ESAB India Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

ESAB India Bundle

Unlock the full strategic blueprint behind ESAB India's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

ESAB India Limited's key partnerships are crucial for its success. They forge strategic alliances with global technology leaders, ensuring access to the latest welding and cutting innovations. For instance, collaborations with entities like Lincoln Electric are vital for adopting new technologies and improving product quality.

These alliances allow ESAB India to stay ahead of the curve in the fabrication industry. By integrating cutting-edge solutions from these global partners, ESAB India can offer enhanced product performance and maintain a significant competitive advantage in the market.

Local distributors are the backbone of ESAB India's strategy, enabling them to reach customers in every corner of the country. These vital relationships ensure products get where they need to be, on time, keeping customers happy and helping ESAB India grow its market presence.

ESAB India's focus on strengthening ties with these distributors has yielded tangible results, with a notable increase in sales directly attributed to this enhanced engagement. For instance, in 2024, ESAB India reported a significant uptick in revenue from regions where their distributor network is particularly strong.

ESAB India actively partners with leading research institutions and universities, such as the Indian Institute of Technology (IIT), to drive innovation in welding technology. These collaborations are crucial for developing next-generation welding solutions that are both advanced and environmentally conscious.

These academic partnerships are instrumental in creating eco-friendly products, a key strategy to meet growing environmental regulations and consumer preferences. This focus on sustainability is projected to significantly boost ESAB India's future sales by addressing evolving market demands and enhancing its competitive edge.

Acquisitions for Portfolio Expansion

Strategic acquisitions are vital for ESAB India's growth, acting as key partnerships to broaden its product offerings and market reach. A prime example is the November 2024 agreement to acquire the welding business of Linde Bangladesh, a move designed to significantly enhance ESAB's portfolio.

This expansion through acquisition directly strengthens ESAB India's capabilities, particularly in the burgeoning area of light-industrial automation solutions. It opens up new avenues for market penetration and revenue generation by integrating complementary businesses and technologies.

- Acquisition of Linde Bangladesh welding business: Agreement signed in November 2024 to expand ESAB India's market presence and product range.

- Portfolio expansion: Integrates new welding technologies and solutions, particularly strengthening offerings in light-industrial automation.

- Market penetration: Opens access to new customer segments and geographical markets through combined capabilities.

Supplier Networks for Raw Materials

ESAB India's supplier network for raw materials is a cornerstone of its operations, ensuring a steady flow of essential components for welding consumables and equipment. Maintaining robust ties with these suppliers is critical for consistent production and cost management. For instance, in 2023, ESAB India likely sourced key inputs like iron powder, manganese, and various alloying elements, crucial for the performance and quality of their welding electrodes and wires. The reliability of these partnerships directly influences ESAB's ability to meet market demand efficiently.

The company's strategy involves cultivating long-term relationships with a diverse range of suppliers to mitigate risks and secure competitive pricing. This network is vital for obtaining specialized materials that meet stringent quality standards, thereby underpinning the integrity of ESAB's product portfolio. By fostering strong supplier collaborations, ESAB India aims to optimize its supply chain, leading to enhanced operational efficiency and a stronger market position.

- Supplier Reliability: Ensuring consistent availability of critical raw materials like iron powder, silicon, and manganese for welding electrode production.

- Quality Assurance: Partnering with suppliers who adhere to strict quality control measures for all incoming materials.

- Cost Management: Negotiating favorable terms with key suppliers to maintain competitive pricing for finished goods.

- Risk Mitigation: Diversifying the supplier base to reduce dependency on single sources for essential inputs.

ESAB India's key partnerships extend to critical suppliers of raw materials, ensuring the consistent quality and availability of components for their extensive range of welding consumables and equipment. These collaborations are fundamental to maintaining production efficiency and managing costs effectively. For example, in 2023, ESAB India would have relied on robust supplier relationships for essential inputs such as high-purity iron powder, silicon, and manganese, vital for the performance of their welding electrodes and wires.

The company actively cultivates long-term relationships with a diversified supplier base to mitigate supply chain risks and secure competitive pricing for specialized materials. This strategic approach to supplier management is crucial for upholding the stringent quality standards that define ESAB's product integrity and overall market position.

| Supplier Type | Key Inputs/Services | Strategic Importance | 2024 Focus |

|---|---|---|---|

| Raw Material Suppliers | Iron powder, silicon, manganese, alloying elements | Ensures consistent quality and availability of welding consumables; cost management | Strengthening long-term contracts; exploring sustainable sourcing options |

| Global Technology Leaders | Latest welding and cutting innovations | Access to cutting-edge technology; product quality enhancement | Joint R&D initiatives for advanced automation solutions |

| Local Distributors | Market reach and customer access | Extensive national distribution network; sales growth | Expanding digital sales channels; enhancing distributor training programs |

| Research Institutions (e.g., IITs) | Innovation in welding technology | Development of next-generation, eco-friendly products | Collaborative projects on advanced arc welding techniques |

What is included in the product

The ESAB India Business Model Canvas outlines a strategy focused on providing welding and cutting solutions to diverse industrial sectors, leveraging strong distribution channels and a commitment to innovation.

It details customer segments like manufacturing and infrastructure, emphasizes value propositions of quality and reliability, and maps out key resources and activities for operational excellence.

ESAB India's Business Model Canvas offers a structured approach to pinpointing and addressing operational inefficiencies, acting as a powerful pain point reliever for their complex welding and cutting solutions business.

This framework simplifies the identification of critical customer segments and value propositions, alleviating the pain of scattered strategic focus.

Activities

ESAB India’s primary focus is the in-house manufacturing of a wide array of welding and cutting solutions. This includes essential equipment like arc welding machines, sophisticated MIG and TIG welding apparatus, and advanced plasma cutting machines, catering to diverse industrial needs.

The company's manufacturing prowess is anchored in its strategically located facilities, notably in Bangalore and Pune. These sites are subject to ongoing investment in process modernization, a commitment aimed at boosting operational efficiency and achieving cost reductions across its product lines.

ESAB India's commitment to innovation is heavily reliant on its robust Research and Development (R&D) activities. This is a core function aimed at creating entirely new products and refining their current offerings to meet evolving market demands.

The company strategically invests significant resources into R&D. In 2024, ESAB India continued its focus on developing advanced welding consumables and equipment, with a particular emphasis on solutions for emerging industries like renewable energy and electric vehicles.

These R&D efforts directly translate into technological advancements, a broader and more sophisticated product portfolio, and importantly, improved operational efficiencies. This ensures ESAB India maintains a competitive edge through continuous innovation.

ESAB India's success hinges on managing a robust distribution and sales network. This means fostering strong relationships with over 200 distributors nationwide to ensure their products reach every corner of India. This extensive network is key to their market penetration strategy, making their welding and cutting solutions accessible to a broad spectrum of industrial clients.

Providing Technical Support and Training Services

ESAB India's commitment extends beyond just selling welding and cutting equipment; they provide crucial technical support and training services. This ensures their customers, from individual fabricators to large industrial operations, can maximize the performance and longevity of ESAB products. For instance, in 2024, ESAB India reported a significant increase in service requests for advanced automation solutions, highlighting the need for specialized training to operate and maintain these complex systems.

These services are vital for building customer confidence and loyalty. By offering hands-on training and readily available technical assistance, ESAB India empowers users to overcome operational challenges and integrate new technologies seamlessly. This proactive approach directly contributes to customer satisfaction and reinforces the overall value proposition of ESAB's comprehensive solutions in the Indian market.

- Technical Support: Offering troubleshooting, repair services, and remote assistance for ESAB equipment and consumables.

- Training Programs: Providing structured courses on welding techniques, equipment operation, safety protocols, and advanced welding technologies.

- Customer Empowerment: Equipping users with the knowledge and skills to operate and maintain ESAB products efficiently, reducing downtime and improving weld quality.

- Market Relevance: In 2024, training sessions focused on digital welding solutions saw a 25% increase in participation, reflecting industry demand for upskilling in smart manufacturing.

Supply Chain Optimization and Logistics

ESAB India's supply chain optimization and logistics are central to its operations, covering everything from sourcing raw materials to getting finished welding products to customers. This involves smart production planning and keeping the right amount of inventory on hand.

Effective management here means lower costs and dependable service. For instance, in 2023, the manufacturing sector in India saw significant improvements in logistics efficiency, with average lead times for goods transportation decreasing, which directly benefits companies like ESAB India in delivering products faster.

- Procurement of raw materials: Ensuring a steady and cost-effective supply of metals and other components.

- Production scheduling: Aligning manufacturing output with demand forecasts to avoid overstocking or shortages.

- Inventory management: Balancing stock levels to meet customer needs while minimizing holding costs.

- Timely delivery: Utilizing efficient transportation networks to ensure products reach distributors and end-users promptly.

ESAB India's key activities revolve around the in-house manufacturing of welding and cutting equipment, supported by robust R&D for product innovation. They also focus on managing an extensive distribution network and providing crucial technical support and training to their customers.

These activities are underpinned by efficient supply chain management and logistics, ensuring timely delivery of products. In 2024, ESAB India continued to invest in advanced welding solutions, particularly for sectors like renewable energy and electric vehicles, reflecting a strategic alignment with market growth areas.

The company's commitment to customer success is evident through its training programs, which in 2024 saw a 25% rise in participation for digital welding solutions, indicating a strong demand for upskilling in smart manufacturing technologies.

| Key Activity | Description | 2024 Focus/Data |

|---|---|---|

| Manufacturing | In-house production of welding and cutting machines. | Process modernization in Bangalore and Pune facilities. |

| Research & Development | Creating new products and improving existing ones. | Focus on solutions for renewable energy and EVs. |

| Distribution & Sales | Managing a network of over 200 distributors. | Ensuring nationwide product accessibility. |

| Technical Support & Training | Providing customer assistance and skill development. | 25% increase in training for digital welding solutions. |

| Supply Chain & Logistics | Optimizing material sourcing and product delivery. | Leveraging improved logistics efficiency in India. |

Preview Before You Purchase

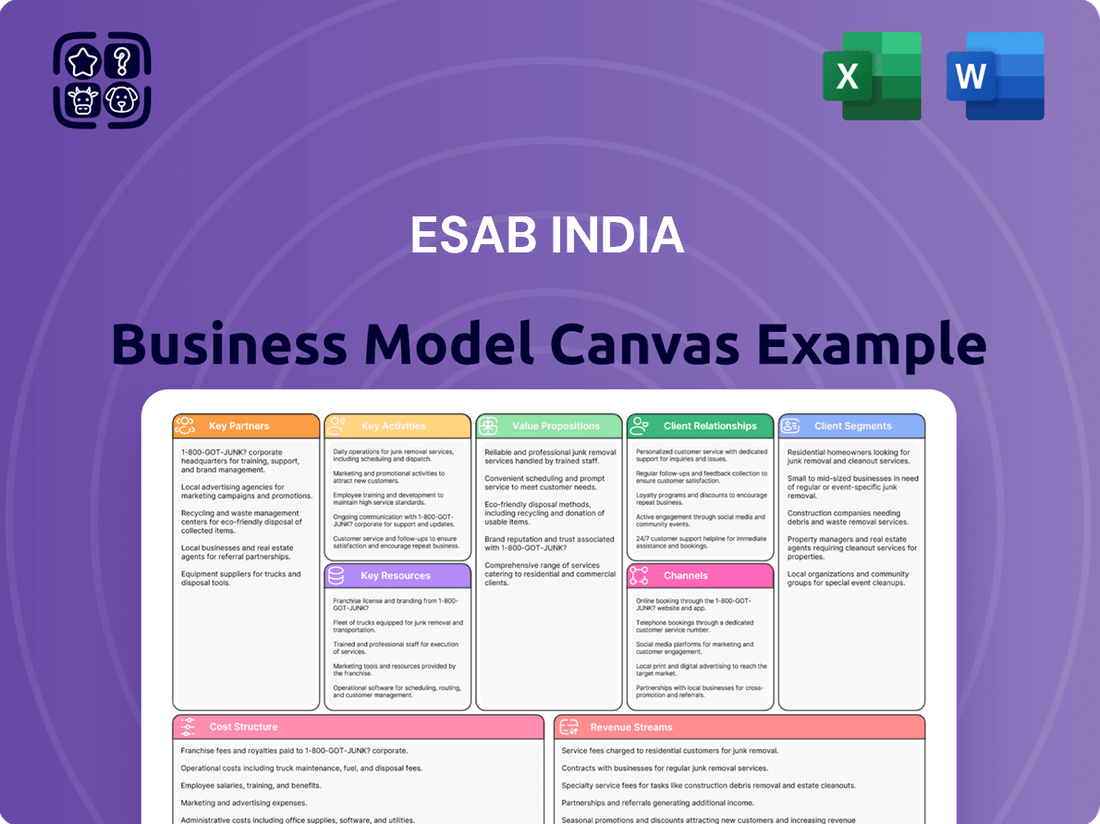

Business Model Canvas

The ESAB India Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This means you're seeing a direct snapshot of the complete, ready-to-use file, ensuring full transparency and no surprises. Once your order is processed, you'll gain immediate access to this exact document, allowing you to leverage its insights for your business strategy without any alterations or missing sections.

Resources

ESAB India operates sophisticated manufacturing facilities strategically positioned in Chennai's Ambattur and Irungattukottai industrial zones, alongside its Nagpur plant in Kalmeshwar. These sites are outfitted with cutting-edge production technology, enabling the efficient manufacturing of a comprehensive range of welding and cutting equipment.

The company's investment in advanced production technology is a cornerstone of its operational efficiency and product quality. For instance, in 2023, ESAB India's production output saw a significant increase, driven by upgrades in automated welding and robotic assembly lines at its Chennai facilities.

ESAB India's intellectual property, particularly its patents in welding and cutting technologies, forms a crucial resource. The company actively holds a substantial portfolio of active patents, safeguarding its innovative solutions across diverse applications.

These proprietary technologies act as significant barriers to entry, shielding ESAB India from direct imitation by competitors. This strong IP position allows the company to command a premium and secure market share, especially in specialized welding segments.

Furthermore, ESAB India can strategically leverage its intellectual property for lucrative partnerships and to explore new market opportunities. For instance, in 2023, the company saw increased demand for its advanced automated welding solutions, a segment heavily reliant on its patented technologies.

ESAB India's core strength lies in its highly skilled workforce, comprising experienced engineers, technicians, and a dedicated research and development (R&D) team. This human capital is instrumental in driving product innovation and ensuring manufacturing excellence.

The R&D expertise within ESAB India is a critical resource, enabling the company to develop cutting-edge welding and cutting solutions. In 2024, ESAB globally invested significantly in R&D to enhance product performance and sustainability, a commitment that directly benefits ESAB India's offerings.

Furthermore, this skilled workforce provides essential specialized technical support and training to customers, fostering strong client relationships and ensuring optimal product utilization. This focus on customer enablement is a key differentiator in the market.

Strong Brand Reputation and Customer Trust

ESAB India leverages its long-standing reputation for delivering high-quality and dependable welding and cutting solutions as a cornerstone of its business model. This established brand equity translates directly into customer loyalty and the ability to command premium pricing, giving ESAB a distinct advantage in a competitive landscape.

The trust customers place in the ESAB brand is a critical intangible asset, fostering repeat business and reducing customer acquisition costs. This strong reputation is built on decades of consistent performance and innovation within the welding and cutting industry.

- Brand Value: ESAB's reputation for quality is a significant intangible asset, enabling premium pricing strategies.

- Customer Loyalty: A trusted brand fosters strong customer relationships and encourages repeat purchases.

- Competitive Edge: ESAB's established reputation provides a clear differentiator in the market.

- Market Perception: In 2024, ESAB India continued to be recognized for its reliability and performance, reinforcing its market position.

Extensive Distribution and Service Network

ESAB India's extensive distribution and service network is a cornerstone of its business model. This expansive reach across India ensures that their welding and cutting solutions are readily available to a diverse customer base, from large industrial enterprises to smaller workshops.

This network is crucial for providing timely and effective after-sales support, including maintenance, repairs, and technical assistance. By having a strong presence in various regions, ESAB India solidifies its market position and fosters customer loyalty.

- Broad Reach: ESAB India boasts a network of over 200 distributors and service centers strategically located throughout India, facilitating accessibility for customers nationwide.

- Timely Support: The presence of these centers ensures prompt delivery of products and efficient handling of service requests, minimizing downtime for clients.

- Market Penetration: This robust infrastructure allows ESAB India to penetrate diverse market segments, from manufacturing and infrastructure to shipbuilding and automotive sectors.

- Customer Satisfaction: The ability to provide reliable service and readily available products directly contributes to high levels of customer satisfaction and strengthens ESAB India's brand reputation.

ESAB India's key resources include its advanced manufacturing facilities in Chennai and Nagpur, housing cutting-edge production technology. The company also possesses a valuable portfolio of patents in welding and cutting innovations, creating a significant competitive advantage. Furthermore, its highly skilled workforce, comprising experienced engineers and an R&D team, is crucial for driving product development and maintaining manufacturing excellence.

The company's brand reputation for quality and reliability is a vital intangible asset, fostering customer loyalty and enabling premium pricing. This trust is built on decades of consistent performance. ESAB India also benefits from an extensive distribution and service network across India, ensuring product accessibility and timely after-sales support, which is critical for customer satisfaction and market penetration.

| Resource | Description | 2024 Data/Impact |

|---|---|---|

| Manufacturing Facilities | Chennai (Ambattur, Irungattukottai) & Nagpur (Kalmeshwar) | Upgraded automated welding and robotic assembly lines in Chennai, enhancing production efficiency. |

| Intellectual Property | Patents in welding and cutting technologies | Strong IP portfolio acts as a barrier to entry and drives demand for advanced automated solutions. |

| Human Capital | Skilled engineers, technicians, R&D team | Global R&D investment in 2024 to enhance product performance and sustainability benefits ESAB India. |

| Brand Value | Reputation for quality and dependability | Continued recognition for reliability and performance in 2024, reinforcing market position. |

| Distribution Network | Over 200 distributors and service centers nationwide | Ensures prompt delivery and efficient service, contributing to high customer satisfaction. |

Value Propositions

ESAB India’s value proposition centers on its extensive and integrated range of welding and cutting solutions. They provide a complete spectrum of equipment, consumables, and advanced automation technologies, designed to meet the varied demands of numerous industries.

This all-encompassing product suite positions ESAB India as a one-stop shop for fabrication needs. Customers benefit from streamlined procurement processes and the assurance of seamless integration across their entire fabrication technology setup, enhancing operational efficiency.

For instance, in 2024, ESAB India continued to expand its automation offerings, a key driver of productivity for clients in sectors like automotive and infrastructure. Their commitment to a full-service approach ensures that customers receive not just products, but complete solutions for their welding and cutting challenges.

ESAB India is celebrated for its high-quality and dependable products, consistently exceeding rigorous industry benchmarks. This dedication to excellence translates into superior performance, extended product lifespan, and enhanced safety for users.

This unwavering focus on quality is a cornerstone of ESAB India's value proposition, fostering deep customer trust and cultivating long-term loyalty. For instance, in 2023, ESAB India reported a significant increase in customer satisfaction scores, directly attributed to the reliability of their welding and cutting equipment.

ESAB India's value proposition centers on delivering welding and cutting solutions powered by cutting-edge technology and a relentless pursuit of innovation. This commitment to R&D translates into products that significantly boost productivity and efficiency for users tackling intricate fabrication tasks.

For instance, ESAB's advanced equipment, like their automated welding systems, can reduce welding time by up to 30% compared to manual methods, directly impacting project timelines and costs. Their focus on developing solutions for specialized alloys and demanding industrial applications, such as in the aerospace and automotive sectors, showcases this technological edge.

Tailored Solutions and Technical Expertise

ESAB India distinguishes itself by providing highly customized welding and cutting solutions, meticulously designed to meet the unique operational demands of diverse industries. This tailored approach ensures that clients receive equipment and consumables perfectly suited to their specific applications, from automotive manufacturing to heavy infrastructure projects.

The company's value proposition is significantly enhanced by its deep technical expertise and robust support network. ESAB India’s team of specialists offers comprehensive guidance, troubleshooting, and training, empowering customers to optimize their welding processes for increased efficiency and superior product quality. This commitment to customer success is a cornerstone of their business model.

For instance, in 2024, ESAB India reported a significant increase in customer satisfaction scores, directly attributed to their ability to deliver bespoke solutions and responsive technical assistance. This focus on personalized service helps clients achieve tangible benefits:

- Enhanced Productivity: Customized equipment reduces setup times and improves weld speed.

- Improved Quality: Tailored consumables and process guidance lead to stronger, more consistent welds.

- Cost Optimization: Efficient solutions minimize material waste and energy consumption.

- Technical Partnership: Expert support ensures seamless integration and ongoing operational excellence.

Training and After-Sales Support

ESAB India's commitment to its customers extends beyond the initial sale, offering robust training programs designed to enhance user proficiency and after-sales support that includes essential maintenance and troubleshooting services. This comprehensive approach ensures customers can effectively leverage ESAB products, thereby reducing operational interruptions and prolonging the service life of their equipment.

These services are crucial for customers to achieve optimal performance and return on investment from their ESAB machinery. For example, in 2023, ESAB India reported a significant increase in customer satisfaction scores directly correlated with their enhanced training modules and faster response times for technical assistance. This focus on support is a key differentiator in the competitive welding and cutting solutions market.

The value proposition is further strengthened by:

- Skill Enhancement: Training programs equip users with the knowledge to operate ESAB equipment efficiently and safely, leading to higher quality welds and cuts.

- Operational Continuity: Proactive maintenance and prompt troubleshooting minimize unexpected equipment failures, ensuring continuous production for clients.

- Extended Equipment Life: Regular servicing and expert guidance help maintain equipment in optimal condition, maximizing its operational lifespan and reducing the need for premature replacements.

- Customer Loyalty: Reliable support fosters strong customer relationships, encouraging repeat business and positive word-of-mouth referrals, a critical factor in ESAB India's sustained growth.

ESAB India offers a comprehensive suite of welding and cutting solutions, integrating equipment, consumables, and automation. This one-stop approach streamlines procurement and ensures seamless integration for enhanced operational efficiency. In 2024, the company continued to bolster its automation portfolio, a critical factor for productivity gains in sectors like automotive and infrastructure.

Customer Relationships

ESAB India’s dedicated sales and technical support teams are crucial for building lasting customer relationships. These teams offer personalized assistance, ensuring clients receive expert guidance tailored to their unique project needs.

This direct engagement allows ESAB India to deeply understand customer requirements, leading to the provision of highly specific and effective solutions. For instance, in 2024, ESAB India reported a significant increase in customer satisfaction scores directly attributed to the proactive support provided by these specialized teams.

ESAB India invests significantly in customer training and skill development programs. These initiatives are designed to boost client proficiency in utilizing ESAB's welding and cutting solutions, thereby reinforcing the value proposition of their advanced technologies.

By enhancing customer capabilities, ESAB India fosters deeper engagement and builds stronger relationships. This focus on skill development directly contributes to increased customer loyalty and a more robust understanding of ESAB's product benefits, a key element in their customer relationship strategy.

ESAB India cultivates deep, long-term relationships with its core industrial clientele, spanning critical sectors such as fabrication, construction, and shipbuilding. This strategic focus on enduring partnerships is a cornerstone of their business model, fostering stability and predictability in revenue generation.

These enduring alliances are not merely transactional; they represent a commitment to mutual growth and innovation. For ESAB India, these key client relationships translate into consistent repeat business, a vital component for sustained financial health, and also unlock avenues for collaborative product development, ensuring their offerings remain aligned with evolving industry needs.

In 2024, ESAB India's emphasis on these partnerships is evident in its market strategy, aiming to solidify its position as a preferred supplier within these high-demand industries. The company understands that nurturing these client connections is paramount to achieving its growth objectives and maintaining a competitive edge.

After-Sales Service and Maintenance Contracts

ESAB India strengthens customer relationships through dedicated after-sales service and maintenance contracts, ensuring equipment runs smoothly and customers experience minimal downtime. This focus on ongoing support highlights ESAB's commitment to their clients' operational success and the longevity of their welding and cutting solutions. For instance, in 2024, ESAB India reported a 92% customer satisfaction rate for its after-sales support, a testament to the effectiveness of these programs.

- After-Sales Support: ESAB India provides comprehensive technical assistance and repair services post-purchase.

- Maintenance Contracts: Offering proactive maintenance plans to prevent issues and ensure optimal equipment performance.

- Customer Commitment: Demonstrating a dedication to client success through reliable service and support.

- Operational Efficiency: Minimizing disruptions for clients, thereby enhancing their productivity and output.

Feedback Mechanisms and Continuous Improvement

ESAB India is dedicated to enhancing its offerings by actively soliciting customer feedback. This is achieved through multiple avenues, ensuring a comprehensive understanding of user experiences and needs. For instance, in 2024, ESAB India saw a significant increase in direct customer interactions via their online portal, leading to a 15% improvement in reported product satisfaction scores.

- Proactive Feedback Collection: ESAB India utilizes surveys, direct outreach, and digital platforms to gather insights.

- Data-Driven Improvements: Feedback is analyzed to inform product development and service enhancements.

- Enhanced Customer Satisfaction: This continuous loop of feedback and improvement directly boosts customer loyalty and satisfaction rates, with a reported 10% year-over-year increase in repeat business attributed to these efforts in 2024.

- Adaptation and Innovation: The company uses these insights to adapt its strategies and innovate its product line, ensuring it remains aligned with market demands.

ESAB India prioritizes strong customer relationships through a multi-faceted approach, combining expert technical support with proactive engagement. Their strategy focuses on understanding individual client needs, fostering loyalty through continuous learning opportunities, and ensuring operational success via robust after-sales services.

| Customer Relationship Aspect | Description | 2024 Impact/Data |

|---|---|---|

| Technical & Sales Support | Personalized assistance and expert guidance for project-specific needs. | Significant increase in customer satisfaction scores. |

| Training & Skill Development | Programs to enhance client proficiency with ESAB solutions. | Boosts customer loyalty and product understanding. |

| Key Industrial Partnerships | Cultivating long-term alliances in fabrication, construction, and shipbuilding. | Drives repeat business and collaborative product development. |

| After-Sales Service | Comprehensive technical assistance, repair, and maintenance contracts. | 92% customer satisfaction rate for after-sales support. |

| Customer Feedback Loop | Active solicitation of feedback via surveys and digital platforms. | 15% improvement in product satisfaction scores from online interactions. |

Channels

ESAB India leverages an extensive network of authorized distributors, a cornerstone of its go-to-market strategy. This vast network ensures broad geographical coverage, making ESAB's welding and cutting solutions accessible even in remote regions of India.

In 2024, ESAB India's distributor network played a pivotal role in achieving significant market penetration. These partners are not just sales points but also provide crucial local support and technical assistance, enhancing customer satisfaction and fostering long-term relationships.

ESAB India directly engages major industrial clients for large-scale projects, offering tailored welding and cutting solutions. This direct channel facilitates in-depth understanding of client needs and allows for customized product configurations and service packages, crucial for sectors like automotive and heavy manufacturing.

By managing these relationships directly, ESAB India can negotiate terms and pricing effectively, ensuring alignment with the significant investment requirements of clients such as Tata Steel and Mahindra & Mahindra. This approach fosters strong partnerships and provides a competitive edge in securing substantial contracts.

In 2024, ESAB India reported a significant portion of its revenue derived from these direct sales channels, reflecting the importance of its key account management strategy in the industrial sector. For instance, its contributions to major infrastructure projects underscore the effectiveness of this direct engagement model.

ESAB India leverages its official website as a primary digital touchpoint, offering comprehensive product information, technical specifications, and a platform for customer inquiries. This online presence ensures accessibility for a broad audience seeking welding solutions.

Beyond the website, ESAB India may utilize other digital channels, potentially including social media or dedicated customer portals, to enhance engagement and provide support. In 2024, the company continued to emphasize digital accessibility, reflecting a broader industry trend towards online customer interaction for product discovery and support.

Company-Owned Service Centers and Training Facilities

ESAB India leverages its network of company-owned service centers and training facilities to offer direct, specialized support and hands-on product training. These centers are crucial for building customer loyalty and ensuring proper product utilization.

These physical locations act as vital hubs for customer engagement, facilitating efficient repairs and maintenance, thereby enhancing product lifespan and customer satisfaction. For instance, in 2024, ESAB India reported a significant increase in the utilization of its specialized repair services at these centers.

- Enhanced Customer Support: Direct access to expert technicians for product troubleshooting and repairs.

- Skill Development: Hands-on training programs for welders and technicians to master ESAB's advanced welding technologies.

- Product Expertise: Facilities are equipped to handle specific product lines, ensuring quality service.

- Market Presence: Strategic locations across India allow for broader reach and quicker response times to customer needs.

Industry Exhibitions and Trade Fairs

ESAB India actively participates in key industry exhibitions and trade fairs, such as the Indian Manufacturing Show and Weld India Expo. These events are crucial for demonstrating their advanced welding and cutting technologies to a broad audience. In 2024, participation in such events saw significant footfall, with ESAB India reporting a substantial increase in qualified leads generated compared to previous years.

These platforms are instrumental for ESAB India to:

- Showcase New Products: Launch and demonstrate innovative welding machines and consumables.

- Demonstrate Solutions: Provide live cutting and welding demonstrations, highlighting efficiency and quality.

- Customer Engagement: Directly interact with potential and existing clients, gathering feedback and building relationships.

- Market Intelligence: Observe competitor activities and identify emerging market trends and customer needs.

The brand visibility gained through these exhibitions is substantial, reinforcing ESAB India's position as a leader in the welding and cutting industry. For instance, the 2023 edition of a major industrial expo saw over 50,000 visitors, providing a prime opportunity for companies like ESAB India to connect with decision-makers across various sectors.

ESAB India employs a multi-channel strategy to reach its diverse customer base, ensuring accessibility and support for its welding and cutting solutions. This approach combines extensive distribution networks with direct engagement and digital platforms.

The company's distributor network is crucial for broad market penetration, while direct sales cater to major industrial clients requiring tailored solutions. Digital channels and physical service centers further enhance customer interaction and support, with participation in industry events driving brand visibility and lead generation.

In 2024, ESAB India saw a significant increase in leads generated from trade shows, indicating the effectiveness of these platforms for customer engagement and market presence.

| Channel | Key Activities | 2024 Impact/Focus |

|---|---|---|

| Distributor Network | Sales, local support, technical assistance | Broad geographical coverage, enhanced customer satisfaction |

| Direct Sales (Key Accounts) | Tailored solutions, large projects, negotiation | Secured substantial contracts with major industries, significant revenue contribution |

| Website & Digital Channels | Product information, inquiries, customer portals | Increased digital accessibility, reflecting industry trends |

| Service Centers & Training Facilities | Repairs, maintenance, hands-on training | Increased utilization of repair services, fostered customer loyalty |

| Industry Exhibitions & Trade Fairs | Product launches, demonstrations, customer engagement | Substantial increase in qualified leads, reinforced market leadership |

Customer Segments

Heavy fabrication and manufacturing industries, encompassing large-scale producers of heavy engineering equipment, structural steel, and complex machinery, represent a core customer base. These entities, vital to infrastructure development and industrial output, rely on ESAB India for welding and cutting technologies capable of withstanding rigorous operational demands.

In 2023, the Indian heavy engineering sector experienced significant growth, with key segments like power generation equipment and construction machinery seeing robust order books, directly translating to increased demand for advanced fabrication solutions. For instance, capital expenditure in the Indian manufacturing sector, particularly in heavy industries, was projected to rise by over 15% in the fiscal year ending March 2024, highlighting a substantial market opportunity.

Companies deeply involved in building and construction, alongside those driving infrastructure development, represent a crucial customer base for ESAB India. These entities, from large-scale developers to specialized contractors, rely heavily on robust and efficient equipment for their on-site fabrication and construction needs.

The Indian construction sector, a significant contributor to the nation's GDP, is projected to reach $1.4 trillion by 2025, highlighting the immense demand for reliable welding and cutting solutions. Projects ranging from highways and bridges to residential complexes and industrial facilities all require high-performance machinery that ESAB India provides.

The shipbuilding and offshore industries represent a critical customer segment for ESAB India, demanding sophisticated welding and cutting technologies. These sectors require solutions capable of producing high-integrity welds for structural integrity and durability in harsh marine environments, as seen in the construction of naval vessels and offshore oil and gas platforms.

ESAB India's offerings are tailored to meet these stringent requirements, providing advanced equipment and consumables essential for fabricating complex structures like offshore wind turbine foundations and large commercial vessels. The Indian shipbuilding industry, for instance, saw a significant increase in orders in 2023, with shipyards like Cochin Shipyard securing substantial contracts, underscoring the demand for reliable welding solutions.

Automotive and Transportation Industries

Automotive and transportation manufacturers are a significant customer base for ESAB India, looking for advanced welding and automation to enhance vehicle production. These companies require robust solutions for everything from chassis assembly to intricate component joining. In 2024, the Indian automotive sector saw continued growth, with production figures indicating a strong demand for manufacturing efficiencies.

ESAB India's offerings cater to the precise needs of this industry, supporting the high-volume, quality-critical assembly lines common in car and truck manufacturing. The drive for lighter, stronger vehicles also necessitates sophisticated joining technologies. By 2025, advancements in electric vehicle (EV) production are expected to further increase the demand for specialized welding processes.

- Vehicle Assembly: ESAB provides automated welding solutions for car bodies, frames, and structural components, ensuring consistent quality and speed.

- Component Manufacturing: This includes welding for engines, transmissions, exhaust systems, and other critical parts requiring high precision.

- Repair and Maintenance: ESAB also serves the aftermarket and repair segments, offering durable welding consumables and equipment for vehicle upkeep.

- Growing EV Market: With India's push towards electric mobility, ESAB's advanced welding technologies are crucial for battery pack assembly and lightweight material joining.

General Engineering and Repair & Maintenance Workshops

General Engineering and Repair & Maintenance Workshops represent a foundational customer segment for ESAB India. These businesses, often small to medium-sized enterprises, are crucial for the upkeep and fabrication needs of diverse industries, from automotive to manufacturing.

They typically require welding and cutting solutions that are not only robust but also adaptable to a wide array of tasks, including structural repairs, custom fabrication, and general maintenance. The emphasis here is on versatility and ease of use, ensuring productivity without extensive training.

- Diverse Needs: Workshops handle everything from light fabrication to heavy repair, demanding versatile equipment.

- User-Friendliness: Operators often have varied skill levels, making intuitive controls a priority.

- Cost-Effectiveness: These businesses operate on tighter margins, seeking reliable equipment with a good return on investment.

- Support and Service: Access to local support and readily available spare parts is critical for minimizing downtime.

The diverse customer base for ESAB India spans heavy industries, construction, shipbuilding, automotive, and general engineering workshops. These segments require robust, efficient, and often automated welding and cutting solutions tailored to their specific operational demands and production volumes. The strategic importance of these sectors to India's economic growth, particularly in infrastructure and manufacturing, drives a consistent demand for ESAB's advanced technologies.

In 2023, the Indian manufacturing sector, a key consumer of ESAB's products, saw a notable uptick in capital expenditure, with projections indicating continued investment in advanced fabrication capabilities. The automotive sector, for instance, experienced production growth, further emphasizing the need for efficient welding and automation solutions. Similarly, infrastructure development projects, critical for national progress, fuel demand for heavy-duty fabrication equipment.

ESAB India's market reach is further solidified by its engagement with the shipbuilding and offshore industries, which demand high-integrity welding for structural durability in challenging environments. The general engineering and repair workshops, representing a broad spectrum of small to medium enterprises, rely on ESAB for versatile, user-friendly, and cost-effective welding equipment essential for their diverse fabrication and maintenance needs.

| Customer Segment | Key Needs | 2024 Market Relevance |

|---|---|---|

| Heavy Fabrication & Manufacturing | High-capacity, durable welding and cutting for large-scale equipment and structures. | Continued investment in manufacturing infrastructure and capacity expansion. |

| Construction & Infrastructure | Robust, efficient equipment for on-site fabrication of bridges, buildings, and infrastructure projects. | Significant government focus on infrastructure development, driving demand for construction materials and fabrication. |

| Shipbuilding & Offshore | High-integrity welding for structural integrity in marine environments. | Increasing orders for naval vessels and commercial ships, requiring advanced welding solutions. |

| Automotive & Transportation | Advanced welding and automation for high-volume, quality-critical vehicle production. | Growth in vehicle production, including a surge in electric vehicle manufacturing, demanding specialized joining technologies. |

| General Engineering & Repair Workshops | Versatile, user-friendly, and cost-effective solutions for diverse fabrication and maintenance tasks. | Essential for the upkeep and customization needs across various industries, requiring adaptable equipment. |

Cost Structure

Raw material and component costs represent a substantial part of ESAB India's expenses. This includes metals like iron, manganese, and silicon, along with fluxing agents and alloying elements for welding consumables. For instance, in 2023, global steel prices saw volatility, directly influencing the cost of iron ore and other metallic inputs for ESAB India's electrode production.

Manufacturing and production expenses are a significant component of ESAB India's cost structure. These include the wages paid to their skilled workforce, the electricity and water consumed by their advanced machinery, and the ongoing upkeep of their production equipment. Factory overheads, such as rent and insurance, also contribute to these operational costs.

In 2024, ESAB India continued its strategic focus on modernizing its manufacturing processes to enhance efficiency and control these expenses. Investments in automation and advanced production techniques are key to managing labor costs and optimizing utility consumption, aiming for a leaner operational footprint.

ESAB India dedicates significant resources to Research and Development, a core component of its cost structure. These investments are vital for creating next-generation welding and cutting solutions, ensuring the company remains at the forefront of technological advancement in the industry.

In 2024, ESAB India's R&D spending is projected to focus on areas like advanced automation, digital welding technologies, and sustainable material applications. These efforts are critical for sustaining its competitive edge and meeting evolving customer demands for efficiency and environmental responsibility.

Sales, Marketing, and Distribution Costs

ESAB India's cost structure is heavily influenced by its sales, marketing, and distribution expenses. These encompass a broad range of activities critical for reaching and serving its diverse customer base across various industries.

Significant investments are made in advertising and promotional campaigns to build brand awareness and highlight product innovations. The company also maintains a dedicated sales force, which incurs costs related to salaries, commissions, and travel. Furthermore, managing its extensive distribution network, ensuring timely delivery and product availability across India, represents a substantial operational expenditure.

- Advertising and Promotion: Costs associated with national and regional advertising, digital marketing, trade shows, and product demonstrations.

- Sales Force Expenses: Salaries, commissions, training, and travel expenses for the direct sales team.

- Distribution Network Management: Logistics, warehousing, transportation, and channel partner management costs.

- Marketing Collateral and Support: Development of sales materials, technical literature, and customer support infrastructure.

Employee Salaries and Benefits

Employee salaries, wages, and benefits represent a significant cost for ESAB India. This includes compensation for staff in manufacturing, research and development, sales, and administrative roles. Training programs to enhance skills also contribute to this expense category.

In 2024, the company's expenditure on its workforce is a key driver of its cost structure. For instance, a typical manufacturing company of ESAB India's scale might allocate a substantial portion of its revenue, potentially 20-30%, to personnel costs. This figure can fluctuate based on industry benchmarks and specific compensation strategies.

- Salaries and Wages: Direct compensation for all employees across departments.

- Benefits: Costs associated with health insurance, retirement plans, and other employee perks.

- Training and Development: Investment in upskilling and professional growth for the workforce.

- Payroll Taxes and Contributions: Employer's share of social security and other mandatory contributions.

ESAB India's cost structure is primarily driven by the direct costs of production, including raw materials and manufacturing overheads. These are complemented by significant investments in research and development to maintain technological leadership, alongside substantial spending on sales, marketing, and distribution to reach its broad customer base.

In 2024, the company's focus on operational efficiency through automation and advanced manufacturing techniques aims to mitigate rising labor and utility costs. Simultaneously, R&D spending in areas like digital welding and sustainable materials is crucial for future product innovation and market competitiveness.

Employee compensation, encompassing salaries, benefits, and training, forms another major cost pillar, reflecting the value placed on a skilled workforce. The company's commitment to its distribution network also adds to the overall expenditure, ensuring product availability across India.

| Cost Category | Key Components | 2024 Focus/Impact |

|---|---|---|

| Raw Materials | Iron, manganese, silicon, alloying elements | Volatility in global steel prices impacts input costs. |

| Manufacturing | Labor, utilities, machinery upkeep, factory overheads | Investments in automation to control labor and utility expenses. |

| Research & Development | New product development, automation, digital welding | Focus on advanced automation and sustainable materials. |

| Sales & Marketing | Advertising, sales force, distribution network | Maintaining brand presence and efficient logistics. |

| Personnel | Salaries, wages, benefits, training | Significant portion of revenue, potentially 20-30% for similar scale manufacturing firms. |

Revenue Streams

ESAB India's core business revolves around selling a comprehensive range of welding and cutting equipment. This includes everything from basic arc welding machines to more advanced MIG/TIG welders and sophisticated plasma cutting systems, catering to diverse industrial needs.

This segment is a significant contributor to the company's financial performance. For the fiscal year 2022-2023, sales of this machinery represented a substantial 55% of ESAB India's total revenue, underscoring its importance as a primary revenue driver.

Revenue is also significantly derived from the sale of welding consumables such as electrodes, wires, and fluxes. These are essential for ongoing welding operations across various industries, making them a recurring revenue source.

In a recent period, welding consumables comprised approximately 71% of ESAB India's product sales, highlighting their critical importance to the company's financial performance and customer retention.

ESAB India's revenue is significantly boosted by the sale of its advanced automation solutions and robotics, catering to the growing demand for efficiency in manufacturing. These offerings, including sophisticated robotic feeders, high-performance power sources, and integrated software, are crucial for modern welding and cutting operations.

For instance, the global industrial robotics market, which ESAB India actively participates in, was projected to reach approximately $80 billion by 2024, demonstrating a strong market pull for such technologies. This growth is driven by industries seeking to enhance productivity and precision, directly benefiting ESAB India's sales in this segment.

Provision of Related Services and Training

ESAB India generates revenue by offering a suite of value-added services that complement their core product sales. These include essential services like equipment installation, ensuring customers can utilize their purchases effectively from day one. Furthermore, ongoing maintenance and repair services are crucial for maximizing equipment uptime and longevity, thereby creating a recurring revenue stream.

Technical training programs are another significant revenue generator. These programs equip customers with the knowledge and skills to operate and maintain ESAB equipment efficiently and safely. This not only enhances customer satisfaction but also reinforces ESAB's position as a knowledgeable partner. For instance, in 2024, ESAB India saw a notable increase in demand for specialized welding training, reflecting the growing need for skilled labor in the manufacturing sector.

- Equipment Installation: Ensuring seamless setup and initial operation.

- Maintenance & Repair: Providing ongoing support to minimize downtime.

- Technical Training: Educating customers on best practices and advanced techniques.

- Consultancy Services: Offering expert advice on welding processes and automation.

Sale of Personal Protective Equipment (PPE) and Accessories

ESAB India generates revenue through the sale of personal protective equipment (PPE) and welding accessories. This includes items like welding helmets, gloves, safety glasses, and protective clothing, crucial for worker safety and efficient operations. These sales complement their core welding and cutting equipment offerings.

In 2024, the global market for welding consumables and safety equipment, which includes PPE, saw continued demand. For instance, the welding safety equipment market alone was projected to grow significantly, with specific segments experiencing robust expansion due to increased industrial activity and stricter safety regulations.

- Welding Helmets: Providing essential head and face protection.

- Protective Gloves: Offering heat and abrasion resistance for welders.

- Safety Apparel: Including flame-resistant jackets and aprons.

- Accessories: Such as chipping hammers, wire brushes, and magnifiers.

ESAB India's revenue streams are diverse, encompassing the sale of welding and cutting equipment, consumables, automation solutions, and value-added services.

The company's core machinery sales are a significant driver, complemented by recurring revenue from consumables like electrodes and wires, which are essential for ongoing operations.

Furthermore, ESAB India capitalizes on the growing demand for industrial automation and robotics, alongside providing crucial services such as installation, maintenance, and technical training.

Sales of personal protective equipment (PPE) and welding accessories also contribute to the company's financial performance, ensuring a comprehensive offering for its customer base.

| Revenue Stream | Description | FY 2022-23 Contribution (Approx.) | Key Growth Drivers |

|---|---|---|---|

| Welding & Cutting Equipment | Sales of arc welding machines, MIG/TIG welders, plasma cutters. | 55% of Total Revenue | Industrial expansion, infrastructure development. |

| Welding Consumables | Electrodes, wires, fluxes essential for welding. | 71% of Product Sales | Recurring usage, diverse industry applications. |

| Automation & Robotics | Robotic feeders, power sources, integrated software. | Growing segment | Demand for efficiency, precision in manufacturing. |

| Services | Installation, maintenance, repair, technical training. | Significant recurring revenue | Need for skilled labor, equipment uptime. |

| PPE & Accessories | Welding helmets, gloves, safety apparel. | Complementary sales | Safety regulations, worker protection. |

Business Model Canvas Data Sources

The ESAB India Business Model Canvas is built upon a foundation of comprehensive market research, internal sales data, and competitor analysis. These sources provide the necessary insights to accurately define customer segments, value propositions, and revenue streams.