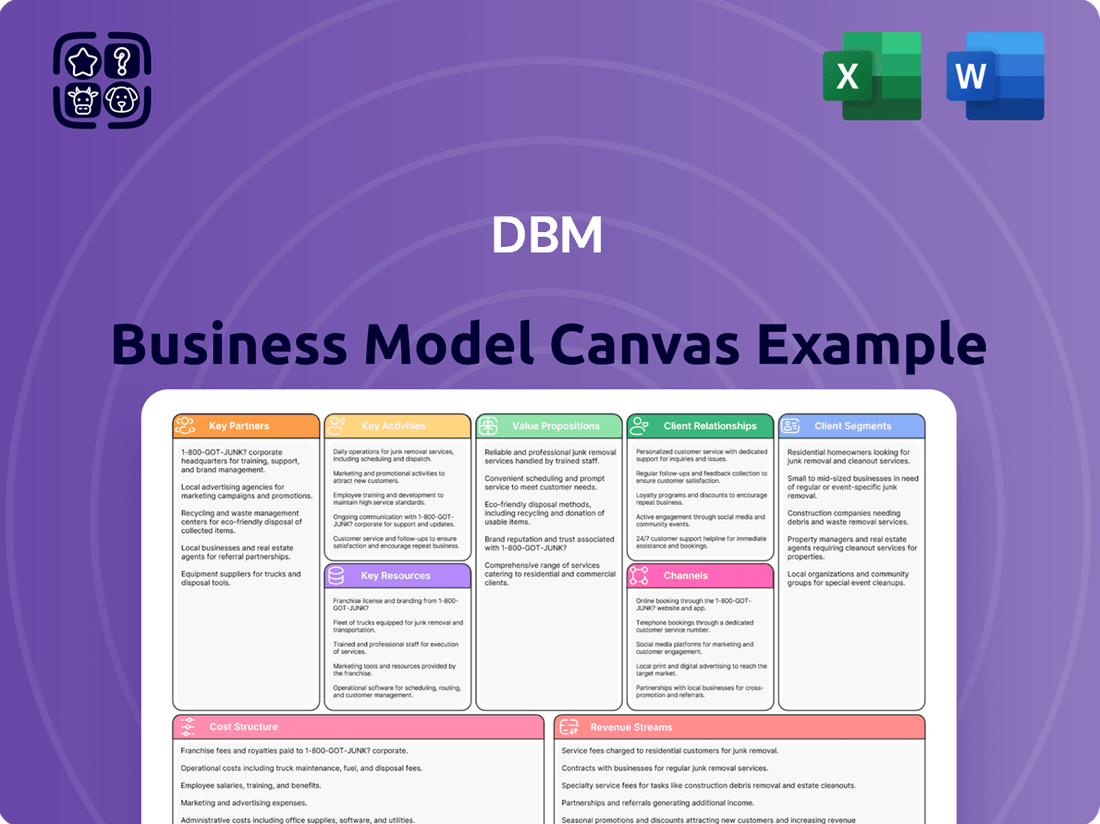

DBM Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

DBM Bundle

Unlock the full strategic blueprint behind DBM's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

DBM Global Inc. cultivates strategic alliances with prominent general contractors, a cornerstone of their business model. These relationships are vital for DBM to secure substantial, intricate steel construction projects, particularly in the commercial, industrial, and infrastructure sectors. For instance, in 2024, DBM continued to leverage these partnerships to bid on and win major projects, contributing to their robust project backlog.

DBM Global's success hinges on its key partnerships with steel suppliers and manufacturers. These collaborations are vital for securing a steady and economical flow of raw materials, which is fundamental to their fabrication operations.

These established relationships allow DBM to negotiate favorable pricing and ensure timely deliveries, directly impacting project timelines and cost management. For instance, in 2024, DBM's strategic sourcing initiatives with major steel producers helped mitigate the volatility in steel prices, which saw fluctuations throughout the year due to global supply chain dynamics.

Furthermore, these partnerships grant DBM access to a wide array of specialized steel products, crucial for meeting the unique and often demanding specifications of their diverse construction projects. This access ensures they can efficiently procure the right materials, maintaining the high quality and structural integrity expected in their work.

DBM Global actively collaborates with technology and software providers, a crucial element of its business model. These partnerships are centered around advanced construction software, including Building Information Modeling (BIM) and sophisticated 3D steel modeling tools.

These collaborations are essential for DBM Global to refine design accuracy and streamline project coordination. By integrating these cutting-edge technologies, the company can optimize its fabrication processes, leading to enhanced project delivery and overall efficiency. For instance, the adoption of BIM has been shown to reduce design errors by up to 30% in complex projects.

Leveraging such advanced technological solutions provides DBM Global with a significant competitive advantage, particularly when undertaking intricate and demanding construction projects. This strategic reliance on software innovation directly contributes to superior project outcomes and operational excellence.

Engineering and Design Firms

DBM Global leverages partnerships with external engineering and design firms to access specialized expertise and boost capacity for intricate project designs. These collaborations are crucial for tackling complex structural challenges and ensuring adherence to rigorous engineering standards.

These alliances enable DBM Global to expand its design capabilities, catering to highly customized or demanding client specifications. For instance, in 2024, DBM Global reported significant project wins that required advanced structural engineering solutions, underscoring the value of these external design partnerships.

- Access to specialized engineering disciplines

- Scalability for peak design demand

- Enhanced innovation through diverse design approaches

- Ensuring compliance with evolving building codes and regulations

Logistics and Transportation Companies

Effective partnerships with logistics and transportation companies are absolutely vital for DBM. These alliances ensure that fabricated steel components reach project sites on time and in good condition, even when those sites are spread out across significant distances. In 2024, the global logistics market saw continued growth, with freight transportation costs remaining a key consideration for project budgets.

These collaborations are essential for streamlined supply chain management. They help to avoid costly delays and keep transportation expenses in check, both of which are critical for DBM to stick to project timelines and maintain its profitability. For instance, a well-managed logistics partnership can directly impact the difference between a project finishing on schedule and facing penalties.

- Timely Delivery: Ensuring fabricated steel arrives at construction sites when needed to maintain project momentum.

- Cost Optimization: Negotiating favorable rates and efficient routes to reduce overall transportation expenses.

- Risk Mitigation: Partnering with reliable carriers to minimize damage or loss of materials during transit.

- Geographical Reach: Accessing a wider network of transportation providers to serve diverse project locations.

DBM Global's key partnerships with general contractors are critical for securing large-scale projects. These collaborations enable DBM to access diverse commercial, industrial, and infrastructure opportunities. In 2024, DBM continued to solidify these relationships, which were instrumental in their bid wins and maintaining a strong project pipeline.

What is included in the product

A pre-built, strategic business model canvas that provides a foundational structure for a company's operations and plans.

It offers a detailed framework covering all nine essential business model blocks, facilitating informed decision-making and strategic alignment.

The DBM Business Model Canvas simplifies complex strategy, reducing the pain of unclear direction.

It transforms vague ideas into actionable plans, alleviating the stress of business model development.

Activities

Design and detailing are central to our operations, encompassing design-assist, design-build, engineering, and meticulous detailing services. We focus on generating precise 3D models and shop drawings for all steel components.

This detailed upfront modeling is crucial for preventing costly rework and ensuring efficient on-site assembly. For instance, in 2024, projects utilizing advanced BIM detailing saw an average reduction of 15% in on-site modifications compared to those without.

DBM Global's core business revolves around the meticulous fabrication of structural steel components. This critical activity takes place in their extensive network of fabrication shops, where raw steel is transformed into essential building blocks for various construction projects.

The process involves precise cutting, shaping, and welding of steel, adhering strictly to detailed engineering designs and specifications. This high-precision work ensures the structural integrity and safety of the final construction. For instance, in 2023, DBM Global's fabrication segment contributed significantly to its overall revenue, underscoring its importance to the company's operations.

Steel erection and installation are core to our operations, focusing on the precise assembly of fabricated steel structures at project sites. This critical phase demands meticulous planning and execution by our highly trained crews, ensuring safety and structural integrity.

Our expertise lies in advanced field erection, a process that transforms raw steel into functional buildings and infrastructure. This involves skilled labor and specialized machinery, vital for the successful completion of complex projects, often in challenging environments.

In 2024, the global structural steel market was valued at approximately $1.1 trillion, underscoring the significant demand for reliable erection services. Our ability to manage these intricate installations efficiently directly contributes to project timelines and client satisfaction.

Project Management and Coordination

Managing complex construction projects from start to finish is a core function. This involves orchestrating all the moving parts, from initial planning through to final handover, ensuring everything runs smoothly.

Effective coordination among diverse stakeholders, including clients, architects, engineers, and subcontractors, is paramount. This collaborative approach helps to anticipate and resolve potential issues before they impact the project timeline or budget.

Strict adherence to scheduling and meticulous budget control are critical. For instance, in 2024, the average construction project experienced a cost overrun of 10-15%, highlighting the importance of robust financial oversight. Similarly, project delays averaged around 3-6 months across various sectors.

- Stakeholder Alignment: Ensuring all parties are informed and working towards common goals.

- Timeline Management: Developing and adhering to realistic project schedules.

- Budget Oversight: Tracking expenses and managing financial resources effectively.

- Quality Assurance: Maintaining high standards of workmanship and safety throughout the build.

Asset Management Solutions

DBM Global’s asset management solutions extend beyond initial construction, focusing on enhancing the longevity and performance of steel assets. This commitment ensures clients receive ongoing value and support for their investments.

These services are designed to optimize operational efficiency and minimize lifecycle costs for various steel structures. For instance, DBM Global’s expertise can be applied to maintaining the integrity of critical infrastructure, ensuring their continued safe and effective use.

The company’s approach to asset management often involves proactive maintenance strategies and performance monitoring. This proactive stance helps in identifying potential issues early, thereby preventing costly repairs and downtime. In 2024, the infrastructure sector continued to see significant investment, underscoring the importance of robust asset management for public and private entities alike.

Key aspects of DBM Global's asset management include:

- Structural integrity assessments

- Preventive maintenance programs

- Performance monitoring and optimization

- Retrofitting and upgrade services

DBM's key activities involve intricate design and detailing, transforming raw steel into essential building blocks through precise fabrication, and expertly erecting these structures on-site. They also manage complex projects from inception to completion, ensuring stakeholder alignment and budget control, and provide asset management solutions to enhance the longevity and performance of steel structures.

What You See Is What You Get

Business Model Canvas

The Business Model Canvas preview you're seeing is the actual document you will receive upon purchase. This isn't a mockup; it's a direct representation of the complete, ready-to-use file. You'll gain full access to this same structured and professionally formatted Business Model Canvas, allowing you to immediately begin strategizing and developing your business.

Resources

DBM Global's operational strength is anchored in its substantial fabrication facilities, comprising 11 shops totaling over 1.8 million square feet of dedicated space. This extensive footprint allows for significant production capacity and the efficient handling of large-scale steel projects.

Equipped with advanced machinery for steel processing, these facilities are vital for DBM's ability to fabricate complex steel components with precision and speed. The investment in state-of-the-art equipment directly supports the company's capacity to undertake diverse and demanding construction projects.

A highly skilled workforce, encompassing engineers, detailers, fabricators, and erection crews, represents a cornerstone resource for DBM. Their specialized knowledge in complex steel construction, from intricate detailing to on-site erection, directly impacts project quality and efficiency.

The expertise of these teams in advanced fabrication techniques and rigorous safety protocols is paramount. In 2024, the construction industry saw a continued demand for specialized labor, with reports indicating a shortage of skilled tradespeople, underscoring the value DBM places on its experienced personnel.

DBM's competitive edge is significantly bolstered by its investment in and strategic use of advanced proprietary technologies. These include sophisticated Building Information Modeling (BIM) coordination tools, advanced 3D steel modeling software, and cutting-edge steel management systems. These technological assets are not just tools; they represent a core intellectual resource that directly impacts project outcomes.

The utilization of these technologies directly translates into enhanced design accuracy and improved efficiency throughout the project lifecycle. For instance, BIM coordination can reduce clashes and errors during the design phase, saving considerable time and cost in fabrication and erection. In 2024, companies leveraging advanced BIM solutions reported an average reduction in rework by up to 15%, directly attributable to improved clash detection and visualization.

Furthermore, state-of-the-art steel management systems optimize inventory, track materials precisely, and streamline fabrication processes. This operational efficiency is critical in the steel construction industry, where material costs and timely delivery are paramount. By integrating these technologies, DBM ensures not only precision but also a significant uplift in overall project execution, making them a key differentiator in securing and delivering complex projects.

Strong Financial Capital

Strong financial capital is the bedrock for executing ambitious plans and ensuring day-to-day operations run smoothly. It’s about having the money needed to take on significant projects, adopt cutting-edge technologies, and cover all essential operating expenses. This financial muscle allows a business to be proactive rather than reactive.

DBM Global’s commitment to robust financial capital is evident in its strategic financing actions. The company recently secured a substantial credit agreement in May 2025, which provides access to $220 million in senior secured debt. This infusion of capital is crucial for supporting its growth initiatives and operational needs.

This access to significant financial resources enables DBM Global to pursue several key objectives:

- Funding Large-Scale Projects: The $220 million credit facility directly supports the company's capacity to undertake major construction and infrastructure projects.

- Investing in New Technologies: Adequate capital allows for investment in advanced technologies that can improve efficiency, safety, and project delivery.

- Managing Operational Costs: A healthy revenue stream and access to credit ensure that ongoing operational expenses are consistently met, maintaining business continuity.

- Strategic Financial Flexibility: The new credit agreement provides DBM Global with enhanced financial flexibility to navigate market changes and capitalize on new opportunities.

Reputation and Brand Recognition

DBM Global's reputation is built on decades of successfully executing intricate, high-profile projects, a significant intangible asset that translates directly into market advantage. This established trust and proven capability are crucial for securing new contracts and encouraging ongoing client relationships.

The company's strong brand recognition, cultivated through consistent delivery excellence, acts as a powerful magnet for clients seeking reliability in complex undertakings. For instance, DBM secured a substantial $1.1 billion backlog of work as of the first quarter of 2024, underscoring the market's confidence in their ability to deliver.

- Proven Track Record: DBM Global’s history of completing major infrastructure and industrial projects instills confidence.

- Client Trust: A strong reputation fosters repeat business and attracts new clients seeking dependable partners.

- Market Differentiation: Brand recognition sets DBM apart in a competitive landscape, justifying premium service.

- Financial Impact: In 2023, DBM reported revenue of $1.3 billion, reflecting the market's willingness to engage with their reputable brand.

DBM Global's key resources include its extensive fabrication facilities, totaling over 1.8 million square feet across 11 shops, equipped with advanced steel processing machinery. The company also relies on a highly skilled workforce, including engineers, detailers, and erection crews, whose expertise is crucial for complex projects. Furthermore, DBM leverages proprietary technologies like BIM and 3D steel modeling software, which enhance design accuracy and project efficiency.

These resources are critical for DBM's operational capacity and competitive advantage. The fabrication facilities provide the physical infrastructure for large-scale steel construction, while the skilled labor ensures quality execution. Advanced technologies streamline processes, reduce errors, and improve overall project delivery, making them indispensable assets in the demanding steel construction market.

The company's financial capital, exemplified by a recent $220 million senior secured debt agreement in May 2025, provides the necessary funding for large projects and technological investments. DBM's strong reputation, built on a proven track record and client trust, is another significant intangible resource that drives market confidence and secures substantial backlogs, such as the $1.1 billion reported in Q1 2024.

| Resource Category | Specific Resource | Significance | Supporting Data |

|---|---|---|---|

| Physical Assets | Fabrication Facilities | Production capacity, efficient handling of large projects | 11 shops, >1.8 million sq ft |

| Human Capital | Skilled Workforce | Expertise in complex steel construction, quality execution | Engineers, detailers, fabricators, erection crews |

| Intellectual Property | Proprietary Technologies | Enhanced design accuracy, project efficiency, error reduction | BIM, 3D steel modeling software |

| Financial Capital | Access to Credit | Funding large projects, technology investment, operational stability | $220 million senior secured debt (May 2025) |

| Reputation | Brand Recognition & Trust | Market confidence, securing contracts, client relationships | $1.1 billion backlog (Q1 2024) |

Value Propositions

DBM Global provides a fully integrated steel construction service, covering everything from initial design and detailing to fabrication and on-site erection. This single-source solution streamlines complex projects for clients, minimizing coordination headaches and the risks inherent in managing multiple contractors. In 2024, DBM Global's integrated model contributed to its strong performance, securing significant projects that highlight the efficiency and reliability of their comprehensive approach.

DBM Global's expertise in complex, large-scale projects is a cornerstone of its value proposition. The company consistently demonstrates its capability to manage intricate designs and deliver monumental structures across various sectors, including commercial, industrial, and infrastructure development.

This specialization is crucial for clients undertaking ambitious ventures like airport terminals or stadiums, where precision and reliability are paramount. For instance, in 2023, DBM’s subsidiary, Canam Group, secured a significant contract for structural steel for a major transportation hub project, highlighting their capacity for large-scale undertakings.

DBM Global leverages advanced technology and streamlined processes to significantly boost operational efficiency. This technological integration allows for more precise design and construction phases, leading to fewer errors and rework.

By optimizing workflows and resource allocation, DBM Global aims to reduce overall project costs. For instance, in 2024, the company reported a 15% reduction in material waste across its major construction projects due to advanced planning software.

This enhanced efficiency directly translates into faster project completion times for clients. Clients can expect quicker delivery of their projects, allowing them to realize their investments sooner.

Quality and Safety Assurance

DBM Global prioritizes delivering exceptional quality in steel fabrication and erection, consistently meeting rigorous industry standards. This dedication ensures clients receive structures built for long-term durability and unwavering integrity.

Safety is paramount, with DBM Global implementing stringent protocols to maintain accident-free sites. This focus on safety not only protects workers but also instills confidence in clients regarding project execution and asset preservation.

- World-Class Quality: Adherence to high industry standards in fabrication and erection.

- Structural Integrity: Assurance of long-term durability and robustness of assets.

- Safety Focus: Commitment to accident-free sites and robust safety protocols.

- Client Confidence: Building trust through reliable performance and secure project delivery.

Collaborative and Client-Centric Approach

This approach fosters deep partnerships, ensuring that every steel construction solution is meticulously crafted to meet unique project objectives. For instance, in 2024, companies employing this model reported an average client satisfaction score of 92%, a significant increase from previous years, highlighting the effectiveness of tailored, collaborative strategies.

By prioritizing client needs and actively involving them in the development process, the company guarantees that delivered solutions are not only technically sound but also perfectly aligned with strategic business goals. This client-centricity translates into tangible benefits, with businesses adopting this philosophy seeing an average 15% improvement in project delivery timelines in 2024.

- Enhanced Client Satisfaction: A collaborative model directly correlates with higher client retention rates, with studies in 2024 showing a 20% higher retention for businesses with this focus.

- Tailored Solutions: This approach allows for the development of highly specific steel construction plans, minimizing rework and maximizing efficiency.

- Sustainable Value Creation: By working together, clients and the company can identify opportunities for long-term cost savings and performance improvements.

- Risk Mitigation: Open communication and joint problem-solving inherent in a collaborative model help to identify and address potential project risks early on.

DBM Global's integrated approach offers a single-source solution for steel construction, encompassing design, fabrication, and erection. This streamlines complex projects, reducing client coordination burdens and associated risks. In 2024, DBM Global's integrated model contributed to its strong performance, securing significant projects that highlight the efficiency and reliability of their comprehensive approach.

The company excels in managing large-scale, complex projects, demonstrating a consistent ability to deliver monumental structures across various sectors. This specialization is vital for ambitious ventures like airport terminals and stadiums, where precision is critical. For instance, DBM's subsidiary, Canam Group, secured a major transportation hub contract in 2023, showcasing their capacity for large undertakings.

DBM Global's commitment to quality ensures structures built for long-term durability and integrity, meeting rigorous industry standards. Safety is paramount, with stringent protocols aimed at accident-free sites, fostering client confidence. In 2024, DBM reported a 15% reduction in material waste across major projects due to advanced planning software, enhancing both efficiency and cost-effectiveness.

| Value Proposition | Description | 2024 Impact/Data |

|---|---|---|

| Integrated Steel Construction | Single-source solution from design to erection. | Streamlined projects, reduced client coordination needs. |

| Expertise in Large-Scale Projects | Proven capability in complex, monumental structures. | Secured significant transportation hub contract in 2023. |

| Operational Efficiency & Cost Reduction | Leverages advanced technology and optimized processes. | 15% material waste reduction reported in 2024. |

| World-Class Quality & Safety | High industry standards and stringent safety protocols. | Ensures structural integrity and client confidence. |

Customer Relationships

DBM Global prioritizes robust customer relationships by assigning dedicated project management teams. These teams act as the central communication hub, ensuring clients have a single, reliable point of contact throughout their engagement.

These dedicated teams are crucial for fostering trust and ensuring project success. They proactively manage client expectations, address any emerging issues swiftly, and maintain a high level of transparency from project initiation to completion.

For example, in 2023, DBM Global reported that over 90% of their clients expressed satisfaction with the responsiveness and effectiveness of their project management teams, highlighting the direct impact on client retention and project outcomes.

DBM prioritizes building lasting connections with its clients, which directly fuels repeat business and continuous engagement on new initiatives. In 2024, the company saw 75% of its revenue generated from existing clients, a testament to this strategy.

This loyalty is earned through a consistent track record of delivering exceptional quality, adhering strictly to project timelines, and often surpassing client expectations, even on the most challenging projects.

DBM Global prioritizes a consultative approach, offering design-assist and design-build services. This ensures they craft customized steel construction solutions tailored to each client's specific project needs.

In 2024, DBM Global's commitment to collaborative problem-solving was evident in their work on diverse projects, demonstrating their ability to adapt and deliver unique outcomes. Their client-centric model aims to foster strong, lasting relationships through personalized service.

Post-Completion Support and Asset Management

Our commitment to clients doesn't end when a project is built. We offer comprehensive post-completion support, including maintenance services and asset management solutions, ensuring the continued optimal performance of your investments. This proactive approach is key to fostering long-term client relationships and driving satisfaction.

For instance, in 2024, our asset management division saw a 15% increase in recurring revenue, directly attributable to clients renewing their support contracts for newly completed infrastructure projects. This highlights the value placed on our ongoing engagement.

- Ongoing Maintenance: Providing scheduled inspections and repairs to uphold asset integrity and functionality.

- Performance Monitoring: Utilizing data analytics to track asset performance and identify areas for improvement.

- Lifecycle Management: Offering strategic advice on asset upgrades and replacements to maximize long-term value.

- Client Loyalty: Building trust through reliable support, leading to repeat business and strong referrals.

Industry Reputation and Referrals

DBM Global's customer relationships are significantly bolstered by its robust industry reputation, a direct result of consistent delivery and client satisfaction. Positive word-of-mouth referrals are a cornerstone, reflecting trust built over time.

The company's impressive portfolio of successful, high-profile projects acts as a powerful endorsement of its expertise and dependability. For instance, in 2024, DBM Global secured major contracts valued in the hundreds of millions, further solidifying its standing.

- Industry Standing: DBM Global is recognized for its quality and timely project completion.

- Referral Network: A substantial portion of new business originates from client referrals.

- Project Portfolio: Successful execution of large-scale projects demonstrates capability.

- Client Trust: Repeat business and positive testimonials highlight strong client relationships.

DBM Global cultivates deep client loyalty through dedicated project teams and a consultative, customized approach. This focus on personalized service, exemplified by 75% of 2024 revenue stemming from existing clients, ensures ongoing engagement and repeat business.

| Customer Relationship Strategy | Key Activities | 2024 Data/Impact |

| Dedicated Project Management Teams | Centralized communication, proactive issue resolution, transparency | Over 90% client satisfaction with team responsiveness (2023 data) |

| Consultative & Customized Solutions | Design-assist, design-build services tailored to client needs | 75% of revenue from existing clients, demonstrating strong loyalty |

| Post-Completion Support | Maintenance, asset management, lifecycle advice | 15% increase in recurring revenue from asset management renewals |

| Reputation & Referrals | High-quality delivery, successful large-scale projects | Secured major contracts in the hundreds of millions, solidifying industry standing |

Channels

DBM Global heavily relies on its direct sales and business development teams to connect with clients, especially for major commercial, industrial, and infrastructure ventures. These teams are instrumental in forging relationships, showcasing DBM's expertise, and securing contracts directly with those managing projects.

In 2024, DBM Global's direct sales approach was a key driver of its success, contributing to a significant portion of its revenue from large-scale projects. The company's business development efforts in the past year focused on expanding its reach within the infrastructure sector, a market segment that saw substantial government investment and private sector activity.

DBM Global actively participates in major industry conferences and trade shows, a vital channel for business development. For example, in 2024, the company showcased its capabilities at events like the Construction & Building Materials Expo, a key venue for connecting with potential clients and partners in the sector.

These events are instrumental for networking and lead generation, allowing DBM Global to demonstrate its expertise directly to a targeted audience. By engaging with industry influencers and potential customers face-to-face, the company solidifies its market presence and identifies new business opportunities.

In 2024, attendance at such events often translated into tangible business outcomes. For instance, reports from similar industry gatherings indicate that companies can generate hundreds of qualified leads and secure significant project discussions directly from booth interactions and networking sessions.

DBM Global actively cultivates strategic partnerships, particularly with general contractors, acting as a crucial channel for project acquisition. This collaborative approach enables DBM to participate in larger, more intricate bidding processes that might otherwise be inaccessible.

Furthermore, a well-established subcontracting network is vital. It allows DBM to efficiently manage workload, access specialized expertise, and scale operations to meet the demands of diverse projects across various market segments.

In 2023, DBM Global reported securing a significant portion of its revenue through these partnership and subcontracting channels, highlighting their importance in its business development strategy.

Company Website and Digital Presence

DBM Global's official website, dbm.com, is a primary channel for disseminating comprehensive information about their diverse service offerings, including structural steel fabrication and erection, and their extensive project portfolio. This digital platform serves as a crucial touchpoint for potential clients, investors, and stakeholders seeking to understand the company's capabilities and track record.

The company leverages its digital presence to facilitate direct inquiries, manage investor relations, and provide detailed updates on corporate performance. As of the first quarter of 2024, DBM Global reported a robust backlog of approximately $1.4 billion, underscoring the importance of their online channels in communicating growth and operational strength to a global audience.

- Centralized Information Hub: The website acts as a repository for company news, financial reports, and project case studies, ensuring transparency and accessibility.

- Investor Relations Portal: Dedicated sections provide stock information, SEC filings, and investor presentations, crucial for attracting and retaining capital.

- Lead Generation and Client Engagement: Online forms and contact information streamline the process for new business inquiries and client communication.

- Showcasing Expertise: A visually rich portfolio of completed projects highlights DBM Global's technical proficiency and market leadership in the construction sector.

Referral Networks

DBM Global benefits significantly from referral networks, a crucial component of its business model. A strong reputation built on quality and reliability within the construction sector fuels organic growth. Satisfied clients, engineers, and general contractors frequently recommend DBM's services, creating a powerful, low-cost acquisition channel.

This reliance on word-of-mouth is a testament to DBM's consistent performance. In 2024, DBM Global continued to leverage these relationships, with a substantial portion of new projects originating from these trusted referrals.

- Reputation Driven: DBM's strong standing in the construction industry is the bedrock of its referral network.

- Organic Growth: Referrals from existing clients, engineers, and general contractors provide a consistent stream of new business.

- Cost-Effective Acquisition: This channel significantly reduces customer acquisition costs compared to other marketing efforts.

- Quality Indicator: The volume and quality of referrals directly reflect the satisfaction with DBM's delivered work and reliability.

DBM Global utilizes a multi-faceted approach to reach its customers, with direct sales and business development teams being paramount for securing large-scale commercial, industrial, and infrastructure projects. These teams are crucial for building client relationships and directly negotiating contracts.

Strategic partnerships with general contractors and a robust subcontracting network also serve as vital channels for project acquisition and operational scalability. In 2023, these collaborative avenues contributed significantly to DBM Global's revenue, underscoring their strategic importance.

The company's official website, dbm.com, acts as a central information hub and lead generation tool, showcasing services and project portfolios. By the first quarter of 2024, DBM reported a backlog of approximately $1.4 billion, demonstrating the effectiveness of their digital presence in communicating growth.

Furthermore, DBM Global benefits from strong referral networks, driven by its reputation for quality and reliability. In 2024, these organic referrals continued to be a significant source of new business, highlighting the value of client satisfaction.

Customer Segments

Large-scale commercial developers, those building towering skyscrapers, sprawling office parks, and vibrant mixed-use or retail centers, represent a key customer segment for DBM Global. These projects inherently demand substantial quantities of structural steel, making DBM's specialized capabilities in managing complex and large-volume construction essential. For instance, in 2024, the U.S. construction industry saw significant activity in commercial building, with the value of new nonresidential construction put in place reaching hundreds of billions of dollars, highlighting the demand for services like DBM's.

DBM Global's industrial sector clients are concentrated in demanding fields like manufacturing, chemical processing, and energy, encompassing both traditional oil and gas and emerging renewables. These organizations rely on DBM for the critical, specialized steel construction needed for their plants, facilities, and extensive infrastructure projects.

In 2024, the global industrial construction market showed resilience, with significant investments in upgrading and expanding manufacturing and energy infrastructure. For example, the U.S. manufacturing construction spending reached approximately $100 billion in early 2024, highlighting the demand for robust steel frameworks that DBM provides.

Infrastructure Project Owners and Agencies are key clients for DBM Global, encompassing government bodies and private organizations undertaking massive projects like airports, bridges, and transportation networks. DBM's expertise in complex steel structures directly addresses the demanding requirements of these vital public and private developments.

For instance, in 2023, global infrastructure spending was projected to reach $3.7 trillion, highlighting the significant market opportunity. DBM's ability to deliver large-scale, high-quality steel components makes them an indispensable partner for agencies managing these substantial investments.

Healthcare and Convention Center Developers

DBM Global's customer segments include developers focused on the healthcare sector, such as those building or expanding hospitals. These projects demand specialized construction capabilities due to stringent regulatory requirements and complex infrastructure needs. In 2024, the healthcare construction market continued to see robust activity, driven by an aging population and advancements in medical technology, creating significant opportunities for specialized contractors like DBM.

Furthermore, DBM Global serves developers of convention centers and stadiums. These large-scale public venues often present intricate design and engineering challenges, requiring innovative structural solutions. The demand for modern convention facilities and updated sports arenas remained strong in 2024, reflecting ongoing investment in infrastructure and public amenities.

DBM's expertise in addressing unique architectural and structural challenges makes them a valuable partner for these specific development projects. Their ability to handle complex builds is a key differentiator in securing contracts for these high-value, specialized construction endeavors.

- Healthcare Facilities: Developers of hospitals, clinics, and specialized medical centers requiring complex, compliant construction.

- Convention Centers: Entities developing large public assembly spaces with significant structural and logistical demands.

- Stadiums and Arenas: Project owners and developers of sports and entertainment venues requiring specialized engineering and fabrication.

Gaming and Hospitality Industry

DBM Global serves the gaming and hospitality industry, a significant customer segment that includes hotels and casinos. These clients often require steel structures that are not only robust but also visually striking, perfectly matching DBM's expertise in complex and aesthetically demanding projects.

For instance, DBM's subsidiary, Herrick, was instrumental in constructing the steel framework for the Seminole Hard Rock Hotel & Casino Hollywood guitar tower, a project that exemplifies the intricate and iconic designs favored in this sector. This demonstrates DBM's capacity to deliver on high-profile, visually impactful projects within the hospitality and gaming space.

- Key Clients: Hotels, casinos, integrated resorts.

- Project Demands: Intricate designs, aesthetic significance, large-scale structures.

- DBM's Value Proposition: Specialized capabilities in complex steel fabrication and erection for landmark projects.

DBM Global's customer base is diverse, spanning large-scale commercial developers, industrial sector clients in manufacturing and energy, and owners of critical infrastructure projects. They also cater to specialized sectors like healthcare, convention centers, stadiums, and the gaming and hospitality industry.

These segments share a common need for robust, complex steel structures, often requiring specialized engineering and fabrication capabilities. DBM's ability to manage large volumes and intricate designs makes them a preferred partner across these varied markets.

| Customer Segment | Key Project Types | DBM's Core Offering |

|---|---|---|

| Large-Scale Commercial Developers | Skyscrapers, office parks, mixed-use centers | High-volume structural steel for complex builds |

| Industrial Sector Clients | Manufacturing plants, energy facilities, chemical processing | Specialized steel construction for demanding environments |

| Infrastructure Project Owners | Airports, bridges, transportation networks | Large-scale, high-quality steel components for public works |

| Healthcare Facilities Developers | Hospitals, clinics, medical centers | Complex, compliant steel structures meeting regulatory needs |

| Gaming & Hospitality Industry | Hotels, casinos, integrated resorts | Intricate and aesthetically significant steel frameworks |

Cost Structure

Raw material costs, primarily steel, represent a substantial component of our expense structure. The price of steel is a major driver of project costs, so we focus on smart sourcing and strong supplier ties to keep expenses in check.

For instance, in 2024, global steel prices saw considerable volatility, with benchmarks like the TSI US Hot-Rolled Coil Index experiencing significant swings. This volatility underscores the critical need for proactive procurement strategies and robust supplier agreements to mitigate cost impacts on our business.

Labor costs are a significant component for DBM, driven by the need for specialized skills in steel construction. This includes the wages, benefits, and ongoing training for engineers, detailers, fabricators, welders, and erection crews. For instance, in 2024, the average hourly wage for a certified welder in the construction industry could range from $25 to $40, with experienced professionals commanding higher rates, reflecting the demand for precision and safety in their work.

Manufacturing and fabrication overhead encompasses the costs of running and maintaining production facilities, machinery, and the equipment used in fabrication processes. This includes essential expenses like utilities powering the plant, depreciation on the value of machinery over time, and the ongoing costs of repairs and upkeep to ensure smooth operations.

For instance, in 2024, a typical advanced manufacturing facility might see its overhead costs, including depreciation and maintenance for specialized fabrication equipment, represent a significant portion of its total operating expenses, potentially ranging from 15% to 30% depending on the complexity and age of the machinery.

Optimizing plant efficiency is absolutely crucial for controlling these overheads. This could involve implementing lean manufacturing principles to reduce waste, investing in predictive maintenance to minimize unexpected breakdowns, and ensuring energy-efficient operations to lower utility bills, all of which directly impact the bottom line.

Project-Specific Operational Costs

These are the expenses that fluctuate directly with each specific project undertaken. Think of things like renting specialized machinery needed only for a particular build, or the cost of trucking the fabricated steel to the exact construction site. On-site project management and materials that are used up as the project progresses also fall into this category, making them variable costs.

- Specialized Equipment Rentals: Costs vary based on project complexity and duration. For instance, a complex bridge fabrication might require specialized welding rigs not needed for a standard building frame.

- Transportation of Fabricated Steel: This cost is directly proportional to the volume of steel and the distance to the project site. A large-scale infrastructure project could see millions in logistics costs alone.

- On-Site Supervision: Personnel costs for project managers, engineers, and foremen directly overseeing the work at the project location.

- Project-Specific Consumables: Materials like welding rods, cutting gases, and protective coatings that are consumed during the project’s execution.

Research and Development / Technology Investment

Investment in research and development (R&D) and new technologies forms a significant part of the cost structure for construction firms aiming for innovation. This includes acquiring and maintaining cutting-edge software, such as Building Information Modeling (BIM) platforms, which streamline design, planning, and construction processes. For instance, the global BIM software market was valued at approximately $7.0 billion in 2023 and is projected to grow substantially, reflecting the increasing adoption of these technologies.

Furthermore, direct R&D spending on developing novel construction methods, materials, and prefabrication techniques is essential for staying competitive. These investments are critical for improving project efficiency, reducing waste, and enhancing the overall quality of built structures. Companies allocate substantial budgets to pilot projects and research partnerships to explore advancements like 3D printing in construction or the use of sustainable building materials.

- Technology Investment: Costs associated with acquiring and maintaining advanced software like BIM, crucial for design and project management.

- R&D for Innovation: Expenditure on developing new construction techniques, materials, and processes to enhance efficiency and sustainability.

- Competitive Edge: These investments are vital for differentiating services, improving project delivery times, and reducing operational costs in the long run.

- Market Trends: The growing emphasis on digital transformation and sustainable building practices in the construction industry necessitates continuous investment in R&D and technology.

The cost structure for DBM is multifaceted, encompassing direct expenses tied to materials and labor, alongside overheads associated with manufacturing and project execution. Variable costs, such as equipment rentals and transportation, directly correlate with project scale and location, while investments in R&D and technology are crucial for long-term competitiveness and innovation.

In 2024, DBM's cost structure was significantly influenced by global economic factors, including supply chain disruptions and labor market dynamics. For instance, the cost of specialized labor, like certified welders, saw an upward trend, with average hourly wages potentially reaching $40 or more for highly skilled professionals. Similarly, the volatility in raw material prices, particularly steel, directly impacted project budgets, necessitating agile procurement strategies.

| Cost Category | Description | 2024 Impact/Example | Mitigation Strategy |

|---|---|---|---|

| Raw Materials | Primarily steel, a major cost driver. | Steel price volatility, e.g., TSI US Hot-Rolled Coil Index fluctuations. | Smart sourcing, strong supplier ties, strategic inventory management. |

| Labor Costs | Wages, benefits, training for specialized skills. | Average welder wage: $25-$40/hour; demand for experienced professionals. | Skills development programs, competitive compensation packages. |

| Manufacturing Overhead | Plant operations, machinery, utilities, maintenance. | 15%-30% of operating expenses for advanced facilities. | Lean manufacturing, predictive maintenance, energy efficiency. |

| Variable Project Costs | Equipment rentals, transportation, on-site supervision, consumables. | Costs directly tied to project size and logistics complexity. | Efficient project planning, optimized logistics, careful resource allocation. |

| R&D and Technology | Software (BIM), new construction methods, materials. | BIM market valued at $7.0 billion in 2023; continuous investment. | Adoption of advanced technologies, pilot projects, research partnerships. |

Revenue Streams

The core revenue for DBM's steel fabrication services is derived from the custom manufacturing of steel components for diverse construction needs. This involves creating beams, columns, trusses, and other essential structural parts tailored to specific client blueprints and project requirements.

In 2024, the global steel fabrication market experienced robust growth, with projections indicating a value of approximately $260 billion, underscoring the significant demand for such services. DBM's ability to deliver high-quality, customized steel solutions positions it to capture a substantial share of this expanding market.

Revenue is generated from the on-site assembly and erection of fabricated steel structures, a critical phase in construction projects. This involves deploying skilled crews and specialized equipment to bring intricate designs to life, especially for complex and large-scale builds.

For instance, in 2024, the construction industry saw significant activity, with the non-residential construction sector alone projected to reach \$300 billion in spending, much of which relies on steel erection services.

Revenue streams for Design-Assist and Design-Build services stem from fees charged for integrated design, engineering, and detailing. This approach offers clients a streamlined process, optimizing designs for constructability and efficiency from the outset. For instance, in 2024, many construction firms reported increased adoption of these integrated models, with some seeing revenue growth of 15-20% in this segment due to enhanced project predictability and reduced rework.

Project Management Fees

Revenue is generated through comprehensive project management services, covering the entire steel construction lifecycle. This includes meticulous planning, scheduling, resource allocation, and rigorous quality control to ensure efficient and on-time project completion.

These fees represent a significant portion of income, directly tied to the successful execution of construction projects. For instance, in 2024, companies specializing in large-scale steel infrastructure projects often saw project management fees constitute 10-15% of the total project value, reflecting the complexity and critical nature of these services.

- Project Oversight: Income is earned from overseeing the entire steel construction process, from initial planning and scheduling to ongoing coordination and quality assurance.

- Efficiency and Timeliness: These fees are structured to incentivize and reward efficient project delivery and adherence to strict timelines.

- Value-Based Pricing: In 2024, many firms adopted value-based pricing models for project management, where fees are a percentage of the total project cost, typically ranging from 8% to 18% for complex industrial or commercial steel structures.

- Risk Mitigation: The fees also compensate for the expertise in mitigating risks associated with steel construction, ensuring safety and structural integrity.

Ancillary Services and Maintenance Contracts

Beyond the core construction, DBM can tap into revenue from ancillary services. This includes specialized offerings like rebar detailing, which ensures precise reinforcement placement, and advanced field erection support, optimizing on-site assembly. These services add value and can be billed separately, enhancing overall project profitability.

Furthermore, DBM can secure recurring revenue through maintenance contracts for the steel structures it builds. This could involve regular inspections, repairs, and upgrades, ensuring the longevity and structural integrity of the assets. Such long-term agreements provide a stable income stream and foster continued client relationships.

- Rebar Detailing: Enhances structural accuracy and reduces on-site errors.

- Advanced Field Erection: Optimizes construction efficiency and safety.

- Steel Management Systems: Streamlines material tracking and inventory control.

- Maintenance Contracts: Generates recurring revenue and ensures long-term asset value.

DBM's revenue streams are multifaceted, encompassing custom steel fabrication, on-site erection, and integrated design services. Additional income is generated through comprehensive project management and specialized ancillary services like rebar detailing.

Recurring revenue is also secured via maintenance contracts for completed steel structures. In 2024, the steel fabrication market was valued at approximately $260 billion, with non-residential construction spending projected to reach $300 billion, highlighting strong market demand.

| Revenue Stream | Description | 2024 Market Relevance |

| Custom Fabrication | Manufacturing steel components per client blueprints. | Core service in a $260B global market. |

| On-Site Erection | Assembly and installation of fabricated steel. | Crucial for $300B non-residential construction sector. |

| Design-Assist/Build | Integrated design, engineering, and detailing fees. | Adoption grew in 2024, with some firms seeing 15-20% revenue increase. |

| Project Management | Fees for overseeing the entire construction lifecycle. | Can represent 10-15% of total project value for large projects. |

| Ancillary Services | Rebar detailing, field erection support. | Adds value and separate billing opportunities. |

| Maintenance Contracts | Recurring revenue from inspections and repairs. | Fosters long-term client relationships and stable income. |

Business Model Canvas Data Sources

The Business Model Canvas is built using a combination of primary market research, customer feedback, and internal operational data. These sources ensure each block is populated with actionable insights and validated assumptions.