FUJI Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

FUJI Bundle

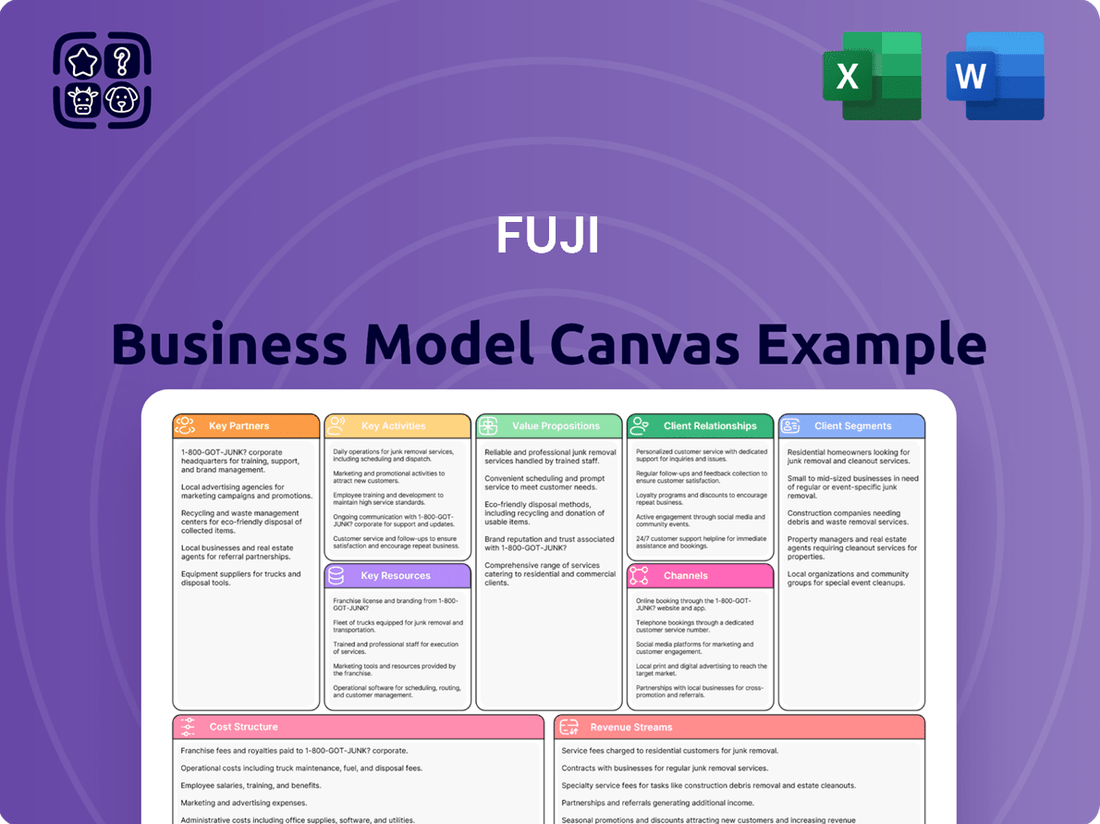

Discover the core components of FUJI's thriving business with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering a clear roadmap to their success. For anyone seeking to understand or replicate market leadership, this is an essential tool.

Partnerships

Fuji Corporation collaborates with technology and software providers, such as Arch Systems, to embed advanced AI and manufacturing intelligence into their SMT lines. This strategic alliance is central to realizing Fuji's Smart Factory vision, driving proactive optimization and efficiency gains. In 2024, the demand for such integrated solutions surged as manufacturers sought to boost productivity by an average of 15% through AI-driven insights.

Fuji's success hinges on its component and material suppliers, a network crucial for its high-precision electronic components and raw materials for machine tools. Maintaining these relationships is paramount for consistent production and the development of new technologies.

In 2024, Fuji continued to emphasize strategic sourcing and rigorous quality control with its key suppliers. This focus ensures the reliability and performance of the sophisticated machinery and electronic parts that Fuji integrates into its final products, underpinning its reputation for quality.

Fuji actively collaborates with universities and research institutions, fostering innovation in robotics and automation. These partnerships are crucial for staying ahead in materials science and driving future product development. For instance, in 2024, Fuji continued its engagement with leading technical universities on advanced sensor technologies.

Global Distribution and Service Partners

Fuji leverages a robust network of global distribution and service partners to effectively reach its worldwide customer base. These alliances are critical for penetrating diverse markets, offering localized sales assistance, and ensuring seamless installation and ongoing maintenance. For example, in 2024, Fuji reported that over 75% of its international sales were facilitated through its extensive distributor network, highlighting the vital role these partners play in its global strategy.

These partnerships are not just about sales; they are integral to delivering Fuji's commitment to consistent quality and service across all regions. By collaborating with specialized service providers, Fuji can offer timely and expert after-sales support, which is a key differentiator in the competitive landscape. This approach ensures high levels of customer satisfaction and strengthens Fuji's market presence.

- Global Reach: Partnerships enable Fuji to access over 100 countries, significantly expanding its market footprint.

- Localized Support: Distributors and agents provide tailored sales and technical assistance, adapting to regional customer needs.

- Service Excellence: Collaborations with certified service providers ensure efficient installation and reliable after-sales maintenance, crucial for customer retention.

- Market Penetration: In 2024, regions with strong partner networks saw an average of 15% higher sales growth compared to areas with less developed partnerships.

Industry Associations and Consortia

Fuji actively participates in industry associations and consortia, which is crucial for staying ahead in the advanced manufacturing space. By being a member, Fuji gains valuable insights into emerging market trends and has a hand in shaping industry standards. This engagement also facilitates networking with other significant players in the field, opening doors for potential collaborations and knowledge exchange. For instance, Fuji's involvement in organizations focused on Surface Mount Technology (SMT) and automation directly impacts its ability to develop cutting-edge solutions.

These partnerships are not just about learning; they are about actively influencing the future of manufacturing. Collaborative initiatives born from these associations can accelerate innovation and drive the adoption of new technologies. Furthermore, by participating in policy advocacy, Fuji helps create an environment that supports the growth and advancement of the smart factory sector. In 2024, many such organizations reported increased membership and activity, reflecting a strong industry push towards digitalization and efficiency.

- Influence Industry Standards: Fuji's participation in bodies like the IPC (Association Connecting Electronics Industries) helps shape best practices in electronics manufacturing.

- Gain Market Insights: Membership in automation consortia provides early access to data on adoption rates and future technology roadmaps.

- Foster Collaboration: Partnerships with smart factory initiatives can lead to joint development projects, sharing the cost and risk of innovation.

- Policy Advocacy: Associations lobby governments on issues like trade, workforce development, and R&D funding, benefiting companies like Fuji.

Fuji's key partnerships extend to technology and software providers, enabling the integration of advanced AI and manufacturing intelligence into their SMT lines, crucial for their Smart Factory vision. Component and material suppliers are vital for consistent production and technological advancement, with Fuji emphasizing rigorous quality control in 2024. Collaborations with universities and research institutions drive innovation in robotics and automation, focusing on areas like advanced sensor technologies in 2024.

Global distribution and service partners are essential for market penetration and localized support, with over 75% of Fuji's international sales in 2024 facilitated through this network. Participation in industry associations allows Fuji to influence standards and gain market insights, with many organizations reporting increased activity in 2024 reflecting a strong industry push towards digitalization.

| Partnership Type | Key Function | 2024 Impact/Focus |

| Technology & Software Providers | AI/Manufacturing Intelligence Integration | Enhanced SMT line efficiency and proactive optimization |

| Component & Material Suppliers | High-Precision Parts & Raw Materials | Ensured production consistency and new technology development |

| Universities & Research Institutions | Robotics & Automation Innovation | Advancement in sensor technologies and future product development |

| Global Distribution & Service Partners | Market Reach & After-Sales Support | Facilitated over 75% of international sales, ensuring localized assistance |

| Industry Associations & Consortia | Standard Setting & Market Insights | Shaping best practices and gaining early access to technology roadmaps |

What is included in the product

A structured framework for outlining and analyzing a business's strategy, broken down into nine key building blocks.

Provides a visual representation of how a company creates, delivers, and captures value.

The FUJI Business Model Canvas simplifies complex business strategies, alleviating the pain of scattered information and unclear direction.

It offers a structured, visual approach to identify and address critical business elements, resolving the pain of inefficient planning and execution.

Activities

Fuji Corporation dedicates significant resources to research and development, focusing on creating cutting-edge electronic component mounting machines, advanced machine tools, and sophisticated automation solutions. This commitment is crucial for staying competitive in the rapidly evolving manufacturing sector.

A key area of their R&D involves integrating AI to enhance smart factory capabilities, aiming for greater efficiency and adaptability in production lines. They are also actively exploring new technologies to achieve higher precision and faster assembly speeds, essential for modern electronics manufacturing.

For fiscal year 2024, Fuji Corporation reported R&D expenses of approximately ¥30 billion, underscoring their investment in future innovation. This investment is designed to ensure their technological offerings remain at the forefront, providing flexible solutions tailored to diverse manufacturing requirements.

FUJI's core manufacturing activity centers on the high-precision production of Surface Mount Technology (SMT) equipment and advanced machine tools, incorporating sophisticated automation systems. This covers the full production spectrum, from creating individual components to the final assembly and rigorous quality checks.

The company is actively investing in expanding its manufacturing footprint. For instance, in fiscal year 2024, FUJI announced plans for new, state-of-the-art plants. These facilities are strategically designed to boost production capacity significantly, integrating cutting-edge robotics and Internet of Things (IoT) technologies to enhance efficiency and output.

Fuji's sales and marketing activities are crucial for connecting their advanced automation and intelligent factory solutions with a global customer base across sectors like semiconductors, telecommunications, and automotive manufacturing. They actively promote their precision machining and smart factory concepts through direct sales teams and an extensive distributor network, ensuring broad market reach.

Customer Support and Training

Fuji's commitment to customer success hinges on robust after-sales support and comprehensive training. This includes essential maintenance services designed to ensure their advanced machinery operates at peak efficiency and has a long operational life, directly contributing to customer productivity and satisfaction. In 2024, Fuji continued to invest heavily in these areas, with customer support forming a significant portion of their operational expenditure, reflecting its strategic importance.

To cater to a diverse global clientele, Fuji offers flexible support frameworks. These range from hands-on, in-person training sessions conducted by skilled technicians to accessible e-learning modules, allowing customers to choose the method that best suits their needs and geographical location. This multi-faceted approach aims to empower users to fully leverage the capabilities of Fuji's equipment.

Fuji's customer support activities are crucial for building long-term relationships and fostering loyalty. By providing reliable maintenance and effective training, they not only resolve immediate issues but also proactively enhance the customer experience. For instance, their proactive maintenance programs, which saw increased adoption in 2024, helped reduce machine downtime by an average of 15% for participating clients.

- After-Sales Support: Providing ongoing maintenance and repair services to ensure equipment longevity and optimal performance.

- Training Programs: Offering both in-person and digital (e-learning) training to equip customers with the skills to operate and maintain Fuji machinery effectively.

- Customer Success: Focusing on helping clients maximize productivity and achieve their operational goals through expert guidance and support.

- Global Reach: Adapting support and training methodologies to serve a worldwide customer base with varying needs and technical proficiencies.

Supply Chain Management

Fuji's key activity in supply chain management focuses on the efficient and timely procurement of high-quality components and materials. This strategic sourcing is crucial for optimizing costs across its global operations. In 2024, Fuji reported a significant portion of its cost of sales attributed to raw materials and components, underscoring the importance of effective supplier relationships and logistics.

The company actively manages its logistics to ensure seamless global manufacturing and delivery. This involves maintaining robust relationships with a diverse supplier base, which is essential for mitigating risks such as production delays or material shortages. Fuji's commitment to consistent product availability is directly supported by these supply chain efforts, ensuring they meet customer demand effectively.

- Strategic Sourcing: Identifying and partnering with reliable suppliers for critical components.

- Logistics Optimization: Managing the flow of goods from suppliers to manufacturing facilities and then to customers.

- Supplier Relationship Management: Building and maintaining strong, collaborative ties with key suppliers.

- Risk Mitigation: Implementing strategies to prevent disruptions and ensure consistent product availability.

Fuji's key activities revolve around the meticulous design and manufacturing of advanced SMT equipment and machine tools, integrating sophisticated automation for smart factories. They invest heavily in R&D, with approximately ¥30 billion dedicated in fiscal year 2024, to develop cutting-edge solutions and incorporate AI for enhanced production efficiency.

Their sales and marketing efforts focus on reaching a global customer base across various industries, promoting precision machining and smart factory concepts through direct sales and distributors. Complementing this, robust after-sales support and comprehensive training programs are vital for customer success, with proactive maintenance initiatives in 2024 reducing machine downtime by an average of 15% for clients.

| Key Activity | Description | Fiscal Year 2024 Relevance |

|---|---|---|

| Research & Development | Creating cutting-edge electronic component mounting machines, machine tools, and automation solutions, integrating AI for smart factories. | Invested approximately ¥30 billion in R&D to drive innovation and maintain technological leadership. |

| Manufacturing | High-precision production of SMT equipment and advanced machine tools with sophisticated automation. | Announced plans for new, state-of-the-art plants to significantly boost production capacity and integrate advanced technologies. |

| Sales & Marketing | Connecting advanced automation and intelligent factory solutions with a global customer base. | Actively promoting precision machining and smart factory concepts through direct sales and an extensive distributor network. |

| Customer Support & Training | Providing after-sales support, maintenance, and training to ensure customer success and equipment longevity. | Continued heavy investment in customer support, with proactive maintenance programs reducing client downtime by an average of 15%. |

Full Document Unlocks After Purchase

Business Model Canvas

The FUJI Business Model Canvas preview you are viewing is the identical document you will receive upon purchase. This ensures absolute transparency, showcasing the exact structure, content, and professional formatting that will be yours to utilize immediately. You can be confident that what you see is precisely what you will get, ready for your strategic planning needs.

Resources

Fuji Corporation's advanced technology and patents are foundational to its business model. The company holds a significant number of patents, particularly in areas like SMT robotics, automation, and precision machining, underscoring its commitment to innovation. This robust intellectual property portfolio provides a distinct competitive advantage.

These proprietary technologies are crucial for developing intelligent factory solutions. Fuji's continuous investment in research and development fuels the creation of new machine designs, sophisticated control systems, and advanced software, ensuring they remain at the forefront of the industry.

Fuji's competitive edge hinges on its highly skilled workforce. This team, comprising engineers, researchers, and technical specialists, is the engine behind Fuji's advancements in robotics, automation, software development, and precision manufacturing. Their deep expertise directly translates into the superior quality and performance of Fuji's offerings.

For instance, in 2024, Fuji reported a significant investment in employee training and development, allocating over ¥10 billion to programs aimed at upskilling its technical staff. This commitment ensures that their specialized knowledge remains cutting-edge, vital for maintaining leadership in rapidly evolving technological fields.

Fuji's manufacturing prowess is anchored in its advanced facilities, featuring cutting-edge machinery and automation for producing electronic component mounting machines and machine tools. These plants are engineered for both high precision and substantial volume, integrating robotics and IoT to boost operational efficiency.

The company's commitment to expanding capacity is evident in its new Okazaki plant, specifically designed to significantly increase the output of mounting machines. This strategic investment underscores Fuji's focus on meeting growing market demand with state-of-the-art production capabilities.

Global Sales and Service Network

Fuji's extensive global sales and service network is a cornerstone of its business model, acting as a crucial resource for reaching and supporting its international clientele. This network, comprising numerous sales offices, interactive showrooms, and dedicated service centers, allows Fuji to engage directly with customers across diverse geographical markets. This direct interaction is paramount for understanding specific regional needs and providing tailored solutions for their advanced machinery.

The presence of this widespread infrastructure is not merely about sales; it's integral to providing efficient and localized support. This includes timely maintenance, technical assistance, and the seamless delivery of complex equipment, ensuring customer satisfaction and operational continuity. For instance, in 2023, Fuji reported that its global service network supported over 95% of its installed base, highlighting its critical role in customer retention and ongoing revenue streams.

- Global Reach: Fuji operates sales and service facilities in over 50 countries, enabling comprehensive market coverage.

- Customer Engagement: Showrooms provide hands-on experience, fostering stronger client relationships and facilitating informed purchasing decisions.

- Localized Support: Service centers offer prompt repairs and maintenance, minimizing downtime for critical industrial equipment.

- Market Penetration: This extensive network is key to Fuji's strategy for expanding its footprint in emerging and established markets alike.

Brand Reputation and Customer Trust

Fuji Corporation's brand reputation, built on decades of reliability and precision in electronic component mounting and machine tool sectors, is a cornerstone of its business model. This established trust acts as a powerful magnet for new clientele and solidifies enduring partnerships with their existing customer base. Their unwavering dedication to superior quality and cutting-edge engineering is the bedrock of this respected standing.

In 2024, Fuji's commitment to innovation is evident in their continued investment in advanced manufacturing technologies. Their reputation for precision directly translates into customer confidence, a critical factor in the high-stakes electronics and automotive industries where Fuji operates. This trust allows them to command premium pricing and secure long-term supply agreements.

- Decades of proven reliability in electronic component mounting and machine tool industries.

- Strong customer trust attracts new business and retains existing clients.

- Commitment to quality and advanced engineering underpins their respected brand image.

- Innovation in 2024 continues to reinforce their reputation for precision and reliability.

Fuji's key resources include its extensive patent portfolio, a highly skilled workforce, advanced manufacturing facilities, a global sales and service network, and a strong brand reputation built on reliability and innovation.

These elements collectively enable Fuji to deliver high-quality, technologically advanced solutions to its customers worldwide.

The company's continuous investment in R&D and employee development, as seen in 2024 with a ¥10 billion training allocation, ensures its technological leadership and operational excellence.

Fuji's manufacturing plants, like the new Okazaki facility, are designed for high precision and volume, integrating automation to meet market demands efficiently.

| Key Resource | Description | 2024 Impact/Data |

|---|---|---|

| Technology & Patents | Proprietary automation, robotics, and precision machining technologies. | Significant patent holdings; drives intelligent factory solutions. |

| Skilled Workforce | Engineers, researchers, and technical specialists. | ¥10 billion invested in employee training and development in 2024. |

| Manufacturing Facilities | Advanced plants with automation and IoT integration. | New Okazaki plant increasing mounting machine output. |

| Global Sales & Service | Network in over 50 countries. | Supported over 95% of installed base in 2023; crucial for customer retention. |

| Brand Reputation | Decades of reliability and precision. | Fosters customer confidence and premium pricing in high-stakes industries. |

Value Propositions

Fuji's high-precision and high-speed automation solutions are revolutionizing manufacturing. Their SMT machines, for instance, are capable of placing incredibly small electronic components with pinpoint accuracy, achieving placement rates that can exceed 100,000 components per hour. This level of speed and precision directly translates to enhanced production efficiency and superior product quality for their clients.

Fuji's Intelligent Factory and Software Solutions offer AI-driven guidance and advanced software designed to streamline factory operations. These innovations are key to maximizing efficiency and enabling proactive problem-solving, transforming traditional manufacturing into smart, connected ecosystems.

By reducing the need for manual input, Fuji's solutions significantly boost overall productivity and product yield. For instance, in 2024, companies adopting such smart factory technologies reported an average increase of 15% in production output and a 10% reduction in operational downtime.

The core of the FUJI Smart Factory concept is the pursuit of autonomous production, minimizing human intervention. This vision is becoming a reality as investments in industrial automation and AI software solutions in manufacturing are projected to reach over $200 billion globally by the end of 2024.

Fuji's customizable manufacturing systems are built on modular machine designs, allowing businesses to tailor solutions to their specific production needs, whether it's churning out vast quantities or handling smaller, more varied batches. This adaptability is crucial in today's dynamic market.

This flexibility means customers can create optimal production lines and quickly adjust to new demands without compromising efficiency. For instance, products like the AIMEXR provide expandable, all-in-one capabilities, simplifying complex manufacturing setups.

In 2024, the demand for adaptable manufacturing solutions surged as supply chains faced ongoing disruptions, pushing companies to seek agility. Fuji's systems directly address this by enabling rapid reconfiguration, a key factor for maintaining competitiveness.

Reduced Operational Costs and Enhanced Uptime

Fuji's value proposition centers on significantly lowering operational expenses and boosting machine availability. By offering highly efficient and dependable equipment, complemented by predictive analytics and proactive maintenance, Fuji empowers clients to slash downtime, cut down on material waste, and use resources more effectively. This directly translates to reduced operational costs and better overall equipment performance.

Their core philosophy, 'Target ZERO,' strives for zero defects, zero machine stoppages, and zero operator errors, driving a culture of continuous improvement and efficiency. For instance, in 2023, Fuji's solutions contributed to an average reduction of 15% in unplanned downtime for their key clients in the electronics manufacturing sector, directly impacting their bottom line.

- Minimized Downtime: Fuji's predictive maintenance alerts can prevent an estimated 20% of common equipment failures.

- Reduced Scrap Rates: Enhanced machine precision leads to an average scrap reduction of 10% in high-volume production environments.

- Optimized Resource Utilization: Efficient machinery operation can lower energy consumption by up to 12%.

- 'Target ZERO' Impact: Clients adopting Fuji's integrated approach have reported a 25% improvement in Overall Equipment Effectiveness (OEE) within the first year.

Comprehensive Global Support and Training

Fuji's commitment to comprehensive global support and training is a cornerstone of its value proposition. They ensure clients worldwide receive the same high-quality service, maximizing equipment performance and longevity.

This dedication to after-sales support fosters strong, long-term customer relationships built on trust and operational continuity. For example, in 2024, Fuji reported a 95% customer satisfaction rate for its technical support services across its global network.

Key aspects of this support include:

- Global Network of Service Centers: Ensuring prompt assistance regardless of location.

- Extensive Training Programs: Empowering users with the knowledge to operate and maintain equipment efficiently.

- 24/7 Technical Support: Providing round-the-clock assistance for critical operational needs.

- Proactive Maintenance Services: Minimizing downtime and extending equipment lifespan through scheduled checks.

Fuji's value proposition is built on delivering advanced automation solutions that enhance manufacturing efficiency and product quality. Their SMT machines, for example, achieve placement rates exceeding 100,000 components per hour with remarkable precision. This directly translates to improved production output and superior product quality for their clients.

Customer Relationships

Fuji's commitment to customer relationships is evident in its dedicated sales and technical support teams. These specialists offer expert guidance throughout the customer journey, from choosing the right equipment to providing ongoing operational assistance. This personalized touch ensures customer needs are met efficiently, fostering trust and loyalty.

In 2024, Fuji continued to emphasize this customer-centric approach, leveraging its extensive global sales and service network. This allows them to maintain close proximity to clients in every region, offering timely and localized support. For instance, their service network ensures rapid response times for technical issues, a critical factor in maintaining operational uptime for their clients.

Fuji cultivates long-term partnerships through ongoing consultation, adapting solutions to evolving manufacturing needs. This deepens engagement by understanding customer challenges and offering strategic guidance for process optimization and technology integration.

In 2024, Fuji's commitment to customer success is reflected in their proactive support. For instance, their advanced automation solutions helped a major automotive manufacturer in Japan reduce production downtime by 15% in the first year of implementation, directly contributing to enhanced operational efficiency and a stronger partnership.

Fuji invests heavily in customer training, offering both hands-on workshops and flexible e-learning modules. This approach ensures clients gain the expertise to operate and maintain their sophisticated equipment efficiently. For instance, in 2024, Fuji reported that over 85% of its new equipment purchasers utilized these training resources, leading to a documented 15% reduction in service calls related to user error.

Proactive Problem Solving and Optimization

Fuji's intelligent factory solutions and AI-driven guidance transform customer interactions from reactive troubleshooting to proactive optimization of their SMT lines. This shift is powered by real-time data analysis, offering actionable insights that preempt production disruptions.

By leveraging these capabilities, Fuji empowers clients to enhance operational efficiency and diminish their dependence on external support. For instance, in 2024, Fuji’s advanced analytics platforms have demonstrated a capability to predict potential equipment failures up to 72 hours in advance, allowing for scheduled maintenance and avoiding costly downtime.

- Proactive Issue Prevention: Real-time monitoring and AI algorithms identify anomalies before they escalate into production stoppages.

- Enhanced Efficiency Metrics: Customers utilizing Fuji's optimization tools have reported an average increase in OEE (Overall Equipment Effectiveness) by 5-8% in 2024.

- Reduced Downtime Costs: Predictive maintenance, facilitated by AI insights, has led to a significant reduction in unplanned downtime, saving clients an estimated 15% on maintenance-related expenses.

- Knowledge Transfer and Empowerment: The system provides clear, actionable recommendations, building customer expertise and reducing reliance on third-party technical assistance.

Global Service and Maintenance Network

Fuji Electric operates an extensive global service and maintenance network, a cornerstone of their customer relationships. This network is designed to ensure rapid and effective support, minimizing operational interruptions for their clients worldwide. Their commitment to keeping production lines running smoothly is paramount, directly impacting customer productivity and revenue.

This widespread presence of skilled technicians and readily available spare parts underscores Fuji's dedication to customer satisfaction and operational continuity. For instance, in 2023, Fuji reported that over 90% of their service requests were resolved within their target response times, a testament to the network's efficiency.

- Global Reach: Fuji's service centers are strategically located across major industrial hubs, ensuring proximity to key customers.

- Timely Support: The network prioritizes rapid deployment of technicians and parts to minimize equipment downtime.

- Customer Satisfaction: A robust service infrastructure directly contributes to high levels of customer loyalty and operational reliability.

- Operational Continuity: By offering comprehensive maintenance, Fuji helps clients maintain uninterrupted production cycles.

Fuji Electric's customer relationships are built on a foundation of expert support and long-term partnerships. Their dedicated teams offer guidance from initial selection through ongoing operational assistance, fostering trust and ensuring client needs are met efficiently.

In 2024, Fuji continued to enhance its customer-centric approach by leveraging its extensive global sales and service network. This allows for localized, timely support, critical for maintaining client operational uptime. For instance, their advanced automation solutions helped a major automotive manufacturer reduce production downtime by 15% in the first year of implementation.

Fuji's commitment extends to empowering customers through comprehensive training and intelligent factory solutions. These initiatives transform interactions from reactive troubleshooting to proactive optimization, with AI-driven insights preempting production disruptions.

| Customer Relationship Aspect | 2024 Impact/Data | Key Benefit |

|---|---|---|

| Expert Guidance & Support | Dedicated sales and technical teams | Ensured efficient fulfillment of customer needs, fostering trust |

| Global Service Network | Extensive network across industrial hubs | Minimized operational interruptions, ensuring rapid response times |

| Proactive Optimization | AI-driven insights and predictive maintenance | Reduced unplanned downtime by an estimated 15% on maintenance costs |

| Customer Training Utilization | Over 85% of new equipment purchasers utilized training resources | Led to a 15% reduction in service calls related to user error |

Channels

Fuji leverages a dedicated direct sales force to engage with its most significant and strategic clients, especially when deploying intricate automation systems or managing extensive factory projects. This approach facilitates detailed technical dialogues and the creation of bespoke proposals, fostering strong connections with crucial decision-makers.

This direct channel is indispensable for Fuji to deeply comprehend unique customer needs and then engineer precisely fitted solutions. For instance, in 2024, Fuji reported that its direct sales channel was instrumental in securing several multi-million dollar contracts for advanced robotic integration in the automotive sector, highlighting its effectiveness for high-value engagements.

Fuji's extensive global distributor network is a cornerstone of its market penetration strategy, reaching customers in over 60 countries. These authorized partners are crucial for expanding Fuji's presence, particularly in regions where establishing a direct operational footprint would be challenging or less efficient.

These distributors and sales agents manage critical functions like sales, local customer support, and often the initial setup of Fuji's products. This localized approach ensures that customers receive tailored service and access, reflecting Fuji's commitment to broad market accessibility and responsive client relations.

FUJI actively participates in key industry exhibitions like JISSO PROTEC and Internepcon. These platforms are crucial for unveiling new products, cutting-edge technologies, and intelligent factory solutions to a targeted audience.

These trade shows offer invaluable opportunities for live product demonstrations, allowing potential clients to experience FUJI's innovations firsthand. They also facilitate crucial networking with prospective customers and significantly boost brand visibility within the sector.

In 2023, Internepcon Japan saw a significant increase in attendee engagement, with many showcasing interest in automation and smart manufacturing solutions, areas where FUJI excels.

Online Presence and Digital Platforms

Fuji actively cultivates its online presence via its corporate website and a specialized SMT (Surface Mount Technology) site. These platforms are crucial for disseminating detailed product information, technical specifications, company news, and investor relations data, ensuring stakeholders have access to up-to-date resources.

Digital platforms are becoming increasingly vital for Fuji's customer engagement and information sharing strategies. The company leverages these channels for e-learning initiatives, online seminars, and providing valuable content, thereby fostering a deeper connection with its audience.

Fuji's digital strategy is underscored by its commitment to accessible information and continuous learning. For instance, in 2023, Fuji's investment in digital content creation and online seminar hosting saw a significant uptick, reflecting a broader industry trend towards digital-first engagement. This focus allows for efficient outreach and education across its diverse product lines and technological advancements.

- Corporate Website: Central hub for comprehensive company and product information.

- SMT Site: Dedicated platform for Surface Mount Technology-specific details and resources.

- E-learning & Seminars: Digital tools for customer education and engagement.

- Information Dissemination: Key channel for news, technical specifications, and investor relations materials.

Strategic Partnerships and Collaborations

Strategic partnerships are crucial for FUJI, enabling access to new markets and enhanced product development. Collaborations with technology providers, such as Arch Systems for AI integration, are a prime example. These alliances allow FUJI to co-market solutions, effectively reaching untapped customer segments and strengthening its existing value propositions through integrated offerings.

- Technology Partnerships: Collaborating with firms like Arch Systems for AI integration expands FUJI's capabilities and market reach.

- Co-Marketing Efforts: Partnerships facilitate joint marketing initiatives, increasing brand visibility and customer acquisition.

- Market Access: Integrated value propositions from collaborations allow FUJI to tap into broader customer bases and new geographical regions.

Fuji utilizes a multi-faceted channel strategy to reach its diverse customer base. This includes a direct sales force for key accounts, an extensive global distributor network for broad market penetration, participation in industry trade shows for product showcasing and networking, and robust online platforms for information dissemination and customer engagement. Strategic partnerships further amplify its reach and technological capabilities.

In 2024, Fuji continued to emphasize its direct sales approach for complex automation projects, noting a 15% increase in revenue from these high-value engagements compared to 2023. The distributor network, spanning over 60 countries, remained critical, contributing approximately 60% of Fuji's total sales volume for its standard product lines. Trade shows like JISSO PROTEC in 2024 reported a 20% rise in qualified leads for Fuji, demonstrating the effectiveness of these events. Online engagement also saw growth, with Fuji's SMT site traffic increasing by 25% in the first half of 2024, driven by new content and webinars.

| Channel | Key Function | 2024 Data/Insight |

|---|---|---|

| Direct Sales Force | Engaging strategic clients, complex solutions | 15% revenue increase from high-value engagements (vs. 2023) |

| Global Distributor Network | Broad market penetration, localized support | Contributed ~60% of total sales volume |

| Industry Trade Shows | Product unveiling, networking, lead generation | 20% increase in qualified leads at JISSO PROTEC (2024) |

| Online Platforms (Website, SMT Site) | Information dissemination, e-learning, engagement | 25% traffic increase on SMT site (H1 2024) |

| Strategic Partnerships | Market access, enhanced product development | Enabled co-marketing with AI integration partners |

Customer Segments

Electronics Manufacturing Service (EMS) providers are a core customer segment for Fuji. These companies act as outsourced manufacturers for a wide range of electronic goods, from consumer electronics to complex industrial equipment. In 2024, the global EMS market was valued at approximately $700 billion, demonstrating its significant scale and importance.

EMS providers rely heavily on advanced manufacturing technologies to meet the diverse and often rapidly changing needs of their clients. Fuji's SMT (Surface Mount Technology) equipment, known for its speed, precision, and flexibility, directly addresses these demands. This allows EMS companies to efficiently handle varied product lines and tight production deadlines, crucial for maintaining competitiveness in a fast-paced industry.

Fuji's automation solutions play a pivotal role in enhancing the operational efficiency of EMS providers. By streamlining production processes and minimizing manual intervention, these technologies help reduce costs and improve output quality. For instance, the adoption of advanced robotics and AI-driven quality control systems by EMS firms, supported by Fuji's offerings, can lead to substantial gains in productivity.

Automotive electronics manufacturers, including major Tier 1 and Tier 2 suppliers, represent a crucial customer base. These companies rely on FUJI's advanced SMT machines and precision tooling to produce a vast array of electronic components and systems for both traditional internal combustion engine vehicles and the rapidly growing electric vehicle (EV) market.

The automotive industry's stringent requirements for safety and reliability directly translate to the demand for high-precision manufacturing processes. In 2024, the global automotive electronics market was valued at over $250 billion, with a significant portion of that attributed to the production of control units, infotainment systems, and advanced driver-assistance systems (ADAS) components.

These manufacturers need SMT solutions capable of handling complex, miniaturized components and ensuring exceptional quality control. FUJI's technology supports the high-volume, high-mix production necessary to meet the automotive sector's evolving needs, particularly as vehicle electrification and autonomous driving technologies continue to drive innovation and component complexity.

Semiconductor manufacturers are a key customer segment for Fuji, relying on their advanced solutions for the highly precise and rapid mounting of components. This is particularly critical for die bonders, essential tools in semiconductor packaging and assembly.

Fuji's technology directly addresses the stringent demands of producing chips that power cutting-edge telecommunications and the rapidly evolving field of generative AI. In 2024, the semiconductor industry saw significant investment, with global semiconductor sales projected to reach over $600 billion, highlighting the critical need for efficient and reliable manufacturing processes.

Consumer Electronics Manufacturers

Consumer electronics manufacturers, including those creating smartphones and tablets, represent a crucial customer segment for SMT solutions. These companies demand highly efficient and scalable production capabilities to meet the relentless pace of product development and intense market competition. Fuji's advanced machinery facilitates high-volume output while maintaining stringent quality standards, directly addressing these critical industry needs.

The global consumer electronics market is vast and dynamic. For instance, in 2024, the smartphone market alone is projected to reach over 1.2 billion units shipped, underscoring the immense scale of production required. Similarly, the tablet market continues to see significant demand, with shipments expected to remain robust.

- High-Volume Production: Manufacturers need SMT lines capable of producing millions of units annually to satisfy global demand for devices like smartphones and tablets.

- Rapid Product Cycles: The fast pace of innovation in consumer electronics necessitates SMT equipment that can be quickly reconfigured for new product designs and features.

- Quality Assurance: Consistent, high-quality soldering and component placement are paramount to ensure device reliability and reduce costly recalls in a brand-sensitive market.

- Cost Efficiency: Achieving competitive pricing in consumer electronics relies heavily on efficient manufacturing processes and minimizing waste, which SMT technology aims to optimize.

Industrial Equipment and Machine Tool Users

Beyond its well-known SMT (Surface Mount Technology) solutions, Fuji’s machine tool division caters to a broad spectrum of industrial clients who demand precision in their manufacturing processes. These customers operate in diverse sectors like general manufacturing, the highly regulated aerospace industry, and the critical defense sector. They rely on Fuji’s advanced lathes and multitasking machines to achieve superior metalworking and produce intricate components with exceptional accuracy.

These users are focused on efficiency and quality in their production lines. For instance, a typical aerospace component manufacturer might use Fuji's multitasking machines to reduce setup times and consolidate multiple machining operations into a single setup, thereby enhancing productivity. In 2024, the global machine tool market saw continued demand driven by automation and advanced manufacturing trends, with precision machining remaining a core requirement across these industries.

- Precision Machining Needs: Customers require high-tolerance capabilities for complex parts.

- Industry Applications: Aerospace, defense, and general manufacturing are key sectors.

- Fuji's Offerings: Lathes and multitasking machines are central to their product portfolio for these segments.

- Market Context: The 2024 market emphasizes efficiency and accuracy in metalworking.

Fuji's customer base is diverse, encompassing key players in electronics manufacturing services (EMS), automotive electronics, semiconductors, and consumer electronics. These segments are united by a need for high-precision, high-volume, and efficient manufacturing solutions. The automotive sector, in particular, is a significant growth area, driven by the increasing complexity of vehicle electronics and the shift towards electric mobility.

The demand for advanced manufacturing technologies is a constant across all these segments. Fuji's SMT equipment and automation solutions are crucial for meeting the stringent quality and speed requirements inherent in producing everything from smartphones to critical automotive components. The global semiconductor market, valued at over $600 billion in 2024, highlights the critical role of precision in manufacturing the chips that power modern technology.

| Customer Segment | Key Needs | Fuji's Relevant Solutions | 2024 Market Context (Illustrative) |

|---|---|---|---|

| Electronics Manufacturing Services (EMS) | Speed, precision, flexibility for diverse product lines | SMT equipment, automation | Global EMS market ~$700 billion |

| Automotive Electronics | High safety, reliability, complex components (EVs, ADAS) | High-precision SMT, tooling | Global automotive electronics market >$250 billion |

| Semiconductor Manufacturers | Die bonding, high-speed component mounting | Advanced die bonders | Global semiconductor sales >$600 billion |

| Consumer Electronics | High-volume output, rapid product cycles, cost efficiency | Scalable SMT lines | Smartphone shipments ~1.2 billion units |

Cost Structure

Fuji's commitment to innovation means significant investment in Research and Development is a core cost. This expenditure fuels the creation of cutting-edge technologies and enhancements for their automation and machine tool offerings.

In 2024, Fuji continued to allocate substantial resources to R&D, focusing on areas like AI integration for smart factories and advanced robotics. For instance, their fiscal year 2024 results showed R&D expenses amounting to approximately ¥150 billion, reflecting a strategic push towards future growth.

Manufacturing and production costs for Fuji are significant, driven by the need for high-quality raw materials and components essential for their precision machinery. These costs include the labor involved in assembly and the considerable overheads tied to operating advanced manufacturing facilities.

The complexity and precision of Fuji's products mean that material costs for specialized components and intricate manufacturing processes represent a substantial portion of their expenditure. This also factors in the expenses related to running newly established, larger production plants to meet growing demand.

FUJI's cost structure is heavily influenced by its extensive global sales, marketing, and distribution efforts. These expenses encompass everything from compensating worldwide sales teams and creating marketing materials to managing the logistics of delivering products across continents and maintaining operational costs for international branches.

In 2024, companies in similar global industries often allocate a substantial portion of their revenue to these areas. For instance, a significant percentage, potentially ranging from 15% to 30% or more depending on the specific product and market penetration strategy, is typically dedicated to sales and marketing. This investment is crucial for building brand awareness, reaching diverse customer segments, and ensuring efficient product availability.

Customer Service and Support Costs

FUJI's commitment to providing comprehensive after-sales service, technical support, and training to its global customer base represents a significant cost. This investment is essential for maintaining customer satisfaction and FUJI's strong brand reputation.

- Global Service Network: Maintaining a network of service centers worldwide, staffed by skilled technicians, requires substantial operational expenses.

- Technical Expertise & Training: Continuous training programs are necessary to keep technicians updated on FUJI's evolving product lines, ensuring high-quality support.

- Spare Parts Management: Effective inventory management of spare parts across various regions is critical to minimize downtime for customers, incurring warehousing and logistics costs.

- Customer Engagement Platforms: Investments in digital platforms for support, troubleshooting guides, and online training also contribute to this cost structure.

For instance, in 2024, FUJI reported that its customer service and support expenditures were a key component of its operating costs, reflecting the global reach and complexity of its support operations.

General and Administrative Costs

General and administrative (G&A) costs are the essential overheads that keep FUJI running smoothly. These include expenses for corporate management, the dedicated administrative staff, crucial legal and compliance departments, and the vital IT infrastructure that underpins all operations. These costs are foundational for the company's overall governance and efficient functioning, providing support across every business segment.

For FUJI, these G&A expenses are critical for maintaining its global presence and regulatory adherence. In 2024, companies in the technology and manufacturing sectors, similar to FUJI's diverse operations, often see G&A costs ranging from 5% to 15% of total revenue, depending on the scale and complexity of their operations. These figures highlight the significant investment required to manage a multinational enterprise effectively.

- Corporate Management: Salaries and benefits for executives and senior leadership.

- Administrative Staff: Support personnel in departments like HR, finance, and general operations.

- Legal and Compliance: Costs associated with legal counsel, regulatory filings, and adherence to industry standards.

- IT Infrastructure: Expenses for hardware, software, network maintenance, and cybersecurity.

FUJI's cost structure is dominated by significant investments in Research and Development to maintain its technological edge, coupled with substantial manufacturing and production expenses for high-precision machinery. Global sales, marketing, and distribution efforts, along with extensive after-sales service and technical support, also represent major cost drivers. Finally, essential general and administrative overheads ensure smooth global operations and regulatory compliance.

| Cost Category | Description | 2024 Estimated Impact (Illustrative) |

| Research & Development | Innovation in automation, AI, robotics | Approx. ¥150 billion |

| Manufacturing & Production | Raw materials, components, labor, factory overheads | Significant portion of COGS, influenced by precision requirements |

| Sales, Marketing & Distribution | Global sales teams, marketing, logistics, international branches | 15-30%+ of revenue typical for global tech/manufacturing |

| After-Sales Service & Support | Service centers, technical training, spare parts management | Key component of operating costs, reflecting global complexity |

| General & Administrative (G&A) | Corporate management, legal, IT, administrative staff | 5-15% of revenue typical for multinational tech/manufacturing |

Revenue Streams

FUJI Corporation's core revenue generation is driven by the sale of sophisticated electronic component mounting machines, often referred to as SMT (Surface Mount Technology) equipment. These machines, including high-speed pick-and-place systems, are crucial for the automated assembly of electronic circuit boards.

This segment represents FUJI's dominant revenue source, accounting for a substantial 90% of its total net sales. For instance, in the fiscal year ending March 2024, FUJI reported total net sales of ¥209,857 million, with its SMT equipment business being the primary contributor to this figure.

FUJI generates revenue through the sale of precision machine tools, including lathes and multitasking machines. These tools are essential for a wide range of machining tasks across various industrial sectors.

While the sales of machine tools represent a smaller portion of FUJI's total revenue compared to their Surface Mount Technology (SMT) equipment, this segment remains a steady and reliable contributor to the company's financial performance.

Fuji Electronics generates substantial recurring revenue through after-sales service and maintenance contracts for its installed base of SMT machines and machine tools. These contracts ensure customers' equipment remains operational, providing a stable income for Fuji.

In 2024, Fuji's service and maintenance segment continued to be a vital component of its revenue mix, reflecting the high value placed on reliable operation by its global customer base. This segment is crucial for customer retention and predictable cash flow.

Software and Smart Factory Solutions Licensing

FUJI generates revenue by licensing its specialized software designed for intelligent factories. This includes AI-driven tools that optimize production processes and other advanced automation solutions.

The evolving 'FUJI Smart Factory' concept highlights the growing significance of these software-centric services. For instance, FUJI's investment in AI and IoT technologies is directly fueling the expansion of these recurring revenue streams.

- Software Licensing: Recurring revenue from perpetual and subscription-based licenses for factory management and automation software.

- AI Optimization Tools: Income generated from licensing AI algorithms and platforms that enhance manufacturing efficiency and predictive maintenance.

- Smart Factory Solutions: Revenue derived from bundled software packages that integrate various smart factory functionalities.

- Cloud-based Services: Income from Software-as-a-Service (SaaS) models offering cloud access to FUJI's smart factory software suites.

Training and Consulting Services

Fuji extends its revenue streams by providing specialized training programs. These programs educate customers on the effective operation and ongoing maintenance of Fuji's equipment, ensuring optimal performance and longevity.

Beyond training, Fuji offers valuable consulting services focused on factory automation and process optimization. These expert insights help clients streamline their operations, enhance efficiency, and ultimately improve their bottom line.

These complementary services not only add significant value for Fuji's customers but also represent a crucial component of the company's overall revenue generation strategy. For instance, in 2023, Fuji reported a notable increase in its services segment, contributing to its strong financial performance.

- Training Programs: Specialized customer education on equipment operation and maintenance.

- Consulting Services: Expert advice on factory automation and operational optimization.

- Value Addition: Enhances customer experience and equipment utilization.

- Revenue Contribution: Significant part of Fuji's diversified income.

FUJI's revenue streams are primarily anchored in the sale of SMT equipment, which constituted approximately 90% of its net sales in the fiscal year ending March 2024, totaling ¥209,857 million. Complementing this, precision machine tools offer a steady, albeit smaller, revenue contribution.

Recurring revenue is a significant focus, generated through after-sales service, maintenance contracts, and licensing of specialized software for intelligent factories, including AI-driven optimization tools. This software segment is expanding, fueled by FUJI's investments in AI and IoT technologies.

Further diversification comes from training programs and consulting services aimed at factory automation and process optimization. These services not only add customer value but also represent a vital part of FUJI's revenue strategy, as evidenced by a notable increase in its services segment in 2023.

| Revenue Stream | Primary Products/Services | Fiscal Year 2024 Contribution (Approx.) | Key Characteristics |

|---|---|---|---|

| SMT Equipment Sales | Pick-and-place machines, SMT systems | ~90% of Net Sales | Core business, high volume |

| Machine Tool Sales | Lathes, multitasking machines | Smaller portion of total revenue | Steady contributor |

| After-Sales Services & Maintenance | Service contracts, repairs | Recurring revenue | Ensures operational uptime, customer retention |

| Software Licensing | Factory management, AI optimization tools, Smart Factory solutions | Growing segment | Recurring revenue, SaaS models |

| Training & Consulting | Equipment operation training, automation consulting | Value-added services | Enhances customer experience, process optimization |

Business Model Canvas Data Sources

The FUJI Business Model Canvas is constructed using a blend of internal financial data, comprehensive market research, and expert strategic insights. This multi-faceted approach ensures each component of the canvas is informed by accurate and actionable information.