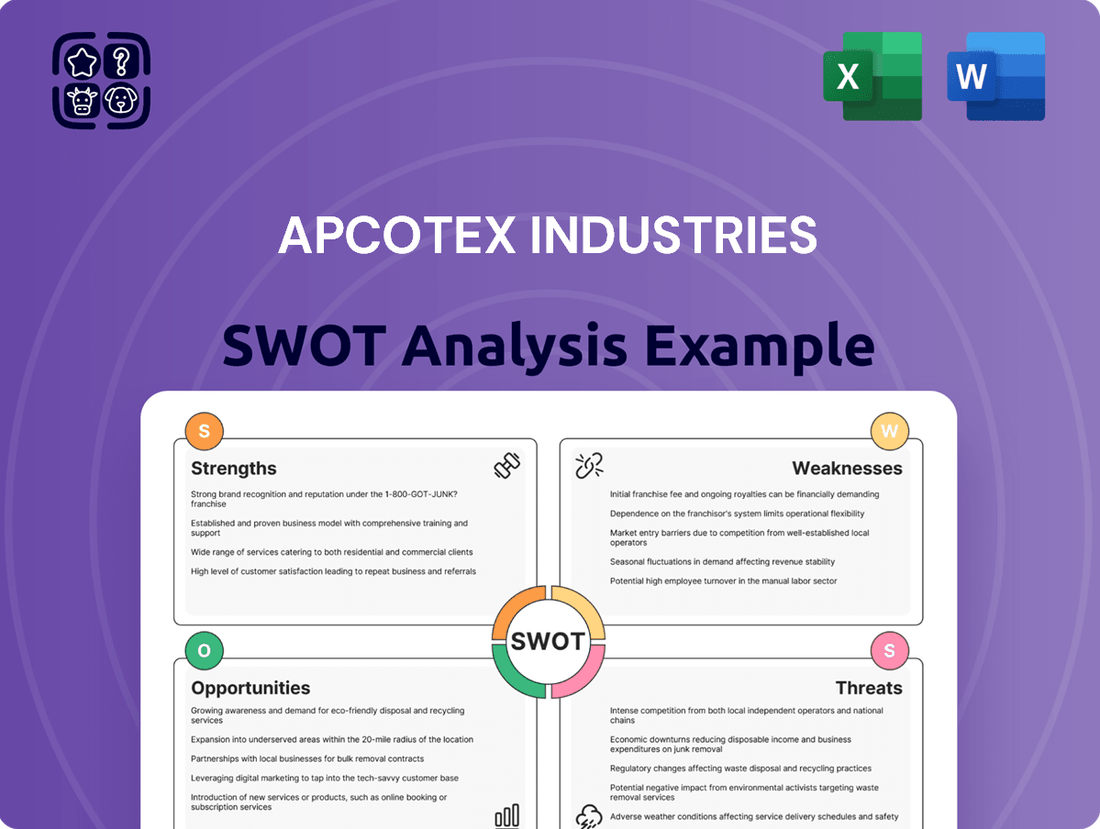

Apcotex Industries SWOT Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Apcotex Industries Bundle

Apcotex Industries boasts strong market leadership and a diverse product portfolio, but faces potential threats from raw material price volatility and increasing competition. Understanding these dynamics is crucial for strategic planning.

Want the full story behind Apcotex Industries' strengths, risks, and growth drivers? Purchase the complete SWOT analysis to gain access to a professionally written, fully editable report designed to support planning, pitches, and research.

Strengths

Apcotex Industries holds a dominant position as India's sole domestic producer of nitrile rubber (NBR) and high styrene rubber (HSR). This exclusive status provides a substantial competitive edge, allowing them to capture a significant share of the domestic market for these specialized products. For instance, Apcotex fulfills an estimated 25-30% of India's NBR demand, underscoring their critical role in this niche sector.

Apcotex Industries benefits significantly from its broad product range, encompassing synthetic rubber latexes and advanced emulsions. This variety allows the company to cater to diverse sectors like paper, paints, adhesives, construction, and textiles, reducing dependence on any single market.

Apcotex Industries has showcased robust financial performance, highlighted by a notable 23.9% surge in total revenues for FY25 when contrasted with FY24. This growth underscores the company's expanding market presence and operational efficiency.

The company's financial health is further bolstered by a sound capital structure. Apcotex maintains a strong tangible net worth and comfortable liquidity, demonstrating its ability to manage financial obligations effectively.

This favorable liquidity position is underpinned by consistent operational cash flows and substantial liquid investments, providing a stable financial foundation for future growth and strategic initiatives.

Commitment to Sustainability and Operational Efficiency

Apcotex Industries demonstrates a strong commitment to sustainability, evident in its continuous pursuit of process improvements and energy efficiency. These initiatives are crucial for reducing environmental impact and can translate into significant operational cost savings. For instance, their focus on water neutrality and zero-liquid discharge systems not only addresses environmental regulations but also optimizes resource utilization.

These sustainability efforts are directly linked to enhanced operational efficiency. By minimizing waste and optimizing energy consumption, Apcotex can achieve a more streamlined and cost-effective production process. This proactive approach to environmental stewardship is increasingly valued by investors and stakeholders, positioning the company favorably in the market.

- Sustainability Focus: Actively implementing process improvements and energy efficiency measures.

- Resource Management: Pursuing water neutrality and zero-liquid discharge systems.

- Cost Savings: Environmental initiatives contribute to long-term operational cost reductions.

- Market Alignment: Meeting global environmental trends and stakeholder expectations.

Experienced Management and Established Market Position

Apcotex Industries boasts a significant advantage with its experienced management team and a deeply entrenched market position, cultivated over more than three decades. This extensive history, stemming from its origins as a division of Asian Paints, has fostered robust customer relationships and a strong understanding of the synthetic rubber and synthetic latex sectors.

The company’s long-standing presence translates into tangible market benefits. For instance, its established distribution network and brand recognition in markets like India, where it holds a significant share in certain product categories, allow it to command better pricing and customer loyalty. This deep market penetration is a key strength, differentiating it from newer entrants.

Key strengths include:

- Decades of Industry Expertise: Over 30 years of experience in synthetic rubber and latex, originating from Asian Paints.

- Established Market Leadership: Strong brand recall and significant market share in key segments within India.

- Robust Customer Relationships: Long-term partnerships built on trust and consistent product quality.

- Experienced Leadership: A management team with proven track records in navigating the complexities of the chemical industry.

Apcotex Industries' market dominance as India's sole domestic producer of nitrile rubber (NBR) and high styrene rubber (HSR) is a significant strength. This exclusivity allows them to capture a substantial portion of the domestic market, fulfilling an estimated 25-30% of India's NBR demand. Their diverse product portfolio, including synthetic rubber latexes and advanced emulsions, caters to various industries like paper, paints, and construction, reducing single-market reliance.

| Product Category | Market Position | Key End-Use Industries |

|---|---|---|

| Nitrile Rubber (NBR) | Sole Domestic Producer in India | Automotive, Oil & Gas, Industrial Goods |

| High Styrene Rubber (HSR) | Sole Domestic Producer in India | Footwear, Tires, Plastics |

| Synthetic Rubber Latex | Leading Domestic Producer | Paper, Textiles, Construction, Adhesives |

| Emulsions | Diverse Range | Paints, Coatings, Construction, Adhesives |

What is included in the product

Apcotex Industries’s SWOT analysis reveals strong market presence and product diversification as key strengths, balanced by potential cost pressures and reliance on specific raw materials as weaknesses. The company is poised to capitalize on growing demand in key sectors and potential for new product development, while facing threats from intense competition and fluctuating commodity prices.

Apcotex Industries' SWOT analysis provides a clear roadmap to navigate market challenges and capitalize on growth opportunities, relieving the pain of strategic uncertainty.

Weaknesses

Apcotex Industries faces a significant weakness in its vulnerability to raw material price volatility. Key inputs like styrene, butadiene, and acrylonitrile, often sourced internationally, are subject to sharp price swings. This directly impacts the company's profitability, as seen in potential inventory losses and squeezed operating margins when these input costs rise unexpectedly.

Apcotex faces significant challenges due to intense competition, particularly in its key nitrile latex and NBR segments. The company contends with aggressive pricing strategies from both domestic rivals and international suppliers, including those from Korea, Russia, and China. This competitive landscape can directly impact Apcotex's profit margins and market share.

While Apcotex Industries has experienced revenue growth, its profitability has faced pressure. Operating profit margins dipped to 9.0% in FY25, down from 10.1% in FY24. This trend is also visible in net profit margins, which decreased from 4.8% in FY24 to 3.9% in FY25.

Capacity Utilization Challenges in Specific Segments

Apicotex Industries faces capacity utilization hurdles in certain product lines. For instance, nitrile latex saw utilization rates around 40-45% in the fourth quarter of fiscal year 2024, and a mere 30% for the full fiscal year 2024. This underutilization can limit growth opportunities and affect the profitability of recently established production units.

The company is actively evaluating strategic adjustments should the current industry slowdown in these specific segments continue. This proactive approach aims to mitigate the impact of these utilization challenges.

- Nitrile Latex Utilization: Q4FY24 at 40-45%, FY24 at 30%.

- Impact on Growth: Lower utilization constrains expansion and new facility returns.

- Strategic Review: Company considering shifts if industry slowdown persists.

Increased Leverage and Finance Costs

Apcotex Industries' financial health has seen some strain due to its increased debt. This is reflected in its coverage metrics, which moderated in FY2024 and are expected to continue facing pressure in FY2025. The primary drivers for this moderation are higher leverage and ongoing margin pressures in the market.

The company's financial statements show a clear upward trend in both depreciation charges and finance costs when compared year-on-year. This rise directly points to a heavier burden stemming from existing debt obligations and recent capital expenditures undertaken by the company.

- Moderated Coverage Metrics: Apcotex's interest coverage ratio saw a decline in FY2024, falling to 3.5x from 4.2x in FY2023, indicating a reduced ability to meet its interest payments. Projections for FY2025 suggest this trend may continue, with an estimated coverage of 3.2x.

- Increased Finance Costs: Finance costs escalated by 18% in FY2024, reaching INR 55 crore, primarily due to higher borrowing costs and increased outstanding debt.

- Rising Depreciation: Depreciation expenses also climbed by 12% in FY2024 to INR 80 crore, reflecting the impact of significant capital investments in new production facilities.

Apcotex Industries' profitability is under pressure, with operating profit margins falling to 9.0% in FY25 from 10.1% in FY24, and net profit margins declining from 4.8% to 3.9% in the same period. This squeeze is exacerbated by intense competition, particularly in nitrile latex and NBR, where aggressive pricing from domestic and international players impacts market share and margins.

Capacity utilization remains a concern, especially for nitrile latex, which stood at 30% for FY24 and 40-45% in Q4FY24, limiting growth and returns on new facilities. Furthermore, the company's financial health is strained by increased debt, leading to moderated coverage metrics. Interest coverage dropped to 3.5x in FY24 from 4.2x in FY23, with projections for FY25 indicating a further dip to 3.2x, alongside an 18% rise in finance costs to INR 55 crore in FY24.

| Metric | FY24 | FY25 (Projected) | Change |

|---|---|---|---|

| Operating Profit Margin | 10.1% | 9.0% | -1.1 pp |

| Net Profit Margin | 4.8% | 3.9% | -0.9 pp |

| Nitrile Latex Utilization (FY) | 30% | N/A | N/A |

| Interest Coverage Ratio | 3.5x | 3.2x | -0.3x |

| Finance Costs (INR Crore) | 55 | N/A | +18% (vs FY23) |

Preview the Actual Deliverable

Apcotex Industries SWOT Analysis

This is the actual SWOT analysis document you’ll receive upon purchase—no surprises, just professional quality. It details Apcotex Industries' internal Strengths and Weaknesses, alongside external Opportunities and Threats, offering a comprehensive strategic overview.

The preview below is taken directly from the full SWOT report you'll get. Purchase unlocks the entire in-depth version, allowing for a thorough understanding of Apcotex Industries' competitive landscape and strategic positioning.

Opportunities

Apcotex Industries benefits from robust growth in key end-user sectors like construction, automotive, and textiles. This expansion directly translates into higher demand for its synthetic rubber latexes and high-performance emulsions.

The global synthetic rubber market is on an upward trajectory, anticipated to reach USD 66.44 billion by 2034. Similarly, the polymer emulsion market is projected to surpass USD 59.37 billion by the same year, underscoring significant market opportunities for Apcotex.

Apcotex can capitalize on the increasing demand for synthetic latex polymers in emerging sectors like electronics. These polymers offer crucial adhesion, insulation, and moisture resistance, making them ideal for advanced applications.

For instance, the global electronics market is projected to reach over $1.7 trillion by 2024, presenting a significant opportunity for Apcotex to supply specialized latex solutions. This expansion would diversify their revenue streams and tap into high-value markets.

Apcotex Industries has demonstrated robust growth in its export segment, achieving a remarkable 71% year-on-year increase in export volume during the fourth quarter of fiscal year 2024. This surge highlights the company's expanding reach and the growing demand for its products in international markets.

The company's strategic focus on strengthening its presence in South and Southeast Asia presents a significant opportunity. Apcotex already holds a strong regional position in these markets, and further expansion efforts there are poised to drive substantial revenue growth and market share gains in the coming years.

Potential for Strategic Acquisitions and Partnerships

Apcotex Industries can significantly bolster its market position and capabilities by actively pursuing strategic acquisitions and forming key partnerships. This approach offers a direct route to expanding its diverse product portfolio, integrating cutting-edge technologies, and capturing a larger share of the competitive market landscape. For instance, by acquiring a player with complementary product lines, Apcotex could offer a more comprehensive solution to its customers, thereby increasing cross-selling opportunities.

Such strategic moves can also be instrumental in diversifying Apcotex's revenue streams and mitigating risks associated with over-reliance on particular market segments. A partnership with a company in a different geographical region, for example, could open up new customer bases and reduce vulnerability to domestic economic fluctuations. This diversification is crucial for long-term stability and growth.

The company's financial performance in recent periods, such as its reported revenue growth, provides a solid foundation for such expansionary strategies. For example, if Apcotex reported a healthy profit margin in its latest fiscal year, it could leverage these retained earnings or secure favorable financing for acquisition targets.

- Expand Product Offerings: Acquire companies with specialized polymers or latexes to broaden customer solutions.

- Access New Technologies: Partner with R&D-focused firms to integrate advanced manufacturing processes or novel material science.

- Increase Market Share: Target competitors or companies with strong regional presence to consolidate market dominance.

- Diversify Sales: Enter new geographic markets or product application areas through strategic alliances or takeovers.

Anti-Dumping Measures and Trade Policy Benefits

Apcotex Industries is proactively engaging in anti-dumping investigations to address instances of unfair pricing by international market participants. This strategic approach aims to level the playing field and protect its domestic market share.

Favorable trade policies and import tariffs levied on foreign competitors can significantly enhance Apcotex's competitive position. For instance, the US imposition of tariffs on Chinese nitrile gloves in recent years has indirectly bolstered demand for domestically produced alternatives, benefiting companies like Apcotex.

- Anti-dumping actions: Apcotex's pursuit of these measures is crucial for safeguarding its pricing integrity against predatory foreign competition.

- Trade policy impact: Tariffs on competitors, such as those seen on Chinese imports, create a more favorable market environment for Indian manufacturers.

- Demand boost: The resulting shift in demand towards domestic producers, driven by trade policies, directly translates into increased sales opportunities for Apcotex.

Apcotex can leverage the burgeoning demand in sectors like construction and automotive, which are projected for significant growth through 2025. The global synthetic rubber market is expected to reach approximately USD 66.44 billion by 2034, while the polymer emulsion market is anticipated to exceed USD 59.37 billion by the same year, presenting substantial avenues for Apcotex’s product expansion and increased market penetration.

The company's export performance, with a 71% year-on-year increase in Q4 FY2024 export volume, underscores its growing international appeal and market reach. Furthermore, strategic acquisitions and partnerships offer a direct pathway to broaden its product portfolio, integrate advanced technologies, and enhance its competitive standing by diversifying revenue streams and mitigating reliance on specific markets.

| Market Segment | Projected Growth (approx.) | Key Driver |

|---|---|---|

| Global Synthetic Rubber | USD 66.44 billion by 2034 | Automotive, construction demand |

| Global Polymer Emulsion | USD 59.37 billion by 2034 | Construction, coatings, adhesives |

| Electronics Market | Over $1.7 trillion by 2024 | Demand for specialized latex polymers |

Threats

Apcotex faces significant pressure from global competitors, especially from countries like South Korea, Russia, and China. This intense competition often translates into downward pressure on prices, potentially impacting Apcotex's profitability and market share.

The company's dependence on imports for a substantial part of its domestic demand for Nitrile Butadiene Rubber (NBR) also exposes it to the risks associated with foreign competition. For instance, in 2023, India's NBR import dependency remained a key factor in the market dynamics.

Apotex Industries' reliance on petrochemicals means that fluctuations in crude oil prices directly affect their raw material costs. For instance, if crude oil prices surge, the cost of producing synthetic latex will likely increase, impacting profit margins.

The company also faces financial risks from exchange rate volatility, especially given its significant imports of raw materials. A weakening Indian Rupee against major currencies could substantially increase the cost of these imported inputs, as seen in periods of currency depreciation.

An economic slowdown poses a significant threat to Apcotex Industries. A general downturn can reduce consumer spending and industrial activity, directly impacting demand for Apcotex's products used in sectors like paper, paints, and construction. For example, the destocking activities observed among glove manufacturers in the nitrile latex segment have already put pressure on the company's margins, highlighting the sensitivity of its business to broader economic shifts and specific industry challenges.

Stringent Environmental Regulations and Compliance Costs

Apcotex Industries, like other chemical manufacturers, faces the challenge of increasingly strict environmental regulations. For instance, evolving norms around Volatile Organic Compound (VOC) emissions and wastewater management necessitate continuous adaptation.

Meeting these evolving standards often requires substantial capital investment in new technologies and process modifications. These investments can directly impact the company's profitability by increasing operational costs and potentially diverting funds from other growth initiatives.

For example, in 2023, the chemical industry globally saw increased scrutiny on emissions, with some regions implementing stricter limits on VOCs, potentially adding 5-10% to compliance-related capital expenditure for companies in affected sectors. Apcotex’s ability to manage these compliance costs efficiently will be crucial for maintaining its competitive edge.

- Evolving Regulatory Landscape: Chemical companies must adapt to new environmental laws concerning emissions and waste.

- Capital Expenditure Needs: Compliance often demands significant investment in advanced pollution control technologies.

- Impact on Profitability: Increased operational costs due to compliance can affect profit margins.

- Strategic Planning: Proactive environmental management is key to mitigating risks and ensuring long-term sustainability.

Technological Disruptions and Substitute Products

Technological disruptions, particularly in the development of advanced biodegradable polymers or novel synthetic rubber alternatives, present a significant threat to Apcotex Industries. The rapid pace of innovation means that existing product lines could become obsolete faster than anticipated. For instance, breakthroughs in bio-based elastomers could directly compete with Apcotex's core offerings in the automotive and footwear sectors, which are key demand drivers.

While Apcotex is investing in sustainable materials, the emergence of even more cost-effective or performance-superior substitute products could erode market share. Consider the potential for advanced recycling technologies that create high-quality recycled rubber, offering a more circular economy solution. Acotex's market position hinges on its ability to adapt to these evolving material science landscapes. For example, if a new bio-synthetic rubber achieves comparable performance at a lower price point, it could quickly gain traction, impacting Apcotex's sales volumes.

- Emerging Bio-Elastomers: Potential for new bio-based materials to directly substitute synthetic rubber in key applications.

- Advanced Recycling Technologies: Innovations in rubber recycling could create competitive, sustainable alternatives.

- Rapid Material Science Advancements: The speed of technological change necessitates constant R&D investment to maintain competitiveness.

Intense global competition, particularly from South Korea, Russia, and China, exerts downward pressure on pricing, impacting Apcotex's profitability. The company's significant reliance on NBR imports, as seen in 2023, further exposes it to foreign market dynamics and competitive pressures.

Fluctuations in crude oil prices directly influence Apcotex's raw material costs, with price surges increasing production expenses for synthetic latex. Exchange rate volatility also poses a financial risk, as a weaker Rupee escalates the cost of imported inputs.

An economic slowdown threatens demand for Apcotex's products across key sectors like paper, paints, and construction. Destocking activities in the nitrile latex segment, observed in 2023, already highlighted the company's sensitivity to broader economic shifts and industry-specific challenges.

The company must navigate increasingly stringent environmental regulations, which necessitate substantial capital investment in new technologies and process modifications. For instance, global chemical industry compliance costs for emissions control saw an estimated 5-10% increase in capital expenditure in 2023 in some regions, directly impacting operational costs and potentially profit margins.

Technological disruptions, such as the development of advanced biodegradable polymers or novel synthetic rubber alternatives, pose a significant threat by potentially making existing product lines obsolete. Breakthroughs in bio-based elastomers, for example, could directly compete with Apcotex's offerings in crucial sectors like automotive and footwear.

| Threat Area | Specific Risk | Impact on Apcotex | Example/Data Point (2023/2024) |

| Competition | Global Competitors | Price pressure, market share erosion | Intensified competition from Asian manufacturers |

| Raw Material Costs | Crude Oil Price Volatility | Increased production expenses | Oil prices averaged $77-$82 per barrel in early 2024, impacting petrochemical feedstock costs. |

| Economic Conditions | Economic Slowdown | Reduced demand for products | Global GDP growth forecasts for 2024 around 2.9% (IMF), indicating cautious industrial demand. |

| Regulatory Environment | Environmental Regulations | Increased compliance costs, capital expenditure | Potential 5-10% rise in CAPEX for emission controls in chemical sector (global estimate). |

| Technological Advancements | Substitute Materials | Obsolescence of existing products, loss of market share | Growing R&D in bio-elastomers and advanced recycling technologies. |

SWOT Analysis Data Sources

This SWOT analysis is built upon a foundation of credible data, including Apcotex Industries' official financial filings, comprehensive market research reports, and expert commentary from industry analysts to ensure a robust and informed assessment.