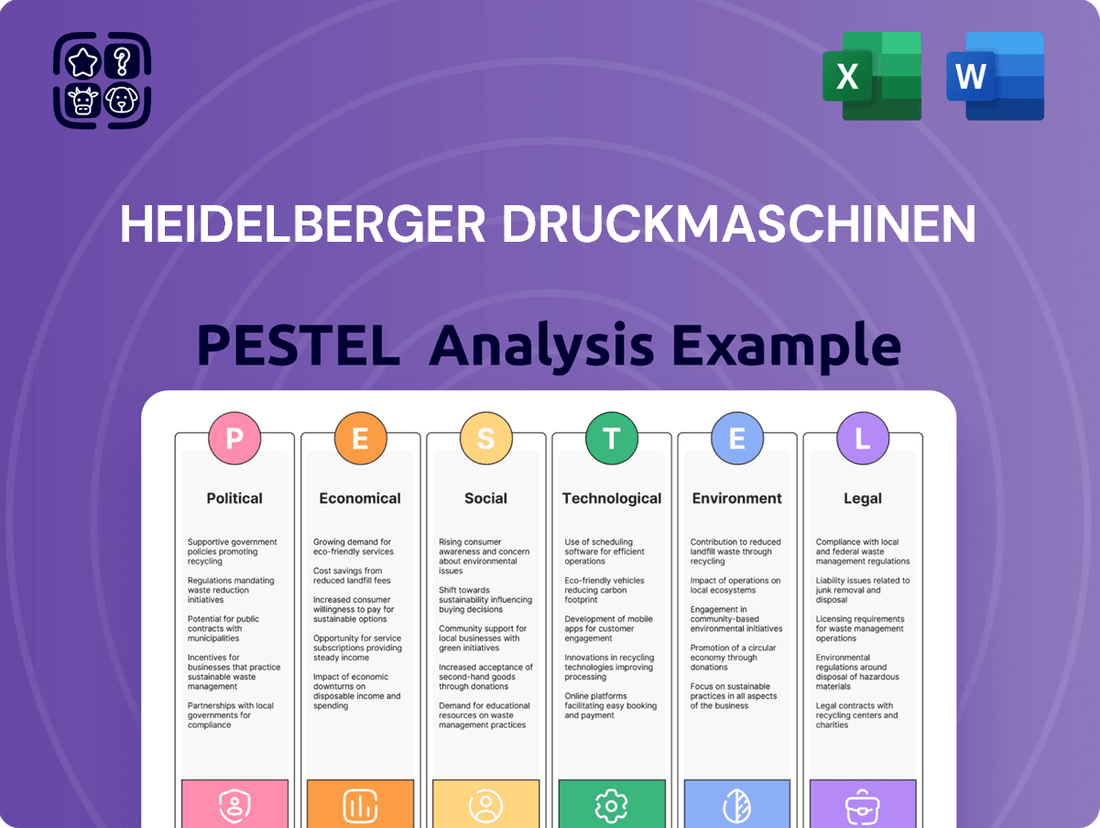

Heidelberger Druckmaschinen PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Heidelberger Druckmaschinen Bundle

Navigate the complex external landscape impacting Heidelberger Druckmaschinen with our comprehensive PESTLE analysis. Understand how political shifts, economic volatility, and technological advancements are shaping the printing industry. Gain a strategic advantage by identifying opportunities and mitigating risks. Download the full PESTLE analysis now for actionable intelligence.

Political factors

Heidelberger Druckmaschinen, operating globally, is significantly influenced by international trade policies and tariffs. Fluctuations in trade agreements, the introduction of new tariffs, or alterations in trade relationships between major economic blocs, such as the US and China or the EU and the US, directly affect the costs of raw materials, components, and final products. This, in turn, impacts the company's profitability and competitive standing in the market.

For example, Germany's export sector, a crucial area for mechanical engineering firms like Heidelberger Druckmaschinen, has experienced pressure due to U.S. tariff considerations. In 2023, German exports to the US saw a slight increase, but ongoing trade policy uncertainties, including potential further tariffs on goods like steel and aluminum, continue to pose a risk to German manufacturers' cost structures and market access.

Governments worldwide are actively promoting advanced manufacturing and Industry 4.0, which directly benefits companies like Heidelberger Druckmaschinen. For instance, Germany's "Digital Hub Initiative" and various federal funding programs aim to boost digitalization across industries. In 2024, the German government continued to allocate significant funds towards Industry 4.0 research and implementation, with specific grants available for SMEs and larger enterprises investing in smart factory technologies. This support often includes R&D grants and tax breaks for adopting automation and digital solutions, directly aligning with Heidelberg's strategic direction.

Geopolitical instability and regional conflicts pose significant risks to Heidelberger Druckmaschinen's operations. Disruptions to global supply chains, as seen with various conflicts impacting shipping routes and raw material availability in 2024, can directly increase production costs and delay deliveries of their capital-intensive printing presses.

Furthermore, economic uncertainty stemming from such events can dampen customer demand for new machinery. For instance, heightened tensions in key European markets in late 2024 could lead to a slowdown in capital expenditure by printing companies, impacting Heidelberger's order intake.

Regulations on Environmental, Social, and Governance (ESG) Reporting

Heidelberger Druckmaschinen, like many global corporations, faces increasingly stringent environmental, social, and governance (ESG) reporting requirements, especially from regions like the European Union. These regulations push companies to transparently disclose their environmental footprint and social impacts, a trend that is expected to intensify through 2025.

Compliance necessitates significant investment in robust data collection systems, enhanced reporting infrastructure, and the integration of genuinely sustainable operational practices. This can directly influence operational costs and, crucially, shape how investors perceive the company's long-term viability and risk profile.

- EU's Corporate Sustainability Reporting Directive (CSRD): This directive, fully applicable from January 2024 for many large companies, mandates detailed sustainability disclosures, impacting companies like Heidelberger Druckmaschinen by requiring comprehensive data on their ESG performance.

- Growing Investor Demand for ESG Data: By 2025, a significant portion of institutional investors are expected to integrate ESG factors into their investment decisions, making transparent and credible ESG reporting a competitive necessity for attracting capital.

- Potential for Increased Compliance Costs: Implementing the necessary systems and processes to meet evolving ESG standards could add an estimated 5-10% to compliance budgets for companies in the manufacturing sector by 2025, depending on their current data maturity.

- Impact on Access to Capital: Companies with strong ESG reporting and performance are likely to see improved access to green financing and lower borrowing costs, a trend projected to become more pronounced in the coming years.

Export Control Regulations and Sanctions

Heidelberger Druckmaschinen, as a German company operating globally, navigates a complex web of export control regulations and international sanctions. These rules, often enacted by entities like the European Union and individual nations, can significantly influence market access and sales opportunities. For instance, restrictions on exporting advanced printing technology to countries under sanctions directly impact potential revenue streams and require meticulous compliance efforts.

The evolving geopolitical landscape in 2024 and 2025 continues to shape these regulations. Companies must remain vigilant regarding sanctions targeting specific regions or industries, which could affect the supply chain for components or the ability to sell finished products. Compliance involves not only understanding the letter of the law but also implementing robust internal systems to prevent violations.

- Geopolitical Tensions: Heightened global tensions in 2024-2025 lead to more frequent imposition and modification of sanctions, impacting international trade for companies like Heidelberger Druckmaschinen.

- Compliance Burden: Adhering to diverse and often changing export control laws requires significant investment in legal counsel, training, and internal auditing processes.

- Market Access Restrictions: Sanctions can outright prohibit sales to certain countries, directly cutting off potential revenue and market share for the company's printing solutions.

- Supply Chain Risks: Regulations can also affect the sourcing of critical components, potentially disrupting production and increasing operational costs.

Government support for technological advancement directly benefits Heidelberger Druckmaschinen. Germany's continued investment in Industry 4.0, with significant funding allocated in 2024, encourages the adoption of smart factory technologies. This aligns with Heidelberg's strategic focus on digitalization, potentially leading to R&D grants and tax incentives for automation investments.

What is included in the product

This PESTLE analysis of Heidelberger Druckmaschinen examines the impact of political, economic, social, technological, environmental, and legal factors on the company's operations and strategy.

It provides a comprehensive overview of the external forces shaping the printing industry, enabling strategic decision-making and risk mitigation.

Provides a concise version that can be dropped into PowerPoints or used in group planning sessions, transforming complex external factors into actionable insights for Heidelberger Druckmaschinen.

Helps support discussions on external risk and market positioning during planning sessions, offering a clear roadmap to navigate challenges and capitalize on opportunities for Heidelberger Druckmaschinen.

Economic factors

The global economic outlook for 2024 and early 2025 suggests a moderate but uneven recovery. While some regions are experiencing renewed growth, others face persistent headwinds. This directly impacts Heidelberger Druckmaschinen as demand for printing solutions is closely tied to overall economic activity and industrial output.

Industrial production growth, a key indicator for capital goods demand, has shown mixed signals. For instance, in the Eurozone, industrial production saw a slight contraction in late 2023 and early 2024, which could translate to cautious spending on new printing equipment by European clients. Conversely, certain Asian markets are demonstrating more robust industrial expansion, potentially offering growth opportunities.

Heidelberger Druckmaschinen's global operations expose it to significant currency exchange rate fluctuations. For instance, a stronger Euro in 2024 could make its printing presses and related services pricier for customers in the United States or the United Kingdom, potentially dampening demand and impacting revenue when converted back to Euros.

Conversely, a weaker Euro can boost Heidelberger's export competitiveness, making its offerings more attractive to international buyers. This dynamic is crucial for managing profitability, as seen in the company's financial reporting where currency impacts are carefully monitored across its diverse markets.

Rising inflation and increasing raw material costs pose a significant challenge for Heidelberger Druckmaschinen. For instance, the producer price index for industrial goods in Germany, a key market, saw a substantial increase in 2023, impacting the cost of metals and other essential components. This trend is expected to continue into 2024, squeezing profit margins for manufacturers like Heidelberger Druckmaschinen.

The cost of key inputs such as aluminum, copper, and specialized chemicals for inks and consumables has seen upward pressure. In 2024, global commodity markets are anticipated to remain volatile, with potential supply chain disruptions further exacerbating these cost increases. Heidelberger Druckmaschinen must therefore focus on robust procurement strategies and consider strategic price adjustments to maintain profitability amidst these inflationary headwinds.

E-commerce Growth and Packaging Demand

The relentless expansion of e-commerce directly fuels the packaging printing industry. As online retail continues its upward trajectory, the need for robust, attractive, and often personalized packaging solutions escalates, creating substantial opportunities for Heidelberger Druckmaschinen's advanced printing technologies.

The global e-commerce market was projected to reach over $6.3 trillion in 2024, a significant increase from previous years. This surge translates into a higher volume of shipments, each requiring protective and presentable packaging. For Heidelberger Druckmaschinen, this means increased demand for their flexographic and digital printing presses, which are crucial for producing the diverse range of packaging needed for online sales.

- E-commerce Market Growth: The global e-commerce market is expected to continue its robust growth, with sales projected to reach approximately $7.5 trillion by the end of 2025, according to various market analyses.

- Packaging Demand: This growth directly correlates with an increased demand for packaging materials, particularly those suitable for direct shipping and consumer unboxing experiences.

- Heidelberger Druckmaschinen's Role: The company's flexographic and digital printing solutions are well-positioned to capitalize on this trend by offering efficient and high-quality printing for corrugated boxes, flexible packaging, and labels.

- Innovation in Packaging: Consumer expectations for sustainable and visually appealing packaging are also rising, pushing printers to adopt more advanced and eco-friendly printing methods, an area where Heidelberger Druckmaschinen invests heavily.

Interest Rates and Access to Capital

Changes in interest rates significantly influence Heidelberger Druckmaschinen's (Heidelberg) cost of capital and its customers' ability to invest. As of mid-2024, major central banks like the European Central Bank (ECB) and the US Federal Reserve have maintained relatively elevated interest rate environments, though some reductions have begun. This means borrowing for both Heidelberg and its print shop clients becomes more expensive, potentially dampening demand for new printing presses and related services.

Higher borrowing costs directly translate to increased financing expenses for Heidelberg's own operations and capital expenditures. For instance, if the ECB's main refinancing operations rate hovers around 4.50% (as seen in early 2024), this impacts the cost of any debt the company takes on. Conversely, a decrease in these rates could lower Heidelberg's financing burden, freeing up capital for research and development or strategic acquisitions.

- Impact on Customer Investment: Higher interest rates increase the cost of financing new printing equipment for customers, potentially leading to delayed or reduced capital spending.

- Heidelberg's Financing Costs: Elevated rates directly increase the expense of any debt Heidelberg utilizes for its operations, R&D, or investments.

- Potential for Sales Slowdown: If print businesses find it harder or more costly to secure loans for new machinery, Heidelberg's sales cycle for its core products could lengthen.

- Monetary Policy Influence: Decisions by central banks on interest rate adjustments are a critical external factor Heidelberg must monitor closely for their effect on market demand and its own financial structure.

The global economic landscape in 2024 and early 2025 presents a scenario of moderate but uneven growth, directly influencing demand for Heidelberger Druckmaschinen's products. Persistent inflation and rising raw material costs, as evidenced by Germany's industrial goods producer price index increase in 2023, continue to squeeze profit margins. Fluctuating currency exchange rates, such as a stronger Euro impacting export competitiveness, also pose a significant challenge for the company's profitability and sales strategies.

| Economic Factor | 2024/2025 Trend | Impact on Heidelberger Druckmaschinen |

|---|---|---|

| Global Economic Growth | Moderate, uneven recovery | Tied to demand for printing solutions and industrial output |

| Inflation & Raw Material Costs | Persistently high, volatile commodity markets | Increased input costs, pressure on profit margins |

| Interest Rates | Elevated, with some central bank reductions beginning | Higher cost of capital for Heidelberg and its customers, potentially slowing investment |

| Currency Exchange Rates | Fluctuating (e.g., Euro strength/weakness) | Affects export competitiveness and revenue conversion |

Preview Before You Purchase

Heidelberger Druckmaschinen PESTLE Analysis

The preview you see here is the exact Heidelberger Druckmaschinen PESTLE Analysis document you’ll receive after purchase, offering a comprehensive overview of the political, economic, social, technological, legal, and environmental factors impacting the company.

This is a real screenshot of the product you’re buying—delivered exactly as shown, no surprises, allowing you to confidently assess the depth and quality of the PESTLE analysis for Heidelberger Druckmaschinen.

The content and structure shown in the preview is the same document you’ll download after payment, providing you with a ready-to-use strategic tool for understanding the external landscape of Heidelberger Druckmaschinen.

Sociological factors

Consumer tastes are evolving, with a growing demand for printed materials that are both unique and environmentally conscious. This trend is reshaping the commercial print and packaging sectors, pushing businesses like Heidelberger Druckmaschinen to innovate.

For instance, the global sustainable packaging market was valued at approximately USD 279.1 billion in 2023 and is projected to grow significantly. This highlights a clear opportunity for Heidelberger Druckmaschinen to align its product development with these consumer preferences, potentially through enhanced digital printing capabilities that facilitate personalization and the use of eco-friendly inks and substrates.

Consumers and businesses are increasingly prioritizing sustainability. This shift fuels demand for printing solutions that utilize eco-friendly inks, recycled paper, and energy-efficient equipment. Heidelberger Druckmaschinen's focus on developing these greener technologies is therefore essential for maintaining its market position.

In 2024, for instance, a significant portion of print buyers indicated a willingness to pay a premium for sustainably produced print materials. This trend is projected to grow, with market research suggesting a substantial increase in the adoption of eco-certified printing processes by 2025, directly impacting machinery choices.

Heidelberger Druckmaschinen, like many manufacturing firms in developed economies, faces the challenge of an aging workforce. For instance, in Germany, the proportion of workers aged 55 and over in manufacturing has been steadily increasing, impacting the availability of experienced technical staff. This demographic shift, coupled with a global shortage of skilled technicians and software developers, creates a significant hurdle for maintaining production and innovation.

To counter these workforce dynamics, Heidelberger Druckmaschinen must proactively invest in comprehensive training programs to upskill its existing employees and attract new talent. Furthermore, embracing automation in manufacturing processes can help mitigate the impact of labor shortages, while a strong employer branding strategy is crucial to drawing in qualified individuals for critical roles in manufacturing, service, and the increasingly important area of software development.

Shift to Digital Media and Reduced Commercial Print Volumes

The persistent migration from traditional print to digital platforms significantly impacts the commercial printing sector, potentially dampening demand for offset printing technology. Heidelberger Druckmaschinen must strategically pivot, expanding its offerings into digital printing, packaging solutions, and ancillary services to counteract this trend.

This shift is evident in the advertising spend, with digital advertising projected to capture over 60% of the global advertising market by 2024, a substantial increase from previous years. Consequently, print advertising volumes, a key market for offset presses, have seen a steady decline.

- Digital advertising's growing market share: Global digital ad spend is expected to reach approximately $700 billion in 2024.

- Print advertising's contraction: Traditional print advertising revenue has been on a downward trajectory for several years.

- Heidelberg's strategic response: The company is investing in digital printing technologies and expanding into packaging to diversify revenue streams.

- Emerging opportunities: Growth in niche print markets like packaging and labels offers alternative avenues for revenue generation.

Urbanization and Supply Chain Localization

Global urbanization continues to reshape demand patterns. By 2050, it's projected that 68% of the world's population will live in urban areas, presenting both opportunities and challenges for logistics. This shift necessitates that companies like Heidelberger Druckmaschinen consider how to efficiently serve these concentrated population centers.

The increasing density of urban populations can influence supply chain strategies, potentially favoring localized production and distribution hubs. For Heidelberger Druckmaschinen, establishing or strengthening regional service centers closer to major urban manufacturing and printing clusters could reduce delivery times and operational costs, while also mitigating the environmental impact of long-haul transportation.

- Urban Population Growth: The UN estimates that urban areas will house 68% of the world's population by 2050, up from 56% in 2021.

- Logistics Efficiency: Proximity to urban centers can decrease last-mile delivery costs, which can account for over 50% of total shipping costs in some regions.

- Environmental Impact: Localized operations can reduce carbon emissions associated with transportation, aligning with growing corporate sustainability goals.

- Market Responsiveness: Shorter supply chains allow for quicker adaptation to changing market demands within specific urban economic zones.

Sociological factors significantly influence the printing industry, with evolving consumer preferences for personalized and sustainable print products driving innovation. Heidelberger Druckmaschinen must adapt to these shifts, particularly the demand for eco-friendly materials and processes. For example, a growing number of print buyers in 2024 expressed willingness to pay more for sustainable options, a trend expected to accelerate by 2025.

The demographic challenge of an aging workforce in manufacturing, especially in regions like Germany, impacts Heidelberger Druckmaschinen by creating a scarcity of skilled labor. This necessitates investment in training and automation to maintain operational efficiency and innovation capacity. The company's strategic pivot towards digital printing and packaging solutions is also a direct response to the ongoing migration of advertising spend from traditional print to digital platforms, a trend projected to see digital advertising capture over 60% of the global market by 2024.

| Sociological Factor | Impact on Heidelberger Druckmaschinen | Supporting Data/Trend |

|---|---|---|

| Evolving Consumer Tastes | Increased demand for personalized and sustainable print materials. | Print buyers willing to pay a premium for sustainable print (2024 data). |

| Demographic Shifts | Aging workforce leading to skilled labor shortages in manufacturing. | Increasing proportion of older workers in manufacturing sectors (e.g., Germany). |

| Media Consumption Habits | Shift from traditional print to digital platforms impacting print advertising. | Digital advertising projected to exceed 60% of global ad spend by 2024. |

Technological factors

Digital printing technologies like inkjet and electrophotography are rapidly evolving, offering significant advantages such as greater flexibility, the ability to handle shorter print runs economically, and enhanced personalization options. These capabilities present a direct challenge to traditional offset printing methods.

Heidelberger Druckmaschinen, to maintain its leadership position, needs to aggressively pursue innovation within its digital printing segment. This includes expanding its product offerings and forging strategic partnerships to adapt to the dynamic market landscape.

Automation and artificial intelligence are fundamentally reshaping print production. These technologies boost efficiency, cut down on labor expenses, and pave the way for smarter operational choices. For instance, the global market for industrial automation is projected to reach over $400 billion by 2025, indicating a significant shift towards automated processes across industries, including printing.

Heidelberger Druckmaschinen's strategic focus on integrating AI-powered software and automated systems is paramount. This commitment allows them to deliver cutting-edge solutions to their clientele, directly improving customer productivity. The company's investments in areas like AI-driven color management and predictive maintenance for their printing presses exemplify this technological advancement.

The print industry is increasingly reliant on seamless software integration for a streamlined production workflow. Heidelberg Druckmaschinen is capitalizing on this by offering a digital ecosystem that connects prepress, printing, and postpress operations, aiming to boost efficiency and connectivity for its clients.

Heidelberg's digital solutions, such as Prinect, are designed to optimize every stage of print production. For instance, in 2023, Heidelberg reported a significant increase in the adoption of its digital services, with a growing number of customers leveraging these integrated platforms to achieve greater automation and cost savings. This focus on a connected workflow is crucial for remaining competitive in a rapidly evolving technological landscape.

Development of Sustainable Printing Technologies

Heidelberger Druckmaschinen is actively investing in sustainable printing technologies, a critical move given growing environmental regulations and consumer demand. Innovations like waterless printing, which significantly reduces water consumption and wastewater, and the development of eco-friendly inks, are key areas of focus. These advancements not only address environmental concerns but also offer operational efficiencies for printing businesses.

The company's commitment to energy-efficient machinery is also noteworthy. For instance, their Speedmaster XL 106 press, a flagship product, has seen improvements in energy consumption. In 2023, Heidelberger Druckmaschinen reported a continued focus on reducing the carbon footprint of its operations and products, aligning with global sustainability goals. This technological development is vital for maintaining market relevance and competitiveness in the 2024-2025 period.

Key technological advancements and their impact include:

- Waterless Printing: Reduces water usage by up to 90% and eliminates fountain solution waste, a significant environmental benefit.

- Eco-friendly Inks: Development of vegetable-based or low-VOC (volatile organic compound) inks to minimize air pollution and improve workplace safety.

- Energy-Efficient Machines: Innovations in press design and operation that lower electricity consumption per printed sheet, contributing to reduced operating costs for customers.

- Digitalization and Automation: Integration of digital workflows and automated processes that optimize resource use and reduce material waste in the printing process.

Emergence of 3D Printing and Additive Manufacturing

While Heidelberger Druckmaschinen's core business remains traditional printing, the evolving landscape of 3D printing and additive manufacturing presents a long-term technological factor to monitor. This technology could reshape specialized packaging and niche print applications, potentially creating opportunities for customized, short-run production where traditional methods might be less efficient.

Heidelberger Druckmaschinen should closely observe the advancements in additive manufacturing for potential synergies and competitive shifts. For instance, the global 3D printing market was valued at approximately $15.1 billion in 2023 and is projected to grow significantly, indicating a growing demand for personalized and on-demand manufacturing solutions that could eventually intersect with printing services.

- Market Growth: The 3D printing market is expected to reach over $100 billion by 2030, signaling a substantial shift in manufacturing paradigms.

- Customization Potential: Additive manufacturing excels in producing highly customized items, a trend that could influence demand for bespoke printing solutions.

- Material Innovation: Advances in printable materials for 3D printing could eventually lead to new applications in packaging and graphic arts, requiring adaptation from established printing technology providers.

The rapid advancement of digital printing technologies, such as inkjet and electrophotography, offers greater flexibility and cost-effectiveness for shorter print runs, directly challenging traditional offset methods. Heidelberger Druckmaschinen's strategic focus on integrating AI-powered software and automated systems, like its Prinect workflow, is crucial for enhancing efficiency and delivering cutting-edge solutions, as evidenced by increased adoption of its digital services in 2023.

Heidelberg is also prioritizing sustainable printing technologies, including waterless printing and eco-friendly inks, to meet growing environmental demands and regulations. For example, their Speedmaster XL 106 press has seen improvements in energy consumption, reinforcing their commitment to reducing operational carbon footprints, a key factor for competitiveness in 2024-2025.

The growing 3D printing market, projected to exceed $100 billion by 2030, presents a long-term technological factor that could influence specialized packaging and niche print applications, necessitating adaptation from established printing technology providers.

Legal factors

Heidelberger Druckmaschinen faces increasing environmental scrutiny, especially within the European Union, with regulations targeting emissions, waste, and hazardous materials in both production and product lifecycles.

Compliance with directives like the EU Ecodesign Regulation and the newer EU Deforestation Regulation (EUDR) necessitates substantial financial commitments for process and product redesign, impacting operational costs and R&D priorities.

For instance, the EUDR, effective from late 2024 for large operators, will require rigorous due diligence for commodities like wood-based products used in consumables, adding a layer of complexity and cost to supply chain management for Heidelberger Druckmaschinen.

Heidelberger Druckmaschinen must navigate stringent product safety and certification standards, such as CE marking in Europe and UL certification in North America, to ensure their printing machinery meets health and safety regulations. Compliance is non-negotiable for market access, preventing costly recalls and safeguarding the company's reputation. Failure to meet these evolving standards can result in significant fines and market exclusion.

Heidelberger Druckmaschinen's (Heidelberg) ability to protect its innovations through patents and trademarks is fundamental to maintaining its edge in the competitive printing industry. For instance, as of fiscal year 2023/24, Heidelberg reported significant R&D investments, underscoring the importance of its intellectual property portfolio. The effectiveness of these legal protections hinges on robust IP enforcement mechanisms across its global markets, ensuring its proprietary technologies in areas like digital printing and workflow automation remain secure.

Labor Laws and Employment Regulations

Heidelberger Druckmaschinen, as a global employer, navigates a complex web of labor laws and employment regulations across its operating regions. These legal frameworks dictate minimum wages, working hours, health and safety standards, and employee rights, directly influencing operational costs and management practices.

The company must adhere to varying national and international employment standards, impacting everything from hiring and firing procedures to collective bargaining agreements. For instance, in Germany, where Heidelberger Druckmaschinen has a significant presence, Works Councils play a crucial role in employee representation and decision-making, as stipulated by co-determination laws.

- Compliance with diverse labor laws: Heidelberger Druckmaschinen must comply with regulations concerning wages, working conditions, and employee representation in all countries of operation.

- Impact on operational flexibility: Strict employment regulations can limit the company's ability to adjust staffing levels or working hours quickly in response to market changes.

- Cost implications: Adherence to minimum wage laws, social security contributions, and employee benefit mandates contributes to the overall cost of labor.

- Employee representation: The presence and influence of trade unions or works councils in key markets require careful management of employee relations and collective agreements.

Data Protection and Privacy Regulations (e.g., GDPR)

Heidelberger Druckmaschinen (Heidelberg) navigates a complex legal landscape, particularly concerning data protection and privacy. As the company increasingly offers digital solutions and software, it handles substantial customer data, making compliance with regulations like the EU's General Data Protection Regulation (GDPR) absolutely critical. Failure to adhere to these stringent rules can result in significant financial penalties and damage to its reputation, impacting customer trust and business operations. For instance, in 2023, fines under GDPR continued to be substantial, with reports indicating millions of euros levied across various sectors for data breaches and non-compliance, underscoring the financial and operational risks involved.

Heidelberg's commitment to data security and privacy is therefore not just a legal obligation but a core business imperative. The company must ensure robust data handling practices across all its digital offerings, from cloud-based services to customer relationship management systems. This involves implementing strong security measures, transparent data usage policies, and obtaining necessary consents. The ongoing evolution of data privacy laws globally, with many countries enacting or updating their own regulations, requires continuous monitoring and adaptation of Heidelberg's compliance strategies to maintain market access and customer confidence in its digital transformation journey.

- GDPR Fines: Reports from 2023 highlighted continued significant GDPR fines, with some exceeding €300 million for major tech companies, demonstrating the financial severity of non-compliance.

- Customer Trust: Data breaches or privacy violations can erode customer confidence, leading to lost business and reputational damage for companies like Heidelberg.

- Digital Services: Heidelberg's expanding portfolio of digital and software-based solutions inherently increases its exposure to data protection scrutiny.

- Global Regulations: The company must stay abreast of varying data privacy laws in all the markets it operates in, adding layers of complexity to its legal compliance efforts.

Heidelberger Druckmaschinen operates within a framework of intellectual property laws, crucial for protecting its technological advancements in printing machinery and digital solutions. The company's investment in research and development, as evidenced by its fiscal year 2023/24 activities, necessitates strong patent and trademark enforcement globally to secure its competitive advantage.

The legal landscape surrounding product safety and market access, including CE marking in Europe and UL certification in North America, mandates strict adherence to health and safety standards for Heidelberg's equipment. Non-compliance can lead to significant financial penalties, costly recalls, and exclusion from key markets, underscoring the importance of rigorous certification processes.

Heidelberg's global operations require navigating diverse labor laws, impacting employment costs and management practices. For instance, German co-determination laws grant Works Councils significant influence, affecting operational flexibility and employee relations.

Data protection laws, such as the GDPR, pose significant compliance challenges for Heidelberg's digital service offerings. Reports from 2023 indicated substantial GDPR fines, with some exceeding €300 million for major tech firms, highlighting the financial risks associated with data privacy violations and the critical need for robust data security measures to maintain customer trust.

Environmental factors

Increasing global awareness of climate change is directly influencing the printing industry, creating a stronger demand for products and processes that minimize environmental impact. This shift means companies like Heidelberger Druckmaschinen must innovate towards solutions with a lower carbon footprint.

Heidelberger Druckmaschinen faces significant pressure to design and market printing presses that consume less energy. Furthermore, the company is tasked with reducing its own operational emissions and actively assisting its clientele in meeting their individual sustainability targets.

In 2023, Heidelberg's sustainability report highlighted a 15% reduction in CO2 emissions from its production sites compared to 2019, demonstrating progress in its carbon footprint reduction efforts.

The printing industry faces growing pressure from the scarcity of natural resources, like paper pulp and energy, driving a significant shift towards circular economy principles. This means companies must prioritize efficient material usage, robust recycling programs, and innovative remanufacturing processes to remain competitive and sustainable.

Heidelberger Druckmaschinen is actively integrating these principles by designing its printing presses with recyclability in mind, aiming to extend product lifecycles and reduce waste. For instance, their focus on modular design and the use of durable, recyclable materials in their equipment directly supports the move away from linear ‘take-make-dispose’ models.

In 2023, the global paper recycling rate hovered around 60%, highlighting the ongoing need for improvement and the potential for greater material recovery within the printing supply chain. Heidelberger's commitment to circularity is therefore not just an environmental imperative but also a strategic business advantage, aligning with evolving customer demands and regulatory landscapes.

Water usage and pollution control are critical environmental considerations for the printing industry. Traditional printing methods often consume significant amounts of water and can release pollutants from inks and cleaning chemicals. Heidelberger Druckmaschinen is actively addressing this by developing innovative waterless printing technologies, which drastically reduce water consumption and minimize the potential for chemical-based water pollution.

Waste Management and Recycling Infrastructure

The printing industry, including companies like Heidelberger Druckmaschinen, generates significant waste, from paper scraps and used ink cartridges to retired machinery parts. This necessitates advanced waste management and recycling systems to handle these materials responsibly. For instance, in 2023, the global paper recycling rate hovered around 50%, highlighting the ongoing need for improved infrastructure across manufacturing sectors.

Heidelberger Druckmaschinen actively addresses this environmental factor by focusing on sustainability. Their efforts include developing and promoting recyclable consumables and implementing programs to facilitate the recycling of their own products. This commitment is crucial for reducing the industry's ecological footprint and aligning with growing regulatory and consumer demands for circular economy practices.

- Waste Volume: Printing operations generate substantial volumes of paper, ink, and equipment waste.

- Infrastructure Needs: Robust waste management and recycling facilities are essential for the printing sector.

- Heidelberg's Role: The company promotes sustainable consumables and recycling initiatives.

- Industry Trend: Increasing global focus on circular economy principles impacts waste handling in manufacturing.

Supply Chain Sustainability and Deforestation

Heidelberg Druckmaschinen must ensure sustainability throughout its supply chain, especially concerning paper and board sourcing, a significant environmental consideration. The company's commitment to responsible procurement directly influences its environmental footprint.

New regulations, such as the EU Deforestation Regulation (EUDR), are now mandating that companies rigorously verify their products do not contribute to deforestation. This directly impacts Heidelberg's procurement processes and requires robust supply chain management to ensure compliance, particularly in sourcing materials.

The EUDR, which came into effect in late 2024, places a significant burden on companies to demonstrate due diligence. For instance, in 2023, global deforestation rates remained a concern, with reports indicating millions of hectares of forest lost annually, underscoring the importance of such regulations for industries reliant on forest products.

- Supply Chain Scrutiny: Increasing regulatory pressure, like the EUDR, necessitates enhanced traceability of raw materials, impacting sourcing strategies for paper and board.

- Deforestation Impact: Global deforestation continues to pose environmental risks, making compliance with regulations designed to curb it a critical operational factor for companies like Heidelberg.

- Procurement Adjustments: Heidelberg's suppliers must provide evidence of deforestation-free sourcing, potentially leading to shifts in supplier relationships and increased costs for certified materials.

- Brand Reputation: Demonstrating a commitment to sustainable and deforestation-free supply chains is becoming crucial for maintaining brand reputation and meeting customer expectations in 2024 and beyond.

The printing industry faces increasing scrutiny regarding its environmental impact, particularly concerning energy consumption and emissions. Heidelberger Druckmaschinen is responding by developing more energy-efficient printing presses and reducing its own operational carbon footprint.

Circular economy principles are gaining traction, pushing companies like Heidelberg to focus on material efficiency, recycling, and product longevity. This includes designing equipment for easier disassembly and material recovery, aligning with a global trend towards waste reduction.

Water usage and pollution control remain critical environmental factors. Heidelberg is innovating with waterless printing technologies to minimize water consumption and the release of harmful chemicals into waterways, a key concern for sustainable manufacturing.

Waste management is another significant challenge, with the industry generating substantial paper, ink, and equipment waste. Heidelberg actively promotes recyclable consumables and implements recycling programs for its products to address this issue.

Supply chain sustainability, especially for paper and board, is under increasing pressure from regulations like the EU Deforestation Regulation (EUDR). This requires rigorous verification of deforestation-free sourcing, impacting procurement strategies and supplier relationships.

| Environmental Factor | Heidelberg's Response | Industry Trend/Data (2023-2024) |

|---|---|---|

| Climate Change & Emissions | Developing energy-efficient presses; reducing operational CO2 (15% reduction vs. 2019 reported in 2023). | Growing demand for low-carbon solutions. |

| Resource Scarcity & Circularity | Designing for recyclability, modularity, extended lifecycles. | Global paper recycling rate around 60% (2023); focus on material efficiency. |

| Water Usage & Pollution | Innovating waterless printing technologies. | Minimizing water consumption and chemical runoff is a priority. |

| Waste Management | Promoting recyclable consumables; product recycling programs. | Global paper recycling rate approximately 50% (2023); need for better infrastructure. |

| Supply Chain Sustainability | Ensuring responsible paper/board sourcing; compliance with EUDR. | EUDR effective late 2024; global deforestation rates remain a concern. |

PESTLE Analysis Data Sources

Our Heidelberger Druckmaschinen PESTLE Analysis is built on a robust foundation of data from official government publications, reputable financial institutions like the IMF and World Bank, and leading industry analysis firms. We meticulously gather information on political stability, economic forecasts, technological advancements, environmental regulations, and social trends to provide a comprehensive overview.