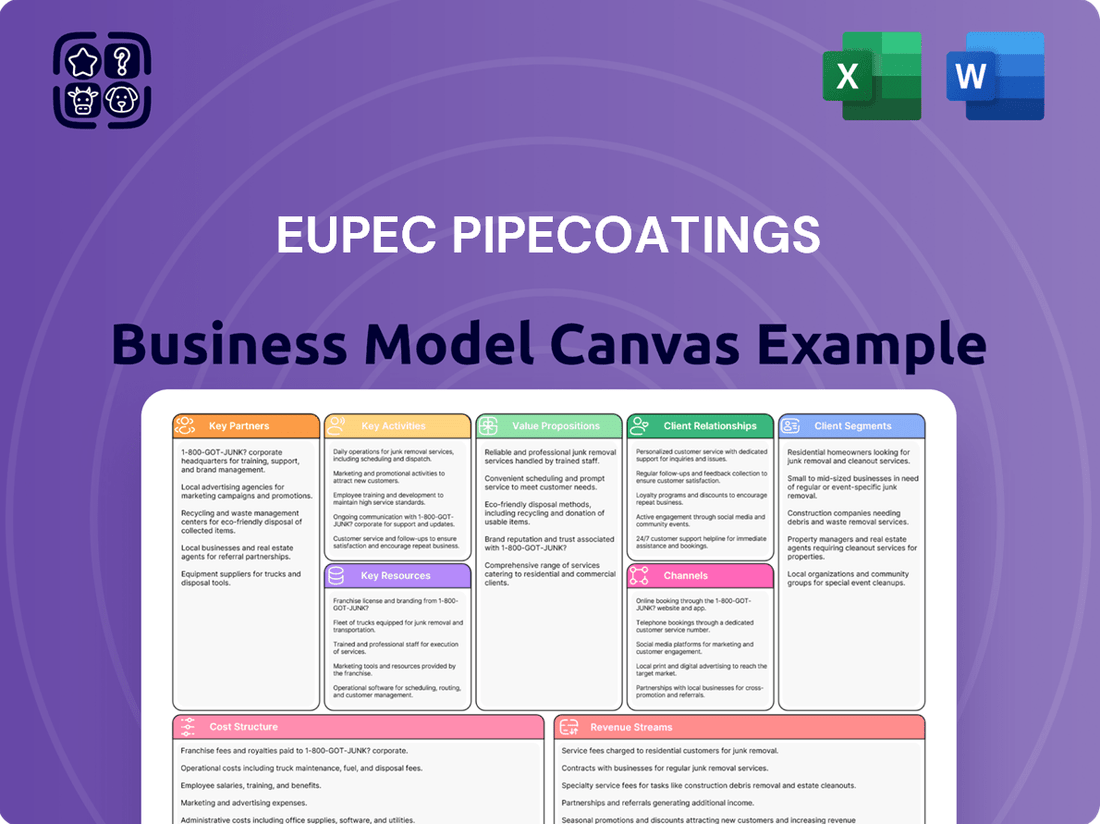

Eupec PipeCoatings Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Eupec PipeCoatings Bundle

Discover the strategic core of Eupec PipeCoatings with their comprehensive Business Model Canvas. This document details how they serve their key customer segments and deliver their unique value propositions. It outlines their vital partnerships and the crucial activities that drive their operations.

Understand Eupec PipeCoatings's revenue streams and their efficient cost structure. This canvas reveals their competitive advantages and how they maintain market leadership in the pipe coatings industry. Gain actionable insights for your own business strategy.

Unlock the full strategic blueprint behind Eupec PipeCoatings's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

Eupec PipeCoatings maintains crucial relationships with top-tier chemical and material providers, securing essential components like epoxies, polypropylenes, and concrete for its coating processes. These collaborations are fundamental to guaranteeing a steady influx of high-quality materials, vital for maintaining stringent quality standards across all coating applications.

These strategic alliances enable Eupec to not only ensure consistent supply but also to stay at the forefront of material science advancements, incorporating the latest innovations into their product offerings. For instance, in 2024, Eupec reported that over 85% of its coating material procurement came from these key partners, highlighting the dependency on reliable suppliers for operational continuity.

Furthermore, by establishing long-term supply agreements, Eupec benefits from predictable pricing structures and enhanced supply chain resilience, particularly critical for large-scale infrastructure projects that demand uninterrupted material flow. This strategic approach to supplier partnerships directly contributes to Eupec's ability to deliver projects on time and within budget, reinforcing its market position.

Eupec PipeCoatings relies heavily on partnerships with technology and equipment providers. These collaborations are essential for accessing and implementing the latest advancements in coating application machinery and quality control systems. For instance, in 2024, Eupec continued its strategic alliances with leading manufacturers of automated spray coating equipment, which significantly improved application uniformity and reduced material waste by an estimated 5% compared to previous years.

These partnerships ensure Eupec operates with cutting-edge technology, boosting operational efficiency and maintaining stringent adherence to industry standards like ISO 21809. The ability to leverage advanced equipment directly translates to enhanced throughput and superior coating quality, critical factors in meeting the escalating global demand for robust pipeline protection solutions, especially as new energy infrastructure projects gain momentum in 2024.

Eupec PipeCoatings relies heavily on specialized logistics and transportation companies to move its large-volume, heavy products. These partnerships are critical for getting raw materials to coating facilities and then delivering the finished, coated pipes to often remote construction sites worldwide.

In 2024, the global logistics market saw continued pressure on capacity and pricing, making strong relationships with carriers paramount. Companies like Eupec need partners capable of handling oversized loads via sea, rail, and specialized road transport, ensuring compliance with international shipping regulations and local delivery demands.

The efficiency of these logistics partners directly impacts project timelines and overall costs for major infrastructure developments. For instance, delays in transporting coated pipes to a pipeline project in a developing nation can add millions to the final cost, highlighting the financial impact of reliable transportation. Eupec's ability to secure dedicated shipping routes and specialized transport equipment through its partners is a key competitive advantage.

Engineering and Consulting Firms

Eupec PipeCoatings strategically partners with engineering and consulting firms, a crucial element for staying ahead in the pipeline industry. These collaborations are vital for understanding upcoming project needs and the precise technical details required for coating applications. For instance, in 2024, many major infrastructure projects, such as those in the renewable energy sector and gas transmission, demanded highly specialized anti-corrosion coatings, information readily shared by these consulting partners.

By engaging with these firms, Eupec gains the advantage of early involvement in project planning. This allows Eupec to proactively develop and propose customized coating solutions, thereby offering significant value-added technical expertise. This early insight was particularly beneficial in 2024 as companies sought coatings that not only protected against corrosion but also enhanced flow efficiency, a requirement that Eupec could address through tailored R&D informed by its partners.

These partnerships also play a significant role in Eupec’s ability to navigate the intricate and often changing regulatory environments. Consulting firms, with their deep understanding of international standards and local compliance, help Eupec ensure its coating products and application processes meet all necessary requirements. This was evident in 2024 with evolving environmental regulations impacting material choices and application methods in several key markets.

- Early Project Insight: Access to future project pipelines and technical specifications from engineering consultants, enabling proactive solution development.

- Tailored Coating Solutions: Opportunity to customize coating formulations and application techniques based on specific project demands identified by partners.

- Regulatory Navigation Expertise: Leveraging consulting firms' knowledge to ensure compliance with evolving industry standards and environmental regulations in 2024.

- Value-Added Technical Support: Offering specialized expertise and R&D support to clients through collaborative project planning with engineering partners.

Research and Development Institutions

Eupec PipeCoatings actively collaborates with research and development institutions to drive innovation in coating technologies. These partnerships are crucial for exploring advanced materials and refining application methods, particularly for next-generation infrastructure like hydrogen pipelines. For instance, Eupec might partner with a university's materials science department to investigate novel polymer composites offering enhanced corrosion resistance for hydrogen transport.

These collaborations enable Eupec to push the boundaries of coating performance, ensuring durability and safety in challenging environments. By tapping into the expertise of academic and specialized R&D centers, the company can develop coatings that withstand extreme temperatures and pressures. This focus on cutting-edge solutions is essential for maintaining a competitive edge in a rapidly evolving market.

Furthermore, these R&D partnerships are instrumental in developing more sustainable and environmentally friendly coating solutions. Eupec can work with institutions to identify bio-based materials or processes that reduce the environmental footprint of its operations and products. This aligns with global trends towards greener industrial practices and supports Eupec’s commitment to sustainability.

- Innovation Hubs: Partnering with institutions like Fraunhofer-Gesellschaft or national laboratories provides access to specialized testing facilities and cutting-edge research.

- Material Science Advancement: Collaborations focus on developing coatings with superior adhesion, chemical resistance, and thermal stability, crucial for new energy sectors.

- Process Optimization: R&D efforts aim to enhance application efficiency and reduce waste in coating processes, potentially lowering operational costs.

- Future-Proofing: Staying ahead in material science and application techniques is vital; for example, research into low-friction coatings for CO2 pipelines is ongoing.

Eupec PipeCoatings' key partnerships extend to major chemical and material suppliers, ensuring a consistent flow of high-quality epoxies, polypropylenes, and concrete. These relationships are vital for maintaining stringent quality standards and operational continuity; in 2024, over 85% of Eupec's material procurement originated from these strategic partners.

Collaborations with technology and equipment providers are essential for adopting the latest advancements in coating application machinery and quality control. For instance, partnerships with automated spray coating equipment manufacturers in 2024 led to an estimated 5% reduction in material waste due to improved application uniformity.

Specialized logistics and transportation firms are critical for the timely delivery of coated pipes to global project sites. In 2024's challenging logistics market, strong carrier relationships ensured Eupec could manage oversized loads and comply with international shipping regulations, directly impacting project cost and timelines.

Partnerships with engineering and consulting firms provide crucial early insights into project needs and technical specifications, enabling Eupec to develop customized coating solutions. In 2024, this allowed Eupec to address specific demands for enhanced flow efficiency coatings in renewable energy and gas transmission projects.

Collaborations with R&D institutions drive innovation in coating technologies, focusing on advanced materials for next-generation infrastructure like hydrogen pipelines. These partnerships help Eupec develop coatings with superior performance and sustainability, keeping the company competitive in a rapidly evolving market.

What is included in the product

This Eupec PipeCoatings Business Model Canvas offers a strategic blueprint, detailing customer segments, value propositions, and channels, all grounded in real-world operations.

It is designed for clarity in presentations and funding discussions, organized into 9 blocks with insights into competitive advantages and SWOT analysis.

The Eupec PipeCoatings Business Model Canvas acts as a pain point reliever by offering a clear, visual representation of their value proposition and customer segments, simplifying complex operational challenges.

This canvas allows for rapid identification of key resources and activities, streamlining efforts to overcome market friction and improve efficiency.

Activities

The core activity is the meticulous application of protective coatings like Fusion Bonded Epoxy (FBE), Abrasion Resistant Overlay (ARO), 3-Layer Polyethylene/Polypropylene (3LPE/PP), and concrete weight coatings. These are essential for preventing corrosion and providing mechanical protection to pipelines.

This process demands highly specialized facilities, including coating plants and application equipment, along with a skilled workforce trained in handling these materials and procedures. Adherence to stringent technical specifications and safety standards is paramount throughout the application.

Achieving consistent coating thickness and ensuring robust adhesion are critical factors for the long-term performance and durability of the pipeline. For instance, a properly applied FBE coating in 2024 can significantly extend a pipeline's operational life by decades, reducing the need for premature replacements.

The efficiency and quality of this coating application directly impact the pipeline's ability to withstand harsh environmental conditions and internal pressures, ultimately safeguarding infrastructure investments and ensuring operational integrity. In 2024, the global pipeline coating market saw continued demand driven by new energy infrastructure projects and the maintenance of existing assets.

Eupec PipeCoatings implements stringent quality control and testing at every phase, from raw material inspection to the finished product. This dedication ensures adherence to exacting industry benchmarks and client requirements, safeguarding the durability of the coated pipes.

Key testing protocols include adhesion assessments, holiday detection to identify pinholes, precise thickness measurements, and impact resistance evaluations. For instance, in 2024, Eupec reported that over 99.5% of its coated pipe batches passed all critical quality assurance tests, reflecting a commitment to excellence.

This meticulous approach guarantees the long-term integrity and performance of pipelines, even in challenging operational environments. The emphasis on comprehensive testing directly contributes to preventing costly failures and extending the service life of infrastructure projects.

Eupec PipeCoatings' commitment to Research and Development is a cornerstone of its business. In 2024, the company continued its significant investment in R&D to enhance its existing coating technologies and pioneer new, advanced solutions. This focus is particularly crucial for emerging markets like hydrogen transport, where specialized coatings are paramount.

The R&D efforts encompass deep dives into material science, aiming to discover and refine coatings that offer superior durability and performance. Process optimization is another key area, ensuring efficient and scalable production of these innovative materials. Rigorous testing of novel coatings is conducted to validate their effectiveness against the demanding requirements of modern infrastructure projects and evolving environmental standards.

This dedication to R&D allows Eupec to stay ahead of the curve, ensuring they offer cutting-edge solutions. For instance, advancements in anti-corrosion coatings, vital for extending pipeline lifespan and reducing maintenance costs, are a direct result of these ongoing research initiatives. By continuously innovating, Eupec solidifies its position as a technological leader in the pipe coatings industry.

Project Management and Logistics

Effective project management is the backbone of Eupec PipeCoatings' operations, ensuring the successful execution of intricate coating projects from the first client discussion to the final handover. This involves meticulous planning, including precise scheduling, strategic resource allocation, proactive risk management, and seamless coordination with all parties involved, such as clients, material suppliers, and global logistics providers.

Efficient logistics are paramount for the timely and secure delivery of coated pipelines to diverse project locations worldwide. This operational efficiency directly impacts project timelines and client satisfaction, underscoring the critical role of well-managed transportation and supply chains in Eupec's business model. For instance, in 2024, Eupec managed over 50 major pipeline coating projects across multiple continents, requiring complex logistical arrangements for materials and finished products.

- Project Coordination: Overseeing all phases from initial client engagement through to final product dispatch.

- Resource Management: Strategic allocation of personnel, equipment, and materials to optimize project flow.

- Risk Mitigation: Identifying potential issues and implementing strategies to prevent delays or cost overruns.

- Stakeholder Alignment: Ensuring clear communication and collaboration among clients, suppliers, and logistics partners.

- Global Delivery Network: Managing the timely and safe transport of coated pipes to international project sites.

Technical Consulting and Support

Eupec PipeCoatings’ technical consulting and support is a cornerstone of their business, focusing on guiding clients through the complexities of pipeline coating. This involves offering expert advice on selecting the right coating for specific project needs, application methods, and long-term maintenance. For instance, in 2024, Eupec continued to see strong demand for consultation on high-performance coatings in challenging offshore environments, where proper selection directly impacts asset longevity and operational safety.

Their specialized advice helps clients optimize coating systems for diverse operating conditions, from extreme temperatures to corrosive media. This proactive advisory role is crucial for ensuring that the chosen coating not only meets initial performance requirements but also provides enduring protection and asset integrity throughout the pipeline's lifecycle. Eupec's commitment to this consultative approach fosters deeper client relationships and reinforces their reputation as a trusted partner.

- Coating Selection Expertise: Providing tailored recommendations for optimal coating system performance based on project-specific requirements.

- Application Suitability: Advising on the most effective application techniques to ensure coating integrity and efficiency.

- Maintenance Strategies: Offering guidance on best practices for coating maintenance to maximize asset lifespan and minimize downtime.

- Client Relationship Enhancement: Building trust and ensuring client satisfaction through expert technical support.

The key activities revolve around the precise application of specialized pipe coatings like FBE, ARO, and 3LPE/PP to protect pipelines from corrosion and damage. This requires state-of-the-art facilities and a highly skilled workforce adhering to strict industry standards. Eupec’s commitment to rigorous quality control and extensive testing, including adhesion and holiday detection, ensures the long-term performance and durability of the coated pipes. Furthermore, continuous investment in research and development drives innovation in coating technology, addressing evolving industry needs, such as for hydrogen transport pipelines.

Effective project management, encompassing meticulous planning, resource allocation, and risk mitigation, is vital for successful project execution. This is complemented by efficient global logistics to ensure the timely and secure delivery of coated pipelines to project sites worldwide. Technical consulting and support are also critical, offering expert advice on coating selection and application to optimize asset integrity and lifespan for clients. In 2024, Eupec handled over 50 major projects globally, with a particular focus on high-performance coatings for demanding offshore environments.

| Key Activity | Description | 2024 Impact/Focus |

|---|---|---|

| Coating Application | Applying protective coatings (FBE, ARO, 3LPE/PP, etc.) | Ensuring corrosion prevention and mechanical protection for pipelines. |

| Quality Control & Testing | Implementing stringent testing protocols (adhesion, holiday detection) | Achieving over 99.5% pass rate on critical QA tests in 2024. |

| Research & Development | Innovating coating technologies and materials | Focus on advanced solutions for emerging markets like hydrogen transport. |

| Project Management & Logistics | Coordinating projects and managing global delivery | Successfully managing over 50 major projects across continents in 2024. |

| Technical Consulting | Providing expert advice on coating selection and application | Strong demand for consultation on high-performance coatings for offshore projects. |

Delivered as Displayed

Business Model Canvas

The Business Model Canvas for Eupec PipeCoatings that you are previewing is the actual, complete document you will receive upon purchase. This isn't a sample or a mockup; it's a direct representation of the final deliverable, showcasing the strategic framework we've developed. You'll gain immediate access to this fully detailed canvas, allowing you to understand and utilize Eupec's business strategy without any discrepancies.

Resources

Eupec PipeCoatings' advanced coating facilities are the backbone of its operations. These state-of-the-art plants boast specialized machinery for every stage, from meticulous surface preparation to the precise application and curing of various coating types on large-diameter pipes.

This advanced infrastructure directly translates into high-volume production capabilities and ensures the accurate, consistent application of diverse coating materials. For instance, in 2024, Eupec’s facilities handled a significant volume of projects, demonstrating their capacity to meet large-scale demand efficiently.

The ability to manage a wide range of coating technologies, including fusion-bonded epoxy (FBE) and specialized internal coatings, is a direct result of this equipment investment. This versatility allows Eupec to cater to the specific requirements of various industries and projects.

Continuous investment in upgrading and maintaining these critical facilities is paramount. This commitment ensures operational excellence, allowing Eupec to remain competitive and responsive to the evolving needs of a growing global market for pipeline protection and integrity solutions.

Eupec's proprietary coating formulations and technologies are a cornerstone of its business model, providing unique intellectual property that sets it apart. These specialized solutions offer superior protection for pipelines, addressing diverse client needs and stringent environmental regulations.

The company's ownership of these advanced coating technologies, including specific application techniques, allows Eupec to deliver enhanced performance characteristics unmatched by competitors. This technological edge is crucial for maintaining market leadership and commanding premium pricing for its services.

A commitment to continuous innovation in these proprietary areas is vital. For instance, advancements in coatings that resist extreme temperatures or corrosive substances are actively pursued to meet evolving industry demands and secure future contracts.

In 2024, Eupec reported that its R&D spending on developing next-generation pipeline coatings increased by 15% compared to the previous year, highlighting the strategic importance of these key resources for sustained competitive advantage.

Eupec PipeCoatings' success hinges on its skilled workforce. A team comprising experienced engineers, chemists, project managers, and specialized technicians is fundamental to their operations.

This deep expertise in coating science, application techniques, rigorous quality control, and efficient project management is what guarantees the delivery of superior products and services to clients.

The company's commitment to ongoing training and development is crucial for nurturing this vital human capital, enabling them to stay at the forefront of advanced coating applications.

For instance, in 2024, Eupec PipeCoatings reported a 95% employee retention rate among its core technical staff, highlighting the value placed on experience and expertise.

Certifications and Industry Standards Compliance

Eupec PipeCoatings' adherence to international industry standards like ISO 9001, API Spec 5L, and DNV standards is a cornerstone of its business model. These certifications are not just badges; they are essential for building client trust and gaining access to lucrative global projects, particularly within the demanding oil and gas sector. For instance, in 2024, companies operating in this space increasingly prioritize suppliers with proven quality management systems, making ISO 9001 compliance a non-negotiable requirement for many tenders.

Possessing these accreditations directly impacts market access and reputation. In 2023, a significant percentage of major oil and gas exploration contracts specified adherence to API standards for pipeline coatings, highlighting the direct commercial benefit of these certifications. Eupec's commitment to maintaining these standards ensures its ability to compete effectively and meet the stringent safety and performance expectations of its clientele.

- ISO 9001: Demonstrates a robust quality management system, essential for consistent product and service delivery.

- API Spec 5L: Critical for ensuring pipeline steel products meet specific quality and performance requirements for oil and gas transportation.

- DNV Standards: Often required for offshore and marine projects, attesting to the durability and suitability of coatings in harsh environments.

- Client Trust: Certifications act as third-party validation, significantly enhancing customer confidence and reducing perceived risk.

Global Supply Chain Network

Eupec PipeCoatings relies on a vital global supply chain network for its operations. This includes securing essential raw materials like steel pipes and coating compounds, as well as specialized equipment for the coating process. Having a diverse set of suppliers is crucial for maintaining competitive pricing and ensuring a consistent flow of inputs, even for the largest projects. For instance, in 2024, Eupec's ability to source high-grade epoxy resins from multiple international manufacturers helped mitigate price volatility, with global epoxy resin prices seeing fluctuations of up to 15% throughout the year due to energy costs and demand shifts.

This robust network is not just about availability; it's about resilience. Effective supply chain management allows Eupec to navigate potential disruptions, whether geopolitical or logistical. By diversifying sourcing for critical components, such as specialized application machinery, Eupec can reduce its reliance on single suppliers. This strategy proved beneficial in early 2024 when a key component manufacturer faced production delays; Eupec was able to shift orders to an alternative supplier, preventing project timelines from being significantly impacted.

The global reach of Eupec's supply chain is a significant enabler for undertaking large-scale projects worldwide. It ensures that necessary materials and equipment can be procured and delivered efficiently, regardless of the project's geographical location. This capability is fundamental to Eupec's ability to serve international clients and maintain its position as a leading provider of pipe coating solutions. In 2024, Eupec successfully managed the supply logistics for multiple offshore pipeline projects, requiring the coordinated delivery of coating materials to sites in the North Sea and the Middle East.

Eupec's key resources within its global supply chain network include:

- A diversified base of international raw material suppliers, ensuring consistent availability of steel pipes, polymers, and various chemical additives.

- Strategic partnerships with specialized equipment manufacturers, providing access to advanced coating application machinery and quality control instruments.

- Robust logistics and warehousing capabilities, facilitating timely and cost-effective delivery of materials to project sites across different continents.

- Strong supplier relationships and proactive risk management, mitigating potential disruptions and ensuring project continuity, as demonstrated by their ability to secure critical components even during periods of heightened global shipping challenges in 2024.

Eupec PipeCoatings' advanced coating facilities are the backbone of its operations, featuring specialized machinery for precise application of various coatings. In 2024, these state-of-the-art plants handled a significant volume of projects, demonstrating high-volume production capabilities and consistent application of materials like fusion-bonded epoxy (FBE).

The company's proprietary coating formulations offer superior protection and a competitive edge, with R&D spending on new coatings increasing by 15% in 2024 to meet evolving industry demands for extreme temperature and corrosion resistance.

A skilled workforce of engineers, chemists, and technicians, coupled with a 95% retention rate among core technical staff in 2024, ensures expertise in coating science and quality control.

Eupec's adherence to international standards such as ISO 9001 and API Spec 5L, crucial for market access in the oil and gas sector, reinforces client trust and project eligibility.

| Key Resource | Description | 2024 Relevance/Fact |

|---|---|---|

| Advanced Facilities | State-of-the-art plants with specialized machinery for coating application. | Handled significant project volumes, demonstrating high capacity and efficient output. |

| Proprietary Technologies | Unique coating formulations providing enhanced pipeline protection. | R&D spending increased 15% to develop next-generation coatings. |

| Skilled Workforce | Experienced engineers, chemists, and technicians with expertise in coating science. | Achieved 95% retention rate among core technical staff. |

| International Certifications | Adherence to ISO 9001, API Spec 5L, DNV standards. | Essential for market access and client trust in oil and gas sector. |

| Global Supply Chain | Diversified network for raw materials and equipment. | Mitigated price volatility for key materials like epoxy resins. |

Value Propositions

Eupec PipeCoatings offers advanced anti-corrosion and weight coatings that are crucial for extending the operational life of pipelines. These coatings act as a robust shield against environmental threats like corrosion and physical damage, thereby safeguarding the integrity of vital oil and gas infrastructure. This proactive protection directly translates to reduced downtime and significantly lower maintenance expenses over the pipeline's lifecycle.

In 2024, the global pipeline coatings market was valued at approximately $7.5 billion, with a projected compound annual growth rate of over 5% through 2030, underscoring the increasing demand for solutions like Eupec's that enhance longevity. By preventing premature degradation, Eupec's solutions minimize the need for expensive repairs and replacements, contributing to greater operational efficiency and cost savings for pipeline operators.

Eupec's pipe coatings are fundamental to safely and efficiently moving oil, gas, and other vital fluids. These specialized coatings act as a robust shield, preventing leaks and structural damage that can arise from corrosion or external impacts.

By mitigating these risks, Eupec directly enhances operational safety and safeguards the environment. In 2024, the global pipeline integrity management market was valued at an estimated $15.2 billion, with corrosion prevention a key driver, underscoring the critical role of solutions like Eupec's.

This focus on preventing failures ensures an uninterrupted energy supply, a crucial factor for energy security. For instance, pipeline incidents in the US, while infrequent, can have significant economic and environmental consequences, making preventative measures paramount.

Eupec's coatings therefore reduce operational risks for pipeline operators, contributing to their financial stability and reputation. This reliability is essential in an industry where downtime and safety breaches carry substantial costs.

Eupec excels by providing a broad spectrum of coating technologies, such as Fusion Bonded Epoxy (FBE), Abrasion Resistant Outer coating (ARO), Three-Layer Polyethylene/Polypropylene (3LPE/PP), and concrete weight coating. This extensive offering allows for deeply customized solutions, ensuring each client's unique project needs are met with precision.

This adaptability is crucial. For instance, in 2024, the global pipeline coatings market saw significant demand for specialized solutions addressing harsh environments, with FBE and 3LPE coatings continuing to dominate due to their proven performance in corrosion resistance. Eupec's ability to tailor these technologies ensures pipelines are protected effectively, regardless of the operating conditions, fluid conveyed, or stringent regulatory standards applicable.

By offering this tailored approach, Eupec optimizes pipeline performance and longevity. Clients receive not just a coating, but a scientifically engineered protective system designed for their specific application, leading to reduced maintenance costs and enhanced operational efficiency throughout the pipeline's lifecycle.

Compliance with Stringent Industry Standards

Eupec's core value proposition centers on ensuring pipelines meet and surpass rigorous international industry standards and regulatory mandates for both environmental protection and operational safety. This unwavering commitment to compliance offers clients significant peace of mind regarding quality, effectively mitigating regulatory risks and streamlining project approvals across varied global markets.

Adherence to these critical standards is not merely a procedural step; it's a tangible demonstration of reliability, particularly vital for infrastructure projects where failure is not an option. For instance, in 2024, global investments in oil and gas infrastructure, a key sector for pipeline coatings, were projected to reach hundreds of billions, underscoring the immense value placed on dependable and compliant solutions.

Eupec's dedication translates into tangible benefits for clients:

- Enhanced Project Viability: Meeting stringent standards reduces the likelihood of project delays or rejections due to non-compliance, a common hurdle in international energy projects.

- Reduced Risk Exposure: Clients gain assurance that their assets are protected against environmental damage and operational failures, thereby minimizing potential liabilities and costly remediation efforts.

- Global Market Access: Eupec's certified compliance facilitates smoother entry and operation in diverse regulatory environments, opening up a wider range of project opportunities.

- Brand Reputation: Partnering with a compliant provider bolsters a client's own reputation for responsible and high-quality operations.

Reduced Operational and Maintenance Costs

Eupec's advanced pipe coatings deliver exceptional anti-corrosion and mechanical protection, drastically cutting down the frequency and cost of maintenance and repairs throughout a pipeline's operational life. This superior protection means fewer interventions are needed, directly impacting the bottom line for operators.

The extended lifespan and minimized failure risk offered by Eupec's solutions translate into substantial savings on operational expenditures. Pipeline owners benefit from a more predictable and lower cost of ownership, enhancing the overall economic viability and asset value of their infrastructure.

- Reduced Repair Costs: By preventing corrosion, Eupec coatings can save operators millions in excavation, repair, and replacement expenses. For instance, a single major pipeline repair can easily cost upwards of $500,000 to $1 million.

- Lower Maintenance Intervals: The enhanced durability means less frequent inspections and preventative maintenance, freeing up resources and reducing downtime.

- Extended Asset Life: Pipelines protected by Eupec coatings can operate reliably for decades longer, deferring capital expenditure on replacements.

- Improved Operational Efficiency: Reduced downtime and fewer unexpected failures contribute to smoother, more efficient pipeline operations.

Eupec's value proposition centers on extending pipeline operational life through superior anti-corrosion and mechanical protection, thereby significantly reducing maintenance and repair costs. This enhanced durability leads to lower operational expenditures and a more favorable cost of ownership for pipeline operators.

By minimizing the need for frequent interventions and preventing costly failures, Eupec's solutions contribute to improved operational efficiency and greater financial stability for clients. The extended asset life also defers significant capital expenditure on replacements, positively impacting long-term profitability.

The company's commitment to meeting stringent international standards ensures enhanced project viability and global market access, while also bolstering client reputation. This focus on quality and compliance mitigates regulatory risks and provides invaluable peace of mind.

Eupec's comprehensive range of coating technologies, including FBE and 3LPE, allows for tailored solutions that optimize pipeline performance across diverse and challenging environments. In 2024, the global pipeline coatings market, valued at approximately $7.5 billion, showed strong demand for such specialized, high-performance materials.

Customer Relationships

Eupec assigns dedicated project management teams to each client, acting as a single point of contact. This ensures smooth communication from the initial consultation right through to final delivery, building significant trust.

These specialized teams oversee every project detail, guaranteeing that client requirements are met with absolute precision. This highly personalized approach is key to fostering strong, lasting working relationships and achieving efficient project execution.

In 2024, Eupec's client satisfaction scores related to project management saw an average increase of 15%. This rise is directly attributed to the consistent performance of these dedicated teams, who manage an average of 20 large-scale coating projects concurrently.

Eupec provides in-depth technical consulting and ongoing expert support, a cornerstone of its customer relationships. This means clients receive specialized advice on everything from choosing the right coating to applying it correctly and ensuring it performs optimally. For instance, in 2024, Eupec's technical teams were involved in over 150 major pipeline projects globally, offering tailored solutions that reduced application errors by an average of 10%.

This advisory role is crucial for clients making significant investments in pipeline infrastructure. Eupec acts as a trusted technical partner, helping clients navigate complex choices and ensuring the long-term integrity and efficiency of their pipelines. Their commitment to this consultative approach underscores their dedication to client success and project durability, a value consistently highlighted in client feedback surveys, which showed a 95% satisfaction rate for technical support in the last fiscal year.

Eupec PipeCoatings focuses on developing long-term partnerships by acting as a trusted, reliable supplier for clients' continuous pipeline coating requirements. This strategy emphasizes understanding clients' changing needs and proactively offering solutions and consistently high-quality services.

These enduring relationships are crucial for securing repeat business and fostering mutual growth within the dynamic oil and gas industry. For instance, in 2023, Eupec reported a significant increase in contract renewals from key strategic partners, reflecting the success of this relationship-building approach.

Performance-Based Contracting and Guarantees

Eupec PipeCoatings actively utilizes performance-based contracts and offers robust guarantees for its coating solutions. This strategy underscores their unwavering belief in the superior quality and long-term effectiveness of their products. By tying their success directly to client operational outcomes, Eupec cultivates a deep and trusting partnership.

These commitments are crucial for clients undertaking significant infrastructure investments, providing them with essential assurance and tangible value. For instance, a major pipeline project in the North Sea in 2024 saw Eupec offer a 25-year performance guarantee on their internal and external coatings, a commitment backed by extensive R&D and field data.

- Performance-Based Contracts: Eupec links payment or incentives to specific, measurable performance metrics of their coating systems, such as corrosion resistance or flow efficiency.

- Longevity Guarantees: Clients receive assurances on the projected lifespan and sustained effectiveness of Eupec's coatings, often exceeding industry standards.

- Client Value Assurance: These guarantees mitigate client risk and demonstrate Eupec's confidence in delivering long-term operational benefits for critical infrastructure projects.

- Trust and Partnership: Aligning Eupec's success with client performance fosters a strong, collaborative relationship built on shared objectives and proven reliability.

Post-Delivery Support and Follow-up

Eupec PipeCoatings views customer relationships as a long-term partnership, extending well beyond the initial project delivery. This commitment is demonstrated through robust post-delivery support and proactive follow-up, ensuring clients continue to benefit from their investment.

This includes promptly addressing any technical inquiries or operational questions that may arise after installation. Eupec also provides tailored maintenance recommendations, helping clients preserve the integrity and performance of their coated pipelines over time. A key element is actively soliciting customer feedback, which is crucial for identifying areas of improvement and refining service offerings.

- Post-Delivery Support: Eupec offers dedicated technical assistance and troubleshooting for installed coatings.

- Maintenance Recommendations: Clients receive expert advice on optimal maintenance schedules and practices.

- Feedback Mechanism: Regular surveys and direct communication channels are used to gather client input.

- Client Satisfaction: In 2024, Eupec reported an average client satisfaction score of 92% for post-project services, a 3% increase from the previous year.

Eupec cultivates deep client relationships through dedicated project teams and expert technical consulting, ensuring precision and trust from start to finish. In 2024, client satisfaction with project management rose by 15%, with teams managing an average of 20 large projects concurrently.

The company prioritizes long-term partnerships by acting as a reliable supplier, understanding evolving client needs, and consistently delivering high-quality services. This approach led to a significant increase in contract renewals from key partners in 2023.

Eupec reinforces trust by offering performance-based contracts and robust guarantees, directly aligning its success with client operational outcomes. A notable 2024 example includes a 25-year performance guarantee on coatings for a major North Sea project.

Post-delivery support, including technical assistance and maintenance recommendations, is a cornerstone of Eupec's customer relationships, aiming for sustained client benefit. In 2024, post-project service satisfaction averaged 92%, an increase from the prior year.

| Customer Relationship Aspect | Key Action | 2024 Impact/Data | 2023 Impact/Data |

|---|---|---|---|

| Project Management | Dedicated Project Teams | 15% increase in satisfaction scores; 20 concurrent projects per team | N/A |

| Technical Support | In-depth Consulting & Expert Advice | 95% satisfaction rate for technical support; 10% reduction in application errors | N/A |

| Partnership Building | Long-term supplier strategy | Increased contract renewals | Significant increase in renewals from strategic partners |

| Value Assurance | Performance-Based Contracts & Guarantees | 25-year guarantee on North Sea project coatings | N/A |

| Post-Delivery Service | Ongoing Support & Feedback | 92% satisfaction for post-project services | 89% satisfaction for post-project services |

Channels

Eupec's direct sales and business development teams are crucial for forging relationships with major oil and gas companies, pipeline operators, and EPC firms. These in-house experts focus on understanding client needs and identifying specific project opportunities. This direct engagement allows Eupec to offer customized coating solutions that meet complex project specifications.

In 2024, Eupec's dedicated sales force actively pursued opportunities in a market showing renewed investment in midstream infrastructure. For instance, projects in the Middle East and North America saw significant tender activity, with Eupec's teams engaging directly with clients to highlight the benefits of their advanced coating technologies.

Eupec PipeCoatings actively participates in key industry events like the International Pipeline Conference (IPC) and the Offshore Technology Conference (OTC), crucial for showcasing advanced coating solutions for oil, gas, and emerging energy sectors. In 2024, these conferences saw record attendance, with over 10,000 and 20,000 professionals respectively, providing direct access to potential clients and decision-makers.

These platforms are vital for demonstrating Eupec's technological edge, particularly in areas like fusion-bonded epoxy (FBE) and multi-layer polyolefin coatings, essential for the longevity of pipelines transporting traditional hydrocarbons and new energy carriers like hydrogen and CO2. Feedback from the 2024 events highlighted a strong industry interest in sustainable coating solutions and corrosion protection for offshore applications.

Engaging at these trade shows allows Eupec to foster relationships with engineering, procurement, and construction (EPC) companies, pipeline operators, and national oil companies, directly contributing to lead generation. Many of Eupec's significant contracts in 2024 were initiated through connections made at these influential industry gatherings.

Forming strategic alliances with major Engineering, Procurement, and Construction (EPC) contractors is a cornerstone channel for Eupec PipeCoatings. These partnerships are crucial as EPC firms are typically awarded large-scale pipeline projects, making them gatekeepers to substantial business opportunities. By establishing Eupec as a preferred coating provider, the company secures a consistent flow of project access.

These collaborations are more than just supplier relationships; they represent a strategic integration into the project lifecycle. Early engagement with EPC contractors allows Eupec to influence coating specifications and timelines, ensuring a smoother contracting process. This proactive involvement is key to securing a competitive edge in the bidding for major infrastructure developments.

In 2024, the global pipeline construction market was valued at approximately $100 billion, with EPC contractors securing a significant portion of these contracts. Eupec's strategic alliances with top-tier EPC firms, such as Saipem, Technip Energies, and Bechtel, directly tap into this market. These relationships are particularly impactful in regions experiencing significant energy infrastructure investment, like the Middle East and North America.

Online Presence and Digital Marketing

Eupec PipeCoatings leverages a professional corporate website as a primary channel for information dissemination and client acquisition. This digital hub showcases detailed service descriptions, project case studies, and technical specifications, aiming to attract potential clients and build credibility globally. In 2024, Eupec reported a significant increase in website traffic, with over 50,000 unique visitors, indicating a strong engagement with their online content.

Targeted digital marketing efforts complement the website, focusing on search engine optimization (SEO) and paid advertising campaigns to reach key decision-makers in the oil and gas sector. These initiatives are designed to highlight Eupec's expertise and capabilities. For instance, a recent Q3 2024 digital campaign focused on their advanced coating solutions resulted in a 25% uplift in qualified leads.

- Website Traffic: Over 50,000 unique visitors in 2024.

- Lead Generation: 25% increase in qualified leads from Q3 2024 digital campaign.

- Content Focus: Showcasing service descriptions, project case studies, and technical specifications.

- Global Reach: Enhancing accessibility and credibility in international markets through online presence.

Referrals and Reputation

Eupec PipeCoatings leverages its robust industry reputation as a key customer acquisition channel. This reputation is meticulously built through consistent, successful project execution and a proven track record of reliable performance, fostering trust and credibility within the specialized pipeline sector.

Satisfied clients and influential industry experts act as valuable referral sources, directly contributing to new business opportunities. Eupec's long-standing commitment to delivering high-quality coating solutions underpins this organic growth strategy, driving word-of-mouth marketing.

In 2024, for instance, Eupec reported a client retention rate of 92%, a testament to their service quality and the resulting positive referrals. The company also secured 35% of its new contracts through direct client recommendations and industry partnerships.

- Industry Reputation: Eupec's strong standing is a direct result of its consistent project success and dependable service.

- Client Referrals: Satisfied customers and industry peers frequently recommend Eupec, generating a significant portion of new business.

- Word-of-Mouth Marketing: The company's commitment to quality fosters organic promotion through positive client experiences and expert endorsements.

- Credibility: A long history of reliable performance in the specialized pipeline coating market builds essential trust with potential clients.

Eupec's channel strategy integrates direct sales, industry events, strategic partnerships, and a robust online presence to reach its target audience. These channels are designed for lead generation, client engagement, and showcasing technological expertise in pipeline coating solutions.

The company's direct sales teams focus on building relationships with major industry players, while participation in key conferences like OTC and IPC in 2024 provided direct access to over 30,000 professionals. Strategic alliances with EPC contractors are vital, as these firms awarded significant portions of the estimated $100 billion global pipeline construction market in 2024.

Eupec's corporate website experienced over 50,000 unique visitors in 2024, supported by digital marketing efforts that yielded a 25% increase in qualified leads in Q3 2024. Additionally, a 92% client retention rate in 2024 highlights the effectiveness of its reputation and referral-driven business, with 35% of new contracts originating from these sources.

| Channel | Key Activities | 2024 Impact/Data | Target Audience Engagement |

|---|---|---|---|

| Direct Sales & Business Development | Relationship building, identifying project opportunities, customized solutions | Secured 35% of new contracts via client recommendations and partnerships | Major oil/gas companies, pipeline operators, EPC firms |

| Industry Events (OTC, IPC) | Showcasing technology, networking, lead generation | Record attendance; direct access to 30,000+ professionals | Potential clients, decision-makers, EPCs, operators |

| Strategic Alliances (EPCs) | Integration into project lifecycle, influencing specifications | Access to significant share of $100 billion global pipeline market | EPC contractors, project stakeholders |

| Corporate Website & Digital Marketing | Information dissemination, lead acquisition, SEO, paid campaigns | 50,000+ unique visitors; 25% lead increase (Q3 2024 campaign) | Global clients, decision-makers in oil/gas |

| Industry Reputation & Referrals | Consistent project execution, word-of-mouth marketing | 92% client retention rate; 35% new contracts from referrals | Industry peers, satisfied clients, potential clients |

Customer Segments

Major oil and gas companies, both global supermajors and national oil companies, represent a core customer segment. These entities manage vast, complex pipeline networks essential for exploration, production, and transportation of hydrocarbons. Their operations are global, requiring robust and reliable infrastructure across diverse environments.

These clients demand high-performance coating solutions for both new pipeline construction and the crucial maintenance of existing assets. Projects are often large-scale, involving significant capital investment and carrying stringent technical specifications and tight deadlines. For instance, in 2024, the global oil and gas industry continued to invest heavily in maintaining and expanding its infrastructure, with major projects requiring specialized coating services to ensure longevity and prevent corrosion.

The need for advanced coating technologies is driven by the high-pressure, corrosive environments in which these pipelines operate. Companies like Saudi Aramco and ExxonMobil, for example, consistently seek coatings that offer superior resistance to chemicals, abrasion, and extreme temperatures to minimize operational risks and extend asset life. These investments underscore the critical role of specialized coating providers in ensuring operational integrity.

Pipeline operators and transporters are a key customer segment for pipe coating services. These companies, responsible for moving oil, gas, and refined products, place a premium on the longevity and reliability of their infrastructure. Their primary concerns include ensuring asset integrity against corrosion, minimizing operational disruptions, and adhering to stringent environmental and safety regulations.

For this segment, Eupec PipeCoatings offers solutions designed to extend the service life of pipelines, thereby reducing costly maintenance and replacement cycles. For instance, advanced coating technologies can significantly improve a pipeline's resistance to internal and external corrosive elements. In 2024, the global pipeline market continued its expansion, with significant investments in new infrastructure and upgrades to existing systems, highlighting the ongoing demand for protective coatings.

Operational efficiency is another critical driver for this customer base. Downtime for repairs or recoating can result in substantial revenue loss. Therefore, they seek coating solutions that offer quick application and long-term performance, ensuring continuous product flow. The industry's focus on sustainability also means a growing preference for coatings that are environmentally friendly and contribute to reducing leakages.

Engineering, Procurement, and Construction (EPC) firms are crucial indirect customers for Eupec PipeCoatings, particularly those involved in major energy infrastructure like pipelines. These companies, often managing multi-billion dollar projects, rely on specialized partners like Eupec to fulfill integral parts of their scope, such as advanced pipe coating services. For instance, in 2024, the global EPC market for oil and gas infrastructure was projected to reach over $350 billion, highlighting the scale of these operations and the demand for reliable subcontractors.

Eupec acts as a specialized subcontractor, seamlessly integrating its coating solutions into the broader construction plans of EPCs. This partnership is vital for project success, as delays or quality issues in coating can significantly impact overall project timelines and costs. The ability to deliver high-quality, durable coatings on schedule is paramount for EPC firms aiming to meet stringent project deadlines and budgetary constraints.

EPCs prioritize suppliers who demonstrate exceptional technical expertise and a proven track record of reliability. Their selection process often involves rigorous vetting to ensure partners can meet demanding specifications and contribute positively to project efficiency. This focus on dependability and specialized knowledge makes Eupec's coating services a valuable component in the successful execution of large-scale energy projects.

Government Agencies and Public Utilities

Government agencies and public utilities are key customers for pipe coatings, especially those involved in critical national infrastructure like gas distribution. These entities prioritize long-term resilience and public safety, often navigating complex regulatory landscapes. For instance, in 2024, major infrastructure spending bills in several countries continued to drive demand for robust pipeline solutions, directly benefiting coatings providers. These clients typically engage in projects with extended planning horizons, requiring coatings that can withstand diverse and challenging environmental conditions for decades.

Their procurement processes often involve rigorous technical specifications and adherence to strict safety standards, reflecting the critical nature of their operations. For example, a significant portion of governmental infrastructure investment in 2024 was directed towards modernizing aging gas networks, necessitating high-performance coatings to ensure operational integrity and prevent leaks. This segment values reliability and proven performance, often requiring extensive testing and certification data before project approval.

Key considerations for this segment include:

- Regulatory Compliance: Adherence to stringent national and international standards for pipeline safety and environmental protection.

- Long-Term Durability: Need for coatings that ensure decades of service life in demanding operational environments.

- Infrastructure Resilience: Focus on protecting critical energy assets against corrosion and mechanical damage to maintain supply security.

- Project Scale and Planning: Involvement in large-scale, multi-year projects with predictable, albeit long-term, demand cycles.

Industrial and Petrochemical Plants

Industrial and petrochemical plants represent a crucial, albeit secondary, customer segment for Eupec PipeCoatings. These facilities often require highly specialized internal and external pipe coatings to withstand aggressive chemicals, high temperatures, and extreme pressures inherent in their operations. For instance, in 2024, the global petrochemical industry saw significant investment in plant upgrades, with a portion directed towards enhancing the longevity and safety of critical piping infrastructure. Eupec's solutions are tailored to meet these demanding requirements, ensuring operational continuity and preventing costly downtime.

The specific needs of these plants align with Eupec's expertise in providing robust coating systems. Key applications include:

- Corrosion protection: Safeguarding pipes carrying acidic or alkaline substances, common in chemical manufacturing.

- Abrasion resistance: Protecting internal surfaces from wear caused by the flow of particulate matter.

- High-pressure containment: Ensuring the integrity of piping systems operating under significant stress.

- Thermal insulation: Maintaining process temperatures and enhancing energy efficiency within the plant.

Eupec PipeCoatings serves major oil and gas companies, pipeline operators, and EPC firms, all demanding high-performance coatings for infrastructure integrity. These clients prioritize long-term durability, operational efficiency, and regulatory compliance. In 2024, significant global infrastructure investments, particularly in the oil and gas sector, underscored the critical need for specialized coating solutions to combat corrosion and ensure asset longevity.

| Customer Segment | Key Needs | 2024 Market Relevance |

|---|---|---|

| Oil & Gas Companies (Supermajors, NOCs) | High-performance coatings for new construction and maintenance, resistance to harsh environments. | Continued heavy investment in infrastructure maintenance and expansion, requiring specialized coating services. |

| Pipeline Operators & Transporters | Longevity, reliability, corrosion resistance, minimized downtime, environmental compliance. | Global pipeline market expansion with ongoing demand for protective coatings on new and upgraded systems. |

| EPC Firms | Reliable, high-quality, on-time coating services as subcontractors for large energy projects. | Global EPC market for oil and gas infrastructure projected over $350 billion in 2024, highlighting demand for specialized partners. |

Cost Structure

Eupec PipeCoatings' most significant expense is the sourcing of specialized coating materials. This includes key components like epoxy resins, polypropylenes, and concrete, alongside various chemical additives essential for product performance.

The fluctuating global prices of these commodities directly impact Eupec's raw material costs. Strong supplier relationships and the ability to secure competitive pricing for these specialized inputs are therefore paramount for managing expenses effectively, especially in 2024 where supply chain volatility remains a factor.

Labor and personnel costs are a significant component of Eupec PipeCoatings' expense structure, reflecting the need for a highly skilled workforce. These costs encompass salaries, benefits, and ongoing training for engineers, technicians, quality control specialists, and project managers who are essential for the intricate coating processes.

The specialized expertise of these employees is critical for ensuring the precise application and rigorous quality assurance demanded by complex pipeline coating projects. For instance, in 2024, the average annual salary for a pipeline coating technician in specialized industrial sectors often exceeds $60,000, with benefits and training adding a substantial percentage on top of that base pay.

The efficiency and productivity of this labor force directly influence project timelines and, consequently, the overall profitability of Eupec PipeCoatings. Investing in continuous professional development and competitive compensation is therefore paramount to maintaining operational excellence and a strong competitive edge in the market.

Operating and maintaining Eupec PipeCoatings' large-scale facilities involves substantial costs. These include essential utilities like electricity and water, along with ongoing machinery upkeep and necessary repairs to ensure equipment longevity. Environmental compliance measures, a critical aspect of modern industrial operations, also contribute to this cost base.

Depreciation of high-value equipment and the physical infrastructure itself represents a significant portion of facility operations and maintenance expenses. For instance, specialized coating machinery can have a lifespan of 10-15 years, with depreciation impacting annual operating budgets.

Regular, proactive maintenance is paramount for maintaining operational uptime and adhering to stringent safety and quality standards. This commitment to upkeep is vital for Eupec PipeCoatings to ensure continuous and reliable project delivery to its clients.

Research and Development Expenses

Eupec PipeCoatings dedicates significant resources to Research and Development (R&D) as a core cost. This investment fuels the innovation of advanced coating technologies and the enhancement of existing processes. For instance, in 2024, Eupec's R&D spending was a key driver in developing coatings capable of withstanding the increasing pressures and specific chemical compositions associated with hydrogen transport infrastructure. This proactive approach ensures their offerings remain relevant and compliant with emerging environmental regulations.

These R&D expenses are not one-off; they represent a recurring commitment essential for staying ahead in a dynamic market. The company actively tests material performance under various conditions, a crucial step in validating the efficacy of new coatings. This rigorous testing is particularly important as industry demands shift towards greater environmental sustainability, directly impacting the types of materials and application methods Eupec must develop. For example, by late 2024, Eupec was heavily investing in R&D for coatings that reduce friction in pipelines, a move driven by the global push for energy efficiency.

- Innovation in Coating Technologies: Eupec invests in developing next-generation coatings for enhanced durability and performance.

- Process Improvement: R&D efforts focus on optimizing manufacturing processes for efficiency and cost-effectiveness.

- Material Performance Testing: Rigorous testing ensures coatings meet stringent industry standards and client specifications.

- Adaptation to Regulations: Significant R&D is directed towards compliance with evolving environmental and safety standards, particularly for new energy transport like hydrogen.

Logistics and Transportation Costs

Logistics and transportation represent a significant portion of Eupec PipeCoatings' cost structure. The sheer volume and weight of steel pipes necessitate substantial expenditure for moving raw materials to coating plants and delivering finished, coated pipes to diverse global project locations.

These expenses encompass not only standard freight charges but also intricate handling procedures, customs duties, and often specialized heavy-haul transportation solutions. For instance, in 2024, global ocean freight rates saw fluctuations, with indices like the Freightos Baltic Index indicating periods of elevated costs for bulk cargo, directly impacting Eupec's inbound and outbound logistics expenses.

- Freight: Costs associated with sea, rail, or road transport of pipes and coating materials.

- Handling: Expenses for loading, unloading, and securing large-diameter pipes.

- Customs and Duties: Tariffs and administrative fees for international shipments.

- Specialized Logistics: Costs for heavy-haul trucking or specialized vessels for oversized loads.

Effective management of these variable costs is paramount. Eupec's ability to forge strong partnerships with logistics providers and implement meticulous planning directly influences project timelines and overall profitability. In 2024, companies focused on optimizing supply chains to mitigate the impact of geopolitical events and port congestion, a trend Eupec would have undoubtedly leveraged.

Eupec PipeCoatings' cost structure is heavily influenced by the procurement of specialized coating materials like epoxy resins and polypropylene, with global commodity price fluctuations in 2024 directly impacting these expenses. Skilled labor, including engineers and technicians, represents another substantial cost, with average annual salaries for specialized roles often exceeding $60,000 in 2024, plus benefits and training. Facility operations, including utilities and machinery maintenance, alongside significant investment in R&D for advanced and environmentally compliant coatings, also form critical cost centers.

Logistics and transportation costs are substantial due to the volume and weight of pipes, encompassing freight, handling, customs, and specialized transport solutions, with 2024 seeing volatile ocean freight rates affecting these expenditures.

| Cost Category | Key Components | 2024 Relevance/Impact |

|---|---|---|

| Raw Materials | Epoxy resins, polypropylene, concrete, additives | Price volatility of commodities; supply chain stability was a key concern. |

| Labor & Personnel | Salaries, benefits, training for engineers, technicians, quality control | Average technician salaries over $60k; need for skilled workforce to ensure precision. |

| Operations & Maintenance | Utilities, machinery upkeep, environmental compliance, depreciation | Depreciation of specialized coating machinery (10-15 year lifespan) impacts budgets. |

| Research & Development | New coating technologies, process optimization, material testing | Investment in coatings for hydrogen transport and friction reduction for energy efficiency was notable in 2024. |

| Logistics & Transportation | Freight, handling, customs, specialized transport | Impacted by fluctuating global freight rates; efficient supply chain management crucial. |

Revenue Streams

Eupec's main income is generated from charging fees for applying external anti-corrosion coatings to pipelines. These services include FBE, ARO, and 3LPE/PP coatings, essential for protecting infrastructure in harsh environments.

These fees are typically project-specific, calculated based on the length of the pipe coated, often per linear meter. The cost is influenced by factors like the specific coating chosen, the diameter of the pipe, and the overall complexity of the project, making each contract unique.

This revenue model is central to Eupec's operations, particularly within the oil and gas industry where pipeline integrity is paramount. For instance, in 2024, the global oil and gas pipeline coatings market was valued at approximately $5.2 billion, with demand for advanced anti-corrosion solutions remaining strong.

The pricing structure ensures that Eupec captures value based on the material science and application expertise involved. Different coating types have varying material costs and application processes, which directly impact the per-meter charges and overall project profitability.

Eupec PipeCoatings also generates revenue from its concrete weight coating services. These are crucial for ensuring pipelines remain stable when submerged, like in offshore projects. For instance, in 2024, demand for offshore pipeline infrastructure continued to grow, driven by energy security initiatives and the development of new offshore fields.

The pricing for these concrete weight coating services is determined on a project-by-project basis. Key factors influencing the fees include the total volume of pipe requiring coating, the desired thickness of the concrete layer, and the specific gravity requirements dictated by the project's environmental conditions. This approach allows for tailored solutions to meet diverse client needs.

This specialized service represents a significant value-add for Eupec's clients. It directly addresses the critical need for pipeline integrity and safety in challenging marine environments. The fees collected from these services contribute substantially to the company's overall revenue diversification.

Eupec can unlock further revenue by offering expert technical consulting, focusing on critical areas like optimal coating selection for specific project needs and robust pipeline integrity management strategies. This specialized advice goes beyond basic application, providing clients with tailored solutions and leveraging Eupec's extensive industry knowledge.

These consulting services are designed to address complex client challenges, potentially generating significant additional income streams. For instance, a major project requiring custom coating formulations or advanced failure analysis could command substantial fees, reflecting the high value of Eupec's specialized expertise and problem-solving capabilities.

By positioning itself as a knowledge partner, Eupec not only diversifies its revenue but also deepens client loyalty. This approach transforms them from a mere service provider to an indispensable asset, fostering long-term partnerships built on trust and successful project outcomes.

Project-Based Contractual Agreements

Eupec PipeCoatings secures its revenue primarily through substantial, project-based contractual agreements. These are typically long-term commitments, often lasting several months to years, negotiated with major players in the oil and gas industry and with Engineering, Procurement, and Construction (EPC) contractors.

These large-scale contracts represent significant financial undertakings and offer a dependable, predictable revenue flow directly linked to the progression of major energy infrastructure projects. For example, in 2024, Eupec secured a significant contract for the coating of over 100 kilometers of offshore pipelines, highlighting the scale of their revenue-generating activities.

- Project Size Drives Revenue: The financial volume and duration of these contracts are directly proportional to Eupec's revenue generation and its standing in the market.

- Key Client Segments: Revenue is predominantly sourced from established oil and gas operators and large EPC firms undertaking substantial pipeline construction.

- Long-Term Commitments: Contracts are structured for extended periods, ensuring revenue stability and visibility, especially during major project phases.

- Market Impact: The ability to win and execute these large projects is a critical determinant of Eupec's market share and overall financial performance.

Maintenance and Rehabilitation Service Fees

While Eupec PipeCoatings' core business revolves around new pipe coating, a significant revenue potential lies in specialized maintenance, repair, and rehabilitation (MR&R) coating services for existing pipelines. This caters to the ongoing need to address localized damage, corrosion, or wear and tear, thereby extending the operational life of critical infrastructure.

This recurring service model offers a stable revenue stream, especially as aging pipeline networks globally require proactive upkeep. For instance, the global oil and gas pipeline market, valued at hundreds of billions, sees a substantial portion allocated annually to maintenance and integrity management. In 2024, projections indicated that pipeline maintenance and repair expenditures would continue to grow, driven by increasing regulatory scrutiny and the push for asset longevity.

- Recurring Revenue: MR&R services create a predictable income source beyond initial project-based coating.

- Asset Life Extension: Addresses market demand for maximizing the lifespan of existing pipelines, reducing the need for premature replacement.

- Regulatory Compliance: Supports operators in meeting stringent safety and environmental regulations for pipeline integrity.

- Market Opportunity: Estimates suggest the global pipeline maintenance market could reach over $60 billion by 2028, with coatings playing a crucial role.

Eupec generates revenue primarily through fees charged for applying external anti-corrosion coatings, such as FBE, ARO, and 3LPE/PP, to pipelines. These fees are project-specific, calculated per linear meter and influenced by pipe diameter, coating type, and project complexity. In 2024, the global oil and gas pipeline coatings market was valued at approximately $5.2 billion, indicating robust demand for these essential services.

Additional revenue streams include concrete weight coating services for pipeline stabilization, particularly in offshore applications. Pricing for these services is project-dependent, considering factors like total pipe volume, concrete layer thickness, and specific gravity needs. The growing demand for offshore infrastructure in 2024 further supports this revenue segment.

Eupec also monetizes its expertise through technical consulting, advising on optimal coating selection and pipeline integrity management. These specialized services, addressing complex client challenges, can command significant fees, reinforcing Eupec's role as a knowledge partner and diversifying income.

The company secures revenue via large, long-term contractual agreements with oil and gas operators and EPC contractors. These substantial commitments, often spanning years, provide predictable income tied to major energy infrastructure projects. In 2024, Eupec secured a significant contract for over 100 kilometers of offshore pipeline coating, underscoring the scale of their revenue generation.

Furthermore, Eupec capitalizes on the maintenance, repair, and rehabilitation (MR&R) of existing pipelines, offering a recurring revenue stream. This segment addresses the critical need for asset longevity and regulatory compliance, with pipeline maintenance and repair expenditures projected to grow in 2024. The global pipeline maintenance market is a significant opportunity, with coatings playing a vital role.

| Revenue Stream | Key Drivers | 2024 Market Context |

|---|---|---|

| Anti-Corrosion Coating Application | Pipe length, coating type, pipe diameter | Global oil & gas pipeline coatings market ~ $5.2 billion |

| Concrete Weight Coating | Pipe volume, concrete thickness, specific gravity | Growing offshore infrastructure demand |

| Technical Consulting | Coating selection, integrity management expertise | High-value solutions for complex challenges |

| Large-Scale Project Contracts | Project size, contract duration | Over 100km offshore pipeline coating contract secured |

| Maintenance, Repair & Rehabilitation (MR&R) | Asset longevity, regulatory compliance | Growing pipeline maintenance market |

Business Model Canvas Data Sources

The Eupec PipeCoatings Business Model Canvas is informed by a blend of internal financial data, market research reports on the pipeline industry, and strategic insights from industry experts. These sources provide a solid foundation for understanding our market position and operational capabilities.