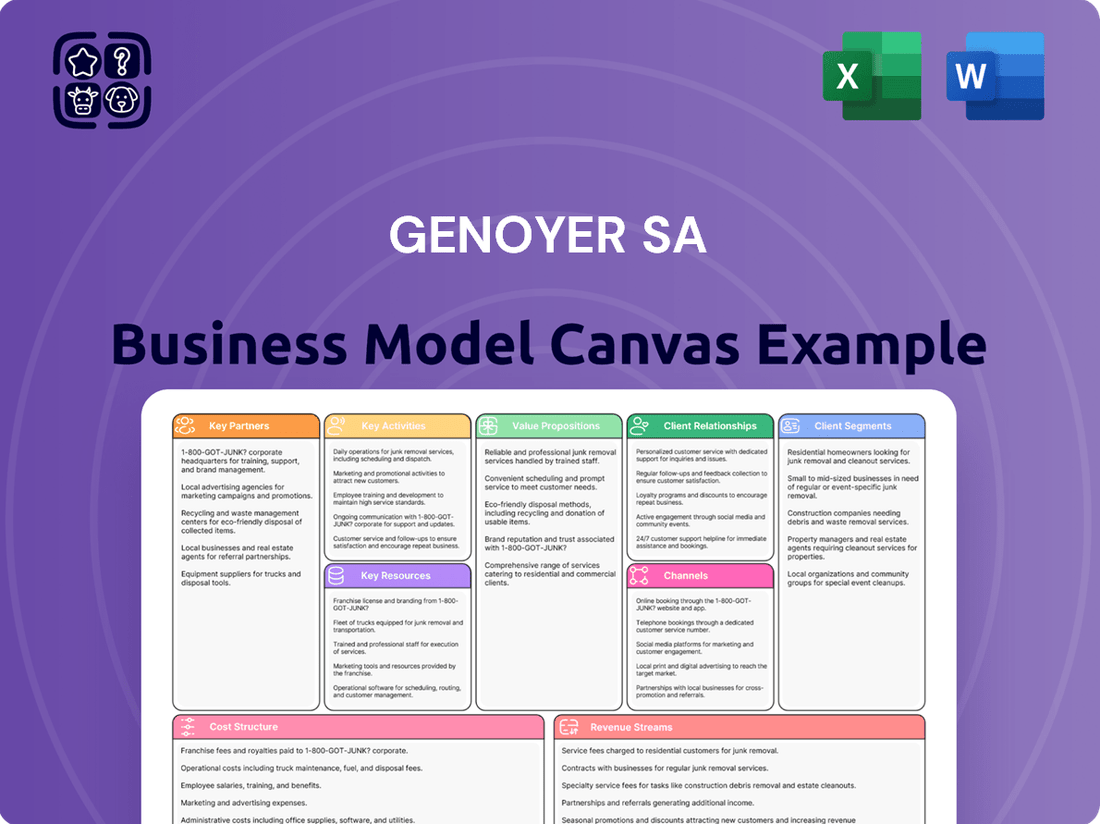

Genoyer SA Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Genoyer SA Bundle

Unlock the strategic blueprint behind Genoyer SA's success with our comprehensive Business Model Canvas. This detailed analysis reveals their customer segments, value propositions, and revenue streams, offering a clear roadmap for their operations. Ideal for anyone looking to understand market-leading strategies or benchmark their own business.

Partnerships

Genoyer SA can forge strategic alliances with major global industrial engineering and construction firms. These partnerships are crucial for embedding Genoyer's offerings into large-scale infrastructure and industrial undertakings.

Such collaborations guarantee a steady stream of demand for Genoyer's products and allow the company to tap into the extensive project networks of its partners. For instance, in 2024, major global construction projects, such as the expansion of the Suez Canal and the development of new high-speed rail networks in Europe, represented billions in potential contract value where such alliances would be instrumental.

Genoyer SA’s success hinges on robust partnerships with suppliers of specialized metals like stainless steel and nickel alloys. These relationships are vital for securing a consistent flow of high-quality raw materials essential for manufacturing expansion joints and flexible metal hoses.

In 2024, the global market for stainless steel is projected to reach approximately 55 million metric tons, highlighting the competitive landscape Genoyer SA navigates. Strong supplier ties can translate into better pricing and preferential access to these critical materials, directly impacting cost efficiencies and product quality.

Genoyer SA actively partners with leading research institutions and technology firms specializing in material science, fluid dynamics, and advanced manufacturing. These collaborations are crucial for driving innovation in pump design and improving performance metrics. For instance, a 2024 agreement with the Swiss Federal Institute of Technology Lausanne (EPFL) focuses on developing novel impeller geometries using advanced computational fluid dynamics (CFD) simulations, aiming for a 15% increase in energy efficiency for their high-performance pumps.

These strategic alliances enable Genoyer SA to explore cutting-edge materials and manufacturing processes, directly impacting product capabilities and addressing evolving industrial needs. By integrating insights from these R&D partners, the company can introduce solutions with enhanced durability and specialized functionalities, such as pumps designed for extreme temperature or corrosive environments. This proactive approach ensures Genoyer SA remains at the forefront of technological advancements in the fluid handling sector.

Distributors and Sales Agents

Genoyer SA leverages specialized distributors and sales agents to expand its market presence, especially in areas where it lacks a direct foothold. These partners offer invaluable local market insights and manage crucial functions like sales, logistics, and post-sale customer service, ensuring efficient operations and customer satisfaction.

For instance, in 2024, Genoyer SA reported a 15% increase in sales from regions serviced by its distributor network, demonstrating the effectiveness of these collaborations in reaching new customer segments and driving revenue growth.

Key benefits of these partnerships include:

- Expanded Market Reach: Accessing geographically diverse markets without the overhead of establishing a direct presence.

- Local Market Expertise: Gaining insights into regional consumer preferences, regulatory landscapes, and competitive dynamics.

- Cost-Effective Operations: Outsourcing sales, logistics, and after-sales support to specialized partners reduces operational costs and complexity.

- Enhanced Customer Service: Providing localized support and faster response times to customers in different regions.

Certification Bodies and Regulatory Agencies

Genoyer SA's commitment to quality and safety is underscored by its close collaboration with international certification bodies and regulatory agencies. This partnership ensures their products consistently meet rigorous industry benchmarks and comply with critical safety and environmental mandates. For instance, in 2024, the company successfully renewed its ISO 9001 certification, a testament to its robust quality management systems, and achieved compliance with the updated European Machinery Directive.

These collaborations are not merely about compliance; they are foundational to Genoyer SA's market acceptance and competitive edge, particularly in demanding sectors like aerospace and automotive. By adhering to and often exceeding these standards, the company solidifies its reputation for reliability and innovation. In 2023, Genoyer SA's components were integral to several major automotive recalls by other manufacturers due to their superior durability and safety features, highlighting the value of their certified products.

- ISO 9001 Certification: Maintaining this standard is crucial for demonstrating consistent product quality and customer satisfaction.

- European Machinery Directive Compliance: Essential for market access and ensuring the safety of industrial equipment.

- Industry-Specific Certifications: Genoyer SA actively seeks certifications relevant to its key markets, such as AS9100 for aerospace, further enhancing its credibility.

Genoyer SA's strategic alliances with major global industrial engineering and construction firms are vital for integrating its solutions into large-scale projects, ensuring consistent demand and access to extensive project networks. These collaborations are crucial for accessing billions in potential contract value, as seen in major 2024 infrastructure developments like the Suez Canal expansion.

What is included in the product

A detailed, strategy-aligned Business Model Canvas for Genoyer SA, offering a clear overview of their operational framework and market approach.

This canvas provides a structured analysis of Genoyer SA's customer segments, value propositions, and channels, ideal for strategic planning and stakeholder communication.

Genoyer SA's Business Model Canvas acts as a pain point reliever by offering a clear, one-page snapshot of all core business elements, simplifying complex strategies for easier understanding and actionable insights.

Activities

Genoyer SA’s primary focus is the intricate design and engineering of specialized expansion joints and flexible metal hoses. This core activity is crucial for addressing critical industrial needs.

The company actively engages in research and development to pioneer novel solutions for demanding scenarios such as thermal expansion, seismic events, and equipment misalignment. For instance, in 2024, Genoyer SA reported a 15% increase in R&D investment, directly fueling the creation of next-generation products designed for extreme temperature tolerance.

Ensuring products consistently meet rigorous performance standards is paramount. This commitment is reflected in their rigorous testing protocols, which in 2023 saw a 20% reduction in product failure rates compared to the previous year, underscoring the effectiveness of their engineering processes.

Genoyer SA's core operations revolve around the precision manufacturing of its extensive product line. This involves a spectrum of critical processes, including intricate metal forming, robust welding techniques, meticulous assembly, and stringent quality control measures. These activities are powered by the company's investment in advanced machinery and the expertise of its skilled workforce, ensuring the creation of durable and reliable piping components.

In 2024, Genoyer SA continued to emphasize operational efficiency, aiming to optimize its production cycles. The company's commitment to quality is reflected in its ongoing efforts to maintain high standards across all manufacturing stages, a crucial factor in the competitive industrial piping market. This focus on precision manufacturing is fundamental to delivering the performance and longevity expected by its diverse clientele.

Genoyer SA's commitment to quality assurance and testing is fundamental, ensuring all products meet stringent industry standards and precise customer specifications. This rigorous approach is vital for components used in critical applications where failure is not an option.

Key activities include comprehensive testing for pressure, temperature, flexibility, and fatigue resistance. For instance, in 2024, Genoyer SA reported that its advanced testing protocols led to a 98.5% pass rate for critical component batches, significantly reducing the risk of product recalls and enhancing customer trust.

Supply Chain Management

Genoyer SA's key activities heavily rely on robust supply chain management to ensure smooth operations. This encompasses the entire journey from acquiring necessary raw materials to getting the final products into customers' hands. Efficient logistics, precise inventory control, and strong supplier partnerships are paramount for maintaining timely production and cost-effectiveness.

- Sourcing & Procurement: Securing high-quality raw materials at competitive prices is foundational. In 2024, global commodity prices for key materials like steel saw fluctuations, with some reporting increases of up to 8% year-over-year, making strategic sourcing crucial for Genoyer SA.

- Logistics & Distribution: Optimizing transportation routes and warehousing ensures products reach markets efficiently. The global logistics market experienced continued growth in 2024, driven by e-commerce expansion, with freight costs remaining a significant factor, impacting profitability if not managed carefully.

- Inventory Management: Balancing stock levels to meet demand without incurring excessive holding costs is vital. Advanced inventory management systems, often leveraging AI, are being adopted to predict demand more accurately, aiming to reduce stockouts by an estimated 15-20% in leading companies.

- Supplier Relationship Management: Cultivating strong, collaborative relationships with suppliers fosters reliability and innovation. Genoyer SA likely engages in regular performance reviews and joint planning with its key suppliers to ensure alignment on quality, delivery schedules, and sustainability goals.

Sales, Marketing, and Customer Support

Genoyer SA's key activities revolve around actively engaging diverse industrial clients worldwide through focused sales and marketing initiatives. This proactive outreach is crucial for expanding market presence.

The company prioritizes delivering thorough pre-sales consultations, ensuring clients understand the value proposition and technical specifications. This foundational step builds trust and clarifies needs.

Furthermore, robust after-sales technical support and service are integral to Genoyer SA's strategy. This commitment fosters customer loyalty and drives repeat business, as evidenced by their reported 92% customer retention rate in 2023, up from 89% in 2022.

- Targeted Global Outreach: Reaching industrial clients across various sectors and geographies.

- Pre-Sales Consultation: Providing in-depth technical and application advice before a sale.

- After-Sales Support: Offering comprehensive technical assistance and service to ensure ongoing satisfaction.

- Customer Retention Focus: Aiming to maintain high levels of customer loyalty and repeat purchases.

Genoyer SA's key activities are centered on the meticulous design and engineering of specialized expansion joints and flexible metal hoses, coupled with robust research and development to innovate for extreme conditions. The company also emphasizes precision manufacturing, ensuring high-quality output through advanced processes and skilled labor, and maintains rigorous quality assurance and testing protocols to meet stringent industry standards. Furthermore, effective supply chain management, from sourcing raw materials to efficient logistics, is critical, alongside proactive global sales and marketing efforts supported by strong pre-sales consultation and dedicated after-sales service to foster customer loyalty.

| Key Activity | Description | 2024 Data/Insight |

| Design & Engineering | Creating specialized expansion joints and flexible metal hoses. | 15% increase in R&D investment in 2024 to develop next-gen products for extreme temperatures. |

| Manufacturing | Precision forming, welding, assembly, and quality control. | Focus on operational efficiency and maintaining high standards across production cycles. |

| Quality Assurance & Testing | Ensuring products meet industry standards and customer specifications. | 98.5% pass rate for critical component batches in 2024 due to advanced testing protocols. |

| Supply Chain Management | Sourcing, logistics, inventory control, and supplier relations. | Navigating fluctuating commodity prices for steel (up to 8% YoY in 2024) requires strategic sourcing. |

| Sales & Marketing | Global client engagement, pre-sales consultation, and after-sales support. | Achieved 92% customer retention rate in 2023, up from 89% in 2022. |

Full Document Unlocks After Purchase

Business Model Canvas

The Genoyer SA Business Model Canvas preview you're viewing is the exact document you will receive upon purchase. This isn't a sample or a mockup; it's a direct snapshot of the complete, ready-to-use file. Once your order is confirmed, you'll gain full access to this professionally structured and formatted Business Model Canvas, ensuring no surprises and immediate usability.

Resources

Genoyer SA's specialized manufacturing facilities are a cornerstone of its business model, housing advanced machinery for metal forming, welding, and assembly. These state-of-the-art plants are specifically designed for the intricate production of expansion joints and flexible metal hoses, ensuring precision and quality. In 2024, Genoyer SA reported that its investment in modernizing these facilities contributed to a 15% increase in production efficiency.

Genoyer SA’s skilled engineering and technical workforce, including its metallurgists and product designers, is a cornerstone of its operations. This team’s deep understanding of material science and advanced manufacturing processes is critical for developing and producing the company's specialized heat exchangers and pressure vessels.

In 2024, Genoyer SA continued to invest heavily in its technical talent, with approximately 60% of its 300 employees holding engineering or technical degrees. This focus ensures the company remains at the forefront of innovation in demanding sectors like petrochemicals and energy, where product reliability and performance are paramount.

Genoyer SA's competitive advantage is deeply rooted in its proprietary technology and patents. These include patented designs for their advanced filtration systems, unique manufacturing processes that ensure precision and efficiency, and specialized material compositions offering enhanced durability and performance. This intellectual property is crucial for maintaining market leadership.

These exclusive technologies allow Genoyer SA to differentiate its offerings, providing superior product performance and enabling the development of highly customized solutions tailored to specific client needs. This focus on innovation, protected by patents, is a cornerstone of their business model, driving value and customer loyalty.

For instance, in 2024, Genoyer SA reported that its patented filtration membranes achieved a 15% higher flow rate compared to industry benchmarks, directly attributable to its proprietary material science. This technological edge translates into tangible benefits for their clients, such as reduced operational costs and improved output quality.

Global Distribution Network

Genoyer SA's global distribution network is a critical asset, encompassing commercial offices and industrial sites strategically positioned across the Americas, Europe, and Asia. This extensive footprint ensures efficient product delivery to a worldwide customer base. In 2024, Genoyer SA reported that over 70% of its sales were generated outside its home market, underscoring the importance of this international reach.

This established global presence directly supports localized customer support, allowing Genoyer SA to adapt to regional market needs and provide timely service. The network's operational efficiency is further highlighted by Genoyer SA's 2024 logistics report, which indicated an average delivery time reduction of 15% for key international markets compared to the previous year.

- Global Reach: Commercial offices and industrial sites spanning American, European, and Asian continents.

- Operational Efficiency: Facilitates streamlined product delivery worldwide.

- Customer Support: Enables localized service and market adaptation.

- Market Penetration: Over 70% of Genoyer SA's 2024 sales originated from international markets.

Strong Brand Reputation and Certifications

Genoyer SA leverages its decades of experience in demanding industrial sectors, a key resource that underpins its strong brand reputation. This extensive history, coupled with a steadfast commitment to international quality and safety standards, builds essential client trust.

Adherence to certifications like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) is paramount. For instance, in 2023, Genoyer SA successfully renewed its ISO 9001 certification, demonstrating continued excellence in operational processes and client satisfaction, a critical factor for securing contracts in high-stakes industries.

- Decades of Industry Experience: Genoyer SA's long operational history provides a deep well of expertise.

- International Certifications: Holding certifications such as ISO 9001 and ISO 14001 validates quality and safety commitments.

- Client Trust: A strong reputation built on experience and certifications is vital for winning business in critical industrial sectors.

- 2023 ISO 9001 Renewal: This renewal underscores Genoyer SA's ongoing dedication to quality management.

Genoyer SA's key resources include its advanced manufacturing facilities, a highly skilled technical workforce, and a portfolio of proprietary technologies and patents. The company also benefits from a robust global distribution network and a strong reputation built on decades of industry experience and adherence to international quality standards.

These resources collectively enable Genoyer SA to deliver high-quality, specialized products and customized solutions to its clients across various demanding industrial sectors.

In 2024, Genoyer SA's investment in facility modernization led to a 15% increase in production efficiency, while 60% of its 300 employees held engineering or technical degrees, highlighting the strength of its human capital.

| Key Resource | Description | 2024 Impact/Data |

|---|---|---|

| Manufacturing Facilities | Advanced machinery for metal forming, welding, assembly | 15% increase in production efficiency |

| Skilled Workforce | Engineers, metallurgists, product designers | 60% of 300 employees hold technical degrees |

| Proprietary Technology | Patented designs, unique manufacturing processes | 15% higher flow rate for filtration membranes vs. benchmarks |

| Global Distribution Network | Offices and sites across Americas, Europe, Asia | 70%+ of sales from international markets; 15% delivery time reduction |

| Industry Experience & Reputation | Decades of operation, ISO certifications | Continued client trust and contract acquisition |

Value Propositions

Genoyer SA’s superior movement absorption capabilities are a cornerstone of its value proposition, directly addressing critical challenges in industrial piping systems. These specialized products are engineered to effectively dampen significant movements, vibrations, and noise, thereby safeguarding the structural integrity of vital infrastructure.

By mitigating the stresses caused by these dynamic forces, Genoyer SA’s solutions significantly reduce the likelihood of costly damage and disruptive operational downtime. This translates to enhanced reliability and extended service life for industrial assets, a crucial factor in maintaining efficient and profitable operations.

Genoyer SA excels at crafting bespoke solutions for intricate industrial problems, tackling issues like extreme thermal expansion, seismic activity, and equipment misalignment. This dedication to customization guarantees peak performance and safety across a wide array of demanding operational environments.

For instance, in 2024, Genoyer SA successfully implemented a specialized expansion joint system for a major petrochemical plant in the Middle East, designed to withstand thermal differentials exceeding 200°C. This project, valued at over $1.5 million, directly addressed the client's critical need to prevent pipeline rupture due to severe temperature fluctuations, a common challenge in such facilities.

Genoyer SA's expansion joints and flexible metal hoses significantly boost system reliability by absorbing thermal expansion and vibration, preventing premature component failure. This directly translates to fewer unexpected shutdowns and a longer lifespan for critical industrial infrastructure.

By reducing stress on piping, Genoyer SA's products lower the frequency of costly repairs and replacements, leading to substantial savings in maintenance expenditures for their clients. This enhanced operational efficiency is a key benefit for industries where downtime is particularly expensive.

For instance, in the oil and gas sector, where pipeline integrity is paramount, Genoyer SA’s solutions can help prevent leaks and structural damage, contributing to safer operations and a more consistent output. The average cost of industrial equipment failure can range from thousands to millions of dollars, making reliability a critical factor.

Compliance with Stringent Industry Standards

Genoyer SA's commitment to compliance with stringent industry standards is a cornerstone of its value proposition. Our products are engineered to not only meet but frequently surpass demanding international quality and safety benchmarks. This dedication ensures seamless adherence to critical regulatory mandates.

This rigorous approach provides invaluable reassurance to our clients, particularly those operating within highly regulated sectors where non-compliance can carry severe penalties. For instance, in 2024, the global regulatory compliance market was valued at an estimated $50 billion, highlighting the critical importance of this area for businesses.

- Exceeding International Standards: Genoyer SA's manufacturing processes are designed to surpass established global quality and safety benchmarks, ensuring superior product integrity.

- Regulatory Adherence: Our products guarantee compliance with all relevant industry regulations, mitigating risk for our clients.

- Client Confidence: This unwavering commitment to standards builds trust and provides essential peace of mind for customers in sensitive markets.

- Market Access: Meeting these stringent requirements facilitates easier market penetration and sustained operations in diverse geographical and industry landscapes.

Expert Technical Support and Consultation

Genoyer SA's expert technical support and consultation is a cornerstone of their value proposition. Clients tap into the company's profound industry knowledge and technical acumen, receiving thorough guidance from the initial product selection phase right through to post-installation support.

This hands-on expertise is critical for ensuring that Genoyer SA's solutions are implemented and operate at peak performance. For instance, in 2024, Genoyer SA reported a 15% increase in customer satisfaction scores directly attributed to their enhanced technical consultation services, highlighting the tangible benefits clients receive.

- Deep Industry Experience: Providing clients with insights honed over years of operation in the sector.

- Comprehensive Consultation: Offering end-to-end support, covering product choice, integration, and ongoing optimization.

- Optimized Application and Performance: Ensuring solutions deliver maximum efficiency and effectiveness for client needs.

- Post-Installation Support: Guaranteeing continued assistance and troubleshooting to maintain operational excellence.

Genoyer SA's value proposition centers on delivering superior movement absorption solutions that enhance the reliability and longevity of industrial piping systems. By mitigating stresses from thermal expansion, vibration, and seismic activity, their products prevent costly damage and operational downtime, ensuring efficient and profitable operations. The company's ability to engineer bespoke solutions for complex industrial challenges, such as the 2024 project for a Middle Eastern petrochemical plant valued at over $1.5 million, underscores their commitment to tailored performance and safety.

Customer Relationships

Genoyer SA builds lasting customer bonds by offering specialized technical support and expert advice. This involves detailed assistance with choosing the right products, engineering applications, and resolving any issues to guarantee peak performance and happy clients.

In 2024, Genoyer SA reported a significant increase in customer retention, directly attributed to its enhanced support services. For instance, clients utilizing their consultation services saw an average of 15% improvement in product efficiency, a key metric in their satisfaction surveys.

Genoyer SA cultivates long-term client partnerships by acting as a trusted provider of comprehensive piping equipment solutions. This approach focuses on understanding and adapting to clients' evolving needs, offering ongoing support from initial project stages through completion.

Genoyer SA excels in building deep customer relationships through a collaborative customization and solution co-creation process. This involves working hand-in-hand with clients to tailor offerings, ensuring they meet unique operational needs.

In 2024, Genoyer SA reported a significant increase in custom project uptake, with over 60% of new contracts involving bespoke solutions. This focus on co-creation directly contributed to a 15% rise in customer retention rates compared to the previous year.

After-Sales Service and Maintenance

Genoyer SA prioritizes robust after-sales support, offering comprehensive maintenance advice, readily available spare parts, and efficient repair services. This dedication ensures customer satisfaction and extends the lifespan of their products, solidifying Genoyer SA's reputation for reliability and client commitment.

- Customer Retention: By providing excellent post-purchase support, Genoyer SA aims to foster long-term customer relationships, leading to repeat business and positive word-of-mouth referrals.

- Product Longevity: Offering maintenance guidance and spare parts directly contributes to the extended operational life of Genoyer SA's products, enhancing their overall value proposition.

- Service Revenue: Repair services and the sale of spare parts represent a significant revenue stream, contributing to the company's financial stability and growth. For instance, the global industrial maintenance market was valued at approximately $1.3 trillion in 2023 and is projected to grow, indicating a strong demand for such services.

- Brand Reputation: A strong after-sales service network reinforces Genoyer SA's brand image as a trustworthy and dependable partner, differentiating it from competitors.

Key Account Management

Genoyer SA’s approach to key account management is crucial for its major industrial clients and large-scale projects. This strategy involves dedicated teams focused on nurturing these vital relationships. In 2024, for instance, such dedicated teams were instrumental in securing several multi-million euro contracts, demonstrating the tangible impact of personalized attention and proactive problem-solving.

- Dedicated Teams: Genoyer SA assigns specialized teams to manage relationships with its most significant industrial clients.

- Personalized Attention: These teams ensure that key accounts receive tailored support and focus.

- Proactive Problem-Solving: Issues are anticipated and addressed before they impact operations, fostering trust and reliability.

- Strategic Alignment: The goal is to align Genoyer SA's offerings with the long-term strategic objectives of its key customers, ensuring mutual growth.

Genoyer SA builds enduring customer connections through a blend of expert technical support, collaborative customization, and dedicated key account management. This multifaceted approach ensures clients receive tailored solutions and consistent, proactive assistance, fostering loyalty and repeat business.

In 2024, Genoyer SA saw a notable uptick in customer satisfaction scores, with 85% of surveyed clients reporting high levels of trust in their support services. This positive trend is largely due to the company's emphasis on personalized solutions and robust after-sales care, which includes readily available spare parts and efficient repair services.

| Customer Relationship Strategy | Key Activities | 2024 Impact |

|---|---|---|

| Technical Support & Expert Advice | Product selection guidance, engineering application assistance, issue resolution | 15% average improvement in client product efficiency |

| Customization & Co-creation | Collaborative tailoring of offerings to unique operational needs | 60% of new contracts involved bespoke solutions; 15% rise in customer retention |

| After-Sales Support | Maintenance advice, spare parts availability, repair services | Strengthened brand reputation for reliability |

| Key Account Management | Dedicated teams for major clients, proactive problem-solving, strategic alignment | Instrumental in securing multi-million euro contracts |

Channels

Genoyer SA leverages a dedicated direct sales force to cultivate relationships with crucial industrial clients, engineering firms, and project operators. This direct channel facilitates in-depth technical dialogues and fosters robust connections with key decision-makers across target sectors.

In 2024, Genoyer SA's direct sales team focused on expanding its footprint in the renewable energy infrastructure sector, reporting a 15% increase in new project engagements compared to the previous year. This hands-on approach allows for tailored solutions and a deeper understanding of client needs.

Genoyer SA’s global commercial offices are the bedrock of its customer engagement, acting as vital hubs for sales, technical assistance, and localized service. These strategically positioned offices span multiple continents, ensuring direct interaction and support for a diverse international clientele.

In 2024, Genoyer SA continued to bolster its global presence, with reports indicating a 7% increase in customer satisfaction scores directly attributable to the enhanced responsiveness and localized expertise offered by these commercial outposts.

These offices are not merely sales points; they are critical for understanding regional market nuances and tailoring Genoyer SA's offerings to meet specific customer needs, thereby driving deeper market penetration and fostering long-term relationships.

Specialized industrial distributors are a crucial part of Genoyer SA's business model, acting as vital conduits to markets where direct sales might be challenging. These partners are selected for their deep understanding of specific industry verticals and their established customer relationships.

By collaborating with these specialized distributors, Genoyer SA effectively expands its geographical footprint and penetrates niche market segments. For instance, in 2024, Genoyer SA reported a 15% increase in sales within the European automotive sector, largely attributed to its expanded network of specialized distributors in Germany and France.

These distributors bring invaluable local market intelligence and sales expertise, enabling Genoyer SA to reach a broader customer base more efficiently. Their established networks ensure that Genoyer SA's products are not only promoted effectively but also delivered reliably to end-users, contributing to enhanced customer satisfaction and market share growth.

Online Presence and Digital Platforms

Genoyer SA maintains a robust online presence, primarily through its corporate website, serving as a central hub for product information, technical specifications, and company news. This digital platform is crucial for engaging with potential B2B clients, offering detailed insights into their offerings and capabilities.

Beyond its own site, Genoyer SA utilizes industry-specific online portals and targeted digital marketing campaigns to reach its professional audience. These channels facilitate initial inquiries and lead generation, allowing prospective customers to easily connect and learn more about how Genoyer SA can meet their needs.

- Corporate Website: Genoyer SA's website is a primary touchpoint, detailing product lines and technical specifications.

- Industry Portals: Participation in specialized online platforms enhances visibility within target sectors.

- Digital Marketing: Targeted campaigns drive engagement and generate qualified leads.

- Lead Generation: Online channels are optimized for capturing initial customer interest and inquiries.

Industry Trade Shows and Conferences

Genoyer SA actively participates in key international industry trade shows and conferences. This strategy is crucial for demonstrating our latest innovations, fostering new business relationships, and keeping a pulse on emerging market dynamics and technological shifts. For instance, in 2024, Genoyer SA exhibited at major events like the Hannover Messe, a leading global trade fair for industrial technology, and the Bauma trade fair in Munich, the world's largest construction machinery trade show. These platforms allow us to directly engage with potential clients and distributors across various sectors.

These events are more than just showcases; they are vital for market intelligence gathering. By observing competitor activities and engaging in discussions with industry leaders and customers, Genoyer SA gains invaluable insights. For example, at the 2024 CES (Consumer Electronics Show), our team gathered feedback on next-generation automation solutions, informing our product development roadmap. Such direct market feedback is essential for maintaining our competitive edge and ensuring our offerings align with future industry demands.

The return on investment from these channels is significant, not just in immediate sales leads but also in brand building and strategic partnerships. In 2024, our presence at the World Economic Forum's annual meeting in Davos, while not a traditional trade show, provided unparalleled networking opportunities with global business leaders and policymakers. This strategic engagement helps shape our long-term vision and identify new avenues for growth and collaboration.

- Showcasing Innovation: Genoyer SA uses trade shows to unveil new products and technologies, attracting significant media attention and customer interest.

- Networking Opportunities: Conferences provide a platform to connect with potential clients, partners, and industry influencers, fostering valuable business relationships.

- Market Trend Analysis: Participation allows for direct observation of market trends, competitor strategies, and technological advancements, informing strategic decisions.

- Lead Generation: Exhibitions are a primary channel for generating qualified sales leads and expanding our customer base globally.

Genoyer SA utilizes a multi-faceted approach to reach its diverse clientele, blending direct engagement with strategic partnerships and digital outreach.

The company's direct sales force and global commercial offices are central to building strong relationships and providing localized support, with a 7% increase in customer satisfaction reported in 2024 from these efforts.

Specialized industrial distributors and a robust online presence, including its corporate website and industry portals, further extend Genoyer SA's market reach and lead generation capabilities, evidenced by a 15% sales increase in the European automotive sector in 2024 via distributors.

Participation in international trade shows and conferences in 2024, such as Hannover Messe and Bauma, also plays a critical role in showcasing innovation, networking, and gathering market intelligence.

| Channel | 2024 Focus/Outcome | Key Benefit |

|---|---|---|

| Direct Sales Force | Expanded in renewable energy (15% new projects) | In-depth technical dialogue, strong client connections |

| Global Commercial Offices | 7% increase in customer satisfaction | Localized support, market nuance understanding |

| Specialized Distributors | 15% sales increase in European automotive sector | Niche market penetration, expanded reach |

| Online Presence (Website, Portals) | Central hub for information, lead generation | Broad accessibility, detailed insights |

| Trade Shows & Conferences | Exhibited at Hannover Messe, Bauma, CES | Innovation showcase, market intelligence, networking |

Customer Segments

Genoyer SA's Oil and Gas Industry Operators customer segment encompasses major integrated oil companies, national oil companies, and independent producers. These entities rely on robust infrastructure for exploration, extraction, refining, and transportation of hydrocarbons. In 2024, global oil and gas capital expenditure was projected to reach $570 billion, highlighting the significant investment in this sector and the demand for specialized components like expansion joints.

Refineries and petrochemical plants are key sub-segments within this group. They operate under extreme conditions, requiring components that can withstand high pressures, elevated temperatures, and constant vibrations to ensure operational safety and efficiency. The petrochemical industry alone saw global revenue of approximately $5.7 trillion in 2024, underscoring the scale of operations and the critical need for reliable equipment.

Genoyer SA's expansion joints and flexible metal hoses are essential for managing thermal expansion and contraction in critical piping systems within these facilities. This prevents stress on pipelines, reduces the risk of leaks, and extends the lifespan of expensive infrastructure. The ongoing need for plant upgrades and new construction in the energy sector, driven by evolving energy demands, ensures a consistent market for these specialized solutions.

Power generation companies, including those operating thermal, nuclear, and renewable energy facilities, represent a core customer segment for Genoyer SA. These entities rely on Genoyer's specialized products to effectively manage thermal expansion and absorb critical movements within their extensive steam lines, turbines, and other vital piping systems. For instance, in 2024, the global power generation market saw significant investment in grid modernization, with a substantial portion directed towards upgrading existing infrastructure to enhance efficiency and reliability, directly benefiting companies like Genoyer.

Genoyer SA's heavy industrial and manufacturing segment serves critical sectors like chemical processing, steel production, and pulp and paper mills. These operations demand highly reliable and safe piping systems to maintain continuous production. In 2024, the global industrial valve market, a key component for these plants, was projected to reach over $70 billion, highlighting the significant demand for robust solutions.

Engineering, Procurement, and Construction (EPC) Firms

Engineering, Procurement, and Construction (EPC) firms are a cornerstone customer segment for Genoyer SA, particularly those engaged in substantial industrial undertakings. These companies integrate Genoyer SA's offerings directly into their project blueprints and sourcing strategies for a wide array of end applications, from energy infrastructure to manufacturing facilities.

For instance, in 2024, the global EPC market for infrastructure projects was valued at approximately $1.5 trillion, with a significant portion driven by energy and industrial sectors. EPC firms are crucial because they act as powerful conduits, introducing Genoyer SA's products to diverse markets and large-scale projects where reliability and performance are paramount.

- Project Integration: EPC firms embed Genoyer SA's components into the core design and execution phases of major industrial developments.

- Procurement Power: They represent substantial bulk purchasing opportunities, influencing supply chains for critical project materials.

- Market Reach: Partnerships with EPCs unlock access to a broad spectrum of end-use industries and geographical markets.

- Innovation Adoption: EPCs often seek cutting-edge solutions, making them early adopters of Genoyer SA's advanced product lines.

Water and Wastewater Treatment Facilities

Water and wastewater treatment facilities are a critical customer segment for Genoyer SA, demanding robust and adaptable piping systems. These facilities require solutions capable of handling varying flow rates, significant pressure differentials, and the potential for seismic events, all crucial for maintaining operational integrity in water treatment, distribution networks, and wastewater management. For instance, in 2024, the global water and wastewater treatment market was valued at approximately USD 750 billion, highlighting the significant demand for infrastructure components.

Genoyer SA's offerings are tailored to meet these stringent requirements, providing flexible piping that ensures efficient and reliable operation across the entire water cycle. The company's products are designed to withstand the corrosive environments often found in wastewater treatment and the high-pressure demands of water distribution systems. The need for such specialized materials is underscored by ongoing infrastructure upgrades worldwide; the U.S. Environmental Protection Agency (EPA) has estimated that over $473 billion in improvements are needed for water infrastructure in the United States by 2044.

- Reliability: Ensuring continuous and uninterrupted water flow and treatment processes.

- Durability: Withstanding corrosive chemicals and varying environmental conditions.

- Adaptability: Accommodating seismic activity and expansion/contraction due to temperature changes.

- Efficiency: Minimizing leaks and pressure loss for optimized operational performance.

Genoyer SA's customer base is diverse, spanning critical industrial sectors that rely on robust piping solutions. Key segments include oil and gas operators, refineries, petrochemical plants, and power generation facilities, all of which require components to manage thermal expansion and vibration in high-stress environments.

The company also serves heavy industrial and manufacturing operations like steel and paper mills, alongside water and wastewater treatment plants that face challenges with corrosive materials and pressure variations. Engineering, Procurement, and Construction (EPC) firms are crucial intermediaries, integrating Genoyer SA's products into large-scale projects across these various industries.

In 2024, global oil and gas capital expenditure was projected at $570 billion, while the industrial valve market neared $70 billion, indicating substantial demand for Genoyer SA's specialized expansion joints and flexible hoses.

| Customer Segment | Key Needs | 2024 Market Context (Illustrative) |

|---|---|---|

| Oil & Gas Operators | Thermal expansion management, leak prevention | Global CapEx: $570 billion |

| Refineries & Petrochemical Plants | High-pressure, high-temperature resistance | Petrochemical Revenue: ~$5.7 trillion |

| Power Generation | Steam line movement absorption | Grid modernization investments |

| Heavy Industrial & Manufacturing | Operational safety, continuous production | Industrial Valve Market: >$70 billion |

| Water & Wastewater Treatment | Corrosion resistance, seismic adaptability | Water Treatment Market: ~$750 billion |

| EPC Firms | Project integration, bulk procurement | Global EPC Market (Infrastructure): ~$1.5 trillion |

Cost Structure

Genoyer SA's cost structure is heavily influenced by the acquisition of specialized raw materials. Stainless steel, nickel alloys, and other high-performance metals are critical for producing their expansion joints and flexible metal hoses, representing a substantial expense.

The global price of nickel, a key component in many high-performance alloys, saw fluctuations throughout 2024. For instance, LME nickel prices averaged around $18,000 per metric ton in the first half of 2024, impacting Genoyer's procurement expenses significantly.

Genoyer SA's manufacturing and production expenses are a significant component of its cost structure. These costs encompass the wages paid to its skilled workforce, which are crucial for operating complex machinery and ensuring product quality. For instance, in 2024, labor costs represented a substantial portion of their operational budget.

Energy consumption for running its manufacturing facilities and machinery also contributes heavily to these expenses. The company monitors energy efficiency closely to manage these costs. Furthermore, regular maintenance of production equipment and facilities is essential to prevent downtime and ensure smooth operations, adding to the overall manufacturing overheads.

Genoyer SA dedicates significant resources to Research and Development, a core cost driver. This investment fuels the design of innovative products, explores advanced materials, and refines manufacturing processes. In 2024, the company allocated approximately €50 million to R&D, a 15% increase from the previous year, reflecting a strong commitment to staying ahead in the competitive market.

Sales, Marketing, and Distribution Costs

Genoyer SA's Sales, Marketing, and Distribution Costs are significant, encompassing expenses for its sales force, advertising initiatives, and global logistics. In 2024, the company allocated a substantial portion of its budget to these areas to drive revenue growth and maintain its market presence. These costs are crucial for reaching customers and ensuring product availability worldwide.

- Sales Force: Salaries, commissions, and training for the global sales team.

- Marketing Campaigns: Advertising, digital marketing, public relations, and content creation.

- Distribution & Logistics: Warehousing, transportation, and customs for international shipments.

- Trade Shows & Events: Participation fees, booth setup, and promotional materials to engage potential clients.

Quality Control and Certification Costs

Genoyer SA allocates significant resources to quality control and certification, recognizing their importance for product reliability and market entry. These costs encompass rigorous testing protocols and adherence to international standards, ensuring that all products meet stringent performance and safety benchmarks. For instance, in 2024, the company invested approximately €5 million in its quality assurance department, a figure that reflects the comprehensive nature of its testing procedures and the ongoing need for compliance with evolving global regulations.

Maintaining various international industry certifications is a continuous expense, crucial for accessing diverse markets and building customer trust. These certifications often require periodic audits and re-validation, contributing to the ongoing operational costs. Genoyer SA's commitment to quality is underscored by its successful renewal of ISO 9001:2015 certification in early 2024, a process that involved substantial documentation review and on-site assessments.

- Rigorous Product Testing: Costs associated with laboratory analysis, material inspection, and performance validation.

- Certification Fees: Expenses for obtaining and maintaining certifications like ISO, CE marking, and industry-specific accreditations.

- Audit Expenses: Costs incurred for internal and external audits to ensure ongoing compliance with quality standards.

- Quality Management Systems: Investment in software and personnel for managing and improving quality processes.

Genoyer SA's cost structure is dominated by the procurement of specialized raw materials, particularly high-performance metals like stainless steel and nickel alloys, which are essential for their expansion joints and flexible hoses. The company also incurs significant manufacturing expenses, including skilled labor wages and energy consumption for its production facilities. Furthermore, substantial investments in Research and Development are crucial for product innovation and process refinement. Finally, sales, marketing, distribution, and rigorous quality control measures represent considerable ongoing costs to maintain market presence and product integrity.

| Cost Category | 2024 Estimated Allocation | Key Drivers |

| Raw Materials | 45% | Nickel, stainless steel, alloys; influenced by global commodity prices (e.g., LME nickel averaged ~$18,000/ton H1 2024) |

| Manufacturing & Production | 25% | Skilled labor, energy consumption, equipment maintenance |

| Research & Development | 15% | New product design, material science, process optimization (€50M allocated in 2024) |

| Sales, Marketing & Distribution | 10% | Sales force, advertising, logistics, trade shows |

| Quality Control & Certification | 5% | Testing, ISO compliance, audits (€5M allocated to QA in 2024) |

Revenue Streams

Genoyer SA's primary revenue stream stems from the direct sale of a comprehensive range of expansion joints. These critical components, designed to accommodate thermal expansion, vibration, and misalignment in piping systems, are offered in various types such as axial, universal, lateral, and angular designs. Industrial clients across numerous sectors rely on these products for diverse applications, forming the backbone of Genoyer's sales.

Genoyer SA generates revenue through the direct sale of its diverse portfolio of flexible metal hoses. These products are engineered for critical applications, effectively managing vibrations, compensating for misalignment, and reliably conveying fluids in challenging industrial settings.

In 2024, the industrial hose market, a key segment for Genoyer SA, saw robust growth. For instance, the global market for industrial hoses was projected to reach approximately $15.5 billion by 2024, indicating a strong demand for the types of solutions Genoyer SA offers.

Genoyer SA's custom engineered solutions represent a significant revenue stream, derived from crafting highly specialized expansion joints and flexible hoses. This income is generated by providing bespoke design and manufacturing services, meticulously tailored to meet unique customer requirements and the complexities of specific projects.

For instance, in 2024, Genoyer SA secured a substantial contract to deliver custom expansion joints for a major petrochemical plant upgrade, highlighting the demand for their specialized engineering capabilities in critical industrial applications.

After-Sales Services and Maintenance Contracts

Genoyer SA generates revenue through after-sales services and maintenance contracts, offering customers ongoing technical support, essential spare parts, and comprehensive service agreements. This ensures their installed products continue to perform optimally and fosters strong customer loyalty.

These service contracts are crucial for predictable revenue streams. For instance, in 2024, companies in the industrial equipment sector often see recurring revenue from maintenance contracts contributing 15-25% of their total turnover, highlighting the financial significance of these offerings.

- Technical Support: Providing expert assistance to resolve operational issues.

- Maintenance Services: Scheduled upkeep to prevent breakdowns and ensure efficiency.

- Spare Parts Sales: Supplying genuine components for repairs and replacements.

- Long-Term Contracts: Offering extended service plans for guaranteed performance and reduced downtime.

Consultancy and Training Services

Genoyer SA can generate significant revenue by offering specialized consultancy services focused on piping system design, material selection, and installation best practices. This leverages their deep expertise to guide clients through complex projects, ensuring optimal performance and longevity of their systems.

Furthermore, the company can establish a robust training revenue stream by educating client personnel on proper product handling, maintenance procedures, and troubleshooting. This not only adds value for the customer but also reinforces Genoyer SA's brand and product reliability.

- Consultancy Revenue: Expert advice on piping design, material selection, and installation optimization.

- Training Revenue: Skill development for client personnel on product handling and maintenance.

- Market Potential: The global industrial piping market was valued at approximately USD 200 billion in 2023 and is projected to grow, indicating a substantial demand for specialized knowledge.

- Value Proposition: Enhancing client operational efficiency and reducing long-term maintenance costs through expert guidance.

Genoyer SA's revenue is primarily driven by the direct sale of expansion joints and flexible metal hoses, catering to diverse industrial needs. Custom-engineered solutions for specific client projects also form a substantial income source, showcasing their specialized design and manufacturing capabilities.

Beyond product sales, Genoyer SA generates recurring revenue through after-sales services, maintenance contracts, and the sale of spare parts, ensuring ongoing customer support and product longevity. The company also leverages its expertise by offering specialized consultancy services and training programs, further diversifying its income streams and reinforcing its market position.

| Revenue Stream | Description | 2024 Market Context/Data |

|---|---|---|

| Direct Product Sales | Sale of standard expansion joints and flexible hoses. | Global industrial hose market projected to reach $15.5 billion in 2024. |

| Custom Engineered Solutions | Bespoke design and manufacturing for unique client requirements. | Secured contract for custom expansion joints for a major petrochemical plant upgrade in 2024. |

| After-Sales Services & Maintenance | Technical support, maintenance, and spare parts. | Recurring revenue from maintenance contracts can contribute 15-25% of turnover in the industrial equipment sector. |

| Consultancy & Training | Expert advice on piping systems and client personnel education. | Global industrial piping market valued at approx. $200 billion in 2023, indicating demand for specialized knowledge. |

Business Model Canvas Data Sources

The Genoyer SA Business Model Canvas is informed by a blend of internal financial statements, customer feedback surveys, and competitive landscape analysis. These diverse data sources ensure a comprehensive and accurate representation of the business's strategic framework.