Grammer Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Grammer Bundle

Unlock the core strategies driving Grammer's success with our comprehensive Business Model Canvas. This detailed analysis breaks down their customer relationships, revenue streams, and key resources, offering a clear roadmap to their market advantage. For anyone seeking to understand industry leaders or refine their own business plan, this is an indispensable tool.

Partnerships

Grammer AG's key partnerships with raw material and component suppliers are foundational to its operations. These suppliers provide essential inputs like specialized plastics, metals, textiles, and electronic parts, vital for producing Grammer's extensive product portfolio, from automotive interiors to agricultural seating. For instance, in 2024, Grammer continued to emphasize strategic alliances to secure high-quality materials at competitive prices, a critical factor given the fluctuating global commodity markets.

Maintaining robust relationships with these upstream partners is paramount for Grammer to ensure consistent product availability and manage costs effectively. These collaborations often extend to joint efforts in material development and quality control, aiming to enhance product performance and reduce supply chain disruptions. In 2024, the company actively worked to diversify its supplier base in key regions to further mitigate risks associated with single-source dependency and geopolitical instability.

Grammer AG's key partnerships are with automotive OEMs, the major car manufacturers. These are deep, direct relationships where Grammer supplies interior components like headrests, armrests, and child booster seats for new car models. These collaborations are crucial for Grammer's business, ensuring their products are integrated from the design phase. For instance, in 2024, Grammer secured significant new business with several global OEMs, contributing to their projected revenue growth.

Grammer AG's key partnerships with commercial vehicle manufacturers are fundamental to its business. These collaborations allow Grammer to develop and supply specialized seating systems for trucks, buses, trains, and off-road machinery. By working closely with original equipment manufacturers (OEMs), Grammer ensures its seating solutions meet specific ergonomic, comfort, and safety standards required by diverse vehicle applications and stringent regulations.

Technology and Research & Development Collaborators

Grammer AG actively collaborates with technology providers and research institutions to enhance its product offerings. These partnerships are crucial for integrating advanced materials and smart features, ensuring Grammer maintains its leadership in seating and interior solutions. For instance, in 2024, Grammer continued its focus on developing lightweight yet durable materials, a trend supported by ongoing research into composite technologies.

The company partners with design houses to ensure its products meet high standards of ergonomics, comfort, and safety. These collaborations allow Grammer to incorporate the latest design trends and user-centric innovations. In 2024, Grammer showcased new seating concepts that emphasized modularity and user customization, a direct result of these strategic design partnerships.

These collaborations are vital for Grammer's continuous innovation pipeline. By working with external experts, Grammer can accelerate the development of cutting-edge manufacturing processes and smart functionalities. This approach ensures Grammer remains at the forefront of the automotive and commercial vehicle interior market.

- Technology Providers: Partnerships focused on advanced materials, sensors, and connectivity solutions.

- Research Institutions: Collaborations on ergonomics, human-machine interfaces, and sustainable manufacturing.

- Design Houses: Joint efforts to create innovative, user-friendly, and aesthetically pleasing interior components.

- Manufacturing Process Innovators: Alliances to implement Industry 4.0 technologies and optimize production efficiency.

Logistics and Distribution Network Partners

Grammer AG, with its vast international presence spanning 19 countries, relies heavily on its logistics and distribution network partners to maintain operational efficiency. These crucial alliances ensure the smooth transit of components to its manufacturing facilities and the precise, just-in-time delivery of finished goods to a global customer base.

- Global Reach: Grammer's network of partners enables its extensive global market penetration, facilitating the movement of goods across diverse geographical regions.

- Supply Chain Efficiency: These partnerships are fundamental to managing the inbound flow of raw materials and the outbound delivery of finished products, optimizing the entire supply chain.

- Just-in-Time Delivery: The reliability of these logistics providers is paramount for meeting customer demands precisely when needed, a critical factor in the automotive industry.

Grammer AG's key partnerships are essential for its innovation and market reach. Collaborations with technology providers and research institutions in 2024 were vital for integrating advanced materials and smart features. Partnerships with design houses in 2024 also played a crucial role in developing user-centric and aesthetically pleasing interior components.

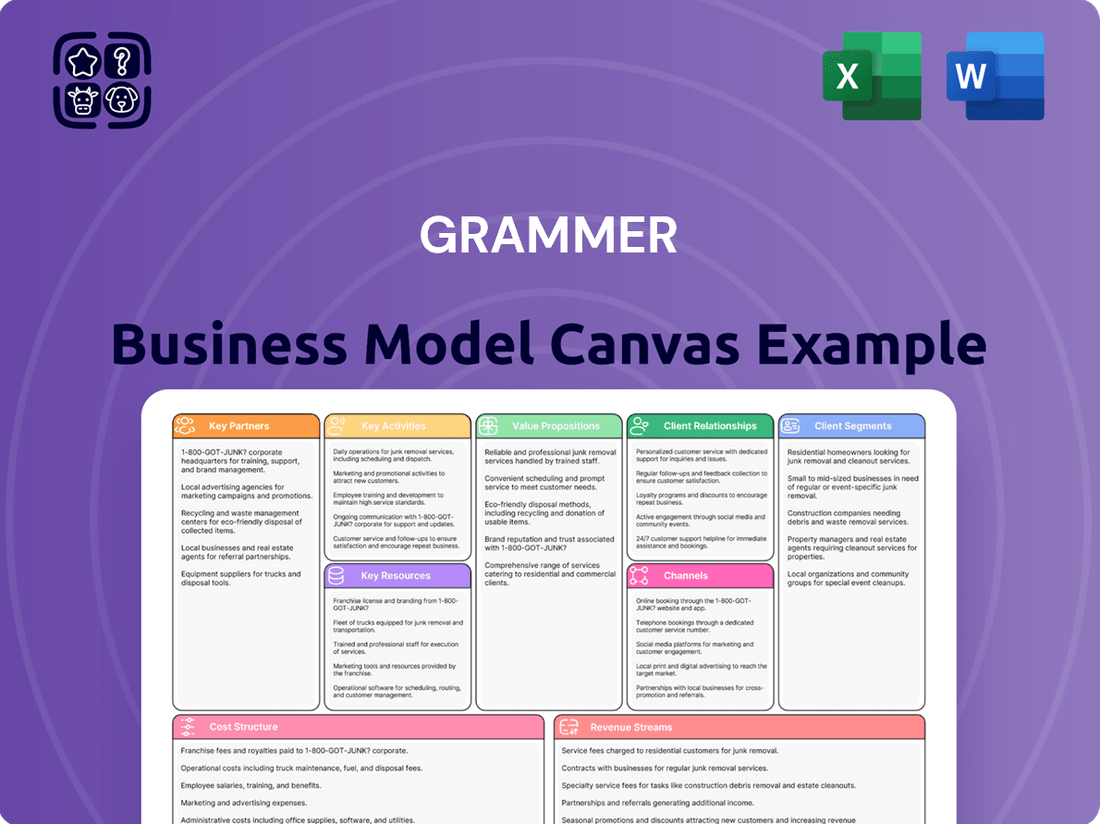

What is included in the product

A structured framework detailing a company's strategy, customer focus, and operational plans across nine key building blocks.

Organized into 9 classic BMC blocks with full narrative and insights, designed to help entrepreneurs and analysts make informed decisions.

Addresses the pain of unstructured thinking by providing a clear, visual framework for organizing business model elements.

Activities

Grammer AG's commitment to Research and Development (R&D) is central to its business model, driving the creation of innovative solutions for the automotive and commercial vehicle sectors. The company invests heavily in developing products that prioritize ergonomics, comfort, and safety, as demonstrated by their focus on advanced seating systems. This dedication to innovation ensures Grammer stays ahead of evolving customer needs and industry standards.

The R&D process at Grammer involves a forward-thinking approach, exploring novel materials, integrating cutting-edge smart technologies, and refining design concepts. A prime example of this ongoing innovation is the recent launch of the NEW REGIO passenger seat, which showcases the company's ability to translate research into tangible, market-ready products. This continuous cycle of development is crucial for maintaining a competitive edge.

Grammer AG's core activities revolve around the detailed design and engineering of automotive interior components and seating systems. This involves translating innovative ideas into tangible products ready for mass production.

The company invests heavily in prototyping and rigorous testing to guarantee that all its offerings meet demanding quality, safety, and performance benchmarks. For instance, in 2024, Grammer continued to emphasize advanced materials and ergonomic research in its prototyping cycles, aiming to reduce vehicle weight and enhance passenger comfort.

This meticulous development phase is vital for ensuring that Grammer's solutions integrate seamlessly into the complex architecture of customer vehicles, a key factor in securing ongoing business with major automotive manufacturers.

Grammer AG's core activity revolves around the large-scale manufacturing and assembly of its extensive product range. This includes essential automotive components like headrests, armrests, center consoles, and complete driver and passenger seats.

These operations are strategically distributed across Grammer's global network of advanced production facilities. The company utilizes highly efficient manufacturing systems to guarantee superior product quality and effectively cater to worldwide market demand.

In 2024, Grammer continued to invest in optimizing its production processes. For instance, the company reported a focus on enhancing automation and lean manufacturing principles across its sites to improve efficiency and reduce lead times for its automotive clients.

Global Supply Chain Management

Grammer AG's key activity in global supply chain management involves the intricate orchestration of material flow from sourcing to customer delivery. This includes strategic procurement of automotive components and raw materials, ensuring quality and cost-effectiveness. In 2024, Grammer continued to refine its logistics networks to mitigate disruptions, a critical focus given the ongoing volatility in global shipping and component availability. The company aims for seamless integration across its international production sites, optimizing inventory levels to prevent stockouts while minimizing holding costs.

Efficient inventory management and just-in-time (JIT) delivery are central to Grammer's operational success. By maintaining lean inventories, Grammer reduces capital tied up in stock and lowers the risk of obsolescence. For instance, in the first half of 2024, Grammer reported efforts to improve supply chain resilience, which directly impacts its ability to meet production schedules. This focus on JIT delivery is crucial for maintaining strong relationships with automotive manufacturers who rely on predictable component supply for their assembly lines.

- Strategic Sourcing: Procuring high-quality raw materials and components from a global network of suppliers.

- Inventory Optimization: Implementing advanced inventory management systems to balance availability with holding costs.

- Logistics and Distribution: Ensuring timely and cost-effective delivery of finished goods to automotive OEMs worldwide.

- Risk Mitigation: Proactively managing supply chain disruptions through diversification of suppliers and enhanced visibility.

Sales, Marketing, and Customer Engagement

Grammer's key activities heavily revolve around robust sales and marketing strategies. They actively engage with automotive and commercial vehicle original equipment manufacturers (OEMs) globally, aiming to understand their unique requirements and secure new business agreements. This proactive approach is crucial for growth in a competitive market.

Central to Grammer's success is effective customer relationship management. Building and nurturing long-term partnerships with OEMs is a core activity, ensuring continued business and fostering loyalty. This focus on relationships underpins their market presence.

Strategic marketing efforts are also vital. Grammer highlights its expertise in providing ergonomic, comfortable, and safe solutions for vehicle interiors. This messaging aims to differentiate them and attract clients seeking high-quality components.

In 2024, Grammer continued to strengthen its global sales network, with a particular focus on expanding its reach in emerging automotive markets. Their marketing initiatives in 2024 emphasized digital channels and industry trade shows to showcase innovations in seating technology and interior systems, contributing to their ongoing efforts to secure major contracts with leading vehicle manufacturers.

- Global Sales Expansion: Actively pursuing new contracts with automotive and commercial vehicle OEMs worldwide.

- Customer Relationship Management: Fostering long-term partnerships through dedicated engagement.

- Strategic Marketing: Showcasing expertise in ergonomic, comfortable, and safe interior solutions.

- 2024 Focus: Strengthening global sales networks and leveraging digital marketing for brand visibility.

Grammer AG's key activities encompass the entire product lifecycle, from initial concept to final delivery. This includes intensive research and development to create innovative automotive seating and interior components, followed by meticulous design and engineering. The company then moves into large-scale manufacturing and assembly across its global production sites, ensuring high quality and efficiency. Crucially, Grammer manages a complex global supply chain, focusing on strategic sourcing, inventory optimization, and risk mitigation to guarantee timely delivery to automotive manufacturers.

Furthermore, Grammer actively engages in robust sales and marketing efforts, building strong relationships with automotive OEMs and showcasing its expertise in ergonomic and safe interior solutions. Their 2024 strategy involved expanding sales networks in emerging markets and utilizing digital marketing to enhance brand visibility and secure new business agreements.

These core activities are supported by a commitment to continuous improvement in production processes, including increased automation and lean manufacturing principles, as seen in their 2024 initiatives. This integrated approach ensures Grammer remains a leading supplier in the automotive industry.

| Key Activity | Description | 2024 Focus/Data |

| Research & Development | Creating innovative automotive interior and seating solutions. | Focus on advanced materials and ergonomic research for weight reduction and enhanced comfort. |

| Design & Engineering | Translating innovative ideas into tangible, mass-producible products. | Development of new passenger seats like the NEW REGIO. |

| Manufacturing & Assembly | Large-scale production of components like headrests, armrests, and seats. | Investment in automation and lean manufacturing to improve efficiency. |

| Supply Chain Management | Orchestrating material flow from sourcing to delivery, managing inventory and logistics. | Refining logistics networks to mitigate disruptions and improve supply chain resilience. |

| Sales & Marketing | Engaging with OEMs, building customer relationships, and promoting solutions. | Strengthening global sales networks and leveraging digital marketing. |

Full Document Unlocks After Purchase

Business Model Canvas

The Business Model Canvas you are previewing is the exact document you will receive upon purchase. This is not a mockup or a sample; it's a direct snapshot of the complete, ready-to-use file. You'll gain full access to this professionally structured and formatted Business Model Canvas, allowing you to immediately begin strategizing and refining your business concept.

Resources

Grammer AG's intellectual property, encompassing patents and proprietary designs, safeguards its innovations in seating and interior technologies. This intellectual capital, along with extensive know-how in ergonomics and materials science, is a key intangible asset. In 2023, Grammer continued to invest in R&D, a critical component for maintaining its competitive edge through new patent filings and design registrations.

Grammer AG's global manufacturing footprint, encompassing 48 production, distribution, and logistics sites across 19 countries, represents a core physical asset. This extensive network is outfitted with specialized machinery and advanced manufacturing systems, crucial for its operations.

These facilities are designed to support localized production, ensuring responsiveness to regional market needs, while simultaneously facilitating a global reach. The investment in advanced equipment allows for efficient scaling, a key factor in meeting the varied demands of its customer base.

Grammer AG's approximately 12,000 employees are a cornerstone of its business model, with a significant portion comprising highly skilled engineers, designers, and production specialists. This human capital is critical for developing innovative seating and interior solutions.

The expertise of these teams in advanced manufacturing and quality control directly translates into Grammer's ability to deliver market-leading products. For instance, in 2023, Grammer continued to invest in R&D, focusing on lightweight construction and sustainable materials, a testament to the importance of its skilled workforce.

Strong Customer Relationships and Brand Reputation

Grammer's established, long-term relationships with leading automotive and commercial vehicle OEMs are a cornerstone of its business. These partnerships, forged over years, are built on a foundation of Grammer's unwavering reputation for quality, reliability, and continuous innovation. This deep trust translates directly into sustained business and a competitive edge.

The Grammer brand itself commands significant recognition and respect within its specialized market segments. It is synonymous with trust and leadership, offering a robust platform for ongoing growth and market penetration. This strong brand equity is a critical intangible asset, fostering customer loyalty and attracting new business opportunities.

- Customer Loyalty: Grammer's long-standing relationships with major OEMs, such as those contributing to its reported €2.1 billion in revenue for 2024, underscore a high degree of customer loyalty and repeat business.

- Brand Equity: The Grammer brand's reputation for quality and innovation, a key factor in securing contracts with industry leaders, directly supports its market position and pricing power.

- Partnership Depth: The collaborative nature of these OEM relationships often leads to joint development projects, further solidifying Grammer's role as a trusted partner and innovator.

Financial Capital and Strategic Investments

Grammer AG's financial capital is the bedrock for its strategic investments. Adequate financial resources are essential for funding ongoing research and development, which is crucial for innovation in the automotive and commercial vehicle interiors sector. In 2024, Grammer continued to prioritize R&D to stay ahead of market trends and technological advancements.

These financial resources also enable necessary capital expenditures for facility upgrades and modernization. Maintaining state-of-the-art production facilities is key to efficiency and quality. Furthermore, financial strength allows Grammer to pursue strategic acquisitions that can expand its market reach or technological capabilities, thereby enhancing its competitive position.

Efficient management of working capital is another critical aspect supported by strong financial capital. This ensures smooth day-to-day operations and the ability to meet customer demands promptly. Grammer's financial stability underpins its operational resilience, allowing it to navigate market fluctuations and invest confidently in future growth strategies.

- Research & Development: Continued investment in R&D to drive innovation in interior solutions for automotive and commercial vehicles.

- Capital Expenditures: Funding for facility upgrades and modernization to enhance production efficiency and quality standards.

- Strategic Acquisitions: Pursuing opportunities for growth through targeted acquisitions to expand market presence or technological expertise.

- Working Capital Management: Ensuring efficient management of financial resources to support ongoing operations and meet market demands.

Grammer AG's key resources also include its extensive portfolio of intellectual property, such as patents and proprietary designs, which protect its innovations in seating and interior technologies. This intellectual capital, combined with deep expertise in ergonomics and materials science, forms a crucial intangible asset. In 2023, Grammer continued its commitment to R&D, evidenced by new patent filings and design registrations, vital for maintaining its competitive edge.

Value Propositions

Grammer AG’s core value proposition centers on delivering an exceptional user experience, achieved through products engineered for advanced ergonomics, superior comfort, and unwavering safety standards. This commitment directly enhances driver and passenger well-being, notably by mitigating fatigue on extended journeys and bolstering overall safety across diverse vehicle types.

For instance, Grammer's innovative seating solutions are designed to actively support the human body, reducing strain and improving posture. This focus on ergonomic design is crucial in commercial vehicle sectors where drivers spend extensive hours behind the wheel. In 2024, the company continued to invest heavily in research and development to push the boundaries of comfort technology, aiming to further reduce driver fatigue, a key factor in road safety and operational efficiency.

Grammer AG excels at crafting bespoke interior components and seating solutions, meticulously engineered for the distinct demands of diverse vehicle types. This adaptability spans everything from sleek passenger cars to robust heavy-duty trucks, public transport buses, high-speed trains, and specialized off-road equipment.

This commitment to tailored design ensures seamless integration and superior performance, whether the application involves the comfort of a long-haul driver or the rugged durability required for agricultural machinery. For instance, in 2024, Grammer's focus on specific segments like commercial vehicles saw continued innovation in ergonomic seating designed to reduce driver fatigue, a critical factor in operational efficiency and safety.

Grammer's value proposition centers on delivering cutting-edge solutions through the continuous integration of advanced technologies and innovative materials. This focus ensures their seating systems offer intelligent functionalities, employ lightweight construction for fuel efficiency, and feature durable surface designs that withstand rigorous use.

By consistently pushing the boundaries of automotive interior technology, Grammer empowers vehicle manufacturers to create distinctive products. For instance, their development of intelligent seating, which can adapt to passenger needs and preferences, directly addresses the automotive industry's drive for enhanced comfort and personalized experiences. This commitment to innovation is crucial in a market where differentiation is key to success.

In 2024, the automotive industry saw a significant emphasis on in-cabin technology and sustainability. Grammer's investment in areas like advanced sensor integration for seating and the use of recycled or bio-based materials aligns perfectly with these market trends. Their ability to provide these advanced features helps manufacturers meet consumer demand for more sophisticated and environmentally conscious vehicles, contributing to a competitive edge.

Global Production and Supply Chain Reliability

Grammer AG's extensive global production and logistics network, featuring numerous sites worldwide, directly translates into superior supply chain reliability for its customers. This widespread infrastructure ensures that Grammer can consistently deliver its products, a crucial factor for international original equipment manufacturers (OEMs) who depend on predictable supply chains to maintain their own production schedules.

This global footprint facilitates efficient, just-in-time delivery, minimizing inventory holding costs for clients and ensuring that components arrive precisely when needed. Furthermore, the localized presence allows for rapid responsiveness to evolving customer requirements and market dynamics, a significant competitive advantage in the fast-paced automotive industry.

- Global Network: Grammer operates production and logistics facilities across multiple continents, supporting a vast international customer base.

- Supply Chain Resilience: The decentralized nature of its operations enhances resilience against regional disruptions, ensuring continuity of supply.

- Localized Support: Proximity to key markets allows for tailored solutions and faster turnaround times, improving customer satisfaction.

- Efficiency Gains: Just-in-time delivery capabilities reduce lead times and operational costs for OEMs.

High Quality and Durability

Grammer AG's commitment to high quality and durability is a cornerstone of its value proposition. Their products are engineered for robust construction, ensuring exceptional performance and an extended operational lifespan. This focus on longevity directly benefits customers by minimizing maintenance needs and enhancing overall satisfaction.

This inherent durability fosters significant trust between Grammer and its clients, particularly vehicle manufacturers. For example, in 2024, Grammer reported a strong focus on material science and advanced manufacturing techniques to further enhance product resilience. This dedication to quality not only reduces total cost of ownership for customers but also solidifies Grammer's position as a preferred supplier in a competitive market.

- Engineered for Longevity: Grammer products are built to withstand demanding operational environments, reducing the frequency of replacements and repairs.

- Reduced Maintenance Costs: The high durability translates into lower lifecycle costs for vehicle manufacturers and end-users.

- Enhanced Customer Satisfaction: Reliable and long-lasting components contribute to greater overall user experience and loyalty.

- Market Preference: Grammer's reputation for quality drives demand and strengthens its competitive advantage.

Grammer AG's value proposition is built on delivering tailored, high-quality interior solutions that enhance user experience and operational efficiency. Their expertise spans ergonomic seating, durable components, and innovative technologies, serving diverse vehicle sectors from passenger cars to heavy-duty trucks.

Customer Relationships

Grammer AG's strategy of dedicated key account management is crucial for its OEM relationships. These specialized managers, acting as primary liaisons, ensure a deep understanding of each major customer's unique requirements. This focus allows for highly collaborative product development cycles and smoother integration processes, reinforcing Grammer's position as a trusted partner.

Grammer AG offers robust technical support throughout a product's life, from its inception to post-production. This commitment ensures customers receive assistance at every stage. For instance, in 2023, Grammer reported a significant increase in customer satisfaction scores related to their technical support services, reflecting the effectiveness of their approach.

Collaborative co-development with Original Equipment Manufacturers (OEMs) is a key strategy. This partnership approach allows Grammer to tailor solutions precisely to the unique and evolving needs of vehicle designs and performance standards. In 2024, Grammer announced several new co-development projects with major automotive manufacturers, highlighting their dedication to innovation and customer-specific integration.

Grammer AG strengthens customer relationships through its dedicated aftermarket service, ensuring the availability of genuine spare parts. This focus on longevity and repairability is crucial for commercial vehicle operators, offering a sustainable and economical solution to maintain their fleets.

In 2024, Grammer's commitment to aftermarket support directly contributes to customer loyalty by reducing total cost of ownership. By providing readily accessible spare parts, Grammer minimizes downtime for its clients, a critical factor in the transportation industry where every hour of operation counts.

Long-Term Strategic Partnerships

Grammer AG cultivates long-term strategic partnerships by acting as an integral supplier within customer innovation and production processes. This goes beyond simple transactions, aiming to embed Grammer deeply into their partners' value chains.

The company proactively anticipates future industry shifts and customer needs, engaging in joint development projects to co-create cutting-edge solutions. For instance, in 2024, Grammer continued its focus on lightweight construction materials and sustainable manufacturing processes, working closely with automotive OEMs to integrate these advancements into upcoming vehicle platforms.

- Collaborative Innovation: Grammer actively participates in customer R&D, co-developing next-generation components.

- Integrated Supply Chain: The company positions itself as a critical, reliable partner in production, ensuring seamless integration.

- Future Trend Anticipation: Grammer invests in understanding and shaping future market demands through joint foresight.

- Customer Retention: This strategic approach fosters strong loyalty and reduces churn by creating high switching costs.

Quality Assurance and Feedback Mechanisms

Grammer AG prioritizes quality assurance through rigorous testing at various production stages. For instance, in 2024, the company continued its focus on defect reduction, aiming for a further decrease in product non-conformities compared to the previous year's already low rates.

Transparent feedback channels are actively maintained, allowing customers to report issues or suggest improvements. This direct communication loop is crucial for Grammer's ongoing product development and service enhancement efforts.

- Stringent Quality Control: Implementing comprehensive checks throughout the manufacturing process to ensure product excellence.

- Customer Feedback Channels: Establishing clear and accessible avenues for customers to share their experiences and concerns.

- Continuous Improvement: Utilizing feedback to refine products and services, fostering customer loyalty.

- Addressing Concerns Promptly: Ensuring that customer issues are resolved efficiently to maintain high satisfaction levels.

Grammer AG fosters deep customer loyalty through a multi-faceted approach, emphasizing collaborative co-development and robust aftermarket support. By actively engaging with OEMs in research and development, Grammer ensures its solutions are precisely tailored to evolving automotive needs. The company's commitment to providing genuine spare parts and efficient service in the aftermarket further solidifies these partnerships, minimizing downtime and reducing the total cost of ownership for its clients.

Channels

Grammer AG's primary sales channel is direct engagement with Original Equipment Manufacturers (OEMs) in the automotive and commercial vehicle sectors. This involves close collaboration with OEM engineering, design, and procurement teams to embed Grammer's seating systems and interior components into new vehicle platforms.

In 2023, Grammer reported that its automotive division, which heavily relies on direct OEM sales, generated a significant portion of its revenue. This direct channel allows for tailored solutions and deep integration, crucial for securing long-term supply contracts with major global automakers.

Grammer AG leverages a robust global production and distribution network, comprising 48 sites across 19 countries. This extensive infrastructure is a cornerstone of its business model, facilitating localized production and efficient supply chain management.

This worldwide presence allows Grammer to manufacture products closer to its international customer base, significantly reducing lead times and transportation expenses. For instance, their strategic placement of facilities ensures prompt delivery of automotive components and agricultural machinery parts to major markets.

The network's efficiency is vital for maintaining competitive pricing and ensuring product availability, directly impacting customer satisfaction and Grammer's market reach. In 2024, the company continued to optimize this network to adapt to evolving global logistics and market demands.

Grammer AG leverages an aftermarket sales and service network comprising authorized distributors and dedicated service centers for its commercial vehicle seating. This crucial channel ensures end-users and fleet operators receive genuine spare parts and essential maintenance, directly contributing to product durability and sustained customer satisfaction.

Trade Shows and Industry Events

Grammer AG leverages major international trade shows like InnoTrans and bauma as crucial channels to connect with the automotive and commercial vehicle sectors. These events are vital for demonstrating new product developments and fostering relationships with both current and prospective clients. In 2024, Grammer continued its active participation, highlighting its commitment to industry engagement and showcasing its innovative solutions.

Participation in these prominent industry gatherings allows Grammer to solidify its position as a technological leader. It's a direct avenue for customer interaction, feedback gathering, and identifying emerging market trends. For instance, at InnoTrans, a leading trade fair for transport technology, Grammer can directly engage with decision-makers in the rail industry, a key segment for their seating and interior solutions.

- Showcasing Innovation: Trade shows provide a physical space to exhibit Grammer's latest advancements in seating technology and interior systems for commercial vehicles.

- Customer Engagement: Direct interaction at events facilitates building stronger relationships with existing customers and identifying new business opportunities.

- Brand Reinforcement: Consistent presence at key industry events reinforces Grammer's brand image and its reputation for quality and technological expertise.

Company Website and Investor Relations Platforms

Grammer AG's company website serves as a primary digital touchpoint, showcasing its extensive product range and innovations to a broad audience, including prospective clients and collaborators. This platform is crucial for disseminating corporate updates and fostering brand awareness.

The dedicated Investor Relations section on Grammer's website is specifically designed for financially astute stakeholders. It offers a wealth of critical information, including financial statements, annual reports, and market-related disclosures, facilitating informed investment analysis.

For instance, as of the first quarter of 2024, Grammer AG reported revenue of €527.4 million, highlighting the tangible financial activities accessible through these channels. This data underscores the platform's role in transparency.

- Website as a comprehensive information hub for products and corporate news.

- Investor Relations section providing detailed financial data and reports.

- Facilitating informed decision-making for investors and business strategists.

- Example: Q1 2024 revenue of €527.4 million demonstrates the financial transparency offered.

Grammer AG's channels are multifaceted, designed to reach diverse customer segments. Direct sales to OEMs remain paramount, complemented by a robust aftermarket network for commercial vehicles. Digital presence via the company website and strategic participation in international trade shows further broaden their market engagement.

These channels are critical for showcasing innovation, fostering client relationships, and ensuring product accessibility. The company's global production network underpins these efforts, enabling efficient delivery and localized support.

Grammer's financial transparency is evident through its website, particularly the Investor Relations section, which provides key data like the €527.4 million revenue reported in Q1 2024, supporting informed stakeholder decisions.

| Channel | Primary Focus | Key Activities/Data Points |

|---|---|---|

| Direct OEM Sales | Automotive & Commercial Vehicles | Securing long-term supply contracts, tailored solutions. Automotive division revenue significant portion of total. |

| Aftermarket Network | Commercial Vehicle Seating | Genuine spare parts, maintenance, service centers. Enhances product durability. |

| Global Production & Distribution Network | All Segments | 48 sites in 19 countries. Reduces lead times, transportation costs. Optimized in 2024 for market demands. |

| International Trade Shows | Automotive & Commercial Vehicles | Showcasing innovations (e.g., InnoTrans, bauma), customer engagement, brand reinforcement. Active participation in 2024. |

| Company Website | Broad Audience | Product range showcase, corporate updates, brand awareness. Investor Relations section for financial data. |

Customer Segments

Grammer's primary customer segment consists of major global automotive manufacturers, the Passenger Vehicle Original Equipment Manufacturers (OEMs). These companies rely on Grammer for essential interior components like headrests, armrests, and center consoles, crucial for vehicle comfort and aesthetics.

OEMs specifically value Grammer's ability to seamlessly integrate these components into vehicle designs, ensuring both form and function. A key driver for this segment is Grammer's commitment to meeting rigorous automotive safety standards, a non-negotiable requirement for mass-produced vehicles.

In 2024, the automotive industry continued to navigate supply chain complexities and the transition to electric vehicles. Grammer's focus on cost-effective solutions for mass production remains vital, as OEMs strive to manage production costs amidst evolving market demands. For instance, the global passenger car market saw significant activity in 2024, with manufacturers producing millions of units, each requiring these interior components.

Truck and Bus Manufacturers (OEMs) represent a core customer segment, seeking advanced seating solutions for their vehicles. These companies prioritize driver ergonomics, aiming to enhance comfort and reduce fatigue during long hauls, which directly impacts productivity and safety. In 2024, the global commercial vehicle market saw continued demand, with manufacturers like Daimler Truck and Volvo Group investing heavily in driver well-being technologies.

Durability and safety are paramount for OEMs in this segment. Seating systems must withstand rigorous operational conditions and integrate features that protect occupants in the event of a collision. For instance, advanced suspension systems and integrated seatbelts are critical components that OEMs specify to meet stringent regulatory requirements and enhance their product's appeal. The focus on safety is underscored by the increasing adoption of Advanced Driver-Assistance Systems (ADAS) in trucks and buses, where seating plays a supporting role.

Passenger comfort is also a key driver for bus manufacturers, particularly in the public transport sector. OEMs are looking for seating that offers a pleasant experience for commuters and long-distance travelers, contributing to passenger satisfaction and ridership. This includes considerations for material quality, adjustability, and ease of cleaning. The ongoing electrification of public transport fleets also brings new considerations for seating design, balancing weight and space with passenger comfort.

Grammer AG serves off-road machinery manufacturers, including those in agricultural, construction, and material handling sectors. These Original Equipment Manufacturers (OEMs) need durable, ergonomic driver seats designed for harsh conditions. For instance, in 2024, Grammer continued to supply its advanced suspension systems to leading tractor manufacturers, aiming to enhance operator comfort and productivity.

Train Manufacturers (OEMs)

Train Manufacturers, often referred to as Original Equipment Manufacturers (OEMs), represent a critical customer segment for specialized seating solutions. These companies are responsible for producing entire railway vehicles, from commuter trains to high-speed rail, and require seating that meets rigorous industry standards.

Their primary concerns revolve around passenger safety, comfort, and the longevity of the seating components. For instance, in 2024, the global railway market saw significant investment, with projected growth in passenger rail services demanding advanced seating technologies. OEMs must ensure their chosen seating suppliers can deliver products compliant with EN 45545 fire safety standards and offer ergonomic designs for enhanced passenger experience on extended journeys.

Key considerations for train OEMs include:

- Regulatory Compliance: Adherence to strict safety and fire resistance standards specific to the rail industry is paramount.

- Passenger Comfort: Designing seating that provides superior comfort for passengers, especially on long-distance routes, is a key differentiator.

- Durability and Reliability: Seats must withstand constant use and harsh environmental conditions inherent in public transportation.

- Customization: The ability to customize seating to match specific train designs and passenger class requirements is often essential.

Aftermarket and Replacement Parts Customers

This customer segment encompasses vehicle owners, fleet operators, and independent maintenance service providers who depend on Grammer for genuine spare parts. These customers are focused on maintaining the longevity and optimal performance of their existing Grammer seating systems and interior components, particularly within the commercial vehicle sector.

The demand for aftermarket and replacement parts is substantial, driven by the extensive installed base of Grammer products in the global commercial vehicle market. For instance, in 2024, the global commercial vehicle aftermarket sector was estimated to be worth billions, with a significant portion attributed to seating and interior components. Grammer's commitment to providing authentic parts ensures that these operators can minimize downtime and maintain operational efficiency.

- Vehicle Owners and Fleet Operators: These end-users require reliable spare parts to keep their vehicles operational, directly impacting their revenue streams.

- Maintenance Service Providers: Garages and repair shops rely on the availability of genuine Grammer parts to service customer vehicles effectively and maintain their reputation.

- Value Proposition: Customers in this segment prioritize the authenticity and quality of parts to ensure product longevity, safety, and adherence to manufacturer specifications.

- Market Relevance: The ongoing need for maintenance and repair in the trucking and bus industries, which heavily utilize Grammer seating, ensures a consistent demand for replacement parts.

Grammer's customer base is diverse, primarily serving Original Equipment Manufacturers (OEMs) across several key industries. This includes major automotive manufacturers for passenger vehicles, where Grammer supplies essential interior components like headrests and armrests, crucial for comfort and safety. In 2024, the automotive sector’s focus on integrated design and cost-effective mass production solutions highlighted Grammer's value to these OEMs, who produced millions of passenger cars globally.

Cost Structure

Grammer AG's cost structure heavily relies on acquiring raw materials like metals, plastics, foams, and fabrics, alongside specialized components such as electronic controls and mechanical parts. These are fundamental to their product manufacturing.

In 2024, global commodity prices experienced volatility, directly influencing Grammer's procurement expenses. For instance, the price of steel, a key material, saw significant shifts throughout the year, impacting the cost of metal components. Similarly, fluctuations in oil prices affected the cost of plastics and synthetic fabrics.

Active management of supply chain dynamics is crucial for Grammer to mitigate the impact of these price variations. This includes strategic sourcing and maintaining strong relationships with suppliers to ensure cost stability and availability of necessary materials.

Manufacturing and Production Expenses represent a significant portion of Grammer AG's cost structure, covering the operational costs of its worldwide production sites. These expenses include wages for its approximately 12,000 employees, energy usage, upkeep of manufacturing equipment, and other factory-related overheads.

In 2023, Grammer AG reported a revenue of €2.1 billion, with a substantial portion of this dedicated to its production activities. The company's strategic focus on optimizing production capacities and relocating to more cost-effective regions is a direct response to managing these inherent manufacturing costs.

Grammer AG channels substantial funds into Research and Development (R&D), recognizing its vital role in fostering innovation and securing its market position. These investments are directed towards the compensation of skilled R&D staff, the upkeep and operation of extensive testing facilities, and the creation of prototypes for new product concepts.

Furthermore, a significant portion of the R&D budget is allocated to exploring and integrating novel technologies and advanced materials. This forward-looking approach ensures Grammer remains at the forefront of developing next-generation products that meet evolving industry demands.

For instance, in 2024, Grammer AG's commitment to R&D is reflected in its continuous efforts to enhance vehicle interiors, particularly focusing on sustainable materials and advanced seating solutions for commercial vehicles.

Sales, General, and Administrative (SG&A) Overheads

Sales, General, and Administrative (SG&A) overheads represent a significant portion of Grammer's cost structure, encompassing expenses from sales and marketing efforts, central administrative functions, and the upkeep of its worldwide office network.

To optimize these costs and boost efficiency, Grammer has implemented strategic initiatives such as establishing a Shared Service Center in Serbia. This move is projected to yield substantial savings, with a target reduction of approximately 15% in administrative costs by 2024.

- Sales and Marketing: Costs associated with promoting and selling Grammer's products globally.

- General and Administrative: Expenses for corporate management, HR, IT, and legal services.

- Global Office Operations: Costs for maintaining offices and facilities in various international locations.

- Efficiency Measures: Initiatives like the Serbian Shared Service Center aim to consolidate functions and reduce overheads.

Logistics and Distribution Costs

Grammer AG's extensive global operations mean significant investment in logistics and distribution. These costs are crucial for moving raw materials to production sites and delivering finished goods to international customers.

Key components include freight charges for air, sea, and land transport, warehousing and inventory management, and the complexities of customs duties and tariffs across various regions. For instance, in 2024, the automotive industry, a major sector for Grammer, continued to grapple with fluctuating shipping rates and supply chain disruptions, directly impacting these costs.

- Freight Charges: Costs associated with transporting raw materials and finished products globally via various modes of transport.

- Warehousing Expenses: Costs for storing inventory at strategic locations to ensure timely delivery.

- Customs Duties and Tariffs: Expenses incurred from international trade regulations and import/export fees.

- Distribution Network Management: Costs related to managing and optimizing the entire supply chain from supplier to customer.

Grammer AG's cost structure is characterized by significant expenses in raw materials, manufacturing, research and development, sales, general and administrative functions, and logistics. The company actively manages these costs through strategic sourcing, operational optimization, and efficiency initiatives, such as its Shared Service Center in Serbia, aiming to mitigate market volatility and enhance profitability.

| Cost Category | Description | 2024 Impact/Focus |

|---|---|---|

| Raw Materials | Metals, plastics, foams, fabrics, electronic and mechanical components. | Volatility in commodity prices (e.g., steel, oil) impacting procurement expenses. Strategic sourcing is key. |

| Manufacturing & Production | Wages, energy, equipment upkeep for global production sites. | Optimizing capacities and exploring cost-effective regions are ongoing strategies. |

| Research & Development (R&D) | Staff compensation, testing facilities, prototypes, new technologies. | Focus on sustainable materials and advanced seating solutions for evolving industry demands. |

| Sales, General & Administrative (SG&A) | Marketing, corporate management, IT, legal, office network. | Shared Service Center in Serbia aims for ~15% administrative cost reduction by 2024. |

| Logistics & Distribution | Freight, warehousing, customs duties, supply chain management. | Navigating fluctuating shipping rates and supply chain disruptions in the automotive sector. |

Revenue Streams

Grammer AG's primary revenue comes from selling automotive interior components directly to car manufacturers, known as Original Equipment Manufacturers (OEMs). This includes a range of products like headrests, armrests, center consoles, and even built-in child booster seats for passenger cars. This segment is a major contributor to the company's financial performance.

In 2024, the automotive industry saw continued demand for advanced interior features. Grammer's sales in this core area reflect this trend, with the company reporting significant revenue generation from these essential automotive parts. The focus on innovation in comfort and safety for vehicle interiors directly fuels this revenue stream.

Grammer generates significant revenue through the sale of advanced seating solutions for commercial vehicles. This includes specialized driver and passenger seats for trucks, buses, trains, and various off-road vehicles. Their established market leadership in this sector provides a reliable income source.

In 2023, Grammer reported sales of €2.2 billion, with a substantial portion attributable to their Commercial Vehicle division, underscoring the importance of this revenue stream. This segment benefits from ongoing demand for durable and ergonomic seating in the global transportation and construction industries.

Grammer AG captures significant revenue from aftermarket sales of spare parts and accessories for its seating systems. This segment is crucial, representing a growing portion of their income, around 15% in recent reporting periods. It fosters customer loyalty by ensuring the longevity and optimal performance of their products.

Customization and Engineering Services

Grammer AG generates revenue by offering specialized design, engineering, and customization services to its original equipment manufacturer (OEM) clients. This allows them to create bespoke interior and seating solutions that go beyond standard product offerings, adding significant value.

These services are crucial for OEMs needing specific functionalities or aesthetic integrations for their vehicles. For instance, Grammer's expertise in developing innovative seating concepts for commercial vehicles, such as advanced driver seats with integrated climate control and ergonomic adjustments, directly translates into revenue from these engineering projects. In 2023, the company highlighted its focus on these value-added services as a key growth driver.

- Specialized Design and Engineering: Grammer provides tailored engineering solutions for unique OEM requirements.

- Customization for Bespoke Needs: Revenue is generated from adapting products to specific client specifications for interiors and seating.

- Value-Added Services: These services enhance product offerings and create additional revenue streams beyond standard component sales.

New Product Line Expansion

Grammer's revenue streams are significantly bolstered by its strategic expansion into new product lines. This approach directly addresses evolving market needs and customer preferences.

For instance, the development and launch of advanced seating technologies and innovative interior features for the automotive and commercial vehicle sectors open up new avenues for revenue generation. This expansion broadens Grammer's market reach and competitive positioning.

- New Product Development: Focusing on advanced seating and interior solutions.

- Market Trend Alignment: Catering to emerging demands in automotive and commercial vehicles.

- Addressable Market Expansion: Reaching new customer segments and geographic regions.

- Revenue Diversification: Reducing reliance on existing product portfolios.

Grammer AG's revenue streams are multifaceted, primarily driven by the sale of automotive interior components to Original Equipment Manufacturers (OEMs) and specialized seating solutions for commercial vehicles. In addition to these core areas, the company also generates income from aftermarket sales, design and engineering services, and the introduction of new product lines.

| Revenue Stream | Description | Key Focus/Examples | 2023 Data Highlight |

|---|---|---|---|

| Automotive Interior Components (OEM) | Direct sales of interior parts to car manufacturers. | Headrests, armrests, center consoles, child booster seats. | Significant contributor to overall performance. |

| Commercial Vehicle Seating Solutions | Specialized seats for trucks, buses, trains, off-road vehicles. | Ergonomic and durable driver/passenger seats. | Substantial portion of €2.2 billion total sales. |

| Aftermarket Sales | Spare parts and accessories for seating systems. | Ensuring product longevity and performance. | Represents approximately 15% of income. |

| Design, Engineering & Customization Services | Bespoke solutions for OEM clients. | Innovative seating concepts, specific functionalities. | Key growth driver, highlighted in 2023. |

| New Product Development | Expansion into advanced seating and interior features. | Catering to evolving market demands. | Broadens market reach and diversifies revenue. |

Business Model Canvas Data Sources

The Business Model Canvas is built using financial statements, customer feedback, and competitive analysis. These sources ensure each canvas block is filled with accurate, up-to-date information about our operations and market position.