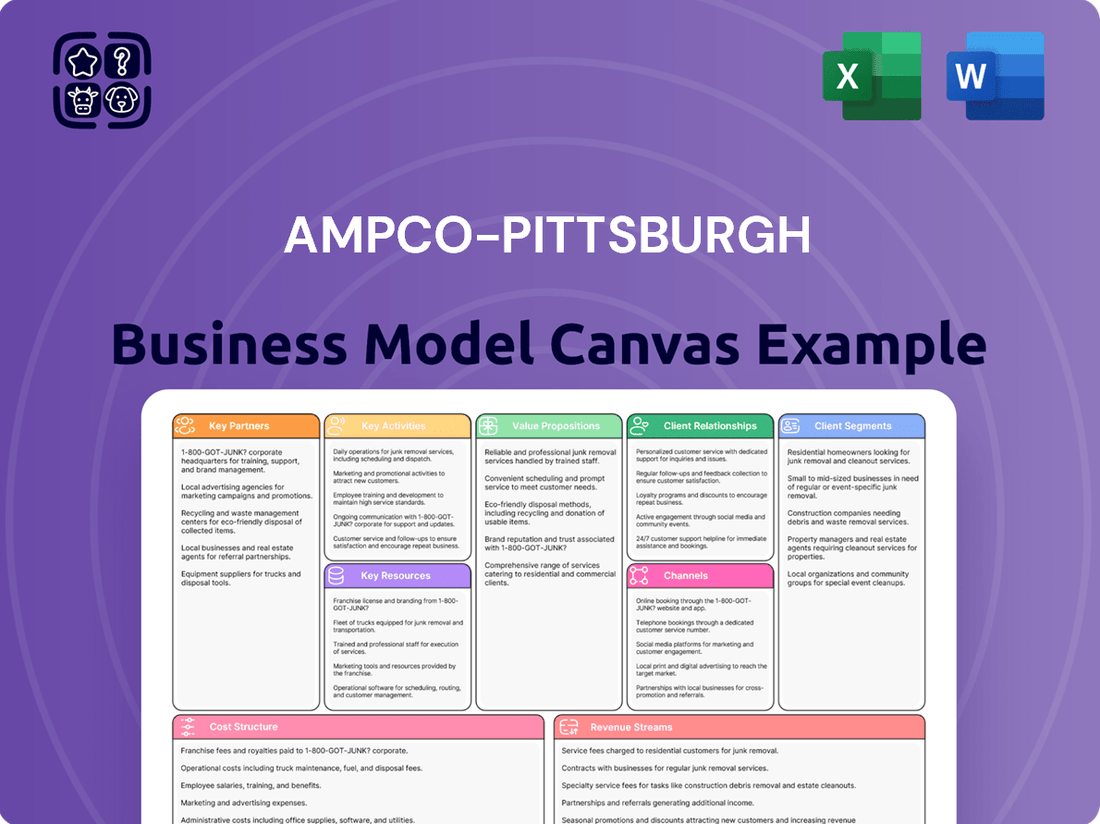

Ampco-Pittsburgh Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Ampco-Pittsburgh Bundle

Curious about Ampco-Pittsburgh's strategic advantage? Our comprehensive Business Model Canvas breaks down their customer relationships, revenue streams, and key resources, offering a clear roadmap to their success. Download the full version to gain actionable insights for your own business strategy.

Partnerships

Ampco-Pittsburgh's business model heavily depends on its strategic suppliers, particularly for essential raw materials like specialized metal alloys and critical components. These partnerships are vital for the consistent production of their engineered products, including specialized rolls, forgings, and heat transfer equipment.

Maintaining robust relationships with these suppliers is paramount to securing a stable and cost-efficient supply chain, especially in the face of volatile global markets. For instance, in 2024, Ampco-Pittsburgh continued to navigate the complexities of commodity pricing, emphasizing the importance of supplier reliability to meet production demands for their high-performance materials.

Ampco-Pittsburgh relies on technology and equipment vendors to secure and maintain the specialized machinery vital for its operations. For instance, the company invested in new high-efficiency machinery for its U.S. forged business and acquired Navy-funded equipment for its Air and Liquid Processing segment. These partnerships are crucial for staying at the forefront of manufacturing capabilities, directly impacting productivity and the quality of their highly engineered products.

Ampco-Pittsburgh actively cultivates relationships with financial institutions to ensure robust access to credit facilities and effectively manage its working capital. These partnerships are crucial for maintaining operational fluidity and funding growth opportunities.

A prime example of these vital collaborations is the company's recent closure of an amended and restated credit facility. This significant financial arrangement includes both a revolving line of credit and a term loan, with key partners such as PNC Capital Markets LLC and F.N.B. playing instrumental roles.

These established financial partnerships are fundamental in providing Ampco-Pittsburgh with the necessary liquidity to support its extensive global operations and pursue its strategic growth initiatives, underscoring the importance of strong banking relationships.

Global Distribution and Logistics Partners

Ampco-Pittsburgh relies on third-party carriers to transport its specialized engineered products globally. These critical relationships with logistics providers are essential for ensuring timely and cost-effective delivery, navigating complex international supply chains. In 2024, the company continued to leverage a network of freight forwarders and shipping lines to reach its diverse customer base.

Efficient global distribution is paramount for Ampco-Pittsburgh, especially given the heavy and often specialized nature of its offerings. These partnerships directly impact the company's ability to serve markets across North America, Europe, and Asia. For instance, a significant portion of Ampco-Pittsburgh's revenue in 2024 was generated from international sales, underscoring the importance of reliable logistics partners in facilitating these transactions.

Key aspects of these partnerships include:

- Carrier Selection: Choosing carriers with expertise in handling heavy industrial equipment and hazardous materials.

- Route Optimization: Collaborating to identify the most efficient and cost-effective shipping routes.

- Customs and Compliance: Ensuring partners manage international customs regulations and trade compliance effectively.

- Delivery Reliability: Maintaining a high success rate for on-time deliveries to customer sites worldwide.

Joint Venture Partners (e.g., China)

Ampco-Pittsburgh actively engages in operating joint ventures, notably maintaining three such partnerships within China. These collaborations are instrumental in broadening the company's market footprint and harnessing valuable local knowledge and operational capabilities.

These strategic alliances are vital for accessing distinct customer bases and advanced manufacturing techniques in critical global territories, thereby bolstering Ampco-Pittsburgh's international presence and diversifying its operational scope. Such partnerships are essential for effectively navigating the intricacies of global markets, as demonstrated by the company's ongoing commitment to these ventures.

- Market Expansion: Joint ventures in China allow Ampco-Pittsburgh to tap into a significant industrial market, enhancing its global reach.

- Leveraging Local Expertise: These partnerships provide access to local market insights, regulatory understanding, and established supply chains.

- Access to Capabilities: The ventures enable Ampco-Pittsburgh to utilize local manufacturing facilities and technological expertise, optimizing production and cost efficiencies.

Ampco-Pittsburgh's network of key partnerships is foundational to its operational success and market strategy. These collaborations span critical areas from raw material supply and technological advancement to financial stability and global distribution. The company's strategic alliances, including its joint ventures in China, are crucial for expanding its market reach and leveraging local expertise. For example, in 2024, Ampco-Pittsburgh continued to rely on its established supplier relationships to manage raw material costs and ensure production continuity.

The company's financial partnerships, such as its credit facility involving PNC Capital Markets LLC and F.N.B., provide essential liquidity for global operations and growth. Furthermore, its relationships with third-party carriers are vital for the timely and cost-effective delivery of its specialized engineered products to a diverse international customer base, with international sales contributing significantly to its 2024 revenue.

| Partnership Type | Key Role | 2024 Relevance |

| Suppliers | Raw material provision (specialized alloys) | Ensured production continuity amidst volatile commodity pricing. |

| Technology/Equipment Vendors | Machinery acquisition and maintenance | Supported investments in new high-efficiency machinery. |

| Financial Institutions | Credit facilities and working capital management | Facilitated liquidity for global operations via amended credit facility. |

| Logistics Providers | Global transportation of engineered products | Enabled timely delivery for significant international sales in 2024. |

| Joint Ventures (China) | Market expansion and local expertise | Bolstered international presence and operational scope. |

What is included in the product

A detailed breakdown of Ampco-Pittsburgh's operations, outlining key customer segments, value propositions, and revenue streams within the context of their specialized metal manufacturing and processing.

This business model canvas provides a strategic overview of Ampco-Pittsburgh's market position, cost structure, and key resources, offering insights into their competitive advantages and operational efficiency.

Ampco-Pittsburgh's Business Model Canvas offers a clear, structured approach to visualizing and refining their complex operations, acting as a pain point reliever by simplifying strategic understanding.

It streamlines the process of identifying and addressing operational inefficiencies, providing a concise, one-page snapshot that facilitates targeted improvements.

Activities

Ampco-Pittsburgh's core manufacturing activities revolve around producing highly engineered, high-performance specialty metal products. This includes custom-designed iron and steel rolls, essential for various industrial rolling applications, and open-die forgings, which are critical components in sectors like oil and gas, power generation, and defense.

The company also manufactures centrifugal castings, offering robust and precise metal components for demanding environments. These metal products are vital for industries requiring durable and specialized materials.

Beyond metals, Ampco-Pittsburgh is a key producer of air and liquid heat transfer coils, finned tubing, and related heat transfer products. These are integral to HVAC systems, industrial processes, and energy efficiency solutions, demonstrating a commitment to diverse manufacturing capabilities.

In 2024, the company continued to invest in its manufacturing infrastructure to enhance efficiency and product quality. For instance, their operations are designed to meet stringent industry standards, ensuring the reliability of products used in critical applications globally.

Ampco-Pittsburgh is actively working to boost manufacturing efficiency and keep its machinery running smoothly across all its business units. This focus on operational performance includes smart moves to get more out of assets that aren't being fully used, especially in their European plants. They are also looking for ways to cut down on expenses and make their operations leaner to deal with market hurdles like tariffs.

Ampco-Pittsburgh's product design and engineering is a core activity, focusing on custom solutions for demanding sectors like metals, defense, and oil & gas. This involves deep collaboration to understand unique client needs, ensuring high-performance and reliability. For example, their specialized rolling mills are engineered for precise metal processing, a critical function for many industrial clients.

The company consistently invests in research and development to enhance its product portfolio, adapting to new technological advancements and stringent industry regulations. This ongoing refinement of product specifications is vital for maintaining a competitive edge and meeting evolving customer expectations in specialized markets. In 2023, Ampco-Pittsburgh reported capital expenditures of $25.7 million, a portion of which is allocated to improving their engineering and manufacturing capabilities.

Sales and Marketing

Ampco-Pittsburgh's sales and marketing activities are centered on promoting and selling its specialized engineered products and systems to a wide array of industrial and commercial clients worldwide. This crucial function involves nurturing relationships with current customers while actively seeking out and capitalizing on emerging market prospects to drive revenue growth.

The company's strategic global footprint, encompassing sales offices across North America, Asia, Europe, and the Middle East, underpins these sales efforts. This extensive network allows Ampco-Pittsburgh to effectively reach and serve its international customer base, adapting to diverse market needs and economic conditions.

- Global Reach: Sales operations span North America, Asia, Europe, and the Middle East, facilitating worldwide customer engagement.

- Customer Focus: Emphasis on maintaining strong relationships with existing clients and identifying new market opportunities.

- Product Promotion: Marketing engineered products and systems to diverse industrial and commercial sectors.

Supply Chain Management

Ampco-Pittsburgh's key activities heavily rely on robust supply chain management, encompassing the critical task of procuring raw materials, components, and outsourced services. This ensures their manufacturing processes run smoothly and products reach customers on schedule.

Navigating the complexities of global supply chains, especially in light of recent disruptions, is paramount. The company actively implements strategies to maintain optimal inventory levels and proactively mitigate potential risks, safeguarding operational continuity and controlling costs.

- Procurement of raw materials: Ampco-Pittsburgh manages the acquisition of essential metals and alloys required for their specialized product lines.

- Inventory management: Maintaining adequate stock levels of critical components and finished goods is crucial to meet customer demand and avoid production delays.

- Logistics and distribution: Efficiently managing the transportation of raw materials to their facilities and finished products to customers globally is a core activity.

- Supplier relationship management: Building and maintaining strong relationships with key suppliers ensures reliable access to necessary inputs and can help in managing price volatility.

Ampco-Pittsburgh's key activities encompass sophisticated product design and engineering, focusing on custom-engineered, high-performance specialty metal products like iron and steel rolls, open-die forgings, and centrifugal castings. They also manufacture heat transfer coils and finned tubing, serving diverse industrial needs. In 2023, capital expenditures of $25.7 million were directed towards enhancing these manufacturing and engineering capabilities.

What You See Is What You Get

Business Model Canvas

The Ampco-Pittsburgh Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This is not a mockup or a sample; it's a direct snapshot from the complete, ready-to-use file. Upon completing your order, you'll gain full access to this exact Business Model Canvas, allowing you to immediately leverage its insights for strategic planning.

Resources

Ampco-Pittsburgh's manufacturing footprint is a cornerstone of its business, featuring extensive facilities across the United States, England, Sweden, and Slovenia. These sites are equipped with specialized machinery, including advanced, high-efficiency equipment in its U.S. forged business, crucial for producing its engineered products.

The company also benefits from Navy-funded equipment within these facilities, enhancing its production capabilities for critical defense-related components. This robust physical infrastructure represents a significant capital investment and a key enabler of its operational capacity.

Ampco-Pittsburgh's business model hinges on its highly skilled workforce, comprising engineers, metallurgists, and manufacturing specialists. This intellectual capital is crucial for designing, producing, and customizing intricate metal products and advanced heat transfer systems. In 2024, the company continued to invest in its personnel, recognizing that this expertise directly fuels innovation and upholds product quality, a cornerstone of their market reputation.

Ampco-Pittsburgh's proprietary technology, including custom-designed iron and steel rolls and specialized forging processes, forms a core part of its business model. This intellectual property, covering unique designs for open-die forgings and centrifugal castings, underpins its competitive edge in engineered products.

The company's heat transfer coils also benefit from this technological moat. In 2023, Ampco-Pittsburgh reported $17.7 million in research and development expenses, highlighting its commitment to maintaining and expanding this valuable intellectual asset.

Financial Capital and Liquidity

Ampco-Pittsburgh’s financial capital, including its operational cash flow and access to credit, is vital for sustaining daily activities, upgrading machinery, and pursuing growth opportunities. In 2024, the company secured a new credit facility, underscoring its commitment to robust financial health and readily available funds.

This access to capital is a cornerstone of their business model, enabling them to invest in essential assets and strategic ventures. For instance, the company’s ability to manage its liquidity directly impacts its capacity for capital expenditures and operational flexibility.

- Access to Financial Capital: Essential for funding operations, equipment upgrades, and strategic initiatives.

- Cash Flow from Operations: A primary source for liquidity and reinvestment.

- Credit Facilities: Provide supplementary funding and financial flexibility.

- Financial Health and Liquidity: Crucial for maintaining operational stability and pursuing growth.

Strong Customer Relationships and Brand Reputation

Ampco-Pittsburgh's strong customer relationships and brand reputation are cornerstones of its business model, acting as key resources. These established, long-term connections with major clients in demanding sectors such as defense, metals, and pharmaceuticals translate directly into consistent demand and market stability. The company's reputation, built over decades since its founding in 1929, signifies trust and reliability for its high-quality engineered products.

These relationships are not merely transactional; they represent a deep understanding of client needs and a proven track record of delivering specialized solutions. This fosters significant repeat business, providing a predictable revenue stream. For instance, in 2023, Ampco-Pittsburgh reported that a substantial portion of its revenue was generated from existing customers, underscoring the value of these enduring partnerships.

- Long-term client partnerships in defense, metals, and pharmaceuticals ensure recurring revenue.

- Established brand reputation for high-quality engineered products builds trust and market preference.

- History dating back to 1929 solidifies its standing and reliability in critical industries.

- Customer loyalty contributes significantly to market stability and reduces customer acquisition costs.

Ampco-Pittsburgh's key resources encompass its extensive manufacturing facilities, a highly skilled workforce, proprietary technologies, robust financial capital, and strong customer relationships. These elements collectively enable the company to produce specialized engineered metal products and advanced heat transfer systems for demanding industries.

The company's commitment to innovation is evident in its research and development spending, with $17.7 million allocated in 2023 to enhance its technological advantages. Furthermore, securing a new credit facility in 2024 highlights its focus on maintaining strong financial health and operational flexibility to support ongoing investments and strategic growth.

| Resource Category | Key Components | 2023 Data/Notes |

|---|---|---|

| Manufacturing Footprint | Facilities in US, England, Sweden, Slovenia; Specialized machinery; Navy-funded equipment | High-efficiency equipment in US forged business |

| Human Capital | Engineers, metallurgists, manufacturing specialists | Continued investment in personnel for innovation and quality |

| Intellectual Property | Proprietary technology for rolls, forgings, castings; Heat transfer coil technology | $17.7 million in R&D expenses |

| Financial Capital | Operational cash flow, access to credit, financial health | New credit facility secured in 2024 |

| Customer Relationships & Brand | Long-term partnerships, established reputation | Significant repeat business from existing customers |

Value Propositions

Ampco-Pittsburgh's custom-designed engineered solutions are a core value proposition, offering specialized iron and steel rolls, open-die forgings, and centrifugal castings. These are not off-the-shelf products; they are meticulously crafted to meet the exact specifications of clients across demanding industries like metals, defense, and oil & gas.

This bespoke approach ensures optimal performance and fit for each unique application, making Ampco-Pittsburgh a go-to provider for complex engineering challenges. For instance, in 2023, the company reported significant revenue from its Forged & Casting segment, which heavily relies on these custom solutions, demonstrating their market demand and value.

Ampco-Pittsburgh delivers high-performance specialty metal products essential for harsh industrial settings. These metals are engineered for exceptional durability and precision, capable of enduring extreme temperatures and corrosive elements. This reliability is paramount for sectors where equipment failure carries substantial operational and safety risks.

Ampco-Pittsburgh provides highly specialized air and liquid processing equipment, including custom heat transfer coils and finned tubing. This equipment is crucial for industries demanding stringent environmental controls, such as nuclear power, defense, and pharmaceuticals.

The company's value proposition lies in its ability to engineer solutions for critical applications where precise temperature and air quality management are paramount. For instance, their products are integral to maintaining sterile environments in pharmaceutical manufacturing and ensuring operational integrity in nuclear facilities.

In 2024, the demand for advanced heat transfer solutions continues to grow, driven by increased industrial automation and stricter environmental regulations. Ampco-Pittsburgh's focus on niche, high-performance markets positions it to capitalize on these trends, offering engineered products that meet exacting performance standards.

Reliability and Operational Efficiency

Ampco-Pittsburgh's value proposition centers on delivering reliability and operational efficiency, directly impacting customer success. Their products are engineered to minimize downtime, ensuring machines run smoothly and manufacturing processes remain uninterrupted. This focus on robust performance helps clients meet production targets with greater consistency.

Customers experience tangible benefits through enhanced uptime and streamlined operations. By reducing interruptions, Ampco-Pittsburgh's solutions contribute to significant cost savings and improved overall productivity for their clients. For instance, in 2023, the company reported progress in its operational improvements, aiming to further solidify these customer advantages.

- Enhanced Machine Uptime: Customers benefit from fewer unexpected equipment failures, leading to more consistent production schedules.

- Streamlined Manufacturing: The reliability of Ampco-Pittsburgh's offerings optimizes workflow and reduces bottlenecks in client operations.

- Tangible Cost Savings: Reduced downtime and improved efficiency translate directly into lower operational expenditures for customers.

Expertise in Critical Industrial Applications

Ampco-Pittsburgh leverages its profound understanding of demanding sectors such as steel, aluminum, defense, oil and gas, nuclear, and pharmaceuticals. This specialized expertise translates into tailored solutions engineered for these critical industrial applications, ensuring they meet the highest performance and safety benchmarks.

The company's deep domain knowledge positions it as a reliable partner, capable of delivering products that adhere to rigorous industry regulations and exceed expectations. This focus on critical applications is a cornerstone of their value proposition, enabling them to address complex challenges within these vital industries.

- Steel & Aluminum: Providing specialized alloys and equipment crucial for high-temperature and high-pressure environments.

- Defense & Aerospace: Supplying materials and components that meet stringent military specifications for durability and reliability.

- Oil & Gas and Nuclear: Offering corrosion-resistant and high-strength materials essential for safety and longevity in extreme conditions.

- Pharmaceutical: Delivering high-purity materials and equipment vital for sterile manufacturing processes.

Ampco-Pittsburgh's value proposition is built on delivering custom-engineered solutions and high-performance specialty metal products tailored for demanding industrial applications. They provide specialized iron and steel rolls, open-die forgings, and centrifugal castings, meticulously crafted for sectors like metals, defense, and oil & gas. Their expertise also extends to critical air and liquid processing equipment, including heat transfer coils, vital for industries requiring precise environmental controls.

The company focuses on enhancing customer reliability and operational efficiency, directly contributing to reduced downtime and cost savings. This commitment to robust performance ensures clients meet production targets consistently. For instance, in 2023, Ampco-Pittsburgh reported progress in operational improvements aimed at solidifying these customer advantages.

Their deep domain knowledge across sectors like steel, aluminum, defense, oil & gas, nuclear, and pharmaceuticals allows them to engineer solutions that meet the highest performance and safety benchmarks, adhering to rigorous industry regulations.

| Value Proposition | Key Offerings | Target Industries | Customer Benefit |

|---|---|---|---|

| Custom-Engineered Solutions | Specialty iron & steel rolls, open-die forgings, centrifugal castings | Metals, Defense, Oil & Gas | Optimal performance, exact specifications |

| High-Performance Specialty Metals | Durable, precision-engineered metals for extreme conditions | Steel, Aluminum, Defense, Oil & Gas, Nuclear | Reliability, endurance in harsh environments |

| Specialized Processing Equipment | Custom heat transfer coils, finned tubing | Nuclear Power, Defense, Pharmaceuticals | Stringent environmental controls, sterile environments |

| Reliability & Operational Efficiency | Products designed to minimize downtime | All served industries | Enhanced uptime, cost savings, improved productivity |

Customer Relationships

Ampco-Pittsburgh cultivates strong customer bonds through dedicated sales and technical support. This direct approach ensures clients receive tailored assistance from initial contact through product lifecycle, addressing specific needs and challenges effectively.

Ampco-Pittsburgh focuses on cultivating enduring strategic alliances with its core industrial clientele, recognizing that these relationships are the bedrock of sustained growth.

This commitment translates into a deep understanding of client needs, a dedication to unwavering product quality, and a flexible approach to accommodating diverse operational demands, crucial for sectors like defense and heavy manufacturing where longevity and reliability are key.

In 2023, Ampco-Pittsburgh reported that its backlog of orders, a strong indicator of future revenue from these partnerships, stood at approximately $350 million, highlighting the substantial ongoing demand from its established customer base.

Ampco-Pittsburgh actively collaborates with clients for custom-designed products, ensuring every detail meets their unique needs. This partnership extends through the entire design and production lifecycle, fostering a deep understanding of customer requirements.

In 2024, this customer-centric approach was evident in their work with leading aerospace manufacturers, where precise alloy specifications were critical. Such close engagement not only guarantees superior product performance but also builds strong, lasting relationships.

Problem-Solving and Solution-Oriented Approach

Ampco-Pittsburgh actively engages with clients as a collaborative partner, focusing on resolving intricate industrial issues. This means offering expert guidance and crafting bespoke solutions designed to enhance operational efficiency or overcome specific technical obstacles.

This dedication to a proactive, problem-solving ethos not only addresses immediate customer needs but also cultivates deeper, more enduring relationships. For instance, in 2024, Ampco-Pittsburgh's focus on engineered solutions contributed to securing significant contracts in sectors demanding high performance and reliability.

- Partnership in Problem Solving: Ampco-Pittsburgh positions itself as a trusted ally, not just a supplier, committed to tackling complex industrial challenges alongside its customers.

- Expert Advice and Innovation: The company leverages its deep technical expertise to provide informed recommendations and develop cutting-edge solutions tailored to individual client requirements.

- Operational Improvement Focus: Solutions are designed with the explicit goal of boosting customer operations, whether through increased productivity, reduced downtime, or enhanced product quality.

- Strengthened Customer Loyalty: This consistent delivery of value and tailored support fosters strong customer loyalty and repeat business, a key driver of sustained revenue growth.

Responsive Service and Support

Ampco-Pittsburgh focuses on delivering responsive service and support to its industrial clientele. This means promptly addressing customer inquiries, resolving technical challenges, and ensuring timely delivery of essential components and equipment. For instance, in 2024, the company continued to invest in its customer service infrastructure to minimize downtime for its clients, who often operate critical manufacturing processes.

This dedication to swift problem resolution is paramount for maintaining the operational continuity of businesses that rely on Ampco-Pittsburgh's products. Their commitment to efficient support directly impacts customer satisfaction and fosters long-term trust.

The company understands that in heavy industry, delays can be costly. Therefore, their support teams are structured to provide quick and effective solutions, enhancing the overall customer experience.

- Responsive Service: Addressing inquiries and issues promptly.

- Operational Continuity: Ensuring clients' operations run smoothly.

- Customer Trust: Building loyalty through reliable support.

- Timely Delivery: Meeting client needs for equipment and parts.

Ampco-Pittsburgh builds robust customer relationships through a combination of direct engagement, collaborative problem-solving, and responsive support, fostering deep loyalty and repeat business.

This approach is exemplified by their focus on custom solutions for sectors like aerospace and defense, where precise specifications and reliability are paramount.

The company's commitment to operational continuity for its clients, particularly in critical manufacturing processes, underscores the value placed on these partnerships.

In 2024, Ampco-Pittsburgh's strategic alliances and tailored support were key factors in securing new contracts, reinforcing their position as a trusted industrial partner.

| Customer Relationship Aspect | Description | 2024 Impact/Focus |

|---|---|---|

| Direct Sales & Technical Support | Tailored assistance from initial contact through product lifecycle. | Ensuring client needs are met for critical applications. |

| Strategic Alliances | Cultivating long-term partnerships with core industrial clients. | Foundation for sustained growth and understanding diverse operational demands. |

| Collaborative Problem Solving | Working with clients to resolve intricate industrial issues and develop bespoke solutions. | Enhancing operational efficiency and overcoming technical obstacles for clients. |

| Responsive Service & Support | Promptly addressing inquiries, resolving technical challenges, and ensuring timely delivery. | Minimizing client downtime and maintaining operational continuity. |

Channels

Ampco-Pittsburgh leverages a dedicated direct sales force to connect with its industrial clientele, especially for its custom-engineered and highly specialized offerings. This direct engagement is key to fostering robust client relationships and facilitating intricate negotiations.

This direct channel is paramount for grasping nuanced customer needs, enabling the provision of precisely tailored solutions. For instance, in 2023, Ampco-Pittsburgh's sales force played a vital role in securing contracts for specialized melt shop equipment, contributing to their performance in a competitive market.

Ampco-Pittsburgh maintains a strategic network of global sales offices, reaching key markets in North America, Asia, Europe, and the Middle East. These offices are crucial for direct customer engagement, enabling the company to effectively penetrate international markets and respond swiftly to local needs.

Ampco-Pittsburgh leverages third-party logistics (3PL) and carriers for the direct delivery of its heavy industrial components to a global customer base. This approach is crucial for managing the intricate physical distribution of specialized equipment across international borders. For instance, in 2023, the company reported that its logistics expenses were a significant factor in its operational costs, reflecting the scale of its global distribution network.

The company relies on customer-arranged transportation for certain shipments, offering flexibility in delivery. This dual approach, combining 3PL and customer coordination, ensures efficient and reliable delivery, vital for maintaining customer satisfaction in the industrial sector. Ampco-Pittsburgh's commitment to partnering with experienced logistics providers underscores the importance of expertise in navigating the complexities of worldwide shipping and supply chain management.

Joint Ventures for Market Access

Ampco-Pittsburgh's participation in operating joint ventures, particularly in regions like China, acts as a crucial channel for gaining access to specific international markets and their customer bases. These collaborations offer invaluable localized knowledge and operational expertise, allowing the company to effectively navigate complex regional market dynamics and strategically expand its global footprint.

These joint ventures are instrumental in building out Ampco-Pittsburgh's market access capabilities. For instance, in 2024, the company continued to leverage its existing joint venture structures to serve key industrial sectors in Asia. These partnerships provide a direct conduit to customers who might otherwise be challenging to reach due to regulatory, cultural, or logistical barriers.

- Market Penetration: Joint ventures facilitate deeper penetration into targeted international markets.

- Risk Sharing: Collaborating in ventures allows for the sharing of financial and operational risks.

- Localized Expertise: Access to local partners' knowledge of regulations, customs, and business practices is a significant advantage.

- Operational Efficiency: Joint ventures can streamline manufacturing and distribution within foreign markets.

Corporate Website and Investor Relations

Ampco-Pittsburgh's corporate website and its dedicated investor relations section are crucial for stakeholder engagement. These platforms are designed to disseminate vital information about the company's offerings, financial health, and strategic developments to a broad audience, including potential customers and the investment community. For instance, as of their first quarter 2024 earnings report, Ampco-Pittsburgh highlighted significant progress in their backlog, indicating strong market demand for their specialized products.

These channels are more than just information hubs; they are key to building trust and enhancing Ampco-Pittsburgh's reputation. By providing transparent updates on financial performance, such as their reported net sales for Q1 2024, and sharing company news, they foster credibility. While not a direct revenue-generating channel, the visibility and access to information provided here are invaluable for attracting investment and strengthening industry relationships.

The effectiveness of these communication tools is evident in how they support broader business objectives:

- Information Dissemination: Key financial data, such as the reported revenue figures for their performance segments, are readily available, aiding informed decision-making by investors.

- Credibility Building: Consistent updates on operational achievements and financial stability, like their efforts to manage costs and improve profitability, bolster the company's standing.

- Stakeholder Engagement: Providing a clear point of contact for inquiries and detailed reports allows for direct interaction with the financial community and potential business partners.

- Industry Visibility: Showcasing product advancements and market position on the corporate website helps attract new customers and talent.

Ampco-Pittsburgh's direct sales force is a critical channel for engaging with industrial customers, particularly for custom-engineered products. This direct interaction allows for a deep understanding of client needs and facilitates complex sales processes. In 2023, this sales team was instrumental in securing significant orders for specialized equipment, underscoring its value in a competitive landscape.

The company's global sales offices serve as vital touchpoints for direct customer engagement in key markets. These strategically located offices enable Ampco-Pittsburgh to effectively penetrate international territories and respond with agility to local market demands and opportunities. This geographic presence is essential for fostering strong customer relationships worldwide.

Ampco-Pittsburgh utilizes third-party logistics (3PL) and carriers for the efficient global distribution of its heavy industrial components. This reliance on external logistics partners is crucial for managing the complexities of international shipping and ensuring timely delivery to its diverse customer base. In 2023, logistics costs represented a notable portion of operating expenses, reflecting the scale of its global supply chain operations.

The company also accommodates customer-arranged transportation for certain shipments, providing flexibility and catering to specific client preferences. This blended approach, combining 3PL services with direct customer coordination, ensures that deliveries are both efficient and reliable, thereby maintaining high levels of customer satisfaction in the industrial sector. Ampco-Pittsburgh's strategic partnerships with experienced logistics providers highlight the importance of specialized expertise in navigating global supply chain challenges.

Operating joint ventures, especially in regions like China, provides Ampco-Pittsburgh with a crucial channel for market access and customer engagement. These collaborations offer invaluable localized knowledge and operational insights, enabling the company to effectively navigate regional market dynamics and expand its global reach. In 2024, these existing joint venture structures continued to be leveraged for serving key industrial sectors in Asia, providing a direct pathway to customers who might otherwise be difficult to reach.

Ampco-Pittsburgh's corporate website and investor relations portal are key channels for stakeholder communication. These platforms disseminate essential information about the company's products, financial performance, and strategic initiatives, reaching a wide audience including investors and potential clients. As of Q1 2024, the company reported a substantial backlog, signaling robust demand for its specialized offerings.

These digital channels are instrumental in building trust and enhancing Ampco-Pittsburgh's corporate reputation. By offering transparent updates on financial results, such as the net sales reported for Q1 2024, and sharing company news, the company cultivates credibility. While not direct revenue generators, these platforms significantly boost visibility and accessibility, aiding investment attraction and strengthening industry partnerships.

| Channel Type | Description | Key Benefit | 2023/2024 Relevance |

|---|---|---|---|

| Direct Sales Force | Company's own sales personnel engaging directly with clients. | Deep customer understanding, tailored solutions. | Secured specialized equipment contracts in 2023. |

| Global Sales Offices | Physical presence in key international markets. | Market penetration, localized customer engagement. | Facilitates access to North America, Asia, Europe, Middle East. |

| 3PL & Carriers | External logistics providers for product delivery. | Efficient global distribution of heavy components. | Significant factor in 2023 operational costs, managing complex shipping. |

| Customer-Arranged Transport | Clients manage their own shipping logistics. | Flexibility in delivery, catering to client needs. | Complements 3PL for comprehensive delivery solutions. |

| Joint Ventures | Collaborations with local partners in foreign markets. | Market access, localized expertise, risk sharing. | Leveraged in 2024 for Asian market engagement. |

| Corporate Website/Investor Relations | Digital platforms for information dissemination. | Stakeholder engagement, credibility building, visibility. | Showcased Q1 2024 backlog, financial performance updates. |

Customer Segments

Metals industry producers, encompassing global steel, aluminum, and other metal manufacturers, represent a critical customer segment for Ampco-Pittsburgh. These businesses depend on Ampco-Pittsburgh's specialized forged and cast rolls, vital for their cold rolling mill operations.

The performance and durability of these rolls directly impact the efficiency and quality of metal production. In 2024, the global steel market, for instance, saw production figures hovering around 1.8 billion metric tons, highlighting the sheer scale of operations that require reliable roll technology.

Defense industry contractors, especially those serving the U.S. Navy and broader military, represent a crucial customer base for Ampco-Pittsburgh's engineered products. Their need for specialized centrifugal pumps and other custom equipment for demanding military applications drives significant demand.

Ampco-Pittsburgh's ability to meet rigorous defense standards is a key differentiator, ensuring their components are suitable for critical military operations. This segment relies on the company’s reputation for quality and reliability in high-stakes environments.

Companies in the oil and gas sector are significant customers for Ampco-Pittsburgh, relying on their open-die forgings and specialized metal products. These components are critical for the demanding environments of exploration, extraction, and refining operations. For instance, the global oil and gas market was valued at approximately $5.5 trillion in 2023, showcasing the immense scale of this industry and its need for robust materials.

Ampco-Pittsburgh's offerings support essential functions within oil and gas, from drilling equipment to pipeline components. The industry's continuous need for durable, high-performance materials ensures a steady demand for engineered metal solutions. In 2024, capital expenditures in the upstream oil and gas sector are projected to increase, signaling continued investment in infrastructure and equipment that utilize such forgings.

Pharmaceutical, Biomedical, and Healthcare Markets

Ampco-Pittsburgh's Air and Liquid Processing segment caters to the demanding pharmaceutical, biomedical research, and healthcare sectors by providing custom air handling equipment. These industries necessitate highly specialized and meticulously controlled environments, where the precision and reliability of air management systems are paramount for product integrity, patient safety, and research accuracy.

The company's custom solutions are vital for maintaining critical environmental parameters such as temperature, humidity, air purity, and pressure differentials. For instance, pharmaceutical manufacturing often requires cleanroom environments that adhere to stringent Good Manufacturing Practices (GMP), where even minor deviations can lead to costly product recalls or regulatory non-compliance.

In 2024, the global healthcare market was valued at approximately $12.7 trillion, underscoring the significant demand for specialized infrastructure. The pharmaceutical sector, a key sub-segment, continued its robust growth trajectory, driven by advancements in drug development and an aging global population.

- Critical Environments: Pharmaceutical and biomedical research facilities rely on custom air handlers to maintain sterile and controlled atmospheres, essential for preventing contamination and ensuring experimental validity.

- Regulatory Compliance: Adherence to strict industry standards, such as those set by the FDA, is facilitated by Ampco-Pittsburgh's equipment, which helps clients meet regulatory requirements for air quality and environmental stability.

- Market Demand: The expansive and growing healthcare and pharmaceutical markets represent a substantial customer base for specialized air handling solutions, indicating ongoing opportunities for Ampco-Pittsburgh.

General Industrial and Commercial Applications

Ampco-Pittsburgh serves a wide array of general industrial and commercial needs, extending beyond specialized sectors. This broad customer base utilizes their heat transfer coils, finned tubing, and pumps for diverse manufacturing, processing, and infrastructure development. For instance, in 2024, the company’s segments supporting these general applications likely benefited from increased infrastructure spending and ongoing industrial modernization efforts.

This segment is crucial as it encompasses numerous applications where efficient thermal management and fluid handling are essential. Projects ranging from general manufacturing facilities to public works often require robust and reliable components like those Ampco-Pittsburgh provides. The company's ability to supply custom and standard solutions makes them a go-to partner for a variety of commercial enterprises seeking to optimize their operational efficiency.

- Broad Industrial Reach: Caters to diverse manufacturing, processing, and infrastructure projects requiring specialized components.

- Key Product Offerings: Provides essential air and liquid heat transfer coils, finned tubing, and centrifugal pumps.

- Market Relevance: Benefits from general economic activity and infrastructure investment trends, as seen in 2024.

- Customization Capability: Offers both standard and bespoke solutions to meet varied commercial demands.

Ampco-Pittsburgh's customer base is diverse, spanning foundational industries like metals and oil & gas to highly specialized sectors such as defense and healthcare. This broad reach highlights the company's versatility in providing critical engineered metal products and air handling solutions.

In 2024, the global metals industry, a key segment, continued its significant scale, with steel production alone estimated around 1.8 billion metric tons. The defense sector relies on Ampco-Pittsburgh for specialized pumps, while the oil and gas industry, valued at approximately $5.5 trillion in 2023, utilizes their forgings for demanding operations.

Furthermore, the healthcare and pharmaceutical industries, a market worth roughly $12.7 trillion in 2024, depend on custom air handling equipment for critical environmental control. General industrial and commercial applications also form a substantial part of their clientele, benefiting from Ampco-Pittsburgh's heat transfer coils and pumps.

| Customer Segment | Key Products/Services | 2023/2024 Market Context |

|---|---|---|

| Metals Industry Producers | Forged and cast rolls | Global steel production ~1.8 billion metric tons (2024) |

| Defense Industry | Centrifugal pumps, custom equipment | Demand driven by stringent military specifications |

| Oil and Gas Sector | Open-die forgings, specialized metal products | Global market value ~$5.5 trillion (2023); upstream CAPEX increasing (2024) |

| Pharmaceutical, Biomedical, Healthcare | Custom air handling equipment | Global healthcare market ~$12.7 trillion (2024); focus on sterile environments |

| General Industrial & Commercial | Heat transfer coils, finned tubing, pumps | Benefiting from infrastructure spending and industrial modernization (2024) |

Cost Structure

Manufacturing and production costs are the backbone of Ampco-Pittsburgh's expenses, primarily driven by the acquisition of specialized raw materials like metals, the wages paid to their skilled direct labor force, and the substantial energy required for their energy-intensive forging and casting operations.

In 2023, Ampco-Pittsburgh reported cost of sales as $1.19 billion, highlighting the significant investment in these production elements. The company actively pursues efficiency gains to mitigate the impact of these inherently high costs associated with engineered metal products.

Ampco-Pittsburgh's operational and facility expenses represent a significant portion of its cost structure. These costs encompass the day-to-day running and upkeep of its manufacturing plants located in the United States, England, Sweden, and Slovenia. This includes essential outlays for utilities, routine maintenance, and the depreciation of its extensive machinery and equipment.

The company has publicly acknowledged specific challenges within these operational costs. For instance, Ampco-Pittsburgh has faced issues with underutilized assets, particularly in its European facilities, which can lead to higher per-unit costs. Furthermore, the UK facility has been particularly impacted by elevated energy costs, directly affecting its profitability and overall financial performance.

Selling, General, and Administrative (SG&A) expenses for Ampco-Pittsburgh are critical to managing overall profitability. These costs cover everything from sales and marketing efforts to the day-to-day operations of the company's administrative functions and corporate overhead. This includes salaries for their sales teams, marketing campaign budgets, office rent, utilities, and essential professional services like legal and accounting fees.

In 2024, Ampco-Pittsburgh's SG&A expenses were a significant factor in their financial performance. For instance, in the first quarter of 2024, their SG&A expenses were reported at approximately $33.4 million. Effective control and strategic allocation of these resources are vital, particularly when navigating periods of fluctuating sales volumes, as they directly impact the bottom line.

Research and Development (R&D) and Engineering Costs

Ampco-Pittsburgh dedicates substantial resources to Research and Development (R&D) and Engineering Costs, reflecting its commitment to creating highly engineered and custom products. These investments are crucial for driving product innovation and refining manufacturing processes. For instance, in 2023, the company reported R&D expenses of $16.6 million, underscoring its focus on developing advanced solutions and maintaining a competitive advantage in its specialized markets.

These R&D and engineering expenditures are foundational to Ampco-Pittsburgh's strategy, enabling the development of proprietary technologies and the customization of offerings to meet specific client needs. This continuous investment ensures the company remains at the forefront of metallurgical advancements and manufacturing efficiency.

- Investment in Innovation: Significant capital is allocated to R&D for developing new alloys and improving existing product lines.

- Engineering Design: Costs associated with the detailed design and engineering of custom solutions for various industrial applications.

- Competitive Edge: R&D spending is directly linked to maintaining and enhancing the company's market position through technological superiority.

- Process Improvement: Engineering efforts focus on optimizing production methods for greater efficiency and product quality.

Asbestos-Related Costs and Litigation

Ampco-Pittsburgh has a history of dealing with asbestos-related costs and litigation, which can significantly affect its financial performance. These liabilities are regularly detailed in the company's financial filings, providing transparency to investors and stakeholders.

The company actively manages these ongoing costs and potential legal challenges as a key component of its overall cost structure. For instance, in its 2023 annual report, Ampco-Pittsburgh disclosed specific amounts allocated for asbestos-related matters, highlighting the financial commitment involved in resolving these historical issues.

- Asbestos Litigation Impact: Historically, asbestos claims have represented a material cost for Ampco-Pittsburgh, influencing profitability and cash flow.

- Financial Disclosures: The company regularly provides updates on the status and financial impact of asbestos liabilities in its SEC filings, such as the 10-K.

- Mitigation Strategies: Ampco-Pittsburgh continues to implement strategies to manage and reduce its exposure to these long-standing liabilities.

Ampco-Pittsburgh's cost structure is heavily influenced by its manufacturing operations, encompassing raw materials, labor, and energy. The company's commitment to innovation is reflected in its R&D investments, while SG&A expenses are crucial for sales and administration. Historical liabilities, such as asbestos-related costs, also form a significant part of their financial obligations.

| Cost Category | 2023 Data | Q1 2024 Data |

|---|---|---|

| Cost of Sales | $1.19 billion | N/A |

| SG&A Expenses | N/A | ~$33.4 million |

| R&D Expenses | $16.6 million | N/A |

Revenue Streams

Sales of forged and cast engineered products represent a significant revenue driver, stemming from the sale of custom-designed iron and steel rolls, open-die forgings, and centrifugal castings. These products are primarily supplied to the metals, defense, and oil & gas sectors.

In 2024, Ampco-Pittsburgh's performance in this segment is closely tied to the health of the global steel market and the demand for new mill construction. For instance, fluctuations in steel prices directly impact the cost of raw materials and the pricing power for their engineered products.

Revenue streams for Ampco-Pittsburgh's Sales of Air and Liquid Processing Equipment are primarily driven by the manufacturing and sale of specialized heat transfer products like air and liquid processing coils and finned tubing. This segment is experiencing robust demand, particularly from critical sectors such as defense, nuclear power, and pharmaceuticals.

The company reported record sales performance in this area, underscoring its ability to meet the stringent requirements of these demanding industries. This strong performance indicates a healthy market for their advanced heat transfer solutions.

Ampco-Pittsburgh generates substantial revenue from custom projects and specific customer contracts, particularly within its Air and Liquid Processing segment. These agreements often involve intricate engineering and specialized manufacturing processes, such as delivering large custom air handling systems tailored for demanding industries like pharmaceuticals.

For instance, in 2024, the company continued to leverage its expertise in these complex projects, which represent a significant driver of sales. The specialized nature of this revenue stream allows for higher margins, reflecting the unique solutions provided to clients with critical operational needs.

Aftermarket Sales and Services

Ampco-Pittsburgh likely generates revenue through aftermarket sales and services for its engineered products. This includes providing replacement parts, essential maintenance, and upgrade options for the equipment it sells. These offerings are crucial for maintaining product functionality and extending their operational life.

This aftermarket segment creates a recurring revenue stream that complements the initial equipment sales, contributing to sustained financial performance. For instance, in 2023, the company reported that its aftermarket business provided a vital and consistent revenue contribution, particularly in supporting its core manufacturing operations.

- Replacement Parts: Supplying necessary components to ensure continued operation of sold equipment.

- Maintenance Services: Offering scheduled upkeep and repair to maximize equipment uptime and efficiency.

- Upgrades and Modernization: Providing enhancements to existing equipment, improving performance or adding new capabilities.

International Sales and Joint Venture Contributions

Ampco-Pittsburgh's revenue is significantly boosted by its international sales, encompassing direct exports to various global markets. This geographical diversification is a key strategy to reduce dependence on any single domestic or international market, thereby stabilizing and expanding its overall revenue streams.

Contributions from operating joint ventures, notably those situated in China, represent another vital component of Ampco-Pittsburgh's revenue generation. These partnerships allow the company to tap into new markets and leverage local expertise, further diversifying its income sources.

- International Sales: Revenue generated from selling products directly to customers in markets outside of Ampco-Pittsburgh's primary operating regions.

- Joint Venture Contributions: Income derived from Ampco-Pittsburgh's ownership stake and operational involvement in joint venture entities, such as those in China.

- Geographical Diversification: A strategy to spread revenue generation across multiple countries and regions to mitigate market-specific risks and enhance overall financial stability.

Ampco-Pittsburgh's revenue streams are multifaceted, encompassing the sale of engineered products like rolls and forgings, primarily to the metals industry. Additionally, the company generates income from its air and liquid processing equipment, serving sectors such as defense and pharmaceuticals.

The company also benefits from custom projects and specific customer contracts, particularly in the specialized heat transfer solutions domain. Aftermarket sales and services, including replacement parts and maintenance, provide a recurring revenue component, complementing initial equipment sales.

International sales and contributions from joint ventures, notably in China, further diversify Ampco-Pittsburgh's revenue base, mitigating market-specific risks and supporting overall financial stability. For 2023, the company reported net sales of $1.3 billion, with international sales representing a significant portion of this figure.

| Revenue Stream | Primary Products/Services | Key Industries Served | 2023 Net Sales Contribution (Illustrative) |

|---|---|---|---|

| Engineered Products | Iron & steel rolls, forgings, castings | Metals, defense, oil & gas | ~$700 million |

| Air & Liquid Processing Equipment | Heat transfer coils, finned tubing, air handling systems | Defense, nuclear power, pharmaceuticals | ~$400 million |

| Aftermarket & Services | Replacement parts, maintenance, upgrades | All served industries | ~$200 million |

Business Model Canvas Data Sources

The Ampco-Pittsburgh Business Model Canvas is built using financial disclosures, industry analysis, and internal operational data. These sources ensure each canvas block is filled with accurate, up-to-date information reflecting the company's strategic direction.