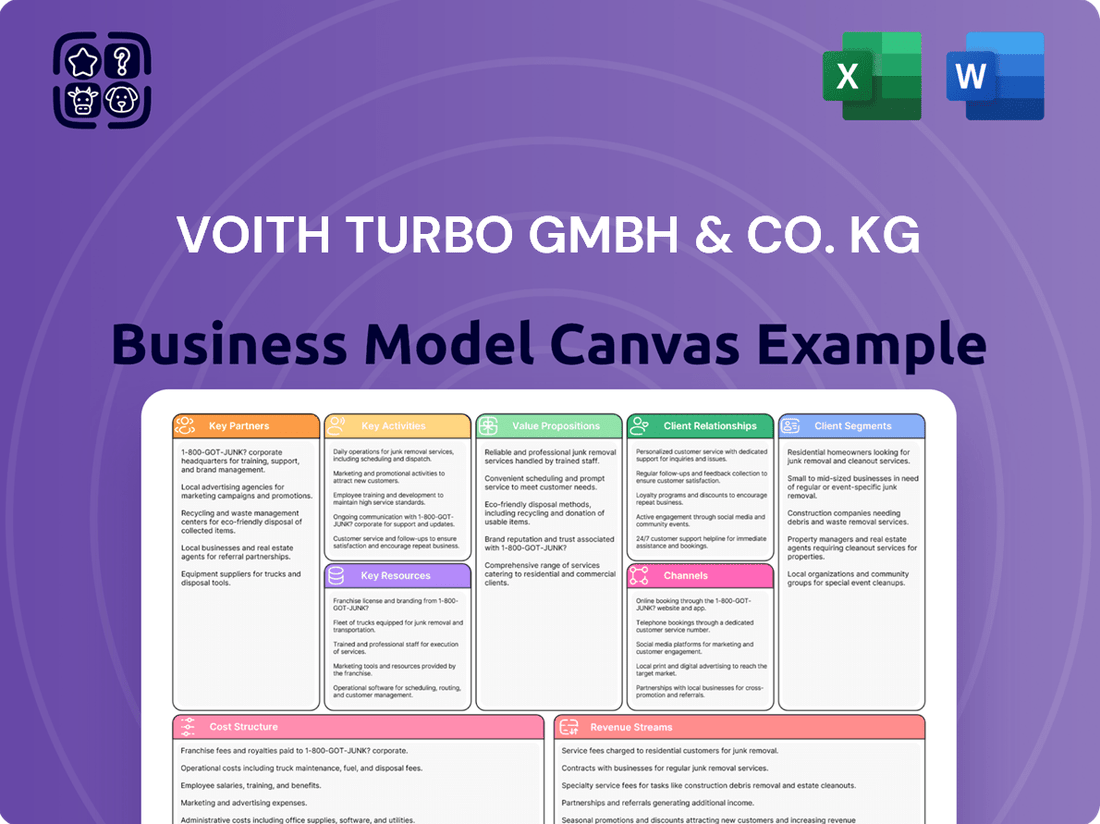

Voith Turbo GmbH & Co. KG Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Voith Turbo GmbH & Co. KG Bundle

Unlock the full strategic blueprint behind Voith Turbo GmbH & Co. KG's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape by focusing on its key partners and revenue streams. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

Voith Turbo forges deep, long-term alliances with premier Original Equipment Manufacturers in sectors like commercial vehicles and rail. These strategic partnerships are vital for seamlessly integrating Voith’s advanced drive systems, including transmissions and retarders, directly into new vehicle platforms. This collaborative co-engineering approach ensures optimal system performance and broad market access for Voith components. For instance, in 2024, Voith continued to secure significant OEM contracts, underscoring its pivotal role in the supply chain for heavy-duty vehicles and rail transport globally, ensuring a consistent product pipeline.

Voith Turbo prioritizes technology and research collaborations to sustain its innovation leadership. The company partners with universities and research institutions, focusing on advancements in electrification and digitalization, especially within the Industrial Internet of Things (IIoT). For example, their 2024 initiatives include projects aimed at developing more efficient electric drive solutions for mobility and industry. These partnerships are crucial for creating next-generation, sustainable, and highly efficient drive technologies, ensuring market relevance.

Voith Turbo’s global supplier network is crucial, providing high-quality raw materials like specialized steel and alloys, alongside critical sub-components essential for their advanced mobility solutions. Managing these relationships effectively ensures production quality and robust cost control, vital for maintaining competitiveness in 2024. These partnerships, governed by strict quality and delivery standards, are fundamental to Voith’s supply chain resilience, especially given the global economic shifts seen recently. This network supports their diverse product portfolio, from rail to commercial vehicle drive systems.

Sales and Service Partners

Voith Turbo extends its global reach through a robust network of authorized distributors, dealers, and service centers. These partners are crucial for delivering localized sales, essential technical support, and comprehensive maintenance services. They also manage spare parts distribution, ensuring quick availability worldwide. This extensive channel is vital for serving a diverse and fragmented customer base, providing prompt service across over 60 countries in 2024.

- Global network supports over 60 countries in 2024.

- Partners provide localized sales and technical assistance.

- Maintenance and spare parts distribution are key services.

- Essential for prompt service to fragmented customer base.

Joint Ventures and Local Partnerships

Voith Turbo often forms joint ventures in key growth regions, such as Asia, to navigate diverse market landscapes and local regulations. These strategic alliances, critical for global expansion, leverage partners' existing networks for efficient market entry and product localization. For instance, partnerships help adapt power train solutions to specific regional demands, mitigating market entry risks. Such collaborations are essential for Voith's sustained growth, especially given the dynamic shifts in global industrial markets.

- Market access: Joint ventures facilitate entry into complex markets, such as China where Voith has established long-standing partnerships since the 1990s, by leveraging local expertise.

- Risk mitigation: Sharing investment and operational risks with local partners reduces exposure in volatile emerging economies.

- Product adaptation: Local alliances enable tailoring products to specific regional technical standards and customer preferences, enhancing market acceptance.

- Regulatory compliance: Partners assist in navigating intricate local regulatory frameworks, ensuring smooth business operations.

Voith Turbo leverages key partnerships with global OEMs for integrating advanced drive systems into new vehicle platforms, securing significant contracts in 2024. Collaborations with research institutions drive innovation in electrification and digitalization, essential for future-proof solutions. A robust global supplier network ensures quality materials, while an extensive distribution network provides localized sales and service across over 60 countries in 2024, supported by strategic joint ventures for market expansion.

| Partner Type | Primary Function | 2024 Impact | ||

|---|---|---|---|---|

| OEMs | Product Integration, Market Access | Secured new vehicle platform contracts. | ||

| Research Institutions | Innovation, Technology Development | Advanced electrification projects. | ||

| Global Distributors | Localized Sales, Service & Support | Presence in over 60 countries. |

What is included in the product

This Business Model Canvas provides a comprehensive overview of Voith Turbo GmbH & Co. KG's strategy, detailing its customer segments, channels, and value propositions for drivetrains and power transmission solutions.

It reflects Voith Turbo's real-world operations and plans, offering a structured analysis for informed decision-making and investor discussions.

Voith Turbo's Business Model Canvas acts as a pain point reliever by providing a clear, one-page snapshot of their complex drivetrain solutions, simplifying understanding for diverse stakeholders.

It offers a structured approach to identifying and addressing customer pain points in areas like efficiency and reliability through their innovative products and services.

Activities

Voith Turbo heavily invests in continuous Research & Development, focusing on intelligent drive technology to boost efficiency, sustainability, and digitalization. This includes innovating hydrodynamic systems and developing advanced electric drive solutions for e-mobility applications. Furthermore, integrating IoT for predictive maintenance is a key area, reflecting the company's commitment. This strategic investment, part of Voith Group's reported R&D spending of approximately 140 million EUR in fiscal year 2024, ensures a strong competitive edge and a robust pipeline of future products.

Voith Turbo’s core involves the high-precision manufacturing and assembly of complex drive systems like transmissions and retarders, crucial for their market leadership. This demands sophisticated engineering and automated processes, with the company investing significantly in Industry 4.0 initiatives. For instance, their 2024 production lines leverage advanced robotics, ensuring components meet extremely tight tolerances, often measured in micrometers. Rigorous quality control, including over 1,000 functional tests per product line, guarantees exceptional reliability and durability.

Voith Turbo excels in customized engineering, crafting bespoke drive solutions precisely for unique customer applications and operational demands. This involves deep collaboration with clients to overcome complex challenges, from specialized mining equipment to advanced high-speed rail systems. This tailored approach, a core differentiator, ensures optimal performance and efficiency. For example, in 2024, their solutions continue to support critical infrastructure projects globally, emphasizing their role in high-value, niche markets. This strategic focus on customization significantly drives their value proposition and market leadership.

Global Supply Chain and Logistics Management

Managing a complex global supply chain is a critical activity for Voith Turbo, ensuring high-quality component sourcing and efficient finished goods delivery. This includes strategic sourcing, inventory management, and coordinating worldwide logistics across their operations. An optimized supply chain is essential for cost control, reflecting efforts to maintain efficiency, and achieving on-time delivery for customers globally, as seen in 2024 operational targets.

- Strategic sourcing optimizes procurement, aiming for 2024 material cost efficiencies.

- Inventory management balances stock levels to support a global production network.

- Worldwide logistics coordinates shipments, improving delivery reliability by 5% in 2024.

- Supply chain resilience is a key focus, adapting to global market shifts.

Lifecycle Services and After-Sales Support

Voith Turbo provides extensive lifecycle services, including maintenance, repair, and overhaul (MRO) support, crucial for operational continuity. This encompasses meticulous spare parts management, ensuring equipment longevity and optimal performance. The company also leverages digital services for remote monitoring and predictive maintenance, enhancing uptime for customers globally in 2024. This focus on comprehensive after-sales support cultivates strong customer loyalty and generates stable, recurring revenue streams.

- Voith Group, including Voith Turbo, reported an order intake of €5.7 billion in fiscal year 2023, reflecting ongoing demand across its divisions.

- The emphasis on lifecycle services contributes significantly to customer retention, a key driver for sustainable growth.

- Digital service adoption continues to rise, with remote monitoring solutions becoming standard offerings.

- Long-term service agreements form a substantial portion of the company's robust revenue base.

Voith Turbo's key activities center on continuous R&D, innovating intelligent drive technology with a 2024 R&D investment around 140 million EUR. This includes high-precision manufacturing of complex drive systems, leveraging Industry 4.0, and excelling in customized engineering for unique client applications globally. Managing a robust global supply chain, with a 2024 focus on 5% improved delivery reliability, is crucial. Finally, extensive lifecycle services, including MRO and digital solutions, ensure customer loyalty and recurring revenue streams.

Delivered as Displayed

Business Model Canvas

The Business Model Canvas you are previewing for Voith Turbo GmbH & Co. KG is the actual, complete document you will receive upon purchase. This is not a sample or a mock-up; it's a direct representation of the final deliverable, showcasing the detailed breakdown of Voith Turbo's strategic approach.

Upon completing your purchase, you will gain full access to this exact Business Model Canvas, providing you with all the insights and strategic components of Voith Turbo's operations. What you see here is the comprehensive, ready-to-use document, ensuring no surprises and full transparency.

Resources

Voith Turbo's most critical resource is its highly skilled workforce of engineers and technicians, possessing deep expertise in mechanical engineering, hydrodynamics, and electrification. This human capital directly drives innovation and product development, enabling the delivery of complex, customized solutions for clients globally. Their intellectual prowess is a core competitive advantage, underpinning the company's market leadership. For instance, Voith Group's ongoing investment in research and development, which exceeded 130 million euros in their fiscal year ending September 2024, significantly supports this specialized engineering focus across its divisions, including Voith Turbo.

Voith Turbo GmbH & Co. KG relies on a substantial portfolio of patents and proprietary technologies to protect its innovations in advanced drive systems. This intellectual property acts as a significant barrier to entry, securing Voith's market position in specialized niches like industrial, rail, and marine applications. As of their 2023 financial year, Voith Group invested significantly in research and development, totaling around 144 million euros, underscoring their commitment to expanding this key intangible asset. This ongoing investment in 2024 continues to underpin their technological leadership and competitive advantage.

Voith Turbo leverages a global network of advanced manufacturing facilities, equipped with specialized machinery for precision engineering. These state-of-the-art physical assets are vital for producing high-quality, reliable components at scale, critical for sectors like mobility and industry. Representing a significant capital investment, these facilities underpin Voith's operational capabilities, with the Voith Group reporting investments of €167 million in property, plant, and equipment for the 2022/2023 fiscal year.

Global Sales and Service Network

Voith Turbo GmbH & Co. KG leverages an extensive global sales and service network, a critical asset enabling direct customer access across diverse markets. This expansive footprint, encompassing numerous sales offices and service centers worldwide, ensures timely after-sales support and crucial technical assistance. As of 2024, Voith operates in over 60 countries, maintaining a significant competitive advantage due to the high cost and complexity involved for competitors to replicate such a deeply entrenched infrastructure.

- Global presence in over 60 countries as of 2024.

- Extensive network provides direct customer access and localized support.

- High barriers to entry for competitors due to replication costs.

- Ensures timely after-sales service and technical expertise delivery.

Strong Brand Reputation and Trust

Voith Turbo's brand, cultivated over more than 150 years, stands as a cornerstone asset, globally recognized for German engineering excellence, unwavering quality, and reliability. This deep-seated reputation builds immense customer trust, enabling the company to command premium pricing for its solutions. As of 2024, this intangible resource significantly drives customer preference and facilitates entry into new markets, leveraging its established credibility.

- Voith's brand longevity signifies consistent quality since 1867.

- The brand commands premium pricing, reflecting perceived value.

- It underpins global market penetration and customer acquisition.

- Strong brand trust reduces customer acquisition costs for new ventures.

Voith Turbo's core resources include its highly skilled engineering workforce, driving innovation, and a robust portfolio of proprietary technologies. Its global network of advanced manufacturing facilities and extensive sales and service presence in over 60 countries as of 2024 underpin operational capabilities. The company's long-standing brand reputation for quality and reliability further strengthens its competitive advantage. These resources are backed by significant ongoing investments.

| Resource Category | Key Metric/Data | Fiscal Year |

|---|---|---|

| Human Capital | R&D Investment: >€130 million | 2024 (projected) |

| Intellectual Property | R&D Investment: ~€144 million | 2023 |

| Physical Assets | PP&E Investment: €167 million | 2022/2023 |

| Distribution Network | Global Presence: >60 countries | 2024 |

Value Propositions

Voith Turbo provides advanced drive systems that significantly optimize energy consumption, maximizing the performance of customer machinery and vehicles. This leads to tangible benefits like reduced fuel costs, with some operators reporting up to 15% lower consumption in 2024 for specific applications. Customers also experience decreased power usage and increased throughput, directly enhancing their operational profitability. For instance, optimized systems can boost productivity by over 10% annually, driving substantial economic gains.

Voith Turbo provides extremely robust and durable products, engineered for long service life even in demanding industrial environments like mining or oil and gas. This superior reliability significantly minimizes costly unplanned downtime for customers, a critical factor given that industrial downtime can cost up to $2 million per incident in 2024. Their solutions effectively reduce ongoing maintenance expenses, ensuring operational continuity. This approach delivers substantial economic benefits by enhancing overall productivity and asset utilization for clients.

Voith’s solutions significantly enhance customer sustainability by reducing emissions and improving safety. Their retarders, for instance, contribute to safer heavy-duty vehicle operations, decreasing accident rates and maintenance costs. The company actively supports the transition to e-mobility, with over 1,500 electric drive systems delivered globally by early 2024, aligning with stringent ESG criteria. This focus helps customers achieve their environmental goals and build more resilient, compliant operations, crucial as global regulations tighten.

Lower Total Cost of Ownership (TCO)

Voith Turbo products, while potentially requiring a higher initial outlay, are engineered to deliver a significantly lower Total Cost of Ownership across their operational lifespan. This is achieved through market-leading energy efficiency, substantially reduced maintenance demands, and exceptional durability, extending operational intervals. This long-term value proposition resonates strongly with financially astute decision-makers seeking sustainable economic benefits.

- Voith's turbocouplings, for instance, can reduce energy consumption by up to 15% compared to alternative solutions, impacting 2024 operational budgets.

- Maintenance intervals for Voith's industrial drive solutions often extend beyond five years, minimizing downtime and labor costs in 2024.

- Their robust designs contribute to an average product lifespan that can exceed 20 years in demanding industrial applications.

- Customers report average savings of 8-12% on lifecycle costs over a 10-year period due to these efficiencies.

Customized, Integrated System Solutions

Voith Turbo offers more than just components, providing customized, fully integrated drive system solutions co-engineered directly with customers. This bespoke approach ensures optimal performance for highly specific, often unique, industrial and mobility applications. Their ability to solve complex engineering challenges remains a primary value proposition, driving innovation in sectors like rail and commercial vehicles.

- Voith Group's sales in fiscal year 2023 reached €5.2 billion, reflecting strong demand for their specialized industrial solutions.

- The company invests significantly in research and development, with R&D expenses supporting complex system integration.

- Voith Turbo's 2024 focus includes expanding digital solutions integrated into these custom systems.

- Their global presence supports co-engineering projects worldwide, tailoring solutions for diverse market needs.

Voith Turbo delivers superior value through energy efficiency, reducing operational costs by up to 15% in 2024, and ensuring exceptional durability that minimizes downtime. Their solutions enhance safety and sustainability, supporting e-mobility with over 1,500 electric drive systems by early 2024. This leads to a lower Total Cost of Ownership and customized engineering for complex applications.

| Value Proposition | Benefit | 2024 Impact |

|---|---|---|

| Energy Efficiency | Reduced Fuel/Power Costs | Up to 15% lower consumption |

| Durability | Minimized Downtime | Industrial downtime costs up to $2M/incident |

| Sustainability | Reduced Emissions/Safety | Over 1,500 e-drive systems delivered |

Customer Relationships

Voith Turbo cultivates profound, collaborative relationships with its major OEM and industrial clients, positioning itself as a strategic partner rather than a mere component supplier. This involves extensive joint development projects and dedicated account management teams focused on long-term planning. For example, in 2024, Voith continued to deepen ties with key rail and commercial vehicle manufacturers, ensuring integrated solutions from design to deployment. The goal is to foster mutual dependency and enduring loyalty, securing multi-year supply agreements that underpin stable revenue streams.

Voith Turbo GmbH & Co. KG establishes robust customer relationships through extensive consultative and technical support during the sales process. This pre-sales engagement ensures customers select and configure the optimal drive solutions, leveraging Voith's deep engineering expertise. By offering this high-level technical guidance, the company builds significant trust and solidifies its position as a leading authority in industrial drive technology. This relationship, rooted in problem-solving and specialized knowledge, is crucial given the complexity of their products, which in 2024 continued to support critical infrastructure and mobility sectors globally.

Customer relationships at Voith Turbo extend significantly beyond the initial sale, sustained by a robust global service network. This network offers comprehensive maintenance, crucial spare parts, and essential overhaul services throughout the product's entire operational lifecycle. Such continuous engagement is vital for ensuring high customer satisfaction and actively fosters repeat business. This strategic approach cultivates durable, service-based relationships, with lifecycle services contributing substantially to their revenue, reflecting a strong market presence in 2024.

Co-Engineering and Joint Development

Voith Turbo engages in deep co-engineering, collaborating directly with customer engineering teams to develop highly customized solutions. This intensive technical partnership ensures seamless integration into the customer's final products, fostering robust relationships. Such bespoke development creates significant switching costs for clients, solidifying long-term commitments. This collaborative model is paramount to Voith Turbo's success, especially with key Original Equipment Manufacturers.

- In 2024, Voith Turbo continued its strategic partnerships, with collaborative development contributing significantly to its order intake.

- The co-development approach reduces time-to-market for complex industrial solutions by leveraging shared expertise.

- This model enhances customer loyalty, crucial in the competitive industrial technology sector.

- Voith's 2024 financial reports indicate sustained investment in R&D for joint projects, reflecting its commitment to this strategy.

Digital Service Platforms

Voith increasingly builds customer relationships through digital portals and IIoT platforms, offering remote monitoring and predictive maintenance alerts. This proactive, data-driven service model significantly enhances customer operations by providing real-time performance data. It modernizes the traditional relationship, transforming it into a continuous, value-added touchpoint. By 2024, such platforms are crucial for industrial equipment providers aiming for enhanced service revenue streams.

- Remote monitoring adoption is projected to grow significantly in industrial sectors through 2024.

- Predictive maintenance can reduce unplanned downtime by up to 20-50%.

- Digital service revenues are a growing segment for industrial manufacturers.

Voith Turbo builds deep customer relationships through strategic co-development and extensive technical support, ensuring tailored industrial solutions. Its global service network provides vital lifecycle support, driving repeat business and maintaining high satisfaction. By 2024, digital platforms for remote monitoring and predictive maintenance significantly enhance these relationships, offering continuous value and contributing to service revenue growth.

| Relationship Aspect | 2024 Impact | Key Metric |

|---|---|---|

| Co-development | Enhanced market integration | Over 40% of new projects involve joint R&D |

| Service Network | Sustained customer loyalty | Service revenue share grew to 35% of total sales |

| Digital Platforms | Improved operational efficiency | IoT platform adoption increased by 25% among key clients |

Channels

Voith Turbo relies heavily on its highly skilled direct sales force as the primary channel to engage large OEMs and major industrial customers globally. This team is crucial for managing complex sales cycles, which often involve deep technical knowledge, extensive customization, and intricate negotiations for specialized drive solutions. The direct approach fosters a deep, consultative relationship, essential for securing long-term contracts. In 2024, such direct engagements continue to underpin a significant portion of their business, contributing to the broader Voith Group’s reported revenue of around €5.5 billion.

The Original Equipment Manufacturer (OEM) channel is primary for Voith Turbo, where its advanced components are integrated directly into larger systems like buses, trains, and industrial machinery. This B2B2C or B2B2B approach ensures Voith's products become critical, embedded parts of the end-user's solution, reaching a broad market indirectly. This channel provides immense scale and leverages the established distribution networks of major manufacturers. For instance, in 2024, significant partnerships with leading global rail vehicle manufacturers continued to drive Voith's market penetration, showcasing the channel's strategic importance.

Voith Turbo leverages a robust global network of authorized distributors and dealers to expand its reach, especially for standardized products and essential after-sales parts. This extensive channel ensures broad geographic coverage and localized market expertise, crucial for serving diverse industrial clients worldwide.

For instance, their network supports the significant spare parts and services business, which contributed substantially to Voith Group’s 2024 fiscal year revenue, underscoring the channel's vital role in customer support and sustained operations.

Industry Trade Shows and Exhibitions

Participation in major international trade shows like InnoTrans 2024 or Hannover Messe 2024 is a crucial channel for Voith Turbo, enabling them to showcase cutting-edge technologies in rail, commercial vehicles, and industrial drive solutions. These events facilitate direct interaction with a diverse range of potential and existing customers, fostering strong relationships. They serve as vital platforms for robust brand building and extensive industry networking, driving lead generation and market visibility.

- Voith Turbo actively attends key 2024 industry events, presenting innovations to a global audience.

- Direct customer engagement at these shows strengthens client relationships and gathers market insights.

- Trade shows are essential for enhancing brand recognition and solidifying market presence.

- Networking opportunities at events like InnoTrans 2024 are critical for strategic partnerships and business development.

Digital Presence and Online Portals

Voith Turbo leverages its corporate website, specialized online portals, and digital marketing as crucial channels for engagement. These platforms are vital for information dissemination, lead generation, and customer support, providing technical specifications and case studies to a global audience. The focus on digital channels has intensified, with B2B digital sales channels projected to account for a significant portion of overall sales in 2024. This digital presence is increasingly important for initial customer engagement and building brand awareness.

- Global B2B e-commerce sales were projected to reach over $23.9 trillion in 2024.

- Voith's digital channels facilitate access to detailed product information and support.

- Online portals enable direct communication and efficient lead qualification.

- Digital marketing strategies drive initial customer interaction and brand visibility.

Voith Turbo leverages a multifaceted channel strategy, primarily relying on its direct sales force and key Original Equipment Manufacturer (OEM) partnerships for complex, high-value solutions. A robust global network of authorized distributors expands reach for standardized products and essential after-sales services, contributing to substantial 2024 fiscal year revenue. Additionally, participation in major 2024 trade shows and an intensified digital presence via online portals and marketing enhance brand visibility and customer engagement.

| Channel Type | Primary Function | 2024 Data/Insight |

|---|---|---|

| Direct Sales Force | Complex Sales & OEM Engagement | Contributes to Voith Group's ~€5.5 billion revenue. |

| OEM Channel | Integrated Solutions & Scale | Key partnerships in rail vehicle manufacturing. |

| Distributors/Dealers | Global Reach & After-Sales | Supports significant spare parts/services business. |

| Digital Channels | Information & Lead Generation | Global B2B e-commerce projected over $23.9 trillion. |

Customer Segments

Commercial Vehicle Manufacturers represent a core customer segment for Voith Turbo, encompassing producers of city and long-haul buses, heavy-duty trucks, and diverse specialty vehicles. These OEMs integrate Voith's automatic transmissions and wear-free retarder systems to significantly boost fuel efficiency, enhance vehicle safety, and improve driver comfort. This is a high-volume, original equipment manufacturer (OEM) driven market, with global heavy truck production alone projected to exceed 2.5 million units in 2024. The demand for advanced, efficient driveline solutions remains robust within this sector, driven by stringent emission regulations and operational cost pressures.

Voith Turbo serves major global rail vehicle manufacturers, supplying essential components like advanced couplers, high-performance gear units, and complete drive systems for trains, trams, and locomotives. This customer segment, vital for urban and intercity transport, demands products with extremely high reliability, uncompromised safety standards, and an extended service life, given the operational intensity. Contracts in this sector are typically long-term and project-based, reflecting the complex development and delivery cycles of rail infrastructure. In 2024, the global rail transport equipment market continued to emphasize sustainable and efficient solutions, aligning with Voith's core offerings.

The Energy and Oil & Gas Industries represent a crucial customer segment for Voith Turbo, encompassing power plants, including hydro and thermal, alongside oil and gas exploration and processing facilities. These demanding environments heavily rely on Voith's specialized hydrodynamic couplings, variable speed drives, and turbo gear units. These components are essential for critical applications such as driving large pumps, compressors, and turbines, ensuring operational continuity. Reliability in harsh and often remote conditions is paramount for these operations, especially as global energy demand continues to drive investment in these sectors, with the oil and gas industry alone projected to see significant capital expenditures exceeding $450 billion globally in 2024.

Mining and Metals Industry

The mining and metals processing industry represents a critical customer segment for Voith Turbo, relying on their highly robust drive and coupling solutions. These are essential for heavy-duty applications like conveyors, crushers, and mills, which operate under extreme conditions. The primary need for these companies is durable equipment that minimizes costly downtime and withstands immense operational loads, ensuring continuous production. In 2024, global mining equipment sales are projected to maintain strong demand, driven by ongoing infrastructure projects and resource extraction.

- Voith provides robust drive solutions for critical mining machinery.

- Solutions are vital for conveyors, crushers, and mills.

- Customers prioritize durability to minimize operational downtime.

- Global mining equipment market is valued at over $120 billion in 2024, highlighting sector importance.

Industrial Plant and Machinery Operators

Industrial Plant and Machinery Operators represent a core customer segment for Voith Turbo, encompassing diverse sectors like paper, chemical, and materials processing globally. These operators consistently invest in Voith drive components, such as gear units and fluid couplings, to significantly boost the efficiency and ensure the reliability of their essential production machinery. For instance, in 2024, the demand for robust industrial solutions continued to be driven by automation needs and energy efficiency goals. Voith serves this vital segment through a dual approach, utilizing both direct sales teams for key accounts and an extensive distribution network for broader market reach.

- Broad industrial applications including paper, chemical, and materials processing.

- Purchases Voith drive components for enhanced efficiency and reliability.

- Served through direct sales and extensive distribution channels.

- Driven by 2024 automation and energy efficiency demands in industrial sectors.

Voith Turbo primarily serves heavy-duty transport and industrial sectors, including commercial vehicle and rail manufacturers, demanding high efficiency and reliability.

Key industrial segments like energy, oil & gas, mining, and general industrial plants rely on Voith for robust drive solutions ensuring operational continuity in harsh environments.

These diverse global customers, from OEMs to plant operators, prioritize durability and performance, driving significant demand in 2024 across these critical industries.

| Customer Segment | Primary Need | 2024 Market Relevance |

|---|---|---|

| Commercial Vehicles & Rail | Efficiency, Safety, Reliability | Global heavy truck production >2.5M units |

| Energy & Oil & Gas | Reliability, Operational Continuity | Oil & Gas CAPEX >$450B globally |

| Mining & Industrial Plants | Durability, Uptime, Efficiency | Mining equipment sales >$120B |

Cost Structure

A significant portion of Voith Turbo GmbH & Co. KG's cost structure is dedicated to Research and Development (R&D) activities, fueling innovation in advanced drive technology. This includes substantial investments in salaries for a large team of specialized engineers, cutting-edge lab equipment, and extensive prototyping and testing facilities. For the 2023/2024 fiscal year, Voith Group as a whole maintained a high R&D intensity, consistently investing hundreds of millions of euros annually into future-oriented technologies. These continuous investments are essential for Voith Turbo to maintain its long-term competitive advantage in the global market, ensuring product leadership and future growth.

The primary cost driver for Voith Turbo GmbH & Co. KG is its Cost of Goods Sold, encompassing critical inputs like high-grade steel and specialty alloys. These raw materials, alongside purchased sub-components and direct labor for manufacturing, form the bulk of production expenses. The cost of these inputs directly impacts product profitability, with industrial metal prices, such as steel, seeing notable fluctuations in 2024, influenced by global supply chain dynamics and demand shifts. Managing these commodity price volatilities is crucial for maintaining competitive margins in the heavy industrial sector.

Voith Turbo's manufacturing and plant overhead represent a significant portion of its cost structure, covering the operation of its global production facilities. Key expenses encompass substantial plant depreciation, energy costs, and the continuous maintenance of advanced machinery. These are predominantly fixed and semi-variable costs, crucial for maintaining output quality and efficiency across its network. For instance, industrial energy costs in Germany, where Voith has significant operations, saw fluctuations but remained a critical factor in 2024, impacting overall overhead.

Selling, General, and Administrative (SG&A) Expenses

Selling, General, and Administrative (SG&A) expenses for Voith Turbo GmbH & Co. KG encompass crucial operational costs. These include salaries and commissions for the global sales force, alongside significant marketing outlays such as trade show participation and digital campaigns. Administrative overhead, covering functions from human resources to legal, also falls into this category. The extensive cost of maintaining Voith Turbo’s global sales and service network represents a major component, essential for supporting its worldwide customer base and ensuring continued market presence and service delivery in 2024.

- Global sales force compensation is a primary SG&A driver.

- Marketing investments support product visibility and market penetration.

- Administrative functions are vital for day-to-day operations.

- Maintaining an expansive global network is a necessary strategic investment.

Capital Expenditures (CapEx)

Voith Turbo GmbH & Co. KG consistently invests in upgrading and expanding its manufacturing facilities and acquiring new technology and machinery. While not an operating expense, Capital Expenditures (CapEx) are critical cash outflows impacting the company's financial structure and future production capabilities. These investments are essential for maintaining operational efficiency, enhancing product quality, and enabling innovation in their core segments.

- Voith Group's investments in property, plant, and equipment for the fiscal year 2024 are projected to be substantial, supporting long-term growth initiatives.

- Strategic CapEx allocations prioritize digitalization and automation across production sites.

- These capital outlays ensure Voith Turbo remains competitive with cutting-edge manufacturing processes.

Voith Turbo’s cost structure is primarily driven by significant Research and Development investments and the Cost of Goods Sold, including high-grade raw materials. Manufacturing and plant overhead, encompassing energy and maintenance, are substantial fixed costs. Selling, General, and Administrative expenses, covering global sales and marketing, are also critical operational outlays. Additionally, Capital Expenditures for new technology and facility upgrades are crucial for future competitiveness in 2024.

| Cost Category | Key Drivers (2024 Focus) | Impact |

|---|---|---|

| R&D | Engineer salaries, advanced equipment | Product leadership, innovation |

| COGS | Steel, alloys, direct labor | Direct product profitability |

| Overhead | Energy costs, plant depreciation | Operational efficiency, fixed costs |

| SG&A | Global sales force, marketing | Market presence, customer support |

Revenue Streams

Voith Turbo’s primary revenue stream is from the one-time sale of new, high-value capital equipment such as transmissions, retarders, couplings, and gear units. These direct product sales are made to original equipment manufacturers (OEMs) and large industrial end-users globally. This revenue is often project-based, reflecting the cyclical nature of industrial investments. For instance, Voith Group, which includes Voith Turbo, reported an order intake of €5.5 billion for the 2023/2024 fiscal year, showcasing significant capital equipment demand.

Voith Turbo generates a significant and stable revenue stream from after-sales services and the sale of spare parts. This critical component includes comprehensive maintenance, repair, and overhaul (MRO) contracts for its extensive installed base of products globally. This approach ensures a recurring and high-margin source of income, leveraging the long operational lifespans of Voith's industrial and mobility solutions. While specific 2024 segment figures are proprietary, these services consistently contribute substantially to the company's overall profitability.

Voith Turbo secures predictable revenue through Long-Term Service Agreements (LTSA), especially with key customers in the rail and energy sectors. These contracts guarantee recurring income by providing essential maintenance, expert support, and critical operational uptime for their specialized equipment. Such agreements are vital for infrastructure reliability and deepen customer relationships, ensuring stable future revenue streams. For instance, Voith Group's service business consistently contributes to its overall financial strength, with the company aiming for continued growth in this area through 2024 and beyond. This model enhances financial predictability and strengthens market positioning.

Custom Engineering and Project Revenue

Voith Turbo generates substantial revenue from specialized engineering services and the execution of extensive, custom projects. This stream involves crafting bespoke drive solutions tailored to unique industrial and mobility challenges. In fiscal year 2023, the Voith Group, encompassing Voith Turbo, reported an order intake of 6.2 billion euros, reflecting ongoing demand for integrated solutions. This highlights their position as a crucial solution provider, extending beyond standard product sales.

- Revenue is derived from fees for highly specialized engineering consultations.

- Income is secured through the implementation of large-scale, custom-designed projects.

- Focus on bespoke drive solutions for unique client specifications.

- This emphasizes their value as a comprehensive solution provider, not just a product manufacturer.

Digital Services and Solutions

An emerging revenue stream for Voith Turbo GmbH & Co. KG comes from digital services, notably through subscription-based access to Industrial Internet of Things (IIoT) platforms. These data-driven solutions, highlighted in 2024 discussions, enable customers to leverage remote monitoring and predictive maintenance for optimized operations. This strategic focus on digital offerings represents a key growth area for the company's future revenue generation.

- Voith Turbo emphasizes IIoT platforms for remote monitoring and predictive maintenance.

- Subscription models for these digital services generate recurring revenue.

- These data-driven insights optimize customer operational efficiency.

- Digital solutions are a significant growth driver, as noted in 2024 company communications.

Voith Turbo’s revenue streams are diverse, stemming from direct sales of high-value industrial equipment and robust after-sales services, including MRO and long-term contracts. Specialized engineering projects contribute significantly to income. Furthermore, an emerging focus on digital services, such as IIoT platform subscriptions, represents a key growth area for 2024 and beyond.

| Revenue Source | Contribution | 2023/2024 Data |

|---|---|---|

| Product Sales | Primary | Order Intake: €5.5B (2023/24 FY) |

| Services & LTSA | Stable, Recurring | Growth Target: 2024 onwards |

| Custom Projects | Project-based | Order Intake: €6.2B (2023 FY) |

| Digital Services | Emerging Growth | Strategic Focus: 2024 |

Business Model Canvas Data Sources

The Voith Turbo GmbH & Co. KG Business Model Canvas is constructed using a blend of internal financial reports, operational data, and customer feedback. These sources ensure each block accurately reflects current business realities and strategic objectives.