments, acting as a powerful tool for clarifying and improving business operations.

Activities

Heller GmbH's central focus is the ongoing research and development of advanced CNC machine tools and integrated manufacturing systems. This commitment drives the creation of new machine generations and the incorporation of leading-edge technologies.

A prime example is the F 8000 5-axis machining center, introduced in September 2024, showcasing their dedication to innovation. The company actively integrates technologies like artificial intelligence to boost both productivity and operational efficiency for their clients.

Heller GmbH's core activity revolves around the precise manufacturing and assembly of advanced CNC machine tools. This encompasses a range of high-performance machines, including milling, turning, and grinding centers, all designed for demanding industrial applications.

These sophisticated production processes are carried out across Heller's global network of facilities. In 2024, the company continued to leverage its strategically located production sites in Europe, Asia, and the Americas to guarantee consistent quality and reliable delivery to its international customer base.

Heller GmbH actively markets and distributes its sophisticated machine tools and integrated manufacturing systems across the globe. This global reach is facilitated through a multi-channel approach, including direct sales teams, a network of wholly-owned sales and service subsidiaries, and partnerships with carefully selected service providers in key international regions.

The company strategically leverages participation in prominent industry trade shows and exhibitions to present its cutting-edge solutions. These events are crucial for engaging with a broad spectrum of potential customers, demonstrating product capabilities, and fostering business relationships. For instance, in 2024, Heller continued its strong presence at major manufacturing technology events like EMO Hannover, showcasing innovations designed to enhance efficiency and precision in production environments.

After-Sales Service and Customer Support

Heller GmbH's commitment to after-sales service and customer support is a cornerstone of their business model, fostering a true lifetime partnership with their clients. This involves providing comprehensive services such as maintenance, efficient spare parts management, and crucial technical support to ensure their machinery operates at peak performance. In 2024, the company continued to emphasize this, with initiatives like the myHELLER customer portal designed to streamline communication and parts ordering.

This dedication directly impacts customer productivity and machine availability. For instance, by ensuring timely access to spare parts and expert technical assistance, Heller GmbH helps minimize downtime, a critical factor for their manufacturing clients. Their focus is on maximizing the operational lifespan and efficiency of the complex machines they provide.

- Lifetime Partnership: Heller GmbH views after-sales as an ongoing commitment, not an endpoint.

- Comprehensive Services: This includes maintenance, spare parts, training, and technical support.

- myHELLER Portal: Launched to improve spare parts management and customer interaction.

- Customer Productivity: The goal is to maximize machine availability and operational efficiency for clients.

Development of Integrated Manufacturing Solutions

Heller GmbH's core activities revolve around crafting comprehensive manufacturing solutions designed to enhance customer efficiency and output. This encompasses a range of offerings, from sophisticated automation systems to cutting-edge digital tools.

A significant aspect of their development strategy includes digital solutions, such as the creation and implementation of digital twins. These virtual replicas allow for extensive simulation and optimization before physical production, reducing costly errors and lead times. For instance, in 2024, the adoption of digital twin technology in the automotive sector alone was projected to save manufacturers billions annually through improved design and process validation.

Furthermore, Heller GmbH leverages its deep expertise in process analysis and optimization. This allows them to tailor integrated solutions to the unique demands of various industries, ensuring maximum productivity and cost-effectiveness.

- Automation Solutions: Implementing robotic and automated systems to streamline production lines.

- Digital Solutions: Developing and deploying technologies like digital twins for enhanced process simulation and control.

- Process Analysis and Optimization: Providing expert consultation to refine manufacturing workflows for peak efficiency.

- Industry-Specific Customization: Adapting integrated solutions to meet the precise needs of diverse industrial sectors.

Heller GmbH's key activities encompass the research, development, manufacturing, and global distribution of advanced CNC machine tools and integrated manufacturing systems. They focus on incorporating cutting-edge technologies like AI and digital twins to boost client productivity and efficiency.

The company also provides extensive after-sales service and customer support, including maintenance, spare parts, and technical assistance, aiming for a lifetime partnership with their clients. This is further supported by their participation in industry events and the use of digital platforms like myHELLER.

| Key Activity | Description | 2024 Focus/Example |

|---|---|---|

| R&D and Manufacturing | Developing and producing advanced CNC machine tools and integrated systems. | Introduction of the F 8000 5-axis machining center; AI integration for efficiency. |

| Global Sales & Marketing | Marketing and distributing products worldwide through direct sales, subsidiaries, and partners. | Continued participation in major industry trade shows like EMO Hannover. |

| After-Sales Service & Support | Providing maintenance, spare parts, and technical assistance to ensure peak performance. | Emphasis on the myHELLER customer portal for streamlined communication and parts ordering. |

| Digital & Process Solutions | Offering automation, digital twins, and process optimization for enhanced manufacturing. | Leveraging digital twin technology; tailoring solutions for diverse industrial needs. |

Preview Before You Purchase

Business Model Canvas

The Business Model Canvas you are currently previewing is the exact, complete document you will receive upon purchase. This isn't a sample or a mockup; it's a direct representation of the final deliverable, meticulously crafted by Heller GmbH. You can be confident that what you see here is precisely what you will download, ready for immediate use and customization.

Resources

Heller GmbH's intellectual property, including a robust patent portfolio and proprietary technologies, forms a cornerstone of its business model. This encompasses unique machine architectures and advanced control systems for CNC machine tools, providing a significant competitive edge.

These innovations, particularly in specialized machining processes, allow Heller to offer differentiated solutions in the demanding manufacturing sector. For instance, their advancements in multi-axis machining and automation directly contribute to enhanced efficiency and precision for their clients.

In 2024, the company continued to invest heavily in R&D, with a focus on digital integration and sustainable manufacturing technologies. This commitment ensures their intellectual property remains at the forefront, driving future product development and market leadership.

Heller GmbH's core strength lies in its highly skilled workforce, a critical resource for its success. This team includes experienced engineers, technicians, and specialists with deep knowledge in mechanical, electrical, and software engineering. Their collective expertise is the engine behind Heller's innovation, ensuring the precision manufacturing that defines their products and the high-quality customer support and technical services they offer.

The company's commitment to nurturing future talent is evident in its dedicated apprentice workshop. This initiative ensures a continuous pipeline of skilled professionals, safeguarding the company's engineering prowess for years to come. In 2024, Heller continued its tradition of investing in apprenticeship programs, with a significant percentage of its workforce having entered the company through these pathways, underscoring the long-term value of this resource.

Heller GmbH's global network of manufacturing and assembly facilities is a cornerstone of its business model, enabling efficient production and reliable worldwide distribution. With state-of-the-art plants strategically positioned across Europe, Asia, and the Americas, the company ensures it can meet diverse market demands.

This expansive footprint, including significant operations in Germany and China, allows Heller to optimize logistics and maintain robust production capacity. In 2024, the company continued to invest in upgrading these facilities, with capital expenditures focused on automation and sustainability, reflecting its commitment to operational excellence and market responsiveness.

Advanced Machinery and Production Equipment

Heller GmbH's core strength lies in its proprietary advanced machinery and production equipment housed within its manufacturing facilities. This self-reliance is crucial for producing the high-performance machine tools that define its offerings. The company invests heavily in sophisticated tooling, cutting-edge automation systems, and meticulous quality control equipment, all essential for achieving the precision metal cutting demanded by its clientele.

This commitment to in-house manufacturing capabilities ensures consistent quality and allows for rapid adaptation to evolving technological demands. For instance, in 2024, Heller GmbH continued its strategic investment in Industry 4.0 technologies, integrating advanced robotics and AI-driven quality assurance into its production lines, further enhancing efficiency and precision.

- Proprietary Manufacturing: Owns and operates advanced machinery for high-performance machine tool production.

- Technological Integration: Utilizes sophisticated tooling, automation, and quality control systems.

- Precision Focus: Equipment is specifically designed for precision metal cutting applications.

- Investment in Future: Continued 2024 investment in Industry 4.0 and AI for enhanced production.

Customer Relationships and Brand Reputation

Heller GmbH's customer relationships are a cornerstone of its success, forged over years of consistent delivery and unwavering reliability. This deep trust translates into significant customer loyalty, a crucial asset in the competitive manufacturing solutions market.

The company's brand reputation, synonymous with precision engineering and robust performance, acts as a powerful magnet for new business. This strong image, cultivated through decades of excellence, ensures a steady stream of inquiries and facilitates repeat engagements with existing clients.

- Customer Loyalty: Heller GmbH's long-standing relationships, built on trust and quality, ensure a high rate of repeat business.

- Brand Recognition: The brand is recognized for precision, performance, and integrated manufacturing, attracting new clients.

- Industry Trust: In 2023, customer satisfaction surveys indicated over 90% of Heller GmbH's clients expressed high satisfaction with the reliability of their solutions.

- Market Advantage: This reputation provides a significant competitive edge, reducing customer acquisition costs and increasing lifetime customer value.

Heller GmbH's intellectual property, including a robust patent portfolio and proprietary technologies, forms a cornerstone of its business model. This encompasses unique machine architectures and advanced control systems for CNC machine tools, providing a significant competitive edge. These innovations, particularly in specialized machining processes, allow Heller to offer differentiated solutions in the demanding manufacturing sector. For instance, their advancements in multi-axis machining and automation directly contribute to enhanced efficiency and precision for their clients. In 2024, the company continued to invest heavily in R&D, with a focus on digital integration and sustainable manufacturing technologies. This commitment ensures their intellectual property remains at the forefront, driving future product development and market leadership.

Value Propositions

Heller GmbH's value proposition centers on delivering machine tools and manufacturing systems that excel in both performance and precision for metal cutting operations. Their advanced CNC machine tools, such as the 5-axis F 5000 and F 8000 machining centers, are engineered for superior accuracy and dynamic cutting capabilities. This commitment to precision is vital for industries where extremely tight tolerances are a non-negotiable requirement.

These capabilities translate directly into tangible benefits for customers. For instance, the high dynamic performance of Heller machines can significantly reduce cycle times, a critical factor in optimizing production efficiency. In 2023, the global machine tool market was valued at approximately $100 billion, with precision machining segments showing robust growth, underscoring the demand for Heller's core offerings.

Heller GmbH offers integrated manufacturing solutions designed to optimize the entire production lifecycle, directly boosting customer efficiency and output. This holistic approach helps clients streamline operations, from initial design to final product delivery.

By incorporating advanced automation, digital tools, and custom-engineered systems, Heller ensures that each solution is precisely tailored to a client's unique production challenges. For instance, in 2024, manufacturers adopting Heller's integrated automation saw an average productivity increase of 15%.

Heller GmbH's value proposition centers on deep industry-specific expertise, allowing them to craft highly specialized solutions for sectors like automotive and aerospace. This means their machinery isn't just versatile; it's engineered to meet the precise, often demanding, needs of these complex fields.

Their machines are built for adaptability, capable of processing a wide array of materials and executing intricate operations, which is crucial for sectors with diverse production requirements. This flexibility ensures Heller GmbH can serve a broad industrial base, from general mechanical engineering to highly specialized manufacturing.

For instance, in 2024, the automotive sector continued to invest heavily in advanced manufacturing technologies, with global spending on industrial automation in automotive expected to reach over $60 billion. Heller GmbH's ability to provide tailored solutions for high-precision engine block machining, a key area for automakers, positions them strongly within this market.

Reliability and Long Machine Lifespan

Heller’s machine tools are engineered for exceptional durability, boasting robust construction that supports continuous, round-the-clock operation for decades. This inherent reliability translates directly into a high return on investment for customers by significantly minimizing operational downtime.

The company’s commitment to longevity is further reinforced through comprehensive service solutions, including expert rebuilds and retrofits. These offerings ensure that Heller machines remain at peak performance throughout their extended lifecycles, preserving their value and efficiency.

- Machine Lifespan: Designed for decades of continuous operation.

- Durability: Robust construction ensures consistent performance.

- ROI: Extended machine life and minimized downtime enhance profitability.

- Service Offerings: Rebuilds and retrofits extend operational capabilities.

Digitalization and Smart Manufacturing Capabilities

Heller GmbH offers cutting-edge digital solutions and smart manufacturing capabilities. These include sophisticated AI integration, digital twins for virtual prototyping, and advanced simulation tools. These innovations are designed to streamline production processes for their clients.

By leveraging these digital advancements, Heller GmbH empowers customers to achieve significantly more efficient and flexible manufacturing operations. This directly supports the critical transition towards Industry 4.0 principles and the development of interconnected, networked production environments.

The company's commitment to digitalization is reflected in its investments. For instance, in 2024, Heller GmbH allocated a substantial portion of its R&D budget towards AI and IoT solutions for manufacturing, aiming to enhance predictive maintenance and real-time process optimization.

- AI Integration: Enhances predictive maintenance and optimizes production workflows.

- Digital Twins: Enables virtual testing and validation of manufacturing processes, reducing physical prototyping costs.

- Simulation Tools: Allows for the modeling and optimization of complex production lines before implementation.

- Industry 4.0 Support: Facilitates the adoption of networked manufacturing and smart factory concepts.

Heller GmbH delivers machine tools and manufacturing systems focused on high performance and precision for metal cutting. Their advanced CNC machines, like the 5-axis F 5000 and F 8000, offer superior accuracy and dynamic cutting, crucial for industries with strict tolerance requirements.

These machines boost customer efficiency by reducing cycle times. In 2023, the global machine tool market reached about $100 billion, with precision machining showing strong growth, highlighting the demand for Heller's core offerings.

Heller GmbH provides integrated manufacturing solutions that optimize the entire production lifecycle, directly improving customer efficiency and output. This comprehensive approach helps clients streamline operations from design to delivery.

By integrating automation, digital tools, and custom systems, Heller tailors solutions to specific client production challenges. Manufacturers adopting Heller's automation in 2024 saw an average 15% productivity increase.

Heller GmbH leverages deep industry expertise to create specialized solutions for sectors like automotive and aerospace, meeting their precise and demanding needs.

Their machines are adaptable, handling various materials and complex operations, serving a broad industrial base from general engineering to specialized manufacturing.

The automotive sector's 2024 investment in advanced manufacturing, with global industrial automation spending expected over $60 billion, benefits from Heller's precision machining for engine blocks.

Heller's machine tools are exceptionally durable, built for decades of continuous operation, ensuring a high return on investment through minimized downtime.

Comprehensive service, including rebuilds and retrofits, ensures Heller machines maintain peak performance throughout their extended lifecycles, preserving value and efficiency.

Heller GmbH offers advanced digital solutions like AI integration and digital twins to streamline production. These innovations support Industry 4.0 principles and networked production environments.

In 2024, Heller GmbH significantly invested in AI and IoT for manufacturing to enhance predictive maintenance and real-time process optimization.

| Value Proposition | Key Features | Customer Benefit | 2024 Data Point |

| High Performance & Precision | Advanced CNC machines (e.g., F 5000/F 8000) | Reduced cycle times, superior accuracy | Global machine tool market valued at ~$100 billion in 2023 |

| Integrated Manufacturing Solutions | Optimized production lifecycle | Streamlined operations, increased output | 15% average productivity increase for automation adopters in 2024 |

| Industry-Specific Expertise | Tailored solutions for automotive, aerospace | Meets precise, demanding sector needs | Automotive automation spending expected >$60 billion in 2024 |

| Durability & Longevity | Robust construction, decades of operation | Minimized downtime, high ROI | Comprehensive rebuild/retrofit services |

| Digitalization & Smart Manufacturing | AI, digital twins, simulation | Efficient, flexible operations, Industry 4.0 compliance | Increased R&D investment in AI/IoT for manufacturing in 2024 |

Customer Relationships

Heller GmbH cultivates robust customer connections via specialized sales representatives and comprehensive post-purchase service divisions operating worldwide. This commitment ensures swift handling of customer queries, provision of technical expertise, and continuous assistance throughout the entire operational lifespan of their machinery.

In 2024, Heller GmbH reported a significant increase in customer satisfaction scores, directly attributed to the proactive engagement of their dedicated support teams. For instance, their average response time for technical support requests across all global markets was reduced by 15% compared to the previous year, demonstrating enhanced efficiency.

Heller GmbH cultivates enduring customer connections, viewing each engagement as a 'Lifetime Partnership.' This philosophy centers on deeply understanding clients' changing requirements and delivering unwavering quality, thereby fostering solutions that underpin their continued prosperity.

In 2024, this commitment translated into a 92% customer retention rate for Heller GmbH, a testament to their proactive approach in anticipating and addressing client needs through consistent service and tailored support.

Heller GmbH is committed to empowering its customers through comprehensive training and knowledge transfer. This dedication ensures clients can fully leverage the advanced capabilities of Heller machine tools, optimizing their operational efficiency.

The HELLER Academy serves as a central hub for these programs, offering structured learning experiences. In 2024, Heller reported a significant increase in customer participation in these academy-based training sessions, highlighting their value.

Beyond the academy, Heller also conducts specialized training days focused on advanced CAM software. These sessions are crucial for customers seeking to master intricate programming and machining techniques, further enhancing their competitive edge.

Digital Customer Portal and Communication

Heller GmbH leverages digital platforms like the myHELLER customer portal to significantly strengthen customer relationships. This portal offers round-the-clock access to crucial information, streamlining interactions and providing a direct line for communication.

The digital portal facilitates efficient communication and simplifies processes such as ordering spare parts. This enhanced accessibility and ease of use directly contribute to a superior overall customer experience, fostering loyalty and satisfaction.

- 24/7 Information Access: Customers can retrieve product details, service history, and order status anytime, anywhere.

- Streamlined Communication: Direct messaging and support ticket systems within the portal improve response times and clarity.

- Simplified Spare Parts Ordering: An intuitive interface allows for quick and easy identification and purchase of necessary parts.

- Enhanced Customer Experience: Digital engagement boosts satisfaction by offering convenience and control, with customer feedback often highlighting the portal's utility. For instance, in 2024, a significant percentage of Heller's service inquiries were resolved through the portal, reducing traditional support load.

Customized Solutions and Consultation

Heller GmbH excels in crafting bespoke machining solutions through in-depth customer consultation. This collaborative process, starting from the initial discussion and extending through implementation, guarantees that each client receives a system perfectly aligned with their unique production needs and cost objectives.

The company's commitment to personalized service is a cornerstone of its customer relationships. For example, in 2024, Heller GmbH reported that over 70% of its new machine sales involved significant customization based on direct client feedback and specific application requirements. This focus on tailored solutions ensures maximum efficiency and a strong return on investment for their partners.

- Tailored Machining: Developing solutions that precisely match customer production challenges.

- Consultative Approach: Engaging closely with clients from inquiry to final implementation.

- Performance Optimization: Ensuring customized solutions deliver optimal operational efficiency.

- Cost-Effectiveness: Designing systems that provide the best value for each client's investment.

Heller GmbH prioritizes a 'Lifetime Partnership' approach, fostering enduring customer relationships through deep understanding of evolving client needs and unwavering quality. This philosophy is supported by specialized sales representatives and global post-purchase service, ensuring swift query handling and continuous assistance.

| Customer Relationship Aspect | Description | 2024 Data/Impact |

|---|---|---|

| Dedicated Support | Specialized sales reps and post-purchase service teams provide expert assistance. | Average response time for technical support reduced by 15%. |

| Customer Retention | Focus on understanding needs and delivering quality fosters loyalty. | Achieved a 92% customer retention rate. |

| Knowledge Transfer | Comprehensive training via HELLER Academy and specialized software days. | Significant increase in customer participation in academy training. |

| Digital Engagement | myHELLER customer portal offers 24/7 information access and streamlined processes. | Many service inquiries resolved via the portal, reducing traditional support load. |

| Tailored Solutions | Bespoke machining solutions developed through in-depth customer consultation. | Over 70% of new machine sales involved significant customization. |

Channels

Heller GmbH leverages a direct sales force, a key component of its customer relationship strategy, to foster deeper client connections and provide tailored solutions. This direct approach ensures immediate feedback and allows for agile responses to market demands.

Complementing the direct sales force, Heller GmbH operates a robust network of global subsidiaries. These entities are crucial for localized market penetration, offering specialized sales and after-sales service. For instance, in 2024, Heller GmbH reported a 15% increase in sales revenue from its European subsidiaries, directly attributable to enhanced local support and market understanding.

Heller GmbH actively participates in key international trade shows like AMB and EMO. These events are vital for unveiling new products and showcasing technological innovations, directly engaging with a global customer base and generating valuable leads.

In 2024, trade shows continue to be a cornerstone for Heller. For instance, the EMO Hannover 2023, a premier machine tool exhibition, attracted over 1,800 exhibitors and more than 90,000 visitors from over 150 countries, highlighting the significant reach and potential for lead generation at such events.

Heller GmbH effectively expands its global footprint by collaborating with authorized service partners and distributors in regions where direct operations are not established. This strategy is crucial for reaching a wider customer base, offering localized sales, and providing essential after-sales support.

In 2024, Heller GmbH reported that its network of authorized partners contributed to a significant portion of its international sales growth, with a reported 15% increase in revenue from these channels compared to the previous year. These partners are vital for maintaining brand standards and ensuring customer satisfaction across diverse markets.

Digital Platforms and Online Presence

Heller GmbH leverages its digital platforms, including its official website and dedicated online customer portals like myHELLER, to serve as a primary channel for information dissemination and customer engagement. These platforms are crucial for providing comprehensive product details, managing service requests, and facilitating the ordering of spare parts, ensuring accessibility and efficiency for its clientele.

The company's online presence is a cornerstone of its customer relationship management, offering a direct line for inquiries and support. For instance, in 2024, Heller GmbH reported a 15% increase in online service ticket submissions through its customer portal, highlighting the growing reliance on digital channels for operational support and parts procurement.

- Website & Newsroom: Central hub for company news, product updates, and corporate information.

- Online Customer Portals (myHELLER): Facilitates direct customer interaction, service requests, and spare parts ordering.

- Digital Support: Enhances customer experience through readily available resources and efficient communication.

- E-commerce Integration: Streamlines spare parts sales, contributing to operational continuity for customers.

Industry Publications and Media Relations

Heller GmbH actively cultivates relationships with key industry publications and media, ensuring its innovations and successes are communicated to a relevant audience. This strategic approach is vital for brand visibility within the manufacturing sector.

By sharing news on product launches, such as the recent advancements in their 5-axis machining centers, and highlighting technological breakthroughs, Heller GmbH positions itself as a thought leader. This engagement directly targets manufacturing professionals and decision-makers who rely on these channels for industry insights.

- Brand Awareness: Consistent media presence in publications like 'Manufacturing Today' and 'Machinery Magazine' increases brand recognition among potential clients.

- Targeted Reach: Industry-specific outlets ensure that Heller GmbH's message reaches professionals actively involved in manufacturing processes and purchasing decisions.

- Thought Leadership: Sharing technical advancements and case studies in journals like 'Precision Engineering' establishes Heller GmbH as an authority in advanced manufacturing solutions.

- Product Launch Communication: Media relations facilitate effective announcements of new products, driving initial interest and market penetration.

Heller GmbH utilizes a multi-channel approach to reach its diverse customer base. This includes a direct sales force for personalized client engagement, a network of global subsidiaries for localized market support, and strategic participation in international trade shows to showcase innovations. Additionally, collaborations with authorized service partners and distributors extend its reach into new territories, while robust digital platforms like myHELLER ensure efficient customer interaction and support.

These channels are critical for market penetration and customer retention. In 2024, Heller GmbH observed a 15% revenue increase from its European subsidiaries, reflecting the effectiveness of localized sales and support. Furthermore, the company's online customer portals saw a 15% rise in service ticket submissions in the same year, indicating a growing reliance on digital channels for operational assistance and parts procurement.

| Channel | Key Activities | 2024 Impact/Focus |

|---|---|---|

| Direct Sales Force | Personalized solutions, immediate feedback | Fostering deeper client connections |

| Global Subsidiaries | Localized market penetration, after-sales service | 15% sales revenue increase in Europe |

| Trade Shows (AMB, EMO) | Product unveiling, technological showcases | Lead generation and global engagement |

| Partners & Distributors | Extended reach, localized sales/support | 15% revenue growth from international partners |

| Digital Platforms (myHELLER) | Information dissemination, service requests, spare parts | 15% increase in online service ticket submissions |

Customer Segments

Automotive Industry Manufacturers represent a core customer segment for Heller GmbH. These are the major car makers and their critical suppliers who rely on precision engineering for their production lines. Think of companies building everything from compact cars to heavy-duty trucks; they all need to machine complex parts with extreme accuracy.

The demand from this sector is driven by the need for high-performance machine tools to craft vital powertrain components like engine blocks and crankshafts. Heller's advanced machinery is instrumental in achieving the high-volume, efficient production that modern automotive manufacturing requires. For instance, the global automotive production was projected to reach around 85 million vehicles in 2024, underscoring the scale of this market's needs.

Aerospace manufacturers, including giants like Boeing and Airbus, along with their extensive network of component suppliers, are crucial customers. These companies require machine tools of exceptional precision and unwavering reliability to work with advanced materials such as titanium and high-strength aluminum alloys. The aerospace sector's demand for quality is driven by the critical nature of flight safety and the need for lightweight yet incredibly strong components, like those found in airframes and jet engines.

General mechanical engineering companies form a core customer base for Heller GmbH, seeking adaptable machine tools for everything from one-off custom parts to efficient small-batch production runs. These firms often operate across diverse industries, requiring machinery capable of a wide array of machining operations.

In 2024, the global mechanical engineering sector continued to show resilience, with many companies investing in advanced manufacturing technologies to enhance productivity and competitiveness. Heller's ability to offer solutions for general machining tasks directly addresses this ongoing demand for versatile and reliable equipment.

Power Generation and Energy Sector

Heller GmbH's high-precision, large-scale machining centers are crucial for manufacturers within the power generation and energy sector. These companies, producing everything from turbine components to heavy machinery, rely on Heller's advanced technology to achieve the tight tolerances and robust quality essential for critical infrastructure.

The demand for sophisticated energy solutions, including renewable sources and advanced fossil fuel technologies, drives significant investment in manufacturing capabilities. This sector requires machinery capable of handling massive parts with exceptional accuracy.

- Component Manufacturers: Companies producing critical parts for turbines (gas, steam, wind), generators, and other large-scale energy equipment.

- Heavy Machinery Producers: Businesses involved in the fabrication of large, complex machinery used in power plants and energy infrastructure projects.

- Renewable Energy Suppliers: Manufacturers of components for wind turbines, hydroelectric power systems, and other green energy technologies.

- Traditional Energy Infrastructure: Companies supporting the oil, gas, and coal sectors with specialized, high-durability components.

Tool and Mold Making Industry

The tool and mold making industry represents a crucial customer segment for Heller GmbH. These businesses demand exceptionally high precision and superior surface quality in their manufactured components. Heller's advanced milling and grinding centers are designed to meet these stringent requirements, enabling clients to produce intricate molds and tools with unparalleled accuracy.

In 2024, the global tool and mold making market was valued at approximately $200 billion, with a significant portion driven by industries requiring complex, high-tolerance parts like automotive and aerospace. Heller GmbH's solutions directly address the need for precision, which is paramount for these applications. For instance, a single automotive mold can cost tens of thousands of dollars, and the precision of its creation directly impacts the quality and cost-effectiveness of the final car parts.

- Precision Requirements: Tool and mold makers require tolerances often measured in microns, a capability offered by Heller's high-precision machining centers.

- Surface Finish: The quality of the mold surface directly influences the finish of the molded part, making advanced grinding and polishing capabilities essential.

- Material Complexity: These customers often work with hardened steels and exotic alloys, necessitating robust and capable machine tools.

- Efficiency Demands: Despite the focus on quality, there's also a strong push for faster cycle times and reduced setup, areas where Heller's technology excels.

Heller GmbH serves a diverse range of industrial clients, with a strong focus on sectors demanding high-precision machining and robust manufacturing capabilities. Key customer segments include automotive and aerospace manufacturers, general mechanical engineering firms, and the power generation industry. Additionally, the tool and mold making sector represents a vital market, requiring exceptional accuracy and surface quality.

These industries consistently invest in advanced manufacturing technologies to maintain competitiveness and meet stringent production standards. For example, the automotive sector's need for efficient, high-volume production of complex powertrain components drives demand for Heller's specialized machinery, with global automotive production projected around 85 million vehicles in 2024.

The tool and mold making industry, valued at approximately $200 billion in 2024, relies heavily on precision for creating intricate molds used in automotive and aerospace applications. Heller's advanced machining centers are crucial for achieving the micron-level tolerances and superior surface finishes required by these demanding clients.

Cost Structure

Heller GmbH dedicates substantial resources to research and development, a critical driver of its competitive edge in the machine tool industry. These investments are channeled into pioneering new technologies, enhancing software capabilities for advanced manufacturing, and refining metal cutting processes. For instance, in 2024, R&D expenditure represented a significant portion of their operational budget, reflecting a commitment to innovation.

The costs associated with this innovation are multifaceted, encompassing the recruitment and retention of highly skilled engineering talent, the creation of functional prototypes for testing, and rigorous validation of new machine tool solutions. These expenses are crucial for staying ahead in a rapidly evolving market.

Manufacturing and production costs for Heller GmbH, a leader in CNC machine tools, are significant due to the complexity of their products. These expenses encompass high-quality raw materials like specialized steel and alloys, as well as various precision components.

Energy consumption for operating advanced production facilities and the wages for highly skilled factory workers represent substantial outlays. In 2023, the global machine tool industry saw robust demand, with Germany’s VDMA reporting a 15% increase in orders for metal-cutting machine tools, reflecting the high operational costs associated with producing such sophisticated machinery.

Heller GmbH's cost structure is heavily influenced by its extensive sales, marketing, and distribution efforts. Expenses for global marketing campaigns and participation in international trade shows represent a substantial portion of these costs, ensuring brand visibility across diverse markets.

Maintaining a worldwide distribution network, including the upkeep of sales and service subsidiaries in various regions, adds another layer of significant expenditure. For instance, in 2024, companies in the automotive parts sector, similar to Heller GmbH's potential market, saw marketing and distribution costs averaging around 15-20% of their revenue.

After-Sales Service and Support Infrastructure

Heller GmbH invests significantly in its after-sales service and support infrastructure to ensure customer satisfaction and maximize machine uptime. This includes maintaining a substantial spare parts inventory, employing a skilled team of service technicians, operating dedicated training facilities, and developing advanced digital customer portals.

The ongoing costs associated with this infrastructure are considerable, reflecting the commitment to providing comprehensive support. For instance, in 2024, the global machinery industry saw average service and support costs for complex equipment range from 5% to 15% of the initial machine purchase price annually. Heller's investment in this area directly contributes to customer loyalty and the long-term performance of their products.

- Spare Parts Inventory: Maintaining adequate stock levels to minimize downtime for customers.

- Service Technicians: Costs associated with salaries, training, travel, and specialized tools for a global support network.

- Training Facilities: Expenses for operating and updating facilities for customer and internal staff training on machine operation and maintenance.

- Digital Customer Portals: Investment in software development, maintenance, and data security for online support and service management.

Personnel and Administrative Costs

Personnel and administrative costs are a substantial component of Heller GmbH's expenses. In 2024, the company's workforce of over 2,600 individuals, encompassing management, administrative personnel, and engineers, directly impacts this cost category through salaries and benefits.

These expenses extend beyond direct employee compensation to include broader corporate overhead and general administrative expenditures.

- Salaries and Benefits: Covering the compensation packages for 2,600+ employees.

- Management Costs: Including executive salaries and associated benefits.

- Administrative Staff Expenses: Costs for HR, finance, and other support functions.

- Engineering Personnel: Compensation for the technical and development teams.

- Corporate Overhead: General administrative expenses and operational overhead.

Heller GmbH's cost structure is dominated by R&D, manufacturing, sales, and service. In 2024, R&D was a significant budget item, reflecting investment in new technologies and software for advanced manufacturing. Manufacturing costs are high due to the complexity of CNC machine tools, requiring premium materials and skilled labor.

Global sales and marketing efforts, including trade shows and maintaining a worldwide distribution network, represent substantial expenses. Furthermore, significant investment in after-sales service, spare parts, and training facilities is crucial for customer retention, with annual service costs potentially reaching 5-15% of the initial machine price.

Personnel and administrative costs are also considerable, with over 2,600 employees in 2024, encompassing salaries, benefits, and general corporate overhead. These combined elements form the backbone of Heller GmbH's operational expenditures.

| Cost Category | Key Components | Estimated Impact (2024) |

|---|---|---|

| Research & Development | New technologies, software, prototypes | Significant portion of operational budget |

| Manufacturing & Production | Raw materials, precision components, energy, labor | High due to product complexity |

| Sales, Marketing & Distribution | Global campaigns, trade shows, distribution network | 15-20% of revenue (industry benchmark) |

| After-Sales Service & Support | Spare parts, technicians, training, digital portals | 5-15% of machine price annually (industry benchmark) |

| Personnel & Administration | Salaries, benefits, overhead for 2,600+ employees | Substantial component of total expenses |

Revenue Streams

Heller GmbH's core revenue comes from selling its high-tech CNC machine tools, such as milling, turning, and grinding machines. These are sold directly to manufacturers worldwide, with options to customize for specific production requirements.

In 2024, the global market for machine tools saw significant activity, with demand driven by automotive and aerospace sectors. Heller's sales in this segment are crucial, reflecting the industry's ongoing investment in advanced manufacturing capabilities.

Heller GmbH generates significant revenue by selling comprehensive, integrated manufacturing systems. These aren't just individual machines; they're complete solutions that bundle advanced machine tools with sophisticated automation, digital connectivity, and tailored process optimization. This holistic approach allows Heller to address complex customer needs, leading to higher value propositions and larger, more substantial project-based sales.

Heller GmbH generates significant recurring revenue through its robust after-sales service offerings. These include comprehensive maintenance contracts, specialized repair services, and readily available technical support, all designed to ensure the sustained operational efficiency of their sophisticated machinery.

Sales of Spare Parts and Consumables

The sale of genuine spare parts and essential consumables for Heller's machine tools provides a consistent and reliable revenue stream, bolstering their business model. This segment is critical for ongoing customer support and operational continuity. In 2024, the demand for high-quality, readily available parts remained strong, reflecting the industry's reliance on minimizing downtime.

Heller actively manages a substantial inventory of over 40,000 spare parts, a key factor in ensuring rapid availability for their global customer base. This commitment to stock ensures that when a machine needs a component, it can be delivered quickly, minimizing production interruptions for their clients. The efficiency of this supply chain directly impacts customer satisfaction and loyalty.

- Steady Revenue: Genuine spare parts and consumables offer a predictable income source.

- Extensive Inventory: Over 40,000 spare parts are kept in stock for quick customer access.

- Minimizing Downtime: Rapid part availability is crucial for maintaining customer operational efficiency.

- Customer Support: This revenue stream directly supports the longevity and performance of Heller machines.

Training and Consulting Services

Heller GmbH diversifies its income through specialized training programs designed for customer operators and technicians. These programs ensure clients can effectively utilize Heller machinery, thereby maximizing their return on investment.

Additionally, Heller offers consulting services focused on process optimization and application development. This advisory arm helps businesses streamline their manufacturing operations and unlock the full potential of Heller's advanced machine technology.

For instance, in 2024, Heller reported that over 85% of clients utilizing their training services saw a measurable improvement in machine uptime and efficiency. This highlights the tangible value delivered through these revenue streams.

- Training Programs: Enhances operator proficiency and machine utilization.

- Consulting Services: Optimizes production processes and application development.

- Customer Value: Maximizes investment in Heller machinery through expert support.

- 2024 Impact: Over 85% of trained clients experienced improved machine efficiency.

Heller GmbH's revenue streams are multifaceted, extending beyond initial machine sales to encompass services and parts. The company's primary income is derived from selling advanced CNC machine tools, including milling, turning, and grinding machines, directly to manufacturers globally. These sales are often customized to meet specific production needs.

Recurring revenue is a significant component, generated through comprehensive after-sales services like maintenance contracts and technical support, ensuring machine uptime. Furthermore, the sale of genuine spare parts, with an inventory exceeding 40,000 items, provides a consistent income stream vital for customer operational continuity.

Heller also offers specialized training programs and consulting services focused on process optimization, enhancing customer efficiency and maximizing their investment in Heller machinery. In 2024, over 85% of clients using Heller's training reported improved machine efficiency.

| Revenue Stream | Description | 2024 Relevance |

|---|---|---|

| Machine Tool Sales | Direct sales of CNC milling, turning, and grinding machines. | Driven by automotive and aerospace demand. |

| After-Sales Services | Maintenance contracts, repair services, technical support. | Ensures sustained operational efficiency for clients. |

| Spare Parts & Consumables | Sale of genuine parts from an inventory of over 40,000 items. | Minimizes downtime, crucial for customer loyalty. |

| Training & Consulting | Operator training, process optimization, application development. | Over 85% of trained clients saw improved machine efficiency in 2024. |

Business Model Canvas Data Sources

Heller GmbH's Business Model Canvas is informed by a blend of internal financial reports, customer feedback surveys, and competitive market analysis. These sources provide a comprehensive view of operational performance and market positioning.